The increase in the number of vehicles in the world and a number of environmental problems that humanity has faced in the past couple of decades has led to major changes in the automotive industry.

They are dictated, first of all, by the significantly tightened environmental standards and the increased price of fuel, in connection with which automakers are forced to look for ways to reduce the amount of toxic emissions and overall fuel consumption in cars.

At the same time, despite the emergence of electric vehicles, the development of vehicles with fuel cells, the only in an efficient way today it turned out to be the creation of cars with hybrid engines - the easiest way to "fit" into the economy and offer the consumer a product that is easy to use.

We will try to tell in this material about what the “hybrid” car market is like today, because today many potential buyers have no idea what a hybrid car means and what advantages it offers.

Hybrid cars - what is it?

Principle vehicle built on a hybrid scheme is quite simple. It is based on the principle of a conventional gas generator, when the power unit of the vehicle rotates the generator and charges the traction battery.

Video - how a hybrid car works:

In turn, the energy of the battery allows the car to move for some time exclusively on electric traction with “zero” emissions. After the energy in the batteries runs out, it starts up again gasoline engine, which allows you to continue moving and at the same time replenishes the charge in the batteries.

I must say that along with this scheme, there is another, called the plug-in hybrid. In it, the battery is charged not only from the motor, but also from a conventional household power supply, and its capacity is sufficient for trips over short distances (usually about 30-40 kilometers). In fact, this means that you can get to work and back without using it at all. Gas engine(and, accordingly, without wasting fuel).

Benefits of hybrid vehicles

Surely many will ask themselves the question, why do they need to “fence the garden” with batteries, electric motors, batteries and an engine internal combustion? What gives hybrid scheme power plant?

Before answering this question, it is worth remembering when a "traditional" car consumes the largest number fuel. It is known that the maximum consumption (and, accordingly, the toxicity of emissions) occurs at the stage of acceleration to cruising speed, as well as in urban driving with frequent acceleration and deceleration.

Video - how you can improve a hybrid car:

Thus, the electric drive in machines with a hybrid power plant comes into action in these modes. With a fully charged battery, the “hybrid” starts moving on electric traction, and when a certain speed threshold is reached (depending on the model, it ranges from 20 to 40 kilometers per hour), the internal combustion engine comes into action.

At the same time, the widest range of "hybrids" from Toyota is presented directly in Japan and the USA. On the intra-Japanese market, cars are sold under the Toyota brand, and in America, Lexus is traditionally the most popular (in Russia, it must be said, the majority of hybrid cars are also sold under this brand).

In terms of the number of hybrid cars from Toyota, the Japanese market should rightfully be considered the most saturated. The company displays all the latest models on it, on which it “runs in” technologies that should go into series on “global” models.

In particular, flagship models Toyota type Avalon and others are already offering a number of technical innovations today related to increased reliability of hybrids, as well as a large range on a single battery charge.

Why did we touch this issue on our portal? And why do we want to educate you about the operation of hybrid engines? Everything is extremely simple and clear. The fact is that many areas of our life are literally permeated with the interaction of all kinds of technologies, which in their symbiosis give rise to much more effective methods, gadgets and mechanisms. And of course, they did not dare to put aside the engines for our four-wheeled pets. And that's it about such units, their positive and negative sides, we will talk about how they work in this topic. And while we do small digression into history. Go!

A bit of history

Cars with hybrid "hearts" - the invention is far from new, as it might seem at first glance. The pioneer and embodiment of the idea of a hybrid engine was a Jesuit clergyman named Ferdinand Verbiest. In 1665 he began working on plans for simple four-wheeled wagons powered by steam and horses. But the first production models with hybrid engines saw the light already at the turn of the 19th and 20th centuries. For ten years, starting in 1887, the French Compagnie Parisienne des Voitures Electrics released a series and cars with hybrid motors. And in 1900 Company General Electric created hybrid car with a four-cylinder petrol engine. The Walker Vehicle Company of Chicago produced hybrid trucks until 1940.

Of course, at that time the production of such cars was limited to small batches and the creation of various kinds of prototypes. However, in our time, an acute shortage of oil resources and an ever-growing economic crisis have prompted automotive designers and developers to return to the roots and resume the production of cars with hybrid engines.

How a hybrid engine works - in simple words about new technologies

Well, now is the time to figure out what kind of unit a hybrid engine is and why so zealously began to produce cars with such hearts? hybrid engine It is a system of two interconnected engines: gasoline and electric. Two motors can work both in conjunction and separately, it all depends on which mode of operation is used in this moment. The process of redistribution of "powers" is controlled by a powerful computer, which at one time or another decides which of the engines should now work. To move in the suburban mode, the fuel engine takes over all the work, because the battery does not last long on the highway. To move around the city, the electric motor is turned on.

If the vehicle is subject to heavy loads or he has to accelerate often and quite intensively, then both engines are already working together. An interesting fact is that while the car is moving on a fuel engine, the electric one is charging at this time. A car with a hybrid engine emits 90% less substances into the atmosphere than we are used to. fuel engines, and this despite the fact that it also includes gasoline unit Same. Also, the consumption of gasoline in the city can be reduced to zero, which, of course, cannot be said about country trips.

Let's take a look at how a hybrid car pulls away. At the very beginning of the movement and at low speeds, only the battery and the electric motor work. The energy that is stored in the battery feeds the energy center, which then distributes it to the electric motors, which already start the car silently and very smoothly. After the maximum speed for the electric motor is reached, the gasoline unit is also connected. Torque to the drive wheels already comes from two engines overnight. In the process of such work, the internal combustion engine gives part of the generated energy to the generator, which further feeds the electric motors, unloading the battery, while the excess energy is transferred to the battery, replenishing it, lost at the start of the movement, the stock.

Let's take a look at how a hybrid car pulls away. At the very beginning of the movement and at low speeds, only the battery and the electric motor work. The energy that is stored in the battery feeds the energy center, which then distributes it to the electric motors, which already start the car silently and very smoothly. After the maximum speed for the electric motor is reached, the gasoline unit is also connected. Torque to the drive wheels already comes from two engines overnight. In the process of such work, the internal combustion engine gives part of the generated energy to the generator, which further feeds the electric motors, unloading the battery, while the excess energy is transferred to the battery, replenishing it, lost at the start of the movement, the stock.

If the vehicle is moving in normal mode, then the automaton is used by the master only front-wheel drive, in other cases, the distribution of torque is already applied to two axles. In acceleration mode, the torque to the wheels comes mainly from the internal combustion engine, and if it is necessary to increase the dynamics, then electric motors are already used to complement the internal combustion engine. But here's more interesting point is still a brake. The electronic "brain" of the car controls the on and off when it is worth connecting the hydraulics, and when the regenerative braking, but the preference is still given to the second. That is, when the driver of a hybrid vehicle presses the brake pedal, the electric motors go into generator operating mode, thereby creating a braking torque on the wheels, which also generates electricity, which feeds the battery through the power distribution center. This is where the whole essence of the "zest" of the hybrid engine is hidden.

In the classics familiar to us, the energy released during braking is wasted, simply lost in space as heat from brake discs and other details. The use of brake energy is very efficient in urban areas where frequent braking at traffic lights is a common thing. VDIM system, which is the control automotive dynamics, manages the work of all automotive systems active safety, uniting them into a single "organism".

In the classics familiar to us, the energy released during braking is wasted, simply lost in space as heat from brake discs and other details. The use of brake energy is very efficient in urban areas where frequent braking at traffic lights is a common thing. VDIM system, which is the control automotive dynamics, manages the work of all automotive systems active safety, uniting them into a single "organism".

Perhaps the first successful instance equipped with a hybrid engine, released to the masses, has already become known Prius from company Toyota. This miracle car consumes only a little more than three liters of gasoline for every hundred kilometers in urban mode. Also Japanese company went further with its luxury hybrid crossover Lexus RX400h. But also the cost this car on average within 70 000 c.u. Note that the first generation Toyota Prius inferior to cars of the same class with internal combustion engines in terms of speed and power characteristics, unlike the Lexus RX400h, which initially competed well in its class.

After Toyota, the world's leading automotive concerns also did not disregard the use of hybrid engines, as they saw this as a solution to the global problem of environmental pollution and fuel economy. And so followed the announcement of the creation of a hybrid cargo and transport technology from Volvo group. According to their calculations, the release of these products will reduce fuel consumption by as much as 35% over time.

But with all the greatest desire and calculations automobile concerns, cars with hybrid engines are not yet sold all over the world like hot cakes. The popularity of hybrid cars is gaining momentum only in Canada and the States. Demand for hybrids among the American population has grown due to a sharp rise in the price of fuel, which was mercilessly fired before. After all, the American auto industry has always been famous for its "muscle cars" with incredibly powerful motors and huge consumption of flammable liquid. European car enthusiasts generally reacted neutrally to cars with hybrid engines. A fairly environmentally friendly and more economical, trustworthy veteran, a diesel, runs there.

But with all the greatest desire and calculations automobile concerns, cars with hybrid engines are not yet sold all over the world like hot cakes. The popularity of hybrid cars is gaining momentum only in Canada and the States. Demand for hybrids among the American population has grown due to a sharp rise in the price of fuel, which was mercilessly fired before. After all, the American auto industry has always been famous for its "muscle cars" with incredibly powerful motors and huge consumption of flammable liquid. European car enthusiasts generally reacted neutrally to cars with hybrid engines. A fairly environmentally friendly and more economical, trustworthy veteran, a diesel, runs there.

Most of the cars in Europe are refueled with diesel, which cannot be said about the USA. Moreover, vehicles with diesel engines much cheaper than hybrid ones, moreover, it is simpler and more reliable in its design. After all, everyone knows such a postulate: "the more complex the system is designed, the less its reliability." It is this factor that determines the number of hybrid cars in our country. Officially, such cars are not delivered to us, and the problem of service stations is simply inevitable in the event of a breakdown. There are simply no specialized service stations for the repair of hybrid engines in our country. And on our own, we think that hardly anyone will undertake to repair such a device.

Hybrid engine device - circuit description

So, we briefly reviewed what a hybrid engine is and why its use is not as widespread in the world as we would like. Now I would like to "dig" deeper and consider the scheme of its structure. But there are three of them. We suggest starting with the simplest circuit, which causes us the least interest is a sequential hybrid engine.

Series diagram of a hybrid engine

In this scheme, the start of the car comes from an electric motor. The internal combustion engine is in conjunction with a generator that feeds the battery. Hybrid vehicles with a sequential powertrain scheme (Plug-inHybrid) are often produced with the ability to connect to the electrical network at the end of the trip. The presence of this function implies the use of batteries with high energy intensity, which significantly reduces fuel costs for the use of an internal combustion engine, which in turn reduces the number of harmful emissions in atmosphere. These cars include Chevrolet Volt and Opel Ampera. They are also called electric vehicles with a wide range. These cars can only run on battery power at a speed of 60 km / h and using the energy of a generator that drives a gasoline engine for as much as 500 kilometers.

In this scheme, the start of the car comes from an electric motor. The internal combustion engine is in conjunction with a generator that feeds the battery. Hybrid vehicles with a sequential powertrain scheme (Plug-inHybrid) are often produced with the ability to connect to the electrical network at the end of the trip. The presence of this function implies the use of batteries with high energy intensity, which significantly reduces fuel costs for the use of an internal combustion engine, which in turn reduces the number of harmful emissions in atmosphere. These cars include Chevrolet Volt and Opel Ampera. They are also called electric vehicles with a wide range. These cars can only run on battery power at a speed of 60 km / h and using the energy of a generator that drives a gasoline engine for as much as 500 kilometers.

Hybrid car parallel circuit

With this scheme, an internal combustion engine and an electric motor connected in parallel are installed in such a way that they can work either separately from each other or together. This effect is achieved due to the design of the unit, in which the gasoline engine, electric motor and transmission are connected by automatically controlled clutches. A car with such a hybrid engine scheme uses a small electric motor, about 20 kW. Its main task is to add ICE power during vehicle acceleration.

Most of these structures the electric motor is installed between the internal combustion engine and It also performs the functions of a generator and a starter. The most famous representatives among cars with a sequential hybrid engine are BMW Active Hybrid 7 Honda Insight Volkswagen Touareg Hybrid, Honda Civic Hybrid. This scheme appeared due to the initiative Honda with its Integrated Motor Assist - IMA. The operation of this system can be divided into several characteristic modes:

Most of these structures the electric motor is installed between the internal combustion engine and It also performs the functions of a generator and a starter. The most famous representatives among cars with a sequential hybrid engine are BMW Active Hybrid 7 Honda Insight Volkswagen Touareg Hybrid, Honda Civic Hybrid. This scheme appeared due to the initiative Honda with its Integrated Motor Assist - IMA. The operation of this system can be divided into several characteristic modes:

- work from the electric motor;

Joint operation of the electric motor and internal combustion engine;

Operation from an internal combustion engine with parallel charging of the battery using an electric motor that acts as a generator;

Charging the battery during regenerative braking.

Series-parallel hybrid circuit

In this scheme, the electric motor and the internal combustion engine are connected using planetary gear. This allows you to simultaneously transfer power from each of the motors to the drive wheels in a ratio of 0 to 100% of the rated power. The series-parallel circuit differs from the previous one in that a generator is installed on the first one, which creates energy for the operation of the electric motor.

Well-known representatives of cars with such a hybrid engine scheme are the Toyota Prius, Ford Escape Hybrid , Lexus RX 450h. In this segment of the "hybrid" market, Toyota is leading with its Hybrid Synergy Drive - HSD system. The power unit of the Hybrid Synergy Drive system is presented as follows:

Well-known representatives of cars with such a hybrid engine scheme are the Toyota Prius, Ford Escape Hybrid , Lexus RX 450h. In this segment of the "hybrid" market, Toyota is leading with its Hybrid Synergy Drive - HSD system. The power unit of the Hybrid Synergy Drive system is presented as follows:

- ICE communicates with the planetary gearbox;

An electric motor that is attached to the ring gear of the planetary gearbox;

The sun gear of the planetary gear is connected to the generator.

The internal combustion engine operates in the Atkinson cycle, which means that low revs it produces less power, resulting in better fuel economy and less exhaust emissions.

Hybrid car - pros and cons

Advantages of hybrid engines

1. The most important advantage of hybrid vehicles is their efficiency. Fuel consumption such cars have 25% less than classic cars with an internal combustion engine. And in our situation with constantly rising gasoline prices, this is a very important factor.

2.

next no less important point The next most important item among positive aspects hybrid engines are environmentally friendly. Hybrid cars cause much less damage to our environment than classic ones. This is achieved through more rational fuel consumption. And when the car comes to a complete stop, the internal combustion engine stops working, transferring the reins of power to the electric motor. Therefore, during the stops of the hybrid car, the atmosphere is not polluted by CO2 emissions.

2.

next no less important point The next most important item among positive aspects hybrid engines are environmentally friendly. Hybrid cars cause much less damage to our environment than classic ones. This is achieved through more rational fuel consumption. And when the car comes to a complete stop, the internal combustion engine stops working, transferring the reins of power to the electric motor. Therefore, during the stops of the hybrid car, the atmosphere is not polluted by CO2 emissions.

3. The batteries of hybrid engines are recharged by a gasoline engine, which is not the case with electric vehicles, which makes the range fuel engine much bigger. And it can go longer without refueling.

4. Modern hybrid cars are in no way inferior to a similar class of traditional ones in all the main characteristics. So let's dispel this myth, which many people most likely believe.

5. In urban, stop-and-go environments, hybrid vehicles perform like electric vehicles.

6. When standing still, a hybrid vehicle is completely silent as it runs on the electric motor only.

7. Refueling of a hybrid is carried out with gasoline and in the same way as a traditional car.

Cons of hybrid cars

There is nothing perfect in the world, which means that hybrid engines also have their disadvantages.

1.

And the main disadvantage is expensive repairs. Since the design of such engines is very complex, it is very difficult to find a specialist who will deal with the elimination of problems. This explains the high cost of maintaining hybrids.

1.

And the main disadvantage is expensive repairs. Since the design of such engines is very complex, it is very difficult to find a specialist who will deal with the elimination of problems. This explains the high cost of maintaining hybrids.

2. Batteries installed in hybrids are subject to self-discharge. They also do not tolerate sudden changes temperatures. And their service life is very limited. But so far, we have not yet figured out what effect on environment batteries, which makes recycling them a problematic task.

It is obvious, of course, that hybrid engines have more pluses than minuses, but in our country they have not taken root yet. The first reason for this is the price. Cost in Ukraine popular Toyota Prius is from 850,000 hryvnia. But he is not only the most-most in his popularity, but also the cheapest. Also in Russia, it was planned to launch the production of a hybrid called Yo-mobile, but the project was curtailed. For today the most powerful car with a hybrid engine is the BMW ActiveHybrid X6.

The fight for the environment in our time is in full swing and very zealously, in connection with which motorists are encouraged to purchase cars with hybrid engines. So in America, the owners of such cars are provided with certain benefits and free parking spaces. Similar laws are also planned to be introduced in our country, in particular, duties on the import of cars with hybrid engines will be reduced. Gasoline engines are already gradually receding into the background, losing their positions. And hybrid engines are one of the main steps being taken for this. But as long as the price category of these cars remains at the same level, the demand for them will be small.

About prices for cars with hybrid engines

Like everything new, unusual and interesting, cars with hybrid engines are more expensive than their classic counterparts. Today, hybrid cars are much more expensive than cars with similar characteristics, but with gasoline engines. For example, a hybrid Toyota Camry outperforms its gasoline counterpart by nearly $7,000. The hybrid Honda Civic has increased by $4,000 over its traditional model. The Lexus GS 450h is a wonderfully dynamic (from 0 to 60 in just 5.9 seconds) car, which is also much more economical than similarly powerful sedans with eight-cylinder engines. The fuel consumption of this car is approximately 8 liters per 100 kilometers in combined cycle. The average retail price for this car in Ukraine will average around $80,000.

Like everything new, unusual and interesting, cars with hybrid engines are more expensive than their classic counterparts. Today, hybrid cars are much more expensive than cars with similar characteristics, but with gasoline engines. For example, a hybrid Toyota Camry outperforms its gasoline counterpart by nearly $7,000. The hybrid Honda Civic has increased by $4,000 over its traditional model. The Lexus GS 450h is a wonderfully dynamic (from 0 to 60 in just 5.9 seconds) car, which is also much more economical than similarly powerful sedans with eight-cylinder engines. The fuel consumption of this car is approximately 8 liters per 100 kilometers in combined cycle. The average retail price for this car in Ukraine will average around $80,000.

On the topic of introducing hybrid cars, of course, you can argue for a long time and take certain positions and defend your points of view, but one thing is clear - the future is not far off and soon this leap will be made. Changes in the automotive industry are coming grandiose! And we hope this will be what we all need.

How it works, consider the example of Touareg, with a hybrid powertrain.

What does the term "hybrid technology" mean?

The term "hybrid" originates from the Latin word hybrida, and means something crossed, or mixed. In engineering, a hybrid is a system in which two different technologies. In connection with drive concepts, the term hybrid drive technology is used to refer to two areas: bivalent (or dual-fuel) powertrain hybrid powertrain

When hybrid technology drive it is a combination of two different power units, whose work is based on different principles actions. Currently, hybrid drive technology means a combination of an internal combustion engine and an electric motor-generator (electric machine). This electric machine can be used as a generator to generate electrical energy, a traction motor to drive a car, and a starter to start an internal combustion engine. Depending on the execution of the main structure, three types of hybrid power unit are distinguished: the so-called. "microhybrid" power unit, the so-called. "medium hybrid" power unit, the so-called. "full hybrid" powertrain.

"Micro-hybrid" powertrain

In this drive concept, the electrical component (starter/alternator) is exclusively used to implement the start-stop function. Part of the kinetic energy can be used again as electrical energy (recuperation). Drive only from electric traction is not provided. The parameters of the 12 volt fiberglass battery are adapted to frequent engine starts.

"Medium hybrid" drive

The electric drive supports the operation of the internal combustion engine. The movement of the car only on electric traction is impossible. With a "mid-hybrid" drive, most of the kinetic energy during braking is regenerated and stored as electrical energy in a high-voltage battery. The high-voltage battery as well as the electrical components are designed for a higher electrical voltage and thus more high power. Thanks to the support of the electric motor-generator, the working mode heat engine can be shifted to the region of maximum efficiency. This is referred to as load point displacement.

"Full hybrid" powertrain

A powerful electric motor-generator is combined with an internal combustion engine. Only electric drive is possible. The electric motor generator, if conditions permit, supports the operation of the internal combustion engine. Movement from low speed carried out only on electric traction. The Startstop function for the internal combustion engine has been implemented. Recovery is used to charge the high voltage battery. Thanks to the decoupling clutch between the internal combustion engine and the electric motor-generator, it is possible to ensure the separation of both systems. The internal combustion engine is connected to work only when necessary.

Fundamentals of hybrid technology

Full hybrid powertrain systems are divided into three subgroups: parallel hybrid powertrain, split powertrain (with split power flows), and series hybrid powertrain.

Parallel hybrid powertrain

Parallel execution of the hybrid power unit is simple. It is used when it is necessary to "hybridize" an existing vehicle. The internal combustion engine, electric motor generator and gearbox are located on the same axis. Typically, a parallel hybrid powertrain system uses a single electric motor/generator. The sum of the unit power of the internal combustion engine and the power of the electric motor-generator corresponds to full power. This concept provides a high degree of borrowing components and parts old car. In all-wheel drive vehicles with a parallel hybrid powertrain, all four wheels are driven using a Torsen differential and a transfer case.

Separate hybrid drive

The split hybrid drive system has an electric motor generator in addition to the internal combustion engine. Both engines are located under the hood. The torque of the internal combustion engine, as well as from the electric motor-generator, is fed through the planetary gear to the vehicle gearbox. In contrast to a parallel hybrid drive, it is not possible to extract the sum of the individual powers for wheel drive in this way. The generated power is partly spent on driving the car, partly, in the form of electrical energy, accumulates in a high-voltage battery.

Series hybrid powertrain

The car is equipped with an internal combustion engine, a generator and an electric motor-generator. However, unlike both of the previously described concepts, the internal combustion engine does not have the ability to independently drive the car through a shaft, or through a gearbox. Power from the internal combustion engine is not transferred to the wheels. The main drive of the car is carried out by an electric motor generator. If the capacity of the high-voltage battery is too low, the internal combustion engine starts. The internal combustion engine charges the high-voltage battery through the generator. The electric motor generator can again be powered by the high voltage battery.

Separate sequential hybrid powertrain

The split series hybrid powertrain is a mixed form of the two hybrid drives described above. The car is equipped with one internal combustion engine and two electric motors-generators. The internal combustion engine and the first electric motor generator are located under the hood. The second electric motor generator is located on rear axle. This concept is used for all-wheel drive vehicles. The internal combustion engine and the first electric motor generator can drive the vehicle's gearbox through a planetary gear. And in this case, the rule applies, according to which single drive powers cannot be taken for wheel drive in the form of total power. A second electric motor generator on the rear axle is activated when needed. In connection with this design of the drive, the high-voltage battery is located between both axles of the vehicle.

Other terms and definitions Other terms and definitions often used in connection with hybrid drive technology will be briefly explained here.

Recovery. IN general case this term in engineering means a way to return energy. During recovery, the available energy of one type is converted into another, used in the subsequent type of energy. The potential chemical energy of the fuel is converted in the transmission into kinetic energy. If the car is braked by a conventional brake, then the excess kinetic energy is converted into heat energy through the friction of the brakes. The resulting heat is dissipated in the surrounding space, and therefore it is impossible to use it in the future.

If, on the contrary, as with hybrid drive technology, in addition to the classic brakes, the generator is used as an engine brake, then part of the kinetic energy is converted into electrical energy, and thus becomes available for subsequent use. Energy balance car is improving. This kind of regenerative braking is called regenerative braking.

As soon as the vehicle speed is reduced by decelerating by depressing the brake pedal in over idle mode, or the vehicle is coasting or the vehicle is moving downhill c The hybrid drive system includes an electric motor-generator and uses it as a generator.

In this case, it charges the high-voltage battery. So in forced idle mode

running, it becomes possible to "refuel" cars with an electric hybrid drive with electricity.

When the car is coasting, the electric motor-generator, operating in generator mode,

converts from motion energy into electrical energy only such an amount of energy that

required for the operation of the 12 volt on-board network.

Electric motor-generator (electric machine)

The term motor-generator, or electric machine, is used instead of the terms generator, electric motor, and starter. In principle, any electric motor can also be used as a generator. If the motor shaft is driven by an external drive, then the motor, like a generator, generates electrical energy. If electrical energy is supplied to the electric machine, then it works like an electric motor. Thus, the electric motor generator of electric hybrid vehicles replaces the conventional combustion engine starter as well as the conventional generator (lighting generator).

Electric booster (E-boost)

By analogy with the Kickdown function of internal combustion engines, which makes available maximum power engine, the hybrid drive has the function of the electric accelerator E-Boost. When using the function, the motor-generator and combustion engine deliver their maximum individual powers, which add up to a higher total power. The sum of the individual powers of both types of engines corresponds to the total power of the transmission.

Due to power losses in the electric motor-generator, its power in the generator mode is lower than in the traction motor mode. The power of the electric motor-generator in the engine mode is 34 kW. The power of the electric motor-generator in generator mode is 31 kW. In the Touareg with hybrid drive, the internal combustion engine has an output of 245 kW and the electric motor-generator has an output of 31 kW. In traction motor mode, the electric motor-generator produces 34 kW of power. Together, the internal combustion engine and the electric motor-generator in the traction motor mode develop a total power of 279 kW.

Start-stop function

|

The hybrid drive technology makes it possible to implement the Start-Stop function in this vehicle design. In the case of a conventional vehicle with a start-stop system, the vehicle must come to a stop in order to switch off the internal combustion engine (example: Passat BlueMotion). However, an all-hybrid vehicle can also run on electric power. This feature allows the StartStop system to shut off the internal combustion engine when the vehicle is moving or coasting. The internal combustion engine is switched on depending on the need. This may happen in case fast acceleration, when driving at high speed, with a heavy load, or when high degree low voltage battery. When the high voltage battery is highly discharged, the hybrid drive system can use the internal combustion engine in combination with the motor generator in generator mode to charge the high voltage battery. In other cases, a full hybrid vehicle may run on electric power. The internal combustion engine is in stop mode. This is also true in the case of slow moving traffic, stopping at a traffic light, when driving in overrun mode downhill, or when the vehicle is coasting. When an internal combustion engine is not running, it does not consume fuel or emit harmful substances into the atmosphere. The start-stop function integrated into the hybrid drive system increases the vehicle's efficiency and environmental friendliness. While the combustion engine is in stop mode, the air conditioner can continue to operate. Compressor air conditioner is an element of the high-voltage system. |

|

Arguments in favor of hybrid technology

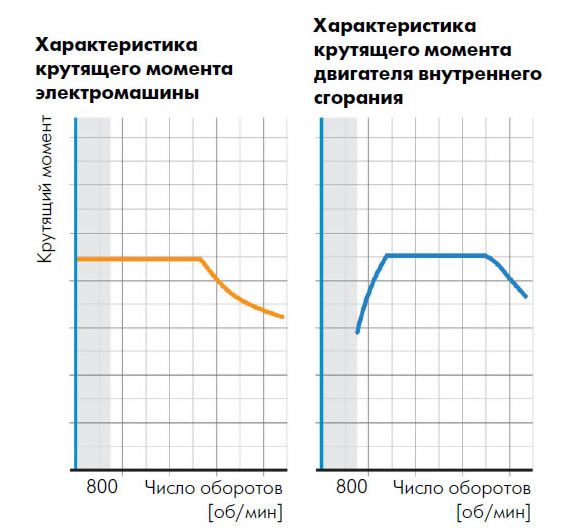

Why do we combine an electric motor-generator with an internal combustion engine? To take off the torque, the rotational speed of the internal combustion engine must not be lower than the idling speed. When stopped, the engine cannot deliver torque. With an increase in the rotational speed of an internal combustion engine, its torque increases. The electric motor generator with the first revolutions produces the maximum torque. It does not have an idle speed. As the speed increases, its torque decreases. Thanks to the operation of the electric motor-generator, the most difficult operating mode is excluded from the internal combustion engine: in the range below idle speed. Thanks to the support of the electric motor-generator, the internal combustion engine can be operated in more efficient modes. This displacement of the load point increases the efficiency of the power unit.

Why use a full hybrid powertrain (drive)?

The full hybrid unit, unlike other hybrid drive options, combines the function of the integrated Start-Stop system, the E-Boost system, the recuperation function and the possibility of driving only on the electric motor (electric traction mode).

Electric motor-generator

The electric motor-generator is located between the internal combustion engine and the automatic transmission. He is synchronous motor three-phase current. With the help of force electronic module constant pressure 288 V is converted into three-phase alternating voltage. Three-phase voltage creates a three-phase electromagnetic field in the electric motor-generator.

high voltage battery

Access to the high voltage battery is provided through the floor covering luggage compartment. It is designed as a module and includes various components of the Touareg high-voltage system. The high voltage battery module has a mass of 85 kg and can only be replaced as an assembly.

The HV battery cannot be compared with a conventional 12V battery. In normal operation, the HV battery is used in a free charge level range of 20% to 85%. A conventional 12 volt battery is unable to carry such loads for a long time. Therefore, a high-voltage battery should be considered as an operational energy storage device for an electric drive. Like a capacitor, it can store and release electrical energy again. In principle, recuperation, energy regeneration, can be considered as the possibility of refueling a car with energy while driving. The use of a high-voltage battery in a hybrid vehicle is characterized by alternating cycles of charging (recovery) and discharging (driving on electric drive) high voltage battery.

Example: If we compare the energy of a high-voltage battery with the energy generated by burning fuel, then the amount of energy that the battery can produce will correspond to about 200 ml of fuel. This example demonstrates that on the path to electric vehicles, batteries need to be significantly upgraded in terms of their ability to store energy.

Installation of hybrid power plants automakers achieve several goals. First, it is the reduction of carbon dioxide (CO₂) emissions, which is the source of greenhouse effect on the planet and lead to global warming. Secondly, reducing the cost of fuel, which are borne by car owners. And thirdly, an increase in the dynamics of acceleration of the car due to two sources of torque.

The first two advantages are achieved due to the possibility of moving on electric traction (especially in modes where the efficiency of the internal combustion engine is low), the braking energy recovery mode (braking by an electric motor that operates in generator mode, generating electricity to recharge the battery), acceleration using the internal combustion engine and electric motor, turning off the internal combustion engine during short stops (start-stop systems).

Structurally, all this happens in different ways, so the resulting effect is also different.

Hybrid classification

The generally accepted classification of hybrids implies three types: series, parallel, and series-parallel.

- a design in which the internal combustion engine (gasoline or diesel) drives only the generator. The internal combustion engine in this scheme operates in the maximum fuel economy mode. The electricity generated by the generator is supplied either to the traction motor or to the battery. The electric motor in this scheme transmits the required torque to the wheels through the transmission, and in the braking mode it works as a generator, recharging the battery (brake energy recovery mode). Such hybrids are marked with the abbreviation REEV (range-extended electric vehicle) or EREV (extended-range electric vehicle).

This design has its advantages and disadvantages. The advantages of this scheme are constant ICE work in the most economical mode, easy operation and no complicated transmission. Of the minuses, it should be noted the low efficiency of the mechanism for transferring energy from the internal combustion engine to the driving wheels of the car. This design is used in the BMW i3 REx, Cadillac ELR sports coupe and Chevrolet Volt 2015 model year, as well as in buses with hybrid power plants, for example Toyota Coaster hybrid.

Parallel design armed with an internal combustion engine and a traction electric motor, which are connected to the driving wheels of the car. The electric motor is powered by a battery. Because the torque from input shaft can be directly transmitted to the wheels of the car, the coefficient useful action such a hybrid is higher. This scheme uses one or two electric motors (generator + traction motor). In the first case, the electric motor can operate both in the generator mode and in the traction motor. But in such a scheme, the transmission design is rather complicated, because the torque must be transmitted to the wheels from both the internal combustion engine and the electric motor. In addition, the internal combustion engine cannot operate in economy mode all the time. This design of power units have Honda models– Civic Hybrid, Insight and CR-Z.

Series-parallel design hybrid power plant combines both of the above schemes. Thanks to this combined scheme succeeded in obtaining the advantages of both systems. In this case, there is both an internal combustion engine and an electric motor, and, depending on the driving conditions, the car can drive either only on electric traction (up to 1.5–2.0 km), or only on traction from the internal combustion engine, or the wheels can also receive motive energy from ICE, and from an electric motor. At Toyota in power Toyota installation The Hybrid System uses a planetary power flow (torque) divider, which comes from an internal combustion engine and can be flexibly changed, transferring part of the energy to the generator, and part to the wheels of the car. The electricity generated in this case can immediately go both to power the power motor and to recharge the batteries. This design has been implemented in a number of Toyota models, including the Prius, Yaris Hybrid, Auris Hybrid, Camry Hybrid, Avalon Hybrid, as well as Lexus models– CT 200h, IS 300h, GS 300h, GS 450h.

The combined hybrid is also used in all-wheel drive models. But in them, the front axle wheels are driven by the above-described combined system, as in front-wheel drive models, and a separate electric motor is used to drive the rear axle wheels. This design is much simpler, without a complex transmission with cardan gears and reducers. It is applied in all-wheel drive SUVs, for example, in Toyota Highlander Hybrid and RAV4 Hybrid.

Plug-in hybrids

It used to be thought that hybrids could only recharge themselves when the electric motor was running in generator mode (during brake energy regeneration, while driving in engine braking mode, etc.). But Toyota was among the first to go further and make the Prius rechargeable. These hybrids are called plug-in hybrid (Plug-in Hybrid Electric Vehicle, PHEV). They have high-capacity batteries on board (Toyota has lithium-ion instead of nickel-metal hydride), which can be recharged from a household power outlet. Therefore, the plug-in hybrid can only travel on electric power over long distances - not 1.5-2.0 km. and from 20 to 80 km and more.

Dear compatriots, today we will talk about what a hybrid engine is in a car, how it works, what it consists of, about the pros and cons of new developments.

In most cases, an internal combustion engine is used as a power plant, but given the depletion of oil reserves and the increasing requirements for the environmental friendliness of engines, auto corporations have been developing new technologies that would make it possible to abandon hydrocarbons as the main fuel or at least reduce their consumption.

Instead of an internal combustion engine, it is not yet effective to install electric motors, because the energy consumption of batteries is associated with a large weight and, accordingly, their high cost.

However, almost all the world's largest auto manufacturers have already begun to produce their own models of hybrid cars. They combine an internal combustion engine and an electrical power plant.

The recognized leader in the development and production of hybrid vehicles remains Toyota. This concern launched the first hybrid in a series back in 1997 and continues to produce several more models of reliable cars.

Hybrid - translated into Russian as crossing. The combination of these two different technologies safely perform the main task - the movement of the car.

The function of the hybrid engine is that the internal combustion engine sets in motion, which gives energy to the power plant: battery-electric motor. And the power plant, in turn, transmits torque to the wheels through the transmission.

Thus, an optimal mode of movement is achieved and an additional force is created. In addition, peak loads and fluctuations are smoothed out, as a result of which productivity and efficiency increase.

hybrid engine. Device

There are several options for a hybrid engine:

- Parallel. gasoline engine powered by the fuel tank, and the electric motor from the battery. As a result, two engines rotate the transmission, which then transmits torque to the wheels.

- Microhybrid. This option was developed by Toyota specialists. Their hybrid car starts and moves at low speeds only with the help of electric propulsion. But at an increased speed, the internal combustion engine starts to work. At the same time, on difficult areas roads - climbs, sand, dirt, other loads, the electric motor is also powered by a battery for parallel operation and increased traction. All these modes are controlled by electronics.

- Medium hybrid. Such a car has its own characteristics - riding on an electric motor is not provided. But electric traction significantly increases efficiency, due to the receipt of more high voltage than gives the battery, and this accordingly increases the power of the power plant as a whole.

- Full hybrid. Here, electricity is in the first place - due to it, movement is provided. The battery is charged by recuperation. And a separate clutch between the two engines makes it possible to decouple these systems. As a result, the petrol engine is switched on only when absolutely necessary.

- Separated. It contains a pair of engine-generator and a gasoline engine. Through planetary gear torque is supplied to the gearbox. Some of the energy is used to propel the car, while the rest is sent to a high-voltage battery.

- Consistent. Here the scheme is as follows: the gasoline engine rotates the generator, which charges the battery, and from it the energy is supplied to the electric motor, and already it rotates the transmission and, in fact, the wheels.

Pros and cons of a hybrid car engine

Of course, the pros outweigh the pros, but there are also cons, as in all new products. For example, a gasoline hybrid engine is more common, although it is not questioned.

But it just so happened - the technology was developed in America, and there diesel fuel is not held in high esteem. Yes, and a hybrid diesel unit would have cost more, and given that the price is already far above average, the issue can be considered closed.

Most of all, car enthusiasts are confused by the hybrid engine because of the battery. This is a very capricious component, as it requires permanent operation Otherwise, its service life will be significantly reduced.

Also, batteries are afraid of temperature changes, self-discharge. Plus, the high cost of spare parts and repairs. And it's unlikely that you can do it yourself.

But let's talk about pleasant things. One of the main advantages of a hybrid engine low flow fuel and minimum emissions harmful substances into the atmosphere, and all this thanks to:

- coordinated work and electric motor;

- the use of a large capacity battery;

- the use of braking energy (regenerative braking), which converts the kinetic energy of movement into electricity.

In addition, the hybrid engine has collected a lot of other innovations that will save fuel and save the atmosphere. Among them:

- change in valve timing;

- stop start;

- exhaust gas recirculation;

- antifreeze heating with exhaust gases;

- electric water pump, climate control and;

- tires with improved rolling.

A noticeable effect is observed when using a hybrid car in the urban cycle, when there are frequent stops, the engine is idling.

But on the highway, when driving with high speed, the hybrid engine is no longer as efficient.

On the other hand, the same battery makes it possible to drive for a longer time without refueling. Moreover, the battery can not be charged, but the car can only be filled with fuel.

The engine, thanks to computer control, always works in the optimal mode, no matter how hard you try to overload it.

Often these hybrid vehicles can run without fuel. And they differ in that the motor runs barely audibly.

I hope that the article will help you find the right solution if the question arises of choosing a car with a hybrid power plant.

See you again.