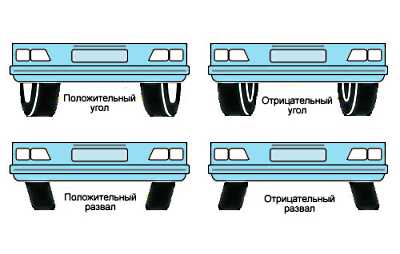

To improve the quality of handling, adjust the negative camber rear wheels, resulting in improved grip of the wheel surface with the road surface. Let's remember what negative and positive collapse is wheelsets.

With negative camber, the top of the wheels converges towards the center, and with positive camber, the wheels deviate slightly from the center of the vertical axis. During the operation of the car, over time, the camber-toe settings are violated, therefore it is recommended that the wheels be adjusted immediately on the front and rear axles.

Correct adjustment The negative camber of the wheelset helps to increase the maneuverability of the car and increases the level of its stability. On average, a change in negative camber by 2? significantly increases the grip of the wheels with the road, however, it should be remembered that this significantly reduces the life of the tires.

Negative camber rear wheels helps to improve the quality of the vehicle entering the turning radius at a significant speed without drifting the axle, and significantly and possible rollover. How can you tell if your car's camber is set correctly?

To do this, it is necessary to check the surface of the wheel pairs for wear. If the tire tread wears out with inside wheels, it is urgently necessary to adjust the negative camber angles, since it exceeds the permissible factory norms. Wheel wear on the outside will tell the car owner that the positive camber angle has been exceeded, which also needs to be adjusted.

How is negative camber adjusted?

Having made some improvements in the chassis of the car, you can significantly increase the level of its handling and stability. To do this, it is recommended, according to factory standards, to adjust the positive camber front axle, and on the rear adjust the negative. Can be enlarged lateral stability, by installing a stabilizer on the front suspension.

Vertical stability can be increased by replacing the old springs with stiffer ones. Skidding can be counteracted when cornering by reducing the number of coils in the rear suspension springs. Depending on the car model, the reduction can be 1 - 1.5 turns. In this case, when entering a turn, the car will press on the outer part of the wheels, completely, excluding drift rear axle.

The process itself

To adjust the camber angle of the rear wheels, camber plates are most often used. Based on what brand of car and the recommended camber-toe angles by the manufacturer, these plates are selected. When installing them, strictly follow the manufacturer's instructions.

Basically, the order of work for many brands of cars will be something like the following. Before starting work, the car is installed on a flat horizontal platform. Then you need to set the stops and jack up the car. After that, you should give the mounting bolts and remove the wheel, and then the drum with brake pads.

Is important aspect in car maintenance. This unit can be adjusted only in specialized car services. We will adjust the wheel alignment on the rear axle with a jeweler's precision in any of our technical centers. To adjust rear wheel alignment, it is necessary to take into account many features of this node and exclude the presence of defects and malfunctions in it

It is important to understand that when adjusting the position of the rear wheels, we are not talking about the camber procedure. The fact is that rear wheel collapse how the definition is fundamentally wrong with respect to possible methods rear axle service. Some motorists mistakenly use the term " rear camber", but in any specialized service station they will explain to you that there is simply no way to adjust the rear axle camber.

Rear toe carried out only after adjusting the front axle. This hard rule which cannot be derogated from under any circumstances. In the conditions of their own garage, car owners perform a rough adjustment of the front wheels, after which they approximately adjust rear convergence. The next step is to repeat the procedure to achieve an accurate result.

As can be understood from the above, configure rear wheel alignment quite difficult on your own. This requires care and time, and it will still not work to achieve an ideal result. Special computer stands, which our auto technical centers are equipped with, allow you to adjust both the front and rear wheels at the same time, without the slightest error.

Descent-raval-services

Why is it necessary to adjust the rear wheels

It is believed that rear wheel alignment required to be carried out less frequently than the front ones. However, this judgment is erroneous, because in case of violation of the collapse - convergence of the front axle, the corners at the rear are automatically shifted.

It is believed that rear wheel alignment required to be carried out less frequently than the front ones. However, this judgment is erroneous, because in case of violation of the collapse - convergence of the front axle, the corners at the rear are automatically shifted.

The design of the rear axle has a slightly different structure than the front. The position of the rear wheels is determined by the following angles

- collapse

- Convergence

- Axis offset

- traction line

Professional approach to rear axle alignment

Our experts know that not all angles can be adjusted. Rear toe characterized by the presence of angles that can only be tracked. Among them is the collapse in this case. The adjustable value is the thrust angle. Professional auto mechanics adjust this undercarriage parameter so that its value is not different from zero. As you understand, high-precision computer equipment is indispensable here. After all, even the slightest excess of this indicator leads to a deterioration in the controllability of the car.

Rear wheel alignment adjustable at a certain position of the front wheels. This angle is called the straightness of motion. The angles at which they stand rear wheels, can only be measured when setting such a position of the front axle, in which each of the front wheels has an equal toe angle with respect to the average longitudinal plane of the vehicle.

Adjust rear wheel alignment in Moscow

In order to precisely adjust rear axle toe, requires not only innovative equipment in the form of stands, which store a huge database of technical specifications any car. It often happens that motorists who are accustomed to servicing the car with their own hands are faced with the banal problem of a flat surface. Any unevenness will negate all your efforts. It is also important that the rear toe adjustment is carried out by professionals. Their invaluable experience combined with the latest equipment help you achieve perfect results.

In order to precisely adjust rear axle toe, requires not only innovative equipment in the form of stands, which store a huge database of technical specifications any car. It often happens that motorists who are accustomed to servicing the car with their own hands are faced with the banal problem of a flat surface. Any unevenness will negate all your efforts. It is also important that the rear toe adjustment is carried out by professionals. Their invaluable experience combined with the latest equipment help you achieve perfect results.

All procedures for adjusting the convergence - collapse, namely the adjustment of the convergence of the rear axle, are successfully carried out on the basis of our auto technical centers. We will adjust the rear toe of any car, whether it is a passenger car or trucks. Using the services of our auto mechanics, you can be sure of the accuracy of the adjustment and that all work will be carried out in compliance with characteristic features your vehicle. Professionals are strictly following technical instruction manufacturer, so adjustment errors are excluded.

If you need to adjust rear convergence, sign up for service at the network auto service center closest to you. You can book by phone or through the website. Employees will advise which of the service stations will be more convenient to get to, answer questions regarding prices and service specific model car.

Regardless of what you are, springs, supports or rubber, after work is done, your wheels need to perform a procedure called. If you ignore this, at first glance, unnecessary or optional procedure, you can create new problems for yourself that promise a new " headache and serious cash injections.

With the help of various settings, specialists can significantly improve / change the behavior of the car on the road. So, I propose to understand what a collapse-convergence is.

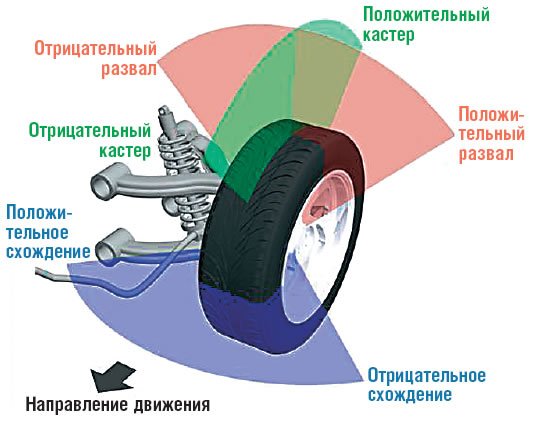

Camber is commonly referred to as the angle of the wheel relative to the road. For example, if the upper part of the wheel is tilted inward (towards the center) of the car, the camber is called negative, if vice versa, it is positive. Although negative camber is a deviation from the norm, it still has its advantages, for example, the wheels of a car will have best contact with pavement. If you don't want to donate car tires in the name of improving grip, you should set the value to 1.5-2 degrees in front and 1.5 degrees in the rear. The difference is explained by the fact that the front axle of the car is more loaded than the rear.

The angle of longitudinal inclination of the axis of rotation of the wheel, that is, the horizontal position of the wheels in the arches, is commonly called the caster. Slightly increased caster, as a rule, has a positive effect on the course of the car.

The car reacts much better (sharper) to a change in the position of the steering wheel, the car becomes well controlled, this is especially felt on high speeds. However, if the caster is excessively increased, the steering wheel will “get heavier” quite a lot. If the caster is too big, the negative camber to the outer wheel increases in turns. For those who like to experiment, I recommend trying it, but do not overdo it, the recommended caster value is +1 or +2 degrees to the standard value.

And, lastly, convergence. What this convergence is is a set of convergences (the sum of the angles between the plane and the longitudinal axis of the car passing through the center of the right and left wheels). First you need to set the convergence of the front wheels. As in the previous case, a small allowance is allowed. The upside of a positive toe is that the car will have better stability at high speeds, the downside of an increased (positive) toe in is that the car will have poor understeer. Negative toe has its own small advantages - improved wheel response to steering wheel, there are also disadvantages - and an increase in the transmission of all road irregularities to the steering wheel, or the occurrence of a beating.

Regarding the rear wheels - the situation is almost the same. In the case of negative toe, the car will be more prone to skidding, experts recommend setting the optimal value, that is, zero toe on both axles.

Introduction

In this book, the author has reviewed some aspects of improving car handling that may be useful for those who build sports cars or kit cars, or trying to improve driving performance car. The moments of carrying out suspension settings for cars with front and rear location engine, with independent front and dependent rear suspension or with fully independent suspension. In other words, the basic information can be applied to almost all types of vehicles.

Small adjustments that can be made in your garage (assuming the floor is flat and level) with a minimum of time will help improve the car's handling.

Naturally, most owners want their car to drive and handle well. On the one hand, the tasks of the concept of “driving” are more or less clear to everyone, and on the other hand, solutions that eliminate handling shortcomings are presented as the result of “black magic”.

Take, for example, two identical kit cars bought and assembled by two different people and customizable by them. With a high probability, the handling of both cars will be noticeably different. Cars will still be up to specification, but if tuning is done without a clear understanding of what the result is to get and what contributes to better handling, in the end, they will lead to the creation of simply dangerous car. And don't blame the manufacturer after that.

As a general rule, most kit cars come with everything necessary equipment, many allow for adjustable and customizable suspension. But having the ability to tune the suspension and not knowing how to do it often leads to worse results.

Many sports cars and kit cars are equipped with parts production cars. In some cases, one donor car is used, whose parts are directly installed on a sports sample. Such an approach from the point of view of manageability leads to an increase in compromise solutions. In other cases, there are multiple donor cars as the designers and manufacturers of the sports car want to install what they think is the best fit. Naturally, questions of the cost of products are also taken into account.

Some cars are built for the circuit, some for the track, some for both. On purely track cars, for obvious reasons, they often install best details that can be bought with money. Circuit and track cars are not as closely related as you might think. The decision to assign a car must be made immediately in order to save time and money thrown away by installing completely inappropriate parts and unnecessary adjustments.

The simplest kit cars are based on a front-engined design and rear wheel drive with dependent rear suspension. The rear suspension can also be independent. Some versions of kit cars, such as the Westfield, are available in both versions. There are many behind And against to apply these two suspension schemes: dependent suspension lighter, but sometimes creates handling problems. Independent suspension is heavier, but usually delivers better traction and improves handling.

On some versions of cars, the engine is installed in the middle of the wheelbase, the drive is carried out on the rear wheels and both independent suspension. There are relatively few such cars, as they are more expensive to make, but they do exist, although their handling is not always as good as one might expect.

In essence, sports cars should have better handling and execution than most conventional machines(a goal not so easily attainable these days when stock cars exceptionally well "hold the road"). pendants different cars have a different design, however, the main goal remains unchanged, i.e. to ensure that the vehicle handles as well as possible within the given limits of cost and expected comfort. The main task of the suspension is to ensure the continuous movement of the wheel along pavement, in all driving conditions. At the same time, it is desirable to achieve the same size contact patches of all tires with the road (correct distribution of the weight of the car on the wheels).

Many vehicles (including popular sports versions) use parts from other cars in production and, although understandable in terms of cost, these parts are not always fully suitable for their intended purposes, but there is a compromise to be made.

Sometimes it is possible to set up the car quite satisfactorily on your own. However, the level of understanding of what needs to be done with the car and awareness of the causes of its behavior and the problems that cause them provide the basis for introducing correct changes that inevitably lead to the desired result. Handling problems can sometimes seem insurmountable, but always the logic and information in this book will help you get rid of the idea that suspension tuning is black magic. The solution ideas and execution procedures described in this book are simple, effective and do not entail significant material costs. Remember that simplicity is often the best solution.

Important Notes

The key to accurately tuning any vehicle's suspension geometry is to measure all variables from a single reference point. This primarily means the need to prepare the measurement plane (floor). The floor must be horizontal and absolutely flat and 1 meter wider and longer than the dimensions of the vehicle. Take the correct measurements and then adjust the suspension without meeting the specified requirements impossible. The deviation of the floor surface from the plane should not exceed 1 mm over the entire surface. This requirement may seem very strict, but ordinary concrete floors can be made with the specified accuracy over a much larger area than is needed for the measurement area. The concrete floor, subjected to additional processing during laying, can be perfectly even. If the floor has already been laid, putting it in order will require additional efforts: on average, the deviation from the plane of concrete floors reaches 3 mm, which does not meet the requirements for measurement accuracy. At the same time, it is possible to actually make suspension adjustments with sufficient accuracy, but you cannot get a car “without a spot”. Any floor, or part of the floor, can be checked for horizontality using a building level. You can level the floor horizontally at no particular cost with the help of a self-leveling compound sold in hardware stores. Usually this compound is used to level the floor before laying tiles and in most cases is not intended for driving a car on it, however, if the floor substrate is strong enough, its use is justified, in addition, anyone can use the compound.

The reason for using the compound lies in its fluidity. The surface to be leveled is enclosed with a small formwork and then the compound is poured. The surface of the compound is horizontal and becomes absolutely smooth before curing. For strength reasons, the minimum thickness of the compound should be greater than 3 mm. a floor prepared in this way can last for several years.

You can make adjustments to the car "on the side", in a room that meets the specified conditions, which also creates certain inconveniences, but you do not have to spend time and money preparing the floor in your own garage.

If work related to suspension adjustment is carried out regularly, the area of the floor where adjustments are made (checked for horizontality and flatness) is usually marked around the perimeter with paint. This area, if possible, should not be used for work other than suspension adjustments, including vehicle storage.

It must be clearly understood that all measurements and tests proposed in this book must be carried out under the above conditions. Violation of these mandatory requirements will lead to errors that will affect the handling of the car.

Terms and Definitions

There are several general terms that are often used when discussing suspension adjustments. These terms include positive and negative camber (camber), pitch axis of rotation of the wheel (castor or caster), angle lower arm, corner upper arm, positive and negative wheel alignment. These terms need to be known and understood. Below is a brief definition of each term and, if possible, their impact on drivability.

If the car tries to maintain a straight line when turning the steered wheels inside the turn, the car is said to be understeered. This a common problem when the vehicle is too close to the limit of its handling capabilities.

There are several causes of understeer, most of which can be compensated for or eliminated through adjustments or component modifications. Most people want to do something about understeer because it constantly confuses the driver. Understeer forces you to take corners in a way that reduces its effect. In any case, this means that the car will move slower than it can. There is nothing better than driving a car that never understeers and is forgiving when cornering.

In most cases, understeer leads to incorrect installation wheels (tires do not have sufficient grip). One way or another, everything usually reverts to suspension geometry, except for the choice of tires. Another factor that causes understeer is front wheel 'fighting' (see Cornering Problems section).

Oversteer manifests itself as the desire of the car to skid the rear axle when cornering. The car enters the turn quite well, but then the rear axle begins to skid in the direction opposite to the turn: as they say, “the car wagged its tail.” This effect can provide a cornering advantage in racing, but it limits the ability of the car to return to a straight line.

If the oversteer is very high, the car almost always goes into an uncontrolled spin. Only one thing will help to cope with the situation to some extent: installing more soft tires, which grip the road instead of sliding on it. Oversteer can be reduced by changing the rear wheel toe or by changing the wheelbase.

Static Negative Camber

Mainly with the collapse of the front wheels are installed. The use of rear wheel camber is usually used only with independent rear suspension. The term "negative camber" is used when the top of the wheel or the vertical axis of the wheel is directed inside the vehicle's track (with positive camber, the vertical axis of the wheel is directed outward). "Static" negative camber is determined by parked car, with normal distribution of the load along the axles and with the steered wheels installed in the position of rectilinear movement. Negative camber requires some adjustment range, usually around two degrees or more. Some special racing cars, for specific reasons, have negative camber up to five degrees. It is accepted that the ideal static negative camber should have adjustments from 0.5 to 1.5 degrees. This angle tolerance accommodates all vehicles traveling at the speed ranges covered in this book.

Although it is set in statics negative angle camber, this does not mean that when cornering with some body roll, the adjustments remain unchanged: this is far from the case.

Negative camber is usually a good thing, but not in all cases.

Dynamic Camber

This term is applicable in a moving vehicle and especially when cornering. Three things can happen to the left front wheel when turning right:

- static decay will not change

- the negative camber angle will increase

- negative camber will turn into positive (up to two or three degrees in a hard turn)

Naturally, the same thing happens with the right wheel in a left turn. Because body roll changes suspension geometry, it is desirable for a wheel to have between 1 degree negative camber and 2 degrees positive camber in a turn. If the dynamic camber is outside the specified limits, adjustments are required, even if the handling remains quite satisfactory. The indicated values of dynamic camber must be strived for when designing the suspension. The right wheel in a right turn should ideally have zero camber. In practice, the most common option is when the right front wheel has a small negative camber (or, worse, a very large negative camber: up to 8°, which is impossible).

So, if the car goes through a sharp right turn to the maximum possible speed the left front wheel can have a camber of minus one to plus six degrees, while ideally the camber should be limited to a range of minus one to plus two degrees.

In the same situation, the right front wheel can have a camber from zero to minus eight degrees. Ideally, this wheel should have a camber from zero to minus two degrees (zero camber is very difficult to obtain, and negative eight degrees indicates a sad state of affairs).

The main reason for the need to be able to adjust the camber is to ensure proper tire contact with the road as the wheel load changes while cornering. Tire position becomes especially important in hard cornering. With a positive camber of more than five degrees, the tire of the left front wheel in the right turn tries to turn on the disk, which impairs handling. If at the same time the inner wheel is in negative camber so that the contact patch is only 30% of the maximum possible, the car will not behave as if it were understeered. Part of the secret to good dynamic camber is revealed in right choice positive longitudinal inclination of the axis of rotation.

Positive castor angle (Positive Castor)

The angle of the longitudinal inclination of the axis of rotation is considered positive if its upper part is deflected to rear axle. wheel hub(knuckle) is attached to the suspension arms through ball joints. The effective pitch angle is defined as the angle between the vertical and the line through the hinge centers knuckle. range of positive longitudinal angle the tilt of the axis of rotation is in the range from 4° to 8°. Angles smaller than 4° have no noticeable effect. Angles greater than 8° do not make sense. Adjustment should always be started from small angles with an initial step of one degree: with an increase in the angle of longitudinal inclination, the steering wheel becomes more and more “heavy”, and adjustment should not be carried out in reverse order from 8° to 4°.

The influence of the angle of the longitudinal inclination of the axis of rotation is manifested in a change in the camber (on one wheel, the camber increases, on the other it decreases, depending on the direction of rotation of the wheel). Additionally, the longitudinal inclination of the axis of rotation leads to stabilization exchange rate stability car. The greater the pitch angle, the greater the increment in the camber angle achieved with the same turn of the steering wheel. So, changing the caster angle is a good method of changing camber when cornering. For example, for a car making a right turn, the left front wheel increases negative camber while right wheel negative camber loses (here we do not take into account body roll).

Recall that the longitudinal and transverse angles of inclination of the axis of rotation are very closely related. Each of them contributes to the change in camber when the steering wheel is turned. A large lateral angle, together with a large caster angle during cornering, results in an increase in loaded camber and a decrease in unloaded camber. We can find a combination of caster and roll angles that results in the required dynamic suspension geometry. Thus, a steering knuckle with a small angle of transverse inclination of the axis of rotation may require the introduction high angle longitudinal slope.

First, we set a small positive longitudinal angle of inclination of the axis of rotation (for example, three degrees), while the negative camber is not sufficient for correct installation tires in a hard turn. Then, in increments of one degree, we will increase the longitudinal inclination (simultaneously on both wheels) until the desired contact of the tire with the road is obtained.

Very important , so that the angles of the longitudinal inclination of the axis of rotation are equal on both sides of the car (the exception is track cars driving along the track with one-way turns).

Although modern cars do not have a kingpin as such, the design of the steering knuckle is as if there is a kingpin and has its own angles of longitudinal and transverse inclination. A real king pin, around which the wheel turns, has been used on continuous bridges for a long time. Many creators racing cars, designed for racing on an oval track, still use a continuous beam of the front axle and, accordingly, install a real kingpin. This design has some advantages in this application over other types of suspension, although it is "old fashioned". So, although there may not be a kingpin as such, the terms longitudinal and transverse slope The king pins are still in use.

Translator's note: the given reasoning about terminology is relevant in the English original. In the English-language automotive literature, the term “king pin inclination” (transverse inclination of the kingpin) has received a legitimate abbreviation for KPI, which no one is going to change. In the translation, we abandoned the terms "caster inclination" and "transverse inclination of the kingpin", replacing them with the terms "longitudinal inclination of the axis of rotation of the wheel" and "transverse inclination of the axis of rotation of the wheel", respectively.

In particular, the lateral inclination of the axis of rotation determines the static camber.

Since the roll is relatively difficult to adjust, a change in the caster angle of the steering axis is usually used to adjust the dynamic camber.

Bump Steer

Shock control occurs when one or both front wheels change their toe under the action of road irregularities. This leads to a loss of vehicle directional stability (“wobble”) when the steering wheel is stationary. Shock control problems can almost always be fixed with suspension geometry adjustments or modifications to individual components.

Shock control can provide a slight improvement in cornering due to reduced toe-in of the inside wheel (body roll and wheel hang). There is no additional effect on the outer wheel. What needs to be changed in a suspension with a small degree of shock control (which cannot be completely eliminated)? In this case, it is preferable to translate the change in toe-in due to shock control to the moment of the lower position of the suspension arms than to the moment of their top position. If you cannot eliminate shock control by simply changing the tie rod connection, then you should at least make this effect work for you, and not against you.

Chapter 7. Rear Suspension Chapter 8 Chapter 9 Vehicle Settings Chapter 10. Vehicle Testing and Adjustments