Vehicle handling is its ability to easily change direction when turning the steering wheel and hold given direction movement.

While driving, it is very important that the steered wheels do not turn arbitrarily and the driver does not have to expend effort to keep the wheels while driving straight.

While driving, it is very important that the steered wheels do not turn arbitrarily and the driver does not have to expend effort to keep the wheels while driving straight. To improve the stability of the car during its movement and facilitate handling, the angles of the steered wheels are structurally provided.

Rice. Wheel alignment angles:

γ is the pitch angle of the axis; α is the camber angle; β is the angle of the transverse inclination of the axis; θin – internal angle of rotation; θn - outer angle of rotation; A - the distance between the inner surfaces of the front of the tires; B - the distance between the inner surfaces of the rear of the tires

Camber angle provides a perpendicular arrangement of the wheels with respect to the road surface when the car is moving, as well as the transfer of the reaction forces of the road to inner bearing that unloads outer bearing smaller wheels, which means less shock transmitted to the steering gear.

The camber angle can be positive when the top of the wheel is tilted outward relative to the vehicle body, negative when the top of the wheel is deflected inward, and zero when the wheel plane is vertical.

- increased tread wear. If the camber angle has a deviation in positive side, then wear is noted on the outer side of the tread, if it is negative, the inner side wears out

- deterioration in vehicle handling. With an increased difference in the camber angles of the left and right wheels, the car leads to the left or to the right side when driving on flat road with the steering wheel released. The car will pull in the direction where the wheel is located, the camber angle of which has a more positive value. As a rule, the difference between the left and right camber angles of most vehicles is limited to 0°30′ (minutes)

- increased fuel consumption

- accelerated wear of the suspension elements due to the increase in the loads acting on them

All of the above applies to both the front and rear wheels of the car.

When diagnosing the geometry of the suspension, the camber angles are always checked, on cars of all brands, and are subject to adjustment only in cases where this is provided for by the design.

The value of the camber angle of the front wheels for different cars varies from -2° to 2…4°. The rear wheels tend to have more significant camber angles. On BMW cars, For example, rear wheels have a camber angle of more than -3°.

Toe angle(distance difference between the inner surfaces of the rear and front of the tires of the front or rear axle(B - A)) is necessary in order to ensure parallel rolling of the wheels, since when the car is moving, due to the installation of wheels with camber, a force arises that contributes to turning the wheels at an angle of 0.5-1.0 ″ from the vertical plane of the car, which causes the wheels to roll in divergent arcs. In addition, the toe angle protects the wheels from slipping in the presence of play in the joints of the steering rods, wheel bearings.

Toe-in can be measured not only in linear (mm), but also in angular units (degrees), and recently measurement in angular units is preferable.

The general convergence can be positive when the distance A is less than B, negative when the distance A is greater than B, and zero when A is equal to B. In addition to the general convergence, there is an individual convergence for each wheel, defined as the angle between the wheel plane and the axle symmetry in plan.

Incorrect camber setting may result from:

- accelerated tire tread wear. If the convergence is more than the norm - too positive, then wear is noted on the outer part of the tread on both wheels, if the convergence is too negative, then wear occurs on both wheels on the inside of the tread

- increased due to increased resistance to movement

Toe-in is always measured and adjusted on all makes of cars by changing the length of the steering rods.

The wheels of front-wheel drive vehicles usually have a slight toe-in, both positive and negative (of the order of ± 2 mm). On rear-wheel drive, as a rule, only positive with a value of no more than 5 mm.

Axis roll angle determined by the angle formed by the suspension axis with the vertical plane. Such an inclination, together with the camber angle, reduces the distance between the point of intersection of the geometric axis of the suspension with the road and the point of the center of contact of the tire, which reduces the moment arm that must be applied when turning the wheels of the car, and therefore facilitates driving.

With a transverse inclination of the kingpin (the axis of rotation of the steered wheels), it is always more difficult to turn the wheel together with the pin than to return it to its original position - moving in a straight line. This is due to the fact that when the wheel is turned, together with the trunnion, the front of the car rises by an amount b (the driver makes a relatively great effort to the steering wheel).

As a rule, this angle is positive and large enough (from +5° to +20°) and is not adjustable in operation.

Pitch Angle serves to stabilize the steered wheels by the moment arising from the shoulder (distance from the suspension axle to the center of tire contact) of the lateral force.

Due to the longitudinal inclination of the kingpin, the wheel is set so that its fulcrum in relation to the axis of rotation (the axis of the kingpin) is shifted back by a certain amount and the wheel always tends to take its original position, i.e. the position of the car when driving in a straight line. In this case, the wheel is located behind the suspension and stretches behind it, this stabilizes the rectilinear motion of the wheel to avoid angular vibrations his. When driving in reverse appears opposite effect– the wheel is pushed by the suspension, so the steering wheel is harder to hold.

The roll angle of the steering axis can be positive when the steering axis is tilted towards the driver, negative when it is tilted away from the driver, and zero when the steering axis is vertical.

Excessively large tilt angles of the axis of rotation lead to a sharp increase in the force applied to the steering wheel when cornering.

Unregulated pitch angles of the axis of rotation leads mainly to the unstable movement of the vehicle. The trajectory of the car's movement deviates towards the wheel, whose axis of rotation is inclined more. On most vehicles, the difference in the longitudinal angles of inclination of the axis of rotation of the left and right wheels should not exceed 0°30'.

The angles of the longitudinal inclination of the axes of rotation of the wheels are subject to verification. Adjustment is not available on all vehicles.

The axis of rotation of the wheels of front-wheel drive vehicles have small, usually positive angles of longitudinal inclination (of the order of + 2 ° ... + 3 °). For rear-wheel drive vehicles, the range of this parameter is much larger (from +2° to +14°).

The difference between the inner and outer steering angles is necessary to prevent slipping of the wheels when they turn.

When the car enters a turn, the convergence of the wheels gradually develops into a divergence due to the special design of the wheel control rods. The inner radius wheel turns more than the outer radius, which automatically increases the change in direction and lightens the steering effort. This is also necessary because when cornering, the inner wheels have a smaller turning radius than the outer ones.

When the steer wheels return to the straight-ahead position, the weight of the vehicle assists in turning the wheels and the driver applies a small amount of force to the steering wheel.

Tires with low internal air pressure also have stabilizing properties, so kingpin angles in passenger cars are smaller or completely absent. However, on vehicles where the air pressure in the tires is low, side slip occurs due to the lateral force causing the tire to sag, with the wheels shifting to the side.

Rice. Wheel slip scheme

Both front axle wheels have the same slip angle. As the wheels are swiveled, the turning radius increases. When pulling wheels rear axle turning radius is reduced. This is especially noticeable if the slip angle of the rear wheels is greater than the front ones - the stability of the movement is disturbed, the car begins to "scour", and the driver has to correct the direction of movement all the time. To reduce the effect of slip on the vehicle's handling, the air pressure in the tires of the front wheels should be somewhat less than in the rear. The slip of the wheels will be the greater, the greater the lateral force acting on the car (for example, on sharp turn where there is a large centrifugal force.

The controllability of the car also depends on the state of the steering. While driving, the driver constantly uses the steering wheel, without releasing it from his hands. If the steering wheel must be turned with great effort, the driver gets tired faster, ceasing to respond to small deviations of the car, cuts the corners of the gate, and thus creates a threat to traffic safety. In case of violation of the adjustment of the front wheel hub bearings, large play in the joints of the steering mechanism and steering gear, incorrect installation front wheels (toe and camber) or tires of the wrong size also significantly degrades the car's handling.

The movement of the car is associated with the implementation of various maneuvers. During turns, centrifugal force acts on the car, while the stability of the car is disturbed and the driver expends much more effort than when driving in a straight line. How longer car and the tighter the turns, the greater the width of the train should be.

Thanks to the presence of the steering trapezoid, the front wheels turn at an unequal angle and roll without slipping. If we assume that the rear wheels are rolling in the wake of the front wheels, then the turning radius is the distance from the center of the turn to the middle of the rear axle. The outer radius is the distance from the center of the turn to the extreme front point of the vehicle, and the inner radius is the distance from the center of the turn to the nearest point of the vehicle at the rear axle.

The minimum turning radius depends on maximum angle the rotation of the front wheels, which is not the same for all cars, but for cars more than for trucks.

For vehicles with trailers, the cornering width must be even wider. In this case, the inside turning radius is determined from the closest point to the turning center at the rear axle of the last trailer.

During cornering, there is a centrifugal force applied at the center of gravity of the car. This force is directed along the radius from the center of rotation (Fig. 201); it can be decomposed into two components, one of which (A) is directed along the axis of the car, and the other (B) in the transverse direction, tending to overturn the car or cause it to skid.

Rice. Decomposition of centrifugal force at a turn

The transverse component of the centrifugal force is determined by the formula

C = Gv2/gR

where C is the transverse component applied to the center of gravity of the car, kgf; G - vehicle weight, kg; v - vehicle speed, m/s; R - turning radius (to the middle of the rear axle), m; g - acceleration of a freely falling body, m/s2.

From the above dependence it can be seen that the greater the mass and speed of movement and the smaller the turning radius, the greater will be the transverse component of the centrifugal force and the worse the stability of the car when turning. Biggest Influence the magnitude of the centrifugal force and its transverse component is affected by the speed of movement, since in the above dependence it is taken squared. If the speed of movement is increased by 2 times, then the transverse component of the centrifugal force will increase by 4 times. To decrease centrifugal force on a curve, the driver must slow down.

Skid is the side slip of the rear wheels with continued forward movement car ahead. Sometimes skidding can cause the car to turn around its vertical axis. If you turn the steered wheels sharply, it may turn out that the inertial forces will become greater than the traction force of the wheels with the road, and the car will skid, especially this often happens on slippery roads.

With unequal traction forces applied to the wheels of the right and left sides, a turning moment occurs, leading to a skid. The immediate cause of skidding during braking is unequal braking forces on the wheels of one axle, unequal grip of the wheels of the right and left sides with the road, or improper placement of the load relative to the longitudinal axis of the vehicle. The reason for skidding a car on a turn can also be its braking, since in this case a longitudinal force is added to the lateral force and their resulting force may exceed the adhesion force that prevents skidding.

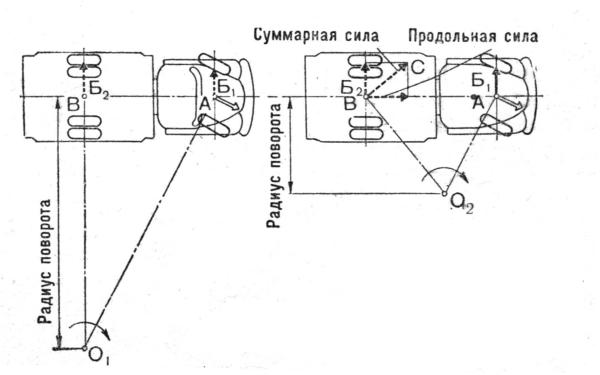

Rice. Scheme of skidding a car on a turn

In order to stop the car from skidding, you must immediately stop braking and, without disengaging the clutch, turn the wheels in the direction of skidding. After the skid stops, you need to align the wheels so that it does not start in the other direction.

Most often, skidding occurs when hard braking on wet or icy roads; skidding occurs especially quickly at high speed, so on slippery or icy roads and when cornering, you need to reduce speed without applying braking. In addition to skidding, the vehicle may roll over under certain conditions.

Caster angle (caster) - the angle between the axis of rotation of the wheel and the vertical in the side view. It is considered positive if the axis is tilted back relative to the direction of motion.

Camber - the inclination of the wheel plane to the perpendicular, restored to the plane of the road. If the upper part of the wheel is tilted outward of the car, then the camber angle is positive, and if inward, then it is negative.

Convergence - the angle between the longitudinal axis of the car and the plane passing through the center of the tire steered wheel. Convergence is considered positive if the planes of rotation of the wheels intersect in front of the car, and negative if, on the contrary, they intersect somewhere behind.

The following are experiments that allow you to understand how wheel adjustments affect the behavior of the car.

The Samara VAZ-2114 was chosen for the tests - most modern foreign cars do not burden the owner with a range and choice of adjustments. There, all the parameters are set by the manufacturer and it is quite difficult to influence them without constructive alterations.

The new car - unexpectedly light handlebar and erratic behavior on the road. The camber angles are within the tolerance range, with the exception of the longitudinal angle of inclination of the axis of rotation of the left wheel (caster). Applied to the front suspension of the domestic front wheel drive car setting angles always starts with adjusting the caster. It is this parameter, on the one hand, that determines the rest, and on the other hand, it has a lesser effect on tire wear and other nuances associated with the car's rolling. Moreover, this operation is the most time-consuming - I think that is why it is “forgotten” at the plant. Only then, having dealt with the longitudinal angles, a competent master begins to adjust the camber, and then the toe-in.

Option 1

The master maximally shifts the angles of the longitudinal inclination of the racks, taking them to the “minus”. We sort of move the front wheels back to the mudguards. wheel arches. A situation that is quite common on old and very "left" cars or after installing spacers that raise back car. The result: light steering, fast responses to its slightest deviations. However, "Samara" has become overly nervous and fidgety, which is especially noticeable at speeds after 80-90 km / h and above. The car has unstable responses when entering a turn (not necessarily fast), strives to take risks to the side, requiring the driver to constantly steer. The situation becomes more complicated when performing the “rearrangement” maneuver.

Option 2

The "correct" position of the racks (tilted to the "plus"), set to "zero" and the angles of convergence and collapse. Steering wheel became elastic and informative, and a little more "heavy". The car drives clearly, clearly and correctly. The fidgetiness, slurred relationships and trajectory yaws have disappeared. At the "rearrangement" VAZ easily outstripped the previous version.

Option 3

Overly "positive" collapse. It is undesirable to change it without correcting the convergence, therefore, a positive convergence is also introduced.

Again, the steering wheel became "lighter", the responses at the entrance to the turn became lazier, the lateral buildup of the body increased. But there are no catastrophic deteriorations in character. However, when modeling extreme situation"Feeling steering" is lost. With the advent of slips, unexpectedly early, it becomes more difficult to get into a given corridor on the "rearrangement" and the car starts to slide too early. In fast corners, the strongest slippage of the front axle dominates.

Option 4

A variant with sporting ambitions: everything is in the "minus", except for the caster. A car with such settings turns more confidently and faster, as well as the “rearrangement” maneuver. Hence the best result.

So, there are a lot of simple and very effective ways change the nature of the car without resorting to costly replacements of components and parts. The main thing is not to neglect the adjustments - they often turn out to be very important.

Which of the options to give preference? For most, the second will be acceptable. It is most logical for everyday driving both with partial and full load. It is only necessary to take into account that by increasing the longitudinal inclination of the rack, you not only improve the behavior of the car, but also increase the stabilizing (return) force on the steering wheel.

The last, most “fastest” setting option is more suitable for the near-sports audience who loves to improvise with the car. Giving preference to these adjustments, it must be borne in mind that with increasing load, the values \u200b\u200bof the toe and camber angles will increase and may go beyond the permissible limits.

Below is some useful information about various terms and wheel alignments and what they are.

The angles that determine the location of the suspension elements on the front axle of the car:

- Wheel alignment (Toe)

- Camber

- Pitch (Caster)

- Roll axis tilt (King pin)

- Axis offset (Set-back)

- Integral angle

The angles that determine the location of the suspension elements on the rear axle of the car:

- Wheel alignment (Toe)

- Tilt or camber (Camber)

- Axis offset (Set-back)

- Thrust line (angle)

Convergence and negative convergence tend to be the most understood term. When measuring toe-in, we look at how parallel the wheels are to each other when viewed from above.

If the wheels are closer together at the front, then the toe-in is positive (+). If the wheels are closer together at the rear, then the convergence is negative (-). The reason why we have convergence or discrepancy is that the mutual position between the wheels of the car in a stationary position and in motion is different, due to deformations in the suspension and the choice of play when the car is moving. As a rule, for rear wheel drive the convergence of the front wheels is set with a slight positive convergence. Anterior and four-wheel drive vehicles, as a rule, have some negative convergence due to the fact that the front wheels are traction, and the backlash when the car is moving is selected inward (that is, in +).

Incorrect convergence can lead to the following consequences:

- Wear on the outer edge of the tire - cause: excessive convergence

- Tire inner surface wear -:excessive negative toe-in

- "Checker wear" of the tire tread, or the so-called "feathers".

- Wrong steering wheel position

- "Bad" rudder return when exiting a turn

- Increased fuel consumption due to tire friction

Possible reasons for incorrect toe adjustment:

- Incorrect adjustment

- Incorrect data used for adjustment

- Incorrect ground clearance

- Deformation of steering elements

- Incorrect calibration of control equipment

Note: Toe is always the last corrected angle.

Negative convergence when turning the car.

When the car is turning, the wheel is on inside the steering wheel has a larger steering angle (smaller turning radius) than the wheel on the outside. If the wheels in a turn have the same angle, they will try to converge. This could cause excessive tire wear and poor handling due to understeer. It is designed that the inner wheel has a larger angle of rotation, which will lead to better handling and reduce tire wear.

Excessive positive convergence can lead to the following consequences:

- Excessive tire wear: plumage

- Tire screeching when cornering, even at low speeds

- Low reaction to the steering wheel, i.e. understeer

Possible causes of excessive positive convergence:

- Toe incorrectly adjusted

- Incorrect tilt of the steering rods

- Tie Rod Deformation

- Incorrect ground clearance

collapse

- Camber is positive (+) when the wheel is tilted at the top outside the vehicle

- Camber is negative (-) when the wheel is tilted at the top towards the inside of the vehicle

- Zero camber when wheel is vertical

The camber is adjustable for the front and rear wheels of the car.

Camber is necessary to evenly distribute the vehicle's load across the tire's entire footprint at the point of contact to minimize tire wear. Camber can also be used to change the handling of a car, sometimes at the expense of tire wear. Negative camber can improve the car's stability in corners, providing good contact tires with the road when cornering.

Improper camber can cause pulls as well as excessive tire wear. As a rule, the camber difference on one axle (cross) should be no more than 30" (in minutes).

Incorrect collapse can lead to the following consequences:

- Tire inner surface wear: - excessive negative camber

- Wear on the outer edge of the tire: - Excessive positive camber

- Pulls to one side

- Excessive wheel bearing wear (due to uneven loading)

- Poor vehicle handling

Possible causes of incorrect collapse:

- Deformation of suspension elements

- Incorrect adjustment

- Incorrect ground clearance

Longitudinal inclination of the kingpin (or axis of rotation) (CASTER)- the angle between the vertical and the projection of the line passing through the centers of the ball bearings on a plane parallel to the longitudinal axis of the vehicle. It contributes to the stabilization of the front wheels in the direction of rectilinear motion.

Otherwise, caster is the longitudinal tilt of the oscillation plane of the wheel and can simply be described as a forward or backward MacPherson lean when viewed from the side of the vehicle. A positive castor (+) is when the top leg of the strut is moved back. and is more commonly used on modern cars.

Negative caster is when the top leg of the strut is moved forward. Positive caster provides better exchange rate stability and stabilization than a negative caster. If you look at the front wheel and fork of a bike, you will see that they form a positive caster, which is what allows you to ride the bike without touching the handlebars. The greater the positive pitch angle, the heavier the steering wheel.

Because for the most part modern cars able to develop high speeds, a positive caster angle is required to ensure high driving stability. Electro-hydraulic steering designed to overcome heavy steering. As a rule, castor on the left and right side vehicle must not differ by more than 30" (in minutes), otherwise the vehicle may pull to one side. The vehicle will pull to the side with the smallest angle.

An incorrect caster can lead to the following consequences:

- Heavy steering - excessive positive caster

- Over-sensitivity to perception road bumps on the steering wheel - excess positive caster

- Rudder wobble - : Excessive negative caster steering wheel force on left and right turns, one-sided tread wear

- Lack of rudder self-stabilization - : excessive negative caster different squealing tires on the turns.

Possible reasons for an incorrect caster:

- Upper support - MacPherson mounted forward or backward

- The trailing arm or its mount moves forward or backward

- The vehicle is not on a level surface when adjusting

- Incorrect vehicle tilt

- Wheels do not lock during adjustment

- Incorrect adjustment (if adjustable)

Roll axis tilt (King pin) (Pan axis tilt (PAN))

(in figure β) is the angle of inclination of the axis of rotation (kingpin) of the wheel (a-b) in the transverse plane when viewed from the front. It is set by the design of the steering knuckle (green in the figure) and is not adjustable.

The included angle (in the figure α + β) is the total angle of camber and the transverse inclination of the kingpin.

LRL, adjustable on some designs.. LRL is the angle that is formed between the vertical and the MacPherson axis, always tilted inward when viewed from the front of the vehicle. Typically, this angle is set by the manufacturer and is not adjustable.. However, some manufacturers use a change in the angle of the LRL for the benefit of decay control. NOP is always positive. The NOP, together with the camber, serves to reduce the perception of bumps from the road and reduce the effect of uneven braking forces on the steering mechanism. Road bumps and uneven braking will cause steering wheel reaction due to the generated moment on the A-B arm, which makes the vehicle unstable and causes strong steering response. The NOP also aids the self-centering of the steering.

An incorrect NOP can lead to the following:

- excessive feedback with the road

- Reduce steering self-stabilization

- Excessive wear of suspension components

- Wrong collapse

- Violation of the straightness of movement on bumps

The Scrub Radius is the straight-line distance between the point at which the wheel's steer axis intersects the roadway and the center of the wheel-road contact patch.

The rolling shoulder is determined not only by the suspension design, but also by the parameters of the wheels.

Simply put, when the shoulder is different from zero, the wheel begins to act as a lever acting on the suspension and steering elements, an additional moment arises that must be compensated by the steering wheel.

With a positive run-in shoulder, an accidental increase in the resistance force of one of the wheels can cause the steering wheel to turn in the same direction and disrupt the vehicle's directional stability.

With a positive value, the force on the steering wheel when turning the wheels in place is less. (the wheel rolls when the steering wheel is turned, and does not just turn on the spot), but jerks will be noticeable when moving bumps.

When changing the wheel diameter, do not forget to change the offset of the disk in order to bring the rolling shoulder to the values you need.

Line thrust pressure(THRUST LINE)- the line of axial pressure (direction of thrust) can be simply understood as perpendicular to the rear axle. This is a somewhat simplified concept, since the installation angles of the rear wheels.

The thrust angle or driving angle is the angle between the vehicle's axis of symmetry and the direction of thrust.

The direction of force on the rear axle, called axle load, is determined by the toe of the rear wheels. The axle pressure line is determined by the difference between the vehicle's longitudinal axis of symmetry and the axle loads.

If the thrust angle is not equal to "0", then the front wheels tend to turn in the same direction as the rear wheels, trying to straighten the vehicle's trajectory into a straight line. As a consequence, the body will be guided at an angle to the direction of travel.

The thrust angle is negative when axial load is directed to the left towards the driver, and is positive when directed to the right of the driver.

The driving angle must be "0" for vehicles with properly adjusted rear wheel alignment. A driving angle (more than 20") can also indicate a violation of the geometry of the body. On a larger number of modern vehicles, rear toe-in can be adjusted, and sometimes camber. If the rear toe-in is on vehicle is erroneous, it will have an effect on the vehicle's handling. To drive in a straight line, the driver will have to steer, compensating for the drift. Incorrect rear toe or asymmetrical rear toe can adversely affect the rear axle steering angle (vehicle traction angle), trust angle.

An incorrect thrust angle can lead to the following consequences:

- Handlebar misalignment

- Excessive rear tire wear

- Yaw

- Understeer or oversteer

- Skew movement

Possible causes of rear axle steering angle (incorrect traction angle):

- Rear toe incorrectly adjusted, no symmetry on the sides

- Rear suspension bent or damaged

- Rear subframe not properly aligned

- car body is not properly aligned

- Rear suspension mounts are worn out.

Clearance- ground clearance height.

It is recommended that before visiting the wheel alignment, make sure that the tire pressure is correct, the tread wear on the left and right wheels is approximately the same, there is no play in the bearings and steering, wheel disks not deformed. On vehicles with adjustable ground clearance check adjustment.

Axis Offset (SET-BACK)- this is the angle formed by a line perpendicular to the longitudinal line of symmetry of the car and the line passing through the (front or rear) axle connecting the centers of the wheels. For example, on the front axle, it occurs when the longitudinal angle of inclination of the wheel axle (Caster-a) is incorrectly adjusted.

Axis offset is positive when right wheel in front (according to the direction of travel) relative to the left wheel. It is negative when the right wheel is behind (according to the direction of travel) relative to the left wheel. You could observe the displacement of the rear axle on the Volga, the car drives as if sideways (by the way, on the Volga this happens when one step-ladder weakens and the bridge moves forward or backward along the spring with one side).

Typically, this situation will not cause problems affecting management until it becomes significant.

Ideally, the wheels should be strictly perpendicular to the road. In this case, maximum stability and minimum resistance to movement are ensured. Tire wear and fuel consumption are also minimized. But, as we know, the ideal is unattainable. The position of the wheels changes when the load changes, road conditions and when turning. Therefore, designers put into the car up to two dozen different parameters that determine optimal installation wheels at various conditions movement. Of these parameters, most are set as constant values, while some are subject to adjustment during operation. This is the well-known “camber” and the lesser-known caster. And in modern foreign cars only one parameter is regulated at all - the toe-in of the wheels. But this seemingly positive circumstance also has back side. If, for example, as a result of an impact, the geometry of the chassis or body is slightly disturbed, then the position of the wheels on a “normal” car can be aligned by “playing” with angle adjustments. If only convergence is regulated, it is necessary to replace the affected (and quite expensive) parts.

"Angular" theory

The angle of longitudinal inclination of the axis of rotation (caster (Caster)) (Fig. 1) is the angle between the vertical and the line passing through the centers of rotation of the ball joint and the bearing of the telescopic strut support, in a plane parallel to the longitudinal axis of the vehicle. It contributes to the stabilization of the steered wheels, that is, it allows the car to drive straight with the steering wheel released. To visualize what a caster is, think of a bicycle or a motorcycle. Their steering column tilted back. Because of this, in motion, the wheel constantly strives to take a straight position. It is thanks to the caster that when the steering wheel is released, the car drives straight, and when exiting the turn, it automatically returns the wheels to their original position. If the angle of inclination is reduced, the car becomes more difficult to control, you have to constantly steer, which is tiring for the driver, and the tires wear out faster. If you increase the caster, the car will drive along the road like a tank, but the rotation of the steering wheel will turn into an exercise in the gym. The above applies to a greater extent to rear wheel drive vehicles. In front-wheel drive, a small positive caster value is set to stabilize the wheels when coasting, braking, or when sudden side loads (wind) occur. Signs of a deviation of the angle from the norm: car pulling to the side while driving, different efforts on the steering wheel in left and right turns.

The angle of longitudinal inclination of the axis of rotation (caster (Caster)) (Fig. 1) is the angle between the vertical and the line passing through the centers of rotation of the ball joint and the bearing of the telescopic strut support, in a plane parallel to the longitudinal axis of the vehicle. It contributes to the stabilization of the steered wheels, that is, it allows the car to drive straight with the steering wheel released. To visualize what a caster is, think of a bicycle or a motorcycle. Their steering column tilted back. Because of this, in motion, the wheel constantly strives to take a straight position. It is thanks to the caster that when the steering wheel is released, the car drives straight, and when exiting the turn, it automatically returns the wheels to their original position. If the angle of inclination is reduced, the car becomes more difficult to control, you have to constantly steer, which is tiring for the driver, and the tires wear out faster. If you increase the caster, the car will drive along the road like a tank, but the rotation of the steering wheel will turn into an exercise in the gym. The above applies to a greater extent to rear wheel drive vehicles. In front-wheel drive, a small positive caster value is set to stabilize the wheels when coasting, braking, or when sudden side loads (wind) occur. Signs of a deviation of the angle from the norm: car pulling to the side while driving, different efforts on the steering wheel in left and right turns.

Camber angle (Fig. 2) - the angle between the plane of rotation of the wheel and the vertical. To put it simply, no matter how the levers and racks tilt when driving or changing the load, the position of the wheel relative to the road must remain within the specified limits. If the top of the wheel is tilted outward, the camber is considered positive, if the wheel is tilted inward, the camber is negative. When the wheel camber deviates from the norm, the car spontaneously leads to the side, and the tire tread wears out unevenly.

Camber angle (Fig. 2) - the angle between the plane of rotation of the wheel and the vertical. To put it simply, no matter how the levers and racks tilt when driving or changing the load, the position of the wheel relative to the road must remain within the specified limits. If the top of the wheel is tilted outward, the camber is considered positive, if the wheel is tilted inward, the camber is negative. When the wheel camber deviates from the norm, the car spontaneously leads to the side, and the tire tread wears out unevenly.

Toe-in (Fig. 3) - the angle between the plane of rotation of the wheel and the longitudinal axis of the vehicle. Wheel alignment contributes correct position steered wheels at different speeds and angles of rotation of the car. With increased convergence of the front wheels, the outer part of the tread wears out strongly in a sawtooth manner, and with negative angle the inside is subjected to the same wear. At the same time, the tires begin to squeal in corners, the controllability of the car is disturbed (the car “scours” along the road), fuel consumption increases due to the high rolling resistance of the front wheels. Accordingly, the run-out of the car is reduced. Convergence and collapse are interdependent quantities.

Toe-in (Fig. 3) - the angle between the plane of rotation of the wheel and the longitudinal axis of the vehicle. Wheel alignment contributes correct position steered wheels at different speeds and angles of rotation of the car. With increased convergence of the front wheels, the outer part of the tread wears out strongly in a sawtooth manner, and with negative angle the inside is subjected to the same wear. At the same time, the tires begin to squeal in corners, the controllability of the car is disturbed (the car “scours” along the road), fuel consumption increases due to the high rolling resistance of the front wheels. Accordingly, the run-out of the car is reduced. Convergence and collapse are interdependent quantities.

In addition to the listed angles, there are angles whose appearance is undesirable: the angles of movement and displacement of one or more axes. If available, the suspension or body of the car needs to be repaired.

a - wheel shift (the defect occurs in operation due to deformation of the suspension elements

a - wheel shift (the defect occurs in operation due to deformation of the suspension elements

- b - deviation of the vehicle's thrust line (reason - operational);

- c - reverse (negative) convergence in a turn (measured as the difference in the angles of rotation of the inner and outer wheels, measured relative to the longitudinal axis; in case of violation, one of the steered wheels slips, which reduces stability when cornering).

When to Adjust and Should You Adjust?

During operation, normal wear and tear suspension parts. As a result, the wheel alignment angles are violated. Therefore, periodically, as prescribed in the manual, it is necessary to carry out their control and, if necessary, adjustment. The car needs “unscheduled” adjustment most often after hitting obstacles or pits, as well as after accidents in which the body was damaged. If after such a case the behavior of the car has changed (it starts to “pull” to the side or it constantly has to be “caught” by the steering wheel on a straight line, the steering wheel is not in the middle position when driving straight, the steering wheel does not return to the middle position when exiting the turn, the tires wear out unevenly and squealing in the corners), then you should go to the service station without delay. And the third reason to call on the “razvalshchiki” is after replacing the suspension and steering parts that affect the position of the wheels.

If none of the above options occurred, and the symptoms of “wrong angles” appear, take your time and analyze the situation. What preceded the change in the nature of the ride? If, for example, other wheels were installed, then vibrations and uneven tread wear may be caused by their imbalance. Shakes the car and with insufficient tightening wheel bolts. Defective, mismatched, mismatched tread patterns, and underinflated tires will also cause the vehicle to behave abnormally. Pulling the machine to the side may be the result of braking one of the wheels due to a malfunction brake mechanism. And faulty shock absorbers provoke unstable behavior on the road. Is the steering wheel hard to turn? It is possible that the hydraulic booster is to blame. Decreased runout? Wheel bearings could be the cause.

Where to do and what to do

The first rule is to look for an intelligent, conscientious master, and not a "fancy" stand. Second, choose a service based on your needs. If, for example, the car is in good condition and you only want to check and adjust the toe-in, you don't need a 3D stand for this. Good specialist cope with the help of a lift and a measuring rod. With the same result, the difference in price will be very noticeable. But if you need a thorough check of the entire "geometry", here you can not do without the appropriate equipment. Stands for monitoring and adjusting wheel alignment can be divided into two large groups: optical and computer.

Optical stands are beam and laser. In beam light source is an incandescent lamp. Two such sources (collimators) are attached to the wheels, and measuring screens (targets) are placed in front and on the side of the car, onto which a beam of light is projected. When adjusting the convergence, the beams are directed to a measuring rod located in front of the machine. Laser stands are more accurate and easier to work with. Measuring screens are installed on the sides of the pit or lift. Holes are made in their centers through which laser beams are directed strictly towards each other. Mirrors are attached to the wheels of the car, from which the rays are reflected on the screens. The advantages of optical stands include simplicity and the resulting reliability. They also differ in low price. But the disadvantages are much more significant - relatively low accuracy, the ability to work simultaneously with only one axis of the car, the lack of a database of models and the inability to measure some parameters (for example, the rotation of the rear axle) that characterize the overall "geometry" of the car. If the car has multi-link suspension, optical stands are contraindicated for him.

Computer stands are divided into sensor (CCD) and 3D. In the first, interconnected measuring heads are attached to each wheel, the information from which is processed by a computer. According to the method of connection between the heads, the stands are corded (a rubber band is pulled between the heads, and the connection to the computer is made via a cable), infrared wired (connection between the heads is provided by means of infrared rays, and with the computer through a cable) and infrared wireless (the heads are connected to the computer via a cable). radio channel). The last type of stands is by far the most common. When choosing, keep in mind that there are still computer stands with no closed loop(with two measuring heads), the functionality of which is much lower than the closed circuit stands (with four heads).

The advantages of computer stands are obvious: high accuracy, the ability to work with two axes at once and measure many more parameters, the presence of a constantly updated database (about 40 thousand models), a program that tells the mechanic the sequence of actions. But CCD stands are not without drawbacks - fragile sensors, dependence on temperature conditions, illumination. They require periodic checks and adjustments (twice a year).

The emergence of computer 3D stands, many experts call a revolution in the field of control and adjustment of wheel alignment. As they say, ingenious is always simple. On the rack in front of the car, video cameras are fixed, which record the position of the plastic reflective targets mounted on the wheels with the highest accuracy. To measure angles, it is enough to roll the car 20-30 cm back and forth and turn the steering wheel left and right. Data from video cameras is processed by a computer and in real time gives out all conceivable geometric parameters. This technology is called "machine vision". To carry out measurements, 3D stands, unlike all others, do not require the car to be placed on a perfectly flat surface. The disadvantage is the price.

Nuances of adjustment

You can go to the "descent-collapse" only if chassis and steering are correct. And before proceeding with the adjustment, the master in without fail should check it out. That is, raise the car on a lift, and then inspect and pull the wheels, rods, levers, supports, springs, turn the steering wheel, etc. It is mandatory to measure and, if necessary, bring the tire pressure to normal. If too large gaps or damage to parts are found, the specialist must refuse to adjust the client (of course, if it is impossible to eliminate the defects on the spot).

If no deviations are found, the car is placed on a horizontal platform (for a 3D stand, horizontality is not required condition) and loaded in accordance with the manufacturer's recommendations. That is, if the factory indicates the values of the angles for a certain load, then adjusting them on an “empty” machine is a violation. In order for the suspension parts to be installed in the working position, it is “squeezed” with effort by pressing on the “front” and “rear” of the machine. Without fail, in order to avoid large errors in measurements, compensation for the runout of the disks must be carried out, no matter on which stand the adjustment is made. Without going into theory, outwardly everything looks like this: the master hangs the axle, attaches it to the wheels measuring instruments and spins the wheels. On 3D stands, compensation is performed without hanging, by rolling the machine back and forth by 20-30 cm.

Since the installation angles are interconnected, they always adhere to a strict sequence when adjusting them. The castor is adjusted first (the angle of the longitudinal inclination of the axis of rotation), then the collapse and in last turn convergence. Most modern foreign cars only convergence is regulated.

Castor (Caster) is regulated by changing the number of washers: on a double wishbone suspension - between lower arm and a cross member, on the MacPherson - at the ends of the extension or suspension stabilizer. In this case, the wheels of the car must be braked by the working braking system(not handbrake!). To do this, the specialist must have in his arsenal a special brake pedal lock. The operation of adjusting the castor is one of the most disliked by the "breakers", because. very time-consuming and time-consuming due to the “sticky” fastening bolts. Some "specialists" in such cases cut down the washers with a chisel, while others simply ignore the castor or try to convince the client that the angle is normal. Be carefull!

Camber on double wishbone suspensions is adjusted in the same way as the castor - by changing the number of washers between the lower arm and the cross member. On the MacPherson suspension, most often the camber is changed by rotating the eccentric bolt that attaches the strut to the steering knuckle. But options are also possible. On some models, a sliding mechanism is provided instead of a bolt, or adjusting bolt located at the base of the lever. There are designs where the collapse is regulated by moving the ball joint along the lever.

Before proceeding with the toe adjustment (Toe), the specialist must set steering rack(on vehicles with worm gear - bipod) to the middle position. The steering wheel must be straight. It is fixed with a special fixative. The adjustment is made by rotating the adjusting sleeves of the tie rod ends on both (not one!) sides. A sign of a correctly performed procedure is the position of the steering wheel straight, without distortion, in a straight line.

On vehicles with independent rear suspension camber (not at all) and toe-in are also adjustable. In this case, you need to set the corners from the rear axle, and then move on to the front.

Ideally, the installation angles of the left and right wheels should match. But it doesn't always work out that way. Therefore, for each angle, the manufacturer regulates the values \u200b\u200bin a certain range. But the extreme value in "plus" from the extreme value in "minus" can differ by more than 1 degree! At the same time, formally, the corners will be normal, but the wheels will be crooked. Absurd! Therefore, the values of the permissible difference between the angles of the right and left wheels are also regulated. For example, castor should have a value of 1°30'±30'. That is, 1° of inclination of one wheel and 2° of inclination of the other will be within the tolerance field. But if allowable difference wheel tilt is set by the manufacturer, say, at 30 ′, then such an adjustment will be a hack. But if one wheel has a longitudinal inclination of 1 ° 30 ′, and the second at 1 ° 45 ′, then there are no complaints.

If the adjustment was carried out on a computer stand, you must be given a printout in which all the parameters described are indicated. Even if you don't feel like going deep into the theory of a car's suspension, it's easy to check if the angles are set correctly with a printout. To do this, it is enough to own only addition and subtraction. It should consist of three columns of data. The first one shows the angle values before the adjustment, the second one after the adjustment, and the third one shows the values from the database for your vehicle. By the way, make sure that your model and its year of manufacture are indicated there, and not just, say, Honda Civic, which has nine generations. Also ask when the stand was last adjusted. The correct answer is at least twice a year.

In addition to adjustable angles, several unregulated, but no less important, are also subject to verification. The main ones include: transverse slope the axis of rotation (King Pin Inclination), the offset of the front and rear axles (Set-back) and the angle of movement (Trust-angle). The values of the axis offset and the angle of movement should ideally be equal to zero. In practice, the closer to zero, the better. Verify from the printout that all non-adjustable parameters are within acceptable limits.

Conventional wisdom says that after any suspension or steering repair, it is imperative to adjust the wheel alignment. However, it is not. Adjustment is only necessary after replacing parts that affect these angles. For example, replacing ball bearings, silent blocks or suspension arms worn out during natural operation will return the wheels to their original position, and nothing needs to be adjusted! But this is on the condition that, as wear was carried out, the correction of the corners was not carried out. If the lever bent as a result of the impact changes, then it is necessary to adjust the angles, since, most likely, the metal parts adjacent to it were deformed along with the lever. After replacing the front strut, it is necessary to adjust the angles. But if the rack, in the upper mount of which there is no “breakup” bolt, was not replaced, but removed, for example, when repairing the suspension, and at the same time it was not disconnected from the steering knuckle - after assembly, the corners will not be broken. There is also no need for adjustment when changing springs, upper supports and removable shock absorbers. But, again - if the rack is not disconnected from the steering knuckle.

Replacing rack and pinion steering parts requires subsequent adjustment of the angles. But in the worm gear, when replacing the steering gear, the pendulum lever and the middle thrust of the trapezoid, the angles are not violated.