Each driver has his own thoughts about which powertrain is actually better. Some believe that a small volume brings great advantage and gives fuel economy. Others believe that it is worth buying only a gasoline engine because of its ruggedness and versatile operation. Still others choose only voluminous turbocharged diesel engines for great pleasure from excellent traction. Let's figure out how to operate a diesel power unit, which has a number of features of use. Proper operation can significantly extend the life of the unit and provide many important advantages. If you move from petrol SUV to diesel without changing habits, then your power unit will not be easy.

The use of engines is a topic that can be discussed endlessly. Based on what features of the trip the owners of the equipment violate in comparison with the factory recommendations, it is very easy to find whole line important recommendations. This question concerns refueling certain fuel and pouring oil, after-sales service as well as repairs. There are certain tips for practical operation to reduce consumption and wear of a diesel engine. You can also remember winter use diesel engine, which must be very careful. Given all the categories presented, we can form several important tips for owners of diesel power units. One has only to say that everything said below applies to modern turbocharged diesel engines that are installed on mass passenger cars.

Refueling and maintenance are the two most important points of use

First of all, when buying a diesel power unit you need to choose a normal place of refueling. It is not only about quality brand filling station, but also about the quality of diesel fuel, which is not always the same. Use the recommendations of experts and check the quality of diesel fuel with the help of simple tests. The fuel must not freeze, become cloudy and must be clean under all conditions. It is also worth following the recommendations for maintenance:

- for a diesel power unit, many manufacturers put a slightly smaller service interval than for gasoline engines, but this is not always the case;

- you must 100% comply with all the service conditions that are set by the car manufacturer, use only original materials on the service;

- when buying an unknown oil, you can say goodbye to the engine after 10-20 thousand kilometers, filters are also worth buying original and very high quality ones;

- special attention should be paid to equipment diagnostics during the service - this will help to avoid the most unpleasant problems associated with the injection pump and the block head;

- diesel engine repairs should be carried out immediately after the car has shown a problem, this will help maintain a certain quality and desired properties installation.

If a gasoline engine is sometimes operated successfully and with malfunctions, then such an idea will not work in diesel power units. Need to use professional service to maintain common rail, turbines, injection pumps and cylinder heads. It is these parts that most often fail and cause certain troubles during operation. A breakdown can completely disable the unit.

How to drive a diesel engine with a modern type of turbine?

Current HFO powertrains do not differ too much from gasoline engines. The issue of ride quality can be quite serious, as improper operation leads to a number of problems. You need to remember the basic recommendations, as well as read the features and individual tips in the owner's manual for your car. The basic recommendations for such engines are as follows:

- use high torque at low rpm - do not spin diesel engine to high speeds of the power unit;

- take advantage of convenient early shifting and excellent traction characteristics a car with a diesel engine, this will help to get comfort;

- do not overheat the unit long work on increased speed or off-road operation in the middle mode disables the high-pressure fuel pump and other important modules;

- you should not drive a diesel car - you buy a car for comfort and low flow so use all important benefits transport with such features;

- in the city it is quite possible to travel at a speed of 60-70 kilometers per hour using last transfer- this is one of the favorite operating modes of a diesel unit.

You need to understand that a diesel engine has a completely different structure than a gasoline engine we are used to. There are a number of advantages, but there are also disadvantages. Therefore, you should always study the manufacturer's recommendations for using the car, otherwise you can get into an unpleasant situation. Use the most quality solutions trips and always strive to follow the factory recommendations. This will help keep your machine running.

What are the important advantages of a diesel engine?

power unit diesel type known for eating less fuel than a gasoline counterpart with similar power characteristics. This is true, but the diesel-type power unit is one of the budget spenders on the service, it requires more money to complete all tasks. Therefore, it is worth highlighting such pure and undeniable advantages of a heavy-fuel power unit:

- the possibility of early gear shifting, very good torque, which picks up the gearbox in any mode and rides great even in an unsuccessfully chosen position;

- very high traction indicators directly in the process of acceleration, that is, on low revs the most high rate optimal useful power of the unit;

- Reduced fuel consumption compared to gasoline evens out the cost of running a HFO powertrain so it won't cost you that much more.

- the service life of a diesel engine, subject to all important recommendations, will be quite high, there are no problems with the device, many reach up to 500,000 km;

- environmental cleanliness of emissions is much better than petrol options, the absence of carbon monoxide, but there are solid particles, and often they exceed the norm for a car of this class.

Modern developments of power units are becoming more sophisticated and demanding. Therefore, you should carefully monitor each update and study the engine, information and reviews about it before buying. The same unit different generations vehicles from the manufacturer may have completely different variants operation. And in this case you can get really disappointed when buying.

How to operate a diesel engine in winter?

Winter operation of a power unit with diesel fuel is somewhat more complicated. If gasoline does not freeze at all in principle, then the cloud point of diesel fuel is -25 degrees Celsius. The freezing temperature already at -35 degrees excludes the operation of a car in such conditions. However, today there is diesel fuel with additives, which is used without problems in any conditions. There are a number of cautionary points:

- in winter, it would be nice to install a turbo timer in a diesel engine, which would continue to slowly reduce the temperature of the engine after a trip, when you have already left the car;

- should also choose winter fuel at the gas station, choosing initially normal filling station on which you will not fill the tank with low-quality liquid;

- you can also use a number of additives to reduce the crystallization temperature of the fuel, when the fuel poured into the tank turns into a gel-like mass;

- after turning diesel fuel into gel, you will have to take the car to the service, moreover, on a tow truck, in order to clean it fuel cells and hoses for further use.

For these reasons diesel cars V northern conditions- it's not the best good option. In central Russia, such cars are quite acceptable and can perform their functions perfectly. In the south, there are no problems with their operation at all. However, you need to take into account a number of features in terms of fuel use and the quality of service for your car. We offer to see short video about features diesel car:

Summing up

Does it make sense to buy a diesel car? In economic terms, this makes little sense. But in terms of travel, your conditions will really seriously change. You will get to know new technology which completely opens up a new perception road transport. There are a number of positive and a number of negative factors in the use of such transport. But diesel enthusiasts often argue that the pros far outweigh the cons. Of course, all this is very conditional. You can buy a diesel and be extremely dissatisfied with the situation at the first breakdown in the winter. But remember that the quality of operation directly depends on you.

You should also be aware of gas station, which can be normal and terrible. If gasoline unit from bad refueling just increase consumption diesel fuel can destroy a number of expensive items in the car. Therefore, in Europe, for example, to exploit diesel units unproblematic. On the other hand, there are always a number of difficulties in owning a car with such a unit. So if you are afraid of these difficulties, you better choose petrol car. If you want to try something new, feel free to buy a turbodiesel. Which engine would you prefer for personal use?

Have Japanese manufacturers reliable diesel engines. And what is the most reliable diesel engine among all reliable in Japan?

Let's look at the most common modern diesel engines in the Japanese car industry.

What are these diesels, what are the weak and strengths Japanese diesels. They now dominate mainly in Europe, but quite often began to appear in Russia.

But, unfortunately, they also have problems when their runs exceed one hundred thousand kilometers, and even some up to one hundred thousand.

The caution in the supply of diesel engines from Japan is due to their capricious attitude to fuel. Their fuel system is rather weak to the use of our diesel fuel.

Another problem is the availability of spare parts. There are practically no non-original spare parts from reliable manufacturers. Chinese ones appear, but their quality leaves much to be desired and does not at all correspond to Japanese quality.

Hence their very high price is dictated, much higher than for German spare parts. There are many factories in Europe producing spare parts decent quality and at prices significantly lower than the original ones.

The most reliable diesel engine from Japan

So what is the most reliable diesel engine from Japan? Let's rank the TOP 5 of the best diesel engines.

5th place

In fifth place, you can safely put the 2.0-liter Subaru engine. Four-cylinder, turbocharged, boxer, 16-valve. Common rail intake system.

It must be said that this is the only boxer diesel engine in the world.

A boxer engine is when mutual pairs of pistons work in a horizontal plane. In this arrangement, careful balancing of the crankshafts is not required.

The weaknesses of this engine are a two-mass flywheel, it failed even up to five thousand kilometers. Cracking crankshaft, until 2009 were destroyed crankshafts and shaft supports.

This engine is very interesting in its design, with good performance, but the lack of spare parts for such engines nullifies its advantages. Therefore, he Japanese series diesel engines take the fifth place of honor.

4th place

We will lift to the fourth place Mazda engine 2.0 MZR-CD. This diesel engine has been produced since 2002, and installed on Mazda car 6, Mazda 6, MPV. It was Mazda's first Common Rail engine.

Four cylinders, 16 valves. Two versions - 121 hp and 136 hp, both of which developed a torque of 310 Nm at 2000 rpm.

In 2005, it underwent modernization, with an improved injection system and a new high-pressure fuel pump. Reduced compression ratio and adaptation of the engine with a catalyst for the emission of harmful gases. Power became 143 hp.

Two years later, a version with a 140 hp engine was released, in 2011 this engine disappeared from the line of installed engines for unknown reasons.

This engine calmly nursed 200,000 kilometers, after which it was necessary to change the turbine and the dual-mass flywheel.

When buying, you should carefully study its history, but it is better to remove the pan and look at the oil sump.

3rd place

Also a Mazda engine, Mazda 2.2 MZF-CD. The same engine of increased, but increased volume. Engineers tried to eliminate all the jambs of the old two-liter engine.

In addition to the increased volume, the injection system has been modernized, another turbine has been installed. On this motor, they put piezo injectors, changed the compression ratio and radically changed particulate filter which caused all the problems previous model two liter engine.

But the worldwide fight for the environment, both in Europe and Japan, adds gimoroya to all engines, and a system is installed on this one, with the addition of urea to the diesel fuel mixture.

All this reduces exhaust emissions to Euro5, but as always, in Russia this adds problems to all modern diesel engines without exception. This is simply solved by us, the particulate filter is thrown out and the afterburning valve of the unburned exhaust is turned off.

The rest of the engine is reliable and unpretentious

2nd place

Toyota 2.0/2.2 D-4D engine.

The first two-liter Toyota 2.0 D-4D CD appeared in 2006. Four-cylinder, eight-valve, cast iron block, timing belt drive, 116 hp The engines came with the "CD" index.

Complaints about this engine were very rare, they all came down to injectors and the recirculation system. exhaust gases. In 2008, it was discontinued, and a new one was launched instead, with a volume of 2.2 liters.

Toyota 2.0/2.2 D-4D AD

They have already begun to make a chain, there are already 16 valves for four cylinders. Block steel to make aluminum with cast iron sleeves. The index of this engine became "AD".

The engine is available in both 2.0 liters and 2.2.

Most good feedback about such an engine, and good returns, and low fuel consumption. But there were also complaints, the main one was the oxidation of the aluminum head at the point of contact with cylinder head gasket, approximately in the period of 150-200 thousand km. run.

Replacing the head gasket does not help, only cylinder head grinding and block, and this procedure is possible only with the removal of the engine. And such a repair is possible only once, the motor will not withstand the second grinding of the head and block, the depth will be critical with the possibility of meeting the valves with the head. Therefore, if the motor passed 300-400 thousand kilometers, with one grinding, it is only for replacement. Although this is a very decent resource.

Toyota in 2009 solved this problem, with such malfunctions, they even got me under warranty for new engines at their own expense. But the problem is very rare, but it does occur. Mostly for those who are not weak on the strongest version of this 2.2-liter engine model.

Such engines are still produced and installed on various models cars: Raf4, Avensis, Corolla, Lexus IS and others.

1 place

Diesel Honda motor 2.2 CDTI. The most reliable small diesel engine. Very productive and very economical diesel engine.

Four-cylinder, 16-valve, variable displacement turbocharged, common rail injection system, sleeved aluminum block.

The injectors are used by Bosch, not capricious and expensive Japanese Denso.

The predecessor of this engine was built back in 2003 with the marking 2.2 i-CTDi. He turned out to be very successful. Trouble-free, dynamic and economical in fuel consumption.

modern in question Honda engine 2.2 CDTi appeared in 2008.

Of course, typical malfunctions did not pass, but all of them were extremely rare. Exhaust manifold cracks, but they occurred in the first releases, the Japanese reacted and this was not observed in subsequent releases.

Sometimes there were malfunctions of the timing chain tensioner. Also, sometimes the play of the turbine shaft appeared prematurely.

All of these failures arose from excessive constant loads and poor maintenance.

Honda installed this engine on Honda models Civic, Accord, CR-V and more.

Of course, this engine has the smallest number of failures and breakdowns in relation to all other engines of Japanese automakers.

We put him five points out of five, assign him the first place of honor and wish you to have a similar one on your car.

The operation of a diesel engine in the last century was associated with bad smell, roar and thick black smoke coming from the chimney. But in the last decade diesel technology are developing by leaps and bounds.

The engines became quieter, the smell of exhaust gases almost completely disappeared, and the harm caused to the environment began to be reduced to zero. However, the principle of operation has not changed.

Working principle of diesel engine

The difference between a diesel engine and a gasoline engine is due to the fact that the mixing of fuel with air occurs not outside, but inside the cylinder.

In addition, the mixture ignites on its own, without a spark plug. Engine design includes:

- Cylinder.

- inlet and Exhaust valve s.

- Piston.

- fuel injector.

In this video, you will learn how a diesel engine works. Watch and take note!

You can describe the principle of operation of the motor by considering the actions of the piston, valves and nozzles during each stroke. Usually there are four.

stroke - fuel inlet

The piston has two dead spots: upper (TDC) and lower (BDC). During the first stroke, the intake valves open and the exhaust valves close. A vacuum is created in the cylinder. Air rushes in.

beat - compression

All valves are closed. The piston moves from BDC to TDC, compressing the air that entered during stroke 1 to 5 MPa. Its temperature rises to 700 C.

Tact - stroke (expansion)

The piston is at TDC. The high pressure fuel pump delivers fuel to the cylinder through the injector. When sprayed, it mixes with heated air and ignites spontaneously.

During combustion, the temperature rises to 1800 C o, and the pressure to 11 MPa. The piston begins to move from TDC to BDC, making useful work. At the end of the working stroke, the temperature inside the cylinder drops to 700-800 C o, and the pressure drops to 300-500 kPa.

stroke - release of gases

The intake valve is closed, the exhaust valve is open. The piston pushes the exhaust gases through it. The temperature inside drops to 500 C o, and the pressure to 100 kPa.

Advantages of diesels

In this video, you will be told what are the differences and advantages of diesel engines from gasoline.

Motors that perform useful work by burning diesel fuel have several advantages over gasoline devices:

- Reduced fuel consumption by a third.

- No ignition system.

- Motor resource increased by one and a half times.

- Stability of control parameters.

- The average efficiency is 40%, for turbocharged engines it is above 50%.

- High torque.

- Low saturation of exhaust gases with carbon dioxide (ecology is less harmed).

- Fire safety due to the fact that diesel fuel cannot ignite spontaneously.

Among the minuses of the "diesel" is noteworthy the difficulty of a cold start. The motor is the source strong vibration and loud noise. However modern models devoid of these shortcomings.

Scheme of operation of individual nodes

The design of a modern diesel engine includes the following components:

- Turbocharger (turbocharger, turbine).

- Intercooler.

- Fuel burner.

Consider the scheme of operation of composite nodes.

Turbocharger

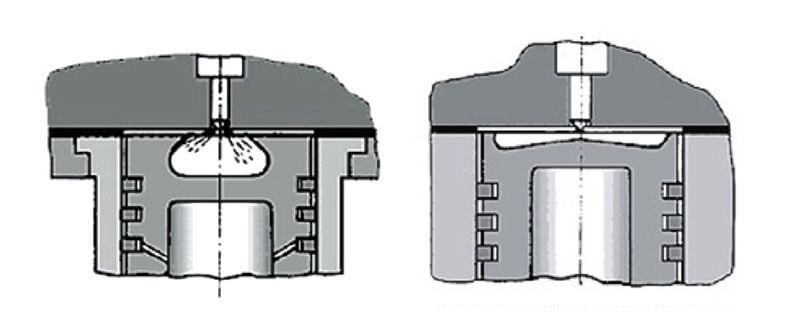

Sectional view of a turbocharger

Experience has shown that the fuel does not have time to burn out at the moment when the piston moves to dead center. Therefore, if you make it burn out completely, the power of the motor will increase dramatically.

For this, a turbocharger was created, which provides fuel supply under excess pressure and contributes to its complete combustion. The design of the turbocharger includes:

- Two casings (one for the turbine, the other for the compressor);

- Bearing housing with a shaft connecting the turbine rotor and the compressor wheel;

- Bearings - support for the assembly;

- Steel protective mesh.

The scheme of his work is as follows:

- The compressor sucks in air from the outside atmosphere;

- The compressor rotor, driven by the turbine rotor, compresses it;

- Compressed air is cooled by an intercooler;

- The air is filtered and supplied through intake manifold motor, after which the exhaust valve closes. It will open after the work stroke is completed;

- Exhaust gases entering through the exhaust manifold, when passing through the narrowing channel of the turbine housing, increase speed and affect the rotor;

- The rotation speed of the turbine increases to about 1500 rpm, as a result of which the compressor rotor is driven (they are connected by a shaft);

- The cycle is repeated.

As air cools, its density increases. Therefore, more is supplied to the engine cylinder. A large amount of air contributes to the complete combustion of the fuel, which increases the power of the diesel engine. At the same time, the negative impact on the environment is reduced.

Type of diesel engine intercooler

intercooler

Compressing air not only increases its density, but also its temperature. On the one hand, the receipt a large number oxygen into the cylinder has a positive effect on fuel combustion. But on the other hand, the inlet of hot air contributes to the rapid destruction of the structure.

Therefore, a device is needed that reduces the temperature of the compressed air. This is the intercooler. The principle of operation of the intercooler is to cool the hot substance by cold heat exchange between them.

It is possible to use two types of intercooler:

- Air to air. The radiator of the device transfers the heat of the heated air to the atmosphere. The design is extremely simple, therefore it is widespread;

- Air to water. First, the exhaust gases enter the compressor, then they pass through the intercooler radiator, which is washed by water. Device is different high efficiency and compactness. But additionally, a radiator for cooling water and a pump for its circulation, a control unit are required.

It does not matter what type of device the intercooler belongs to.

The result of the work is unchanged: the temperature of the air compressed by the compressor is reduced by the radiator.

The intercooler itself can be called a cooling radiator, consisting of tubes made of materials with a high thermal conductivity.

Nozzle

The device of a diesel engine provides for the presence of one or more nozzles. These parts are designed to dispense and spray fuel.

The scheme of the diesel engine injector

With their help, the combustion chamber is sealed. Modern nozzles work from the cam camshaft through the pusher. Fuel is supplied and drained through channels located in the head of the block.

Its dosage is provided by a control unit that sends signals to shut-off valves with electromagnetic properties. The injectors operate in pulse mode. This means that before the main injection of fuel, its preliminary supply is carried out.

At the same time, the operation of the diesel engine becomes softer, and the level of toxic emissions into the atmosphere decreases.

Thus, a diesel engine is a set of interconnected nodes.

The turbocharger supplies compressed air cooled by the intercooler into the combustion chamber. Fuel is supplied to it through the nozzle. If at least one of the nodes fails, the operation of the motor is impossible.

Consider the history of creation, the principle of operation of a diesel engine, try to understand the reasons for its popularity, its design features, advantages, disadvantages and scope.

Rudolf Diesel assembled his brainchild in 1897. It was a smoothly running, extremely simple, easy-to-operate mechanism.

The technical documentation for the invention fit on 13 pages - Rudolf Diesel drew and described the engine on them, which was then named after him.

Thus began the story, as a result of which we now have millions of trucks, passenger cars mobiles and ships with diesel engines.

Working principle of diesel engine

And yet, what is the principle of operation of a diesel engine? The principle of operation of a diesel engine is the compression ignition of fuel in the combustion chamber when mixed with a heated air mixture.

The mixture is supplied separately - first, air is injected, then the piston compresses it and top dead point fuel is injected through the injector

Air, in the process of compression, is heated to 800ºС, fuel is supplied with a pressure of up to 30 MPa, self-ignition occurs.

This process is accompanied by vibrations and noise. That is, a diesel engine is noisier than a gasoline engine.

The principle of operation of a diesel engine allows engines to be both two-stroke and four-stroke, but the majority of cars, nevertheless, are equipped with four-stroke engines.

IN two-stroke diesel, in comparison with the four-stroke, due to a different principle of operation, the combination of two cycles, intake and exhaust (purge).

The two-stroke version is about one and a half times more powerful than the four-stroke version of the same size.

Diesel engine design

A diesel engine is almost the same as a gasoline engine - it just does not have an ignition system, and the principle of operation of a diesel engine is ignition fuel mixture not from a spark plug, but from air heated by high pressure.

True, high pressure (up to 30 atm.) in the combustion chamber implies increased requirements for details.

According to the design of the combustion chambers, diesel engines are divided into 3 types:

- Divided vortex combustion chamber;

- Undivided combustion chamber;

- Divided prechamber.

In such a device, the fuel mixture is supplied not to the main, but to an additional vortex chamber.

It is located in the cylinder head and is connected to the cylinder through a special channel. Ignition occurs in the vortex chamber and spreads to the main chamber.

Undivided combustion chamber

With this design, the chamber is located in the piston, and the fuel mixture enters the cavity above the piston.

This version of the chamber allows you to reduce fuel consumption, but increases the noise level during engine operation.

Divided prechamber

The diesel engine is equipped with a plug-in prechamber, it is connected to the cylinder by channels of small cross section.

The size and shape of the channels affect the speed of movement of gases during the combustion of fuel, while reducing noise and toxicity, increasing the resource.

Any diesel engine has a special fuel system. The high-pressure system delivers the right amount of fuel mixture to the cylinders. Let's look at its elements.

The main elements of the fuel system

- pump high pressure for fuel supply ();

- fuel filter;

injection pump

Pump supplies fuel to the injectors in an amount that depends on the speed, the position of the regulator lever and the turbo boost pressure indicators.

In modern diesel engines, two systems of fuel pumps are used - in-line (plunger) or distribution. More about pumps.

Several other pumps are used in modern system injection, they are called trunk.

In the Common Rail system, the injection pump pumps fuel into the rail, where pressure is maintained in all channels up to the injectors.

Special nozzles are electronically controlled and in right moment open to inject fuel into the combustion chamber. You can read about this system.

Fuel filter

The filter is set based on the engine model. Its function is to separate and remove water from diesel fuel and excess air from the system.

nozzles

To supply the fuel mixture to the combustion chambers, two types of nozzles are used - with multi-hole and font distributors.

The nozzle distributor determines the shape of the flame required for a more efficient ignition process.

Preheating

For a cold start diesel engine is used preheating. It is provided by glow plugs installed in the combustion chamber.

When starting, the glow plugs heat up to 900ºС, heating air mixture that enters the camera.

The heating system makes it possible to safely start even at the lowest temperatures.

Turbocharging

Turbocharging in diesel engines increases power and efficiency.

With an increase in air supply, it is provided high blood pressure in the cylinders, the combustion of the mixture is improved accordingly, thereby increasing engine power.

To obtain optimal pressure supercharging in all operating modes, a turbocharger (turbine) is used.

Diesel advantages and disadvantages

Advantages

The main advantage of a diesel engine is its high-torque power.. He is able to develop more power at low speeds, easily tolerates overloads, hard braking and starts.

The second plus is economy.. A liter of diesel costs a little less than a liter of high-octane gasoline, although fuel sellers shamelessly equate it with the most expensive gasoline.

Coefficient useful action for a diesel engine at medium speeds it reaches 45 percent, and with a turbocharger it goes up to 50, for a gasoline engine such figures are not realistic at all. In addition, diesel consumes less fuel.

The third plus is environmental friendliness. The diesel engine has lower toxicity of exhaust gases.

The next advantage is durability and reliability., since diesel fuel at the same time and lubricant protecting engine parts from wear.

Flaws

As for the shortcomings, one of the most significant is poor frost resistance. Summer fuel becomes thick at minus 5°C, winter fuel at minus 35°C.

Diesel repair and gasoline engine they are approximately equivalent in cost if the high-pressure fuel pump does not fail. In this case, the owner gets into serious money. And it breaks from domestic diesel fuel Low quality. In turn, good imported fuel is already a slightly different price.

Diesel engine is good at low and medium speeds. The desire to squeeze the maximum out of it brings rapid wear knots and parts.

Also cars in diesel version can cost a third more than a gasoline counterpart.

The turbodiesel has its drawbacks - the resource of the turbocharger is less than the resource of the engine itself. Usually it is no more than 150,000 kilometers. In addition, the turbine makes high demands on the quality of engine oil.

Well, at the expense of the smell of exhaust from diesel engine. Perhaps for someone this is not critical, but the smell is there, and at the same time quite unpleasant.

Areas of use

Diesel engines currently use:

- on heavy trucks;

- on stationary power plants;

- on cars and trucks;

- on diesel locomotives and ships;

- on agricultural, special and construction equipment.

Well, you have learned what a diesel engine is, how many big pluses and small minuses it has.

Now, knowing how a diesel engine works, you will wonder what next car buy: .

Just visit the site!

Before buying a new car, any driver has a choice between two types of engines - gasoline and diesel. Of course, every motorist has his own preferences and beliefs about the advantages of a particular motor. However, which one is better? In this article you will not find a clear answer to this question. Here we will objectively and in detail consider all the pros and cons of each motor, but final choice behind you, dear readers. To do this, we compare both types of engines in several of the most important operational parameters.

Type installed engine one of the most important characteristics car

Power and torque

Gasoline engines are shorter stroke than diesel engines. As a result, they have less torque, but they give out more power and are able to spin up to high speed. Thanks to this, gasoline engines have good acceleration dynamics. Only modern turbocharged diesel engines can compete with them in this.

If you often transport heavy loads and need excellent traction, then diesel is your choice. Its torque is much higher and is fully realized at low revs due to the higher compression ratio required for self-ignition of diesel fuel (17:1 versus 9-10:1 for gasoline engines).

According to this parameter, it is impossible to single out a leader unambiguously, so let's move on to the next characteristic.

Economy

Most often, cars with diesel engines are bought to save money on fuel. But is it possible to save money by purchasing diesel? Let's try to figure it out.

As mentioned above, diesel engines have more a high degree compression. This increases the efficiency (coefficient of performance), which is 20-40% higher than that of gasoline counterparts. So it is easy to guess that a diesel engine eats much less fuel per kilometer than its gasoline competitor.

In addition, in a diesel engine, fuel is injected directly into the combustion chamber, which means that its losses are minimal. In gasoline engines, fuel is mixed with air in the intake manifold.

Everything would be fine, but the days when a liter of diesel fuel cost an order of magnitude cheaper than a liter of even the most low quality gasoline. In modern realities, the cost of diesel fuel has already surpassed the expensive 95th gasoline, which means that fuel savings are practically leveled by the difference in price.

Let's take a simple example. Diesel Ford Focus consumes 5.2 liters of fuel per 100 kilometers, it petrol version- 6.4 liters per 100 km. At the same time, in most regions of our vast country, diesel fuel is mainly 3 rubles more expensive than the most common 92nd gasoline. By a simple calculation, we find out that in order to close the difference in cost, you will have to drive at least 145 thousand kilometers on a diesel engine. With the annual mileage of most motorists of 20-30 thousand km, buying a diesel engine for the sake of economy is at least impractical.

Noise and vibration

Currently, all automakers are actively working to reduce the noise and vibration of diesel engines. Modern diesels have already come close in terms of these indicators to their gasoline counterparts. However, even on the street it is very easy to distinguish diesel from gasoline by the characteristic knock and vibration when working on idling. The gasoline engine is so quiet that it is sometimes difficult to tell by ear whether it is working or not.

There is a clear advantage for gasoline engines.

Something else useful for you:

Starting and working in cold weather

Probably, everyone knows the problems of a diesel engine in frosty weather. The whole point is that in diesel engine fuel ignites spontaneously by heating the air under strong compression. At temperatures below -30 degrees, the air cannot warm up enough to ignite the fuel. To get around this problem, diesel engines use glow plugs to heat the combustion chamber to the correct temperature before starting.

However, if a car with a diesel engine starts up in the cold, this still does not give any guarantees that it will get from point A to point B. If poor quality or summer fuel, then in the cold, paraffin crystals instantly form in it, which, in turn, clog the fuel line and filters, and the car simply stalls on the go. Experienced diesel drivers advise not to lower the fuel level in the tank below ½ in winter in order to avoid such phenomena.

With a gasoline engine, this will not happen in winter. The fuel is stably ignited by a spark, providing easy starting. You just have to keep an eye on the level and choose the right engine oil.

Another point in favor of petrol cars.

Service

About ten years ago, it was generally accepted that servicing a diesel engine is much more expensive than gasoline engines. At present, the situation has changed radically: the prices for consumables for diesel engines are quite acceptable. True, diesel fuel additives should be added to the expense item. They are sometimes worth adding because Russian diesel fuel is not always of good quality.

Another issue is maintenance. By by and large for labor costs for the bulkhead of a diesel engine no more than a gasoline engine: the same pistons, cylinders, crankshaft, rings, sometimes turbines, etc. However, not everything is as good as it would seem. There is one detail that greatly spoils the picture - fuel injection pump ( fuel pump high pressure). In itself, the device of such a pump is simple, however, it uses very precise processing of parts, which not every service can provide. As a result, for the repair of high-pressure fuel pumps, you need to look for a long time good master, and for the work you will have to pay from 400 to 1500 dollars. Installing a new pump can be quite commensurate with buying a used foreign car.

Environmental friendliness

Despite the fact that the diesel engine burns fuel more efficiently, it is still inferior to gasoline engines in terms of emissions. Diesel fuel contains more sulfur and forms soot when burned. Smoky diesel is also more common. Finally finishes the fact that according to research scientists, the products of combustion of diesel fuel greatly increase the risk of cancer in humans.

Gasoline is a lighter fuel, burns faster with less deposits. Consequently, cars with these engines are much more environmentally friendly.

Durability

A diesel engine runs at a lower RPM than a gasoline engine. The operating range of passenger car diesel engines is most often limited to 5000-6000 rpm, while gasoline ones spin up to 8000-9000 rpm. Petrol engines for the most part, they go 300-350 thousand kilometers to overhaul, while some diesels are capable of driving up to a million kilometers without major intervention.

Price

The compression ratio in diesel engines is much higher, so the pistons, cylinder block, connecting rods, crankshaft, cylinder head, etc. are subjected to higher loads, and therefore must be reinforced accordingly. As a result, diesel engines lose out on gasoline counterparts in terms of price.

Conclusion

Comparing gasoline and diesel engines according to the parameters described above, it becomes easier to make the final choice. If you need good acceleration dynamics, you do not plan to carry heavy loads and are satisfied with a resource of 300 thousand km, then petrol cars for you. Diesels are more suitable for trucks, "workhorses" that often carry any cargo with high annual mileage.

However, whatever you say, each type of motor has a lot of fans, and the debate about which is better will continue as long as these engines exist. No wonder they say - there are no comrades for the taste and color.