Steering - with mechanical linkage, without power steering. Steering mechanism - "globoidal worm - double-ridged roller", gear ratio - 16.4.

The steering trapezoid is formed by three steering rods (one middle and two side), a bipod, a pendulum lever and steering knuckle levers. The side rods consist of two tips connected by a threaded split coupling.

On the inner (short) tip - right-hand thread, on the outer - left.

On the coupling, the threads are also of different directions, so when it is turned, the length of the lateral thrust can increase or decrease, which is necessary to adjust the toe-in.

The coupling is fixed on the tips with clamps. At the ends of the steering rods are ball joints. Their pins are tapered into the levers and locked into them with cotter pin nuts.

The ball head of the finger rotates in a plastic insert, pressed against the hinge body by a spring. The other end of the spring rests against a steel plug rolled into the hinge body.

Due to the taper of the outer surface of the liner and the inner surface of the hinge body, when the liner is pressed, a play is selected between the liner and the ball head of the pin.

To make sure that the insert is not jammed in the body, press the hinge body in the direction of the finger with a hand or a mounting blade - while the finger should go inside the body by 0.5–1.5 mm.

If the hinge is jammed or there is a noticeable backlash, the tie rod (steering tip) is replaced in it.

The hinge is protected from moisture and dirt by a rubber cover pressed onto the body.

If the boot is damaged, immediately replace it by removing old grease from the hinge surface and adding new grease (SHRB-4).

The pendulum arm bracket is attached to the right side member with two bolts with self-locking nuts.

The body of the bracket is cast, made of aluminum alloy. It has two plastic bushings in which the axis of the pendulum lever rotates.

Top and bottom washers are put on the axle, which press the bushings to the bracket body. The lower washer rests against the pendulum lever fixed on the axle with a self-locking nut, the upper one against the nut with a cotter pin.

This nut is tightened on the removed bracket so that the pendulum lever does not rotate under its own weight, but only under a load of 1–2 kgf.

On the working surfaces of the bushings and in the space between the axle and the body, Litol-24 grease is laid. To protect against dirt, two rubber o-rings are installed between the washers and the lever body.

When the bushings are worn, they are replaced; when the body or axle is worn, the bracket is replaced. The steering mechanism is attached with three bolts with self-locking nuts to the left side member.

Its body is cast aluminum alloy. In its lower (elongated) part, two bronze bushings are pressed in, in which the steering arm shaft rotates.

At the lower splined end of the shaft, the steering arm is fixed with a nut (it is installed on the shaft only in a certain position).

On the upper part of the shaft, a tide with a cutout is made; it contains a double-ridged roller rotating in ball or needle bearings.

The T-slot on the upper end of the shaft includes a screw head, which adjusts the gap between the roller and the worm (see below).

The axial play of the head in the groove should not exceed 0.05 mm; this is achieved by selecting the thickness of the adjusting plate put on the screw.

The screw moves along the thread in the steering gear cover and is locked with a nut and figured washer.

The worm of the steering mechanism rotates in two ball angular contact bearings, the clearance in which is regulated by the selection of gaskets between the body and the bottom cover (in this case, oil is poured out of the mechanism, after the adjustment is completed, its level must be restored).

With a properly adjusted gap, the moment of turning the worm shaft (with the bipod shaft removed) should be within 20–49 N.cm.

If it is less, reduce the thickness of the gasket package, if more, increase it.

After installing the bipod shaft, the gap in the engagement of the roller with the worm is adjusted: the moment of resistance to turning the worm shaft when turning 30 ° to the right and left from the middle position should be 88–118 N.cm, and at large angles - no more than 69 N.cm.

In practice, the simplest control is as follows: on the removed steering mechanism, the worm shaft must be rotated by hand with a noticeable increase in effort near the middle position, there should be no axial play of the shaft.

To fill oil into the crankcase of the steering mechanism, an opening is provided in the top cover, which is closed with a screw plug.

Transmission oil is poured up to the edge of this hole (0.215 l), and the level is controlled through it.

Oil leakage is possible from under the bottom cover of the worm shaft bearing (due to its deformation) or through the stuffing box seals of the bipod and worm shafts.

Repair of the gearbox at home (with the exception of adjusting clearances and replacing oil seals) is not recommended.

The steering shaft is two-link, consists of the upper and intermediate shafts.

The upper shaft rotates in two bearings with rubber bushings, rolled in the shaft bracket tube.

In the lower part, a ring with a groove is welded to the shaft, into which the locking bolt of the anti-theft device enters.

A steering wheel is fixed on the upper splined end of the shaft, its fastening nut is screwed.

The intermediate shaft has cardan joints at the ends with split splined tips, tightened by bolts; the lower one is connected to the worm shaft, the upper one - to the upper steering shaft.

Steering safety is ensured by folding the steering shaft due to cardan joints and special fastening of the steering shaft bracket.

The latter is attached to the body bracket at four points: on top - on welded bolts with nuts and washers, on the bottom - with special detachable bolts with fixing plates.

In a collision, the edges of the fixing plates are deformed and slip through the rectangular holes of the steering shaft bracket. At the same time, due to the folding of the steering shaft, the steering wheel does not move back, but up and forward, reducing the likelihood of injury to the driver's chest.

Possible malfunctions of a steering and methods of elimination

- Cause of malfunction

Elimination Method

Increased steering wheel play

Loose steering gear housing bolts

Tighten nuts

Loose ball joint nuts

Check and tighten nuts

Adjust gap

Increased clearance in the engagement of the roller with the worm

Adjust gap

Too much clearance between pendulum axle and bushings

Increased clearance in worm bearings

Adjust gap

Loose bolts securing the intermediate shaft to the worm shaft or to the upper shaft of the steering mechanism

Tighten the bolts

Steering wheel tight

Deformation of steering gear parts

Replace deformed parts

Incorrect setting of the angles of the front wheels

Check wheel alignment and adjust

Adjust gap

The adjusting nut of the pendulum arm axle is overtightened

Low pressure in the tires of the front wheels

Set normal pressure

Damage to parts of ball joints

Check and replace damaged parts

No oil in steering gear housing

Check and top up. Replace seal if necessary

Upper steering shaft bearing damage

Replace bearings

Noise (knocking) in the steering

Increased clearance in the front wheel bearings

Adjust gap

Check and tighten nuts

Increased clearance between the pendulum axle and bushings

Replace bushings or bracket assembly

Swing arm axle adjusting nut loose

Adjust nut tightening

The gap in the engagement of the roller with the worm or in the bearings of the worm is broken

Adjust gap

Increased clearance in ball joints of steering rods

Replace tips or tie rods

Loosening the swing arm nuts

Tighten nuts

Loosening of bolts of fastening of an intermediate shaft of a steering

Tighten the bolt nuts

Self-excited angular oscillation of the front wheels

Tire pressure not correct

Increased clearance in the front wheel bearings

Adjust gap

Wheel imbalance

Balance the wheels

Loosening the nuts of the ball pins of the steering rods

Check and tighten nuts

Loose steering gear housing or swingarm bracket

Check and tighten bolt nuts

The gap in the engagement of the roller with the worm is broken

Adjust gap

Driving the vehicle away from straight ahead in one direction

Tire pressure uneven

Check and set normal pressure

Front wheel alignment misaligned

Check and adjust wheel alignment

Different settling of front suspension springs

Replace bad springs

Deformed steering knuckles or suspension arms

Check knuckles and levers, replace bad parts

Incomplete release of one or more wheels

Check the condition of the brake system

Vehicle instability

Front wheel alignment misaligned

Check and adjust wheel alignment

Increased clearance in the front wheel bearings

Adjust gap

Loosening the nuts of the ball pins of the steering rods

Check and tighten nuts

Too much play in the ball joints of the steering rods

Replace tips or tie rods

Loose steering gear housing or swingarm bracket

Check and tighten bolt nuts

Increased clearance in the engagement of the roller and the worm

Adjust gap

Deformed steering knuckles or suspension arms

Check the knuckles and levers; replace deformed parts

Oil leakage from crankcase

Deterioration of the shaft seal of the bipod or worm

Replace seal

Loosening the bolts securing the steering gear housing covers

Tighten the bolts

Damage to gaskets

Replace gaskets

Adjusting the gap in the engagement of the roller with the worm gear of the steering mechanism on a VAZ 2121 and Niva 2131 car is performed in the case of an increased free play of the roller, which in turn is observed on the steering shaft, namely its vertical movement - play. Adjustment should be performed only if there is no axial clearance of the worm movement in the bearings. To perform repair work, prepare a standard set of tools, and then do the following sequence of actions:

Open the hood of the car and clean the surface of the steering column from dirt.

Prying off with a flat screwdriver, remove the cap from the adjusting screw.

Next, with a nineteen ring wrench, unscrew the lock nut of the screw, after which we remove it and the lock washer located under it. Please note that the washer with its antennae enters the corresponding groove on the screw, thereby counteracting its rotation. The sliding of the washer itself on the surface of the steering mechanism is counteracted by the corresponding influxes made on the column cover.

Pry off the washer with a flathead screwdriver and remove.

Then check the rotation of the steering wheel. It should rotate without jamming or difficulty.

While holding the screw from turning, put on the lock washer and tighten the lock nut. We put on a cap.

This completes the repair work.

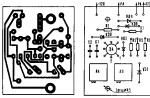

Steering Steering gear assembly with drive 1 – bipod; 2 - medium thrust; 3 - body of the pendulum arm bracket; 4 - axis of the lever; 5 - pendulum lever; 6 - bushing; 7 - adjusting nut; 8 – an internal tip of draft; 9 - adjusting clutch; 10 - lower ball bearing; ...

18.1 Design features

Design features Steering - with mechanical linkage, without power steering. Steering gear - globoidal worm - double-ridged roller, gear ratio - 16.4. The steering trapezoid is formed by three steering rods (one middle and two side), a bipod, a pendulum lever and steering knuckle levers. The side rods consist of two tips connected by a threaded...

Replacement of oil in a steering reducer PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. To check the oil level in the gearbox (the vacuum booster is removed for clarity in the photo) ... ... use the 8 key to unscrew the oil filler plug. The cork has a conical thread. Rod pr...

Replacement of oil in a steering reducer PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. To check the oil level in the gearbox (the vacuum booster is removed for clarity in the photo) ... ... use the 8 key to unscrew the oil filler plug. The cork has a conical thread. Rod pr...

Adjustment of a backlash in engagement of a roller with a worm of the steering mechanism PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. Adjustment is made when a free play of the bipod of the steering mechanism is detected. Before adjustment, it is necessary to make sure that there is no axial movement of the worm in the bearings (see Removing the steering gear and r...

Adjustment of a backlash in engagement of a roller with a worm of the steering mechanism PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. Adjustment is made when a free play of the bipod of the steering mechanism is detected. Before adjustment, it is necessary to make sure that there is no axial movement of the worm in the bearings (see Removing the steering gear and r...

Removal of lateral draft PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. Hang and remove the wheel. To remove the right lateral thrust, turn the steering wheel all the way to the left. We take out the cotter pin with pliers ... ... and with a 22 key we unscrew the nut securing the side rod to the lever ...

Removal of lateral draft PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. Hang and remove the wheel. To remove the right lateral thrust, turn the steering wheel all the way to the left. We take out the cotter pin with pliers ... ... and with a 22 key we unscrew the nut securing the side rod to the lever ...

Removal of average draft PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. We take out the cotter pin with pliers ... ... and with a 22 key we unscrew the nut securing the medium thrust to the pendulum lever. Using a fork puller, we press the medium-thrust ball pin out of the pendulum lever hole ....

Removal of average draft PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. We take out the cotter pin with pliers ... ... and with a 22 key we unscrew the nut securing the medium thrust to the pendulum lever. Using a fork puller, we press the medium-thrust ball pin out of the pendulum lever hole ....

Replacement of mud-protective caps and tips of steering rods PERFORMANCE ORDER Mud-protective caps and tips of steering rods can be replaced on the car. For clarity, these operations are performed on the removed thrust. To replace the dirt cap ... ... knock it down with a soft metal punch. Cleaning the ball...

Replacement of mud-protective caps and tips of steering rods PERFORMANCE ORDER Mud-protective caps and tips of steering rods can be replaced on the car. For clarity, these operations are performed on the removed thrust. To replace the dirt cap ... ... knock it down with a soft metal punch. Cleaning the ball...

Removal and dismantling of an arm of the pendular lever PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. Remove the right wheel. We press out from the holes of the pendulum lever the ball pins of the rods: middle (see Removing the middle rod) and side (see Removing the side rod). We turn off the head by 17 ...

Removal and dismantling of an arm of the pendular lever PERFORMANCE ORDER We carry out work on a viewing trench or the elevator. Remove the right wheel. We press out from the holes of the pendulum lever the ball pins of the rods: middle (see Removing the middle rod) and side (see Removing the side rod). We turn off the head by 17 ...

Steering wheel removal PERFORMANCE ORDER Disconnect a negative wire from the storage battery. With a slotted screwdriver, pry off the decorative trim of the horn switch cover ... ... and remove it. Turn off the steering wheel nut with a 24 head. Shaking...

Steering wheel removal PERFORMANCE ORDER Disconnect a negative wire from the storage battery. With a slotted screwdriver, pry off the decorative trim of the horn switch cover ... ... and remove it. Turn off the steering wheel nut with a 24 head. Shaking...

Removal of a steering column PERFORMANCE ORDER We remove a steering wheel (Removal of a steering wheel see). We remove the facing casings of the steering column (see Removing the steering column three-lever switch). Remove the ignition switch (see Removing the ignition switch). Using a 13 wrench, unscrew the nut of the bolt securing the fork of the lower cardan ...

Removal of a steering column PERFORMANCE ORDER We remove a steering wheel (Removal of a steering wheel see). We remove the facing casings of the steering column (see Removing the steering column three-lever switch). Remove the ignition switch (see Removing the ignition switch). Using a 13 wrench, unscrew the nut of the bolt securing the fork of the lower cardan ...

Dear customers, in order to avoid errors when sending the steering mechanism of the gearbox, VAZ 2131 column assembly, short shaft, in the "Comment" line, indicate the model and year of manufacture of your car.

Steering is necessary in order to convert the rotation of the steering wheel around its axis into the rotation of the wheels. Moreover, the rotation of the wheels must be performed synchronously to ensure a smooth ride. On the VAZ 2131, a worm-type gearbox is installed as a steering wheel rotation converter. In its design there is one important element - a worm gear. It is due to it that the rotation is converted into the transverse movement necessary to change the position steering rods

1 - crankcase; 2 - bipod; 3 - lower crankcase cover; 4 - adjusting shims; 5 - the outer ring of the worm shaft bearing; 6 - separator with balls; 7 - bipod shaft; 8 - adjusting screw; 9 - adjusting plate; 10 - lock washer; 11 - worm shaft; 12 - top cover of the crankcase; 13 - sealing gasket; 14 - bipod shaft sleeve; 15 - worm shaft seal; 16 - bipod shaft seal

Steering gear worm 21213-3401035, bipod 21213-3401090.

The gearbox, otherwise called the steering column, is located in the engine compartment, immediately under the vacuum brake booster. As such, the VAZ 2131 steering gear does not require maintenance, it is enough just to make sure that no oil flows out of it. Attention: The backlash in the gearbox causes some inconvenience, since the VAZ steering wheel has a fairly large free play and it becomes problematic to maneuver.

To reduce the backlash of the steering wheel, you need to perform a few simple manipulations. The first step is to call an assistant who will rotate the steering wheel during the adjustment. Prepare a tool - a key for 19 and a wide flat screwdriver.

The steering column lends itself to only one adjustment; in case of failure, the most optimal option is to completely replace it.

loosen adjusting plate 9 on adjusting screw 8, you can even unscrew it completely. The assistant rotates the steering wheel in different directions a quarter of a turn from its original position. At the same time, you, using a screwdriver, screw in the screw until the backlash disappears. This adjustment will reduce the free play, the steering wheel will rotate a little tighter. Finally, tighten the screw securely. It will be a little more difficult to replace the gearbox, but the steering will become more reliable.

In stores, you can buy a repair kit to restore the column. It is worth noting that such a repair is highly undesirable, because the gearbox housing has its own output, which can be an obstacle when installing new gears. Because of this, the rotation of the steering wheel of the VAZ 2131 will either be tight or will be jammed.

With steering play, the column may be in good order, but the fasteners to the car body may be loosened. They must be checked first of all, because there may be cracks on the side member and because of this the column may hang out.

The gearbox is subject to repair if the threaded part on its shafts is damaged, and due to damage or severe wear of the threaded part of both shafts that are in the gearbox, bearings, the following steering problems may occur, namely, the steering wheel can rotate and have play at the same time, in addition, the steering wheel can rotate, but the wheels themselves do not, and the steering wheel can simply lock in one place and not move anywhere and will stand there, oil can still flow from the steering gear, but this will already happen in another reason, the gearbox housing is damaged and has through cracks (this can happen after corrosion). If something happened to the oil seals, then the oil will also constantly flow out of the gearbox and in connection with this the steering wheel will spin harder (the oil will all leak out) and on the body or at the bottom of the cars you will notice constant traces of oil leaking from the gearbox.

If a leak is found, it is advisable to repair or replace the assembly. If this is not possible, try to keep the oil level normal.

Other articles of the product and its analogues in the catalogs: 21213340001010.

VAZ 21213-21214i, VAZ 2131, VAZ 2120.

Any breakdown - this is not the end of the world, but a completely solvable problem!

Causes of failure of the steering gear VAZ 2131 in a car of the NIVA family.

How to independently replace the steering gear VAZ 2131by car of the NIVA family.

With Internet Shop AvtoAzbukarepair costs will be minimal.

Just COMPARE and BE SURE!!!