How to restore functionality car battery

Recovery of battery capacity

The simplest and most common way is to repeatedly charge with a small current with breaks between charges. By the end of the first and subsequent charges, the voltage on the battery rises, and it ceases to accept the charge. During the break, the electrode potentials on the surface and in the depth of the active mass of the plates are equalized, while the denser electrolyte from the pores of the plates diffuses into the interelectrode space and reduces the voltage on the battery during breaks. In the process of cyclic charging, as the battery gains capacity, the density of the electrolyte increases.

When the density becomes normal for of this type battery, and the voltage on one section reaches 2.5-2.7 V, the charge is stopped.

Multiple charge modes:

Charging current 0.04-0.06 rated capacity. The time of the first and subsequent charges is 6-8 hours. The break time between charges is 8-16 hours. The number of cycles (charge-break) - 4-6 hours.

J charge = 0.04+0.06*Cn.

Restoration of a lead battery, with not a complete loss of capacity.

To restore a battery that has lost its capacity - to dissolve sulfates (disulfate), you just need to apply high voltage to it, and for a long time, keep it that way. However, as the voltage increases, the outgassing intensity also increases. Therefore, we need to pause to calm the battery.

We take a battery that has lost capacity due to sulfation. We pour water into it if it has boiled away, but not much, about as many cubic centimeters as according to the ampere-hour passport. And that may be less. We connect it, through a time relay, to a current source, which connects the battery to the source for 13 minutes and disconnects it for 13 minutes. First, we apply 14.3-14.4 volts, we do 2 full cycles. We keep it under voltage, after it reaches the set value, on the battery, in this case 14.3-14.4 volts, day. After that, we increase the voltage to 14.5-14.6 V, we also do two cycles. Then we increase the voltage to 14.8 V, and do so many cycles until, with a control discharge, you find a sharp reduction in the increase in capacity. Cycles are needed, not only to keep track of how much capacity is added, but also to ensure that the electrolyte mixes with the newly formed acid from lead sulfate. After the battery has been restored, add water, until you see that the water has ceased to be absorbed, be careful not to overfill. After that, a couple of cycles for mixing the electrolyte need to be done, but it is not necessary to charge with a high voltage.

Experimental data

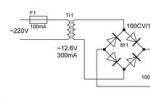

For experiments with the disulfation process, a time switch was made, which turned on the current for 13 minutes and turned it off for 13 minutes. The conditions and the duration of the voltage are approximately the same. Duration of action, about a day.

If applied, the voltage is 14.3 volts on a sulfated battery 10 Ah, a day, 13 minutes, after 13 minutes. After that, we conduct a control discharge on a 2 ampere bulb, then an increase in the glow time of this bulb by 6-7 minutes is observed, if at good battery, such a capacity, it shines for 5 hours. When applying 14.5 volts, for the same session, 10-13 minutes of glow are added. When applying 14.8 volts, 24-29 minutes of capacity are added. In all cases, strong outgassing is observed, the higher the voltage, the greater the outgassing.

From these data it follows that it is more profitable to apply 14.8 volts for disulfation.

The addition of capacitance occurs at the moment the voltage is applied, and depends on the time of its action.

The optimal time, I consider 1 day, the time of action of the voltage of 14.8 volts. That is, after the voltage has reached 14.8 volts, you need to hold the battery for a day, through a time relay, 13 minutes after 13 minutes.

Due to the fact that during disulfation there is a strong gas evolution, I recommend not to pour a lot of water, pour as many cubic centimeters as the number of ampere-hours the battery has according to the passport. So that pores remain, for the release of gas, otherwise, mechanical gas action can shower the spread.

Restoring battery capacity is fast, but not very easy

The method is different high efficiency and efficiency (the battery is restored in less than an hour).

A discharged battery is pre-charged. The electrolyte is drained from a charged battery and washed 2-3 times with water. An ammonia solution of Trilon B (ETHYLENEDIAMINETETRAACETACEETIC Sodium) containing 2 weight percent of Trilon B and 5 percent of ammonia is poured into the washed battery. The time of desulfation with a solution is 40-60 minutes.

The process of desulfation is accompanied by the evolution of gas and the appearance of small splashes on the surface of the solution. The cessation of gas evolution indicates the completion of the process. In case of strong sulfation, the treatment with the solution should be repeated.

After treatment, the battery is washed at least 2-3 times with distilled water, then filled with an electrolyte of normal density.

The flooded battery is charged with charging current to the nominal capacity according to the recommendations in the passport.

On the issue of preparing a solution, it is advisable to contact enterprises that have chemical laboratories. Store the solution in a dark place in a vessel with a hermetic lid to prevent evaporation of ammonia.

Restoration of capacity by disulfation method with a constant, stabilized voltage.

This recovery method has 100 percent efficiency, in other words, if it is not possible to restore the battery in this way, then it will not be possible to restore it in any other way. I restored all kinds of batteries in this way and with a complete loss of capacity, the voltage on which was about zero volts (0.5V), and not a complete loss when the voltage was less than 13.0V.

The method itself is very simple.

We supply 14.7 - 15 Volts (we limit the current to 1.5 amperes, if the battery is 10-15 Ah) to the battery that has lost its capacity, and so we leave it for 12-15 hours. The battery will boil, but do not be afraid, it should be so.

After that, we discharge a little, for example, we connect a light bulb so that the electrolyte is mixed.

Then we put it on charge just like the first time: we supply 14.7-15 Volts (the voltage will drop, but it should not exceed 14.7-15 Volts when the battery is charged, that is, limit 14.7-15 V), and so leave for another 12-15 hours.

After that, turn off the voltage stabilizer, and let the battery settle for about a day, after which we measure the voltage, which should be in the region of 13.0-13.2 volts at +20 degrees.

If the voltage is less than this value, we repeat the recovery cycles until the voltage rises to the indicated figures.

If the voltage on the battery does not reach 13.0 V, but somewhere around 12.7 V, this may not be bad either, for a weak electrolyte density this normal voltage. If the voltage did not even reach 10 volts, this battery was mechanically broken: the plates were shorted, the plates were sprinkled, etc. Such a battery is expensive only for scrap metal.

It is better, of course, to do a check discharge after each recovery cycle, so that we have an idea of adding or not adding capacity. To do this, we find a light bulb with such a load that the battery is discharged in 4-5 hours, so that we do not have to wait a lot and measure the discharge time, but keep in mind that the battery voltage cannot be allowed to drop below 10.5 V during discharge.

Another very important note. If the battery is sealed AGM or gel, then do not leave the valves open, air must not enter the plates, otherwise the capacity will be lost. Before restoring such batteries, it is advisable to add water. To do this, tear off the top plastic cover to get to the rubber valves, raise the valves and add distilled water from the syringe, but not much so that the water covers the plates a little (do not pour more!). To see the water, you need to shine something, for example, with a lighter-flashlight. We close the valves, press the lid on top and wrap it with tape.

If the battery has lost all capacity, this is when the voltage is less than 10 V.

We connect the rechargeable battery to a stabilized voltage source on which 15 V should be configured (the current is limited to 1/10 of the battery capacity). And wait 15 hours. At this time, look from time to time, at some time the battery will start to slowly receive current, and the voltage will drop at that moment, then the current will increase to the maximum and the voltage will drop to the lowest point (usually it is about 12.4 c), after this moment we wait 15 hours for the battery to charge. Then we restore the battery as having partially lost its capacity (see above).

There are cases when the battery does not start to receive current even after 15 hours. Then you should increase the voltage to 20 volts, I added more, sit for a few minutes and look at the current, it can go right away.

If the current does not go right away, then you need to look more often, the main thing is not to miss the moment when the battery is charged so that the voltage on it does not exceed 15 V, that is, we need to limit the voltage as quickly as possible before charging.

Yes, another very important note, do not stop the recovery process halfway, be sure to complete the cycle.

Restoring the battery with a short current pulse of large magnitude.

Sometimes it happens that due to some reason, the plates of one of the battery cans are somehow closed and their charge becomes impossible.

It is logical to assume that the cause of the short circuit can be eliminated by burning the problem area. To do this, the battery is connected to a source of very strong current, at least 100 amperes, for example, a welding machine, with a rectifier diode at the output. The circuit closes for 1-2 seconds, during which time the cause of the circuit should evaporate due to severe overheating.

Several applications and the effectiveness of this method in practice.

Personally, I came across one 7 a.h. lead battery Closed can CSB. The battery has been sitting for several years without being charged. The reason for the short circuit, most likely, was that the battery plates, due to abundantly deposited sulfate, were warped, and the separator was pierced.

By connecting to the welding machine for 2-3 seconds, the short circuit was eliminated, but subsequent recovery measures were unsuccessful, which is not surprising, because the lead maintenance-free batteries are not restored. But application this method to other types of batteries may be justified.

Example 2

One friend told me about his experience of applying this method to a nickel-cadmium (NiCd) battery, he managed to revive and put into operation a mine nickel cadmium battery, "KCSL 12", for horse racing.

Example3.

Another friend drained the lithium-ion (Li-ion) battery from a portable DVD player. IN lithium-ion batteries at deep discharge sometimes a copper short shunt is formed between the plates. The result of the restoration was that the capacity of the battery was higher than it was when it was new.

Restoration of serviced batteries, in particular automobile ones.

There is one way to restore your battery.

The essence of the method

Pour out all the electrolyte. Pour distilled water into the battery until the plates are covered. Connecting to the battery constant pressure about 14 volts and leave for 1-2 hours. Then we listen to the battery, if we hear that it is bubbling, we slightly reduce the voltage. We leave it for half an hour and listen again: our task is to keep such a voltage on the battery so that gas emission is minimal, but so that it exists.

We keep, under this voltage, the battery for a week, and preferably two. After that, the distilled water in the battery will turn into an electrolyte of low density, due to the dissolution of lead sulfate and its transformation into sulfuric acid molecules, as a result of a chemical reaction. We drain all the electrolyte, and fill again with distilled water. Also, we connect the voltage, make sure that the battery is a little, sometimes bubbles, and hold for 1-2 weeks.

If the electrolyte no longer changes density, then disulfation can be stopped.

After that, we drain the formed weak electrolyte and pour in the electrolyte of normal density. We connect your charger and charge the battery as usual, until it is fully charged.

After that, you need to measure the density of the electrolyte and align to normal density in all banks.

Your battery has been restored.

If you have nothing to measure the level of low-density electrolyte, then, just in case, you can perform one more, third, such cycle.

It makes sense to apply these procedures if the battery plates are still intact, if sediment is clearly visible in your battery, especially with pieces of lead plates, then it is clearly not worth it.

Like any product, a lead acid battery has its own expiration date and correct operation will last quite a long time. Failed car power sources are replaced with new ones, but in some cases repairs are possible, after which the battery will last for some more time. You should be aware that a restored car battery will last for some time, but you should prepare yourself for purchasing a new one.

Basic battery malfunctions

The main and most common battery malfunction is sulfation of the plates, while the battery capacity is greatly reduced. It is possible to completely eliminate this malfunction only in the early stages, which will not require significant effort, and the battery will last a long time.

The next most common malfunction is shedding of plates and, as a result, a short circuit. The biggest trouble is the breakage of the plates. This phenomenon is quite rare and usually occurs when high voltage, at insufficient level electrolyte in banks. You should be aware that sulfation of the plates occurs due to the constant undercharging of the battery, and an excess of voltage leads to shedding, short circuit and breakage of the plates. After repairing or replacing the power source, the causes that led to the failure of the battery should be identified and eliminated. Let's try to figure out how to restore a car battery at no extra cost.

Materials and devices

Sulfation of the plates leads to the fact that a charged battery does not produce full power, and the discharge is very fast. To carry out battery restoration work, you will need:

- Charger;

- Electrolyte;

- Distilled water;

- Safety goggles and gloves;

- Desulfating additive;

- "Ariometer".

Elimination of sulfation

The battery is fully charged, after which the electrolyte is drained from it and it is washed. You can find out how to do this correctly on the pages of our website in the appropriate section. Poured into jars new electrolyte and an appropriate desulfating additive is added.

The battery is fully charged, after which the electrolyte is drained from it and it is washed. You can find out how to do this correctly on the pages of our website in the appropriate section. Poured into jars new electrolyte and an appropriate desulfating additive is added.

The rules for its use should be studied before starting work. The electrolyte with additive should be completely filled to the jar to the level recommended by the manufacturer. The battery should be infused for two days, during which time the additive should eliminate deposits on the plates.

Capacity Recovery

After removing deposits, properly restore the capacity of the power source. To do this, charging should be carried out with low currents, not higher than 0.1A. The battery is fully charged, the density is checked and, if necessary, aligned to the required values. Next, we discharge the battery to a voltage of 10.5 volts, while the voltage in each bank should not be lower than 1.7 volts.

As a load, you can use series-connected car lamps. After that, the battery is fully charged, while charging current should not exceed half of the normal values when charging. It is necessary to determine the power of the lamps and the discharge time to the indicated values. Using a simple formula, the battery capacity is calculated, and in case of insufficient power supply capacity, the “discharge-charge” cycle should be carried out until acceptable battery capacity values are reached. After completing the work, you can add a small amount of additive to the electrolyte, wrap the plugs and use the restored battery.

As a load, you can use series-connected car lamps. After that, the battery is fully charged, while charging current should not exceed half of the normal values when charging. It is necessary to determine the power of the lamps and the discharge time to the indicated values. Using a simple formula, the battery capacity is calculated, and in case of insufficient power supply capacity, the “discharge-charge” cycle should be carried out until acceptable battery capacity values are reached. After completing the work, you can add a small amount of additive to the electrolyte, wrap the plugs and use the restored battery.

Deep sulfation

There are other ways to restore a car battery that is almost completely sulphated. However, these methods are quite dangerous and require special facilities for work.

Reverse current recovery

You will need a power supply to perform a restore using this method. increased power. For example, a welding transformer is suitable for this (not to be confused with an inverter). This source output voltage must be at least 20 volts, and the current strength must be more than 80 amperes. Please note that the battery must not be short circuit plates, in which case the consequences can be unpredictable. Recovery is underway reverse current, for which we connect the plus of the transformer to the minus of the battery, and the minus to the positive terminal of the battery.

Renewable power supply plugs must be inverted and the electrolyte level correct. Charging is turned on for 30 minutes, while abundant gas formation and abundant heat generation are formed, electrolyte can even splash out of the necks of the cans. Therefore, security measures must be observed impeccably. At the end of charging with reverse current, the electrolyte is drained, washed with distilled water and a new sulfuric acid solution of the required density is poured.

Renewable power supply plugs must be inverted and the electrolyte level correct. Charging is turned on for 30 minutes, while abundant gas formation and abundant heat generation are formed, electrolyte can even splash out of the necks of the cans. Therefore, security measures must be observed impeccably. At the end of charging with reverse current, the electrolyte is drained, washed with distilled water and a new sulfuric acid solution of the required density is poured.

Further charging is carried out in the usual charger correct polarity minus to minus, plus to plus. At the end of charging, you can carry out several checks - training cycles. It should be remembered that these works do not guarantee recovery and may lead to the final failure of the battery.

Recovery with sodium ethylenediaminetetraacetic acid solution

This method, like the previous one, should be carried out on a battery, which, in case of failure, will not be a pity to dispose of. The battery is charged to the maximum, the electrolyte is drained and washed with distilled water. A solution of sodium ethylenediaminetetraacetic acid is poured into the empty container. For its preparation, it is better to use a chemical laboratory.

The time it takes to desulfate the battery is 40 to 60 minutes, with abundant gas evolution and heating of the container. At the end of gas evolution, the solution is drained, washed 2-3 times with distilled water, a new electrolyte is poured in and the battery is charged. If you are lucky, the restored battery will last for some time.

With all the variety of models and types of cars, they are all assembled from units, blocks and mechanisms that perform a clearly defined role. The battery also faces its own tasks in this engineering design, the price tag of which cannot be called cheap. In the event of a battery failure, do not rush to dispose of this device: after proper restoration, the car battery will work even better than a new one.

The role of batteries in the system

Battery in automotive design solves two problems at once:

Launches power unit which consists of, clutch and gearbox;

Provides nutrition to all onboard network with the engine off.

Without a battery, the car will not start and will freeze.

Reasons why the battery may fail:

Improper maintenance of the device;

How it works accumulator battery

Since their invention, batteries have been constantly improved in order to increase the life of the device and its performance. Engineering innovations used emerging new materials with improved performance.

Car batteries consist of a closed plastic container, inside of which there are forming tanks with plates of different polarity. Tanks are made of ebonite, glass or lead-coated wood, and special alloys are used to produce plates. The main space of the vessel is filled with sulfuric acid.

The principle of operation of the battery

Sulfuric acid is necessary for the formation of a galvanic couple. When the current flows to the terminals, the process of accumulating electricity in the battery starts inside the battery, which at a certain stage already becomes a current source with an ultra-low voltage of 12 volts - conditionally safe for human health and life.

When the driver, going on a flight, turns on the starter, the car battery is discharged. During the operation of the battery motor without fail should replenish the spent electricity, but this is not always the case. The reasons why the battery does not have enough power to rotate the starter are determined by the specialist.

What are battery failures?

Most common the following reasons battery failure:

Sulfation of plates.

Signs: rapidly falling battery capacity, lack of power to rotate the starter, increased voltage at the outputs, overheating of the plates and electrolyte.

Broken integrity of the plates, and for coal - their shedding.

Signs: darkened color of sulfuric acid. In this case, the battery is not recoverable.

The closure of adjacent section plates.

Signs: hot walls of the section, boiling electrolyte. In this case, it is possible to restore the battery by replacing the failed plates.

Non-compliance with storage rules (especially in winter period) and battery operation.

Signs: damage to the container body and lead plates. In this case, there can be no question of restoring the battery.

Battery resuscitation

A faulty current source is brought back to life step by step.

Act one

After removing the terminals from the battery, it is carefully inspected. Lead electrodes coated with plaque are cleaned with a rag, and its conclusions are cleaned with fine-grained sandpaper. The layer of powder on the electrodes can be of different thickness and different color(green, white, blue). By the way, contacts coated with such a powder are in many cases the main cause of weak starter operation.

Action two

It is more complicated, because it includes a chain: charging - discharging the battery. The battery is first properly charged and then completely discharged.

Today, modern devices with such a unique function are on sale. In impulse stationary devices, these two opposing actions are, as they say, “in one package” in order to combat the unpleasant process of plate sulfation at the very initial stage.

Old chargers will require a lot of patience from the performer, since at a current strength ten times less than the battery capacity itself, it takes an average of ten hours to recharge. The following example clearly convinces of this: to charge a battery with a capacity of 75 A / h, a current of 7.5 Amperes is determined.

When the old-style charger completes its work, the process of discharging the batteries begins. To do this, use an ordinary car light bulb: connect it to the battery and wait for it to stop burning. After the light goes out completely, it is removed, and the battery is reconnected to the charger.

This is how, through strictly sequential cycles, the resuscitation of current sources for cars takes place.

Act Three

If a short circuit occurs in the battery, a special desulfating additive is used. It will take several days to restore the battery, because the additive is completely dissolved in the electrolyte within two days. This ingredient is added to the electrolyte with a density of 1.28 g/cu. cm.

After two days, the resulting liquid agent is poured into the battery and the density is checked again. If new indicator remained the same or turned out to be very close to this figure (1.28), several consecutive cycles of charging / discharging the battery are carried out.

During charging, it is necessary to observe the electrolyte. If it does not boil, and the walls of the container have a temperature environment and do not heat up, it is possible to halve the amount of incoming current.

After two hours, the density of the electrolyte is measured again, and if the nominal value is obtained again, then the charging process is completed - the battery is fully restored and ready for use.

If the electrolyte density index changes upwards, it is diluted with distilled water. If the density index is below 1.28 g / cu. see, add sulfuric acid. In both cases, after adjusting the density, the battery is put on charge again.

Fast Charging

The principle of charging the battery at an accelerated pace is as follows:

1. The battery is charged and after that the electrolyte is drained from it.

2. The container is washed with distilled water and filled for an hour with a solution (trilon B - 2% and ammonia - 5%). In some cases, washing is repeated.

3. Repeated flushing with water is performed, after which the container is filled with fresh electrolyte.

4. The battery is put on full charge.

In order for the batteries to serve for a long time and reliably, you do not need to make extra efforts: just keep the battery clean and once every six months make it fully charged with a stationary device.

April 27, 2017

Like any product, a lead-acid battery has its own shelf life and, if properly maintained, will last a long time. Failed car power sources are replaced with new ones, but in some cases repairs are possible, after which the battery will last for some more time. You should be aware that a restored car battery will last for some time, but by and large you should prepare yourself for the acquisition of a new one.

In order to better understand the information that will be discussed below, we suggest that the reader familiarize himself with the device of a car battery. It is clearly shown in this diagram:

The main reasons for the failure of car batteries

The most common malfunction of car batteries is. At the same time, the battery capacity drops noticeably, and as a result, the device does not have enough power to turn the starter.

You can determine the sulfation of the plates by the following signs:

- Decreased capacity;

- electrolyte boiling;

- Plate overheating;

- Increased voltage on the electrodes.

Next common cause malfunctioning battery - destruction and shedding of coal plates. This malfunction can be determined by the dark color of the electrolyte. Restoring the car battery in this case is possible, although not always.

The third common malfunction is related to by shorting lead plates in one of the battery sections. It is quite easy to identify this failure. When charging, the faulty section will heat up excessively, and the electrolyte will boil away. It is possible to restore the battery in this case, although it is somewhat more difficult than in the first case. The solution to the problem is to replace the lead plates in the section, which is quite expensive, although cheaper than buying a new battery.

The fourth reason for battery failure is related to with improper operation and storage of batteries. It is known that an incompletely charged battery sub-zero temperature may freeze. Freezing may damage lead plates, as well as the body of the device. This can lead to short circuits in the device case and electrolyte boiling. In this case, unfortunately, the battery cannot be restored.

Do-it-yourself car battery recovery

Having found out the reasons, you can proceed to consider ways to restore the battery.

Having found out the reasons, you can proceed to consider ways to restore the battery.

SULFATION REMOVAL

Sulfation of the plates causes a charged battery to not produce full power, and the discharge occurs very quickly. To carry out battery restoration work, you will need:

- Charger;

- Electrolyte;

- Distilled water;

- Safety goggles and gloves;

- Desulfating additive;

- "Ariometer".

The battery is fully charged, after which the electrolyte is drained from it and it is washed. A new electrolyte is poured into the jars and an appropriate desulphating additive is added.

The rules for its use should be studied before starting work. The electrolyte with additive should be completely filled to the jar to the level recommended by the manufacturer. The battery should be infused for two days, during which time the additive should eliminate deposits on the plates.

CAPACITY RECOVERY After removing deposits, properly restore the capacity of the power source. To do this, charging should be carried out with low currents, not higher than 0.1A. The battery is fully charged, the density is checked and, if necessary, aligned to the required values. Next, we discharge the battery to a voltage of 10.5 volts, while the voltage in each bank should not be lower than 1.7 volts.

After removing deposits, properly restore the capacity of the power source. To do this, charging should be carried out with low currents, not higher than 0.1A. The battery is fully charged, the density is checked and, if necessary, aligned to the required values. Next, we discharge the battery to a voltage of 10.5 volts, while the voltage in each bank should not be lower than 1.7 volts.

You can determine the battery capacity by calculating the battery discharge time. To do this, multiply the charge current by the time. If the battery capacity is below the nominal capacity, charge-discharge cycles should be carried out until full recovery car battery.

Charging the battery As a load, you can use car lamps connected in series with each other. After that, the battery is fully charged, while the charging current should not exceed half of the usual indicators when charging. It is necessary to determine the power of the lamps and the discharge time to the indicated values. Using a simple formula, the battery capacity is calculated, and in case of insufficient power supply capacity, the “discharge-charge” cycle should be carried out until acceptable battery capacity values are reached. After completing the work, you can add a small amount of additive to the electrolyte, wrap the plugs and use the restored battery.

DEEP SULFATION

There are other ways to restore a car battery that is almost completely sulphated. However, these methods are quite dangerous and require special facilities for work.

REVERSE CURRENT RECOVERY Restoring using this method will require a high-capacity power supply. For example, a welding transformer is suitable for this (not to be confused with an inverter). This source must have an output voltage of at least 20 volts, and a current of more than 80 amperes. It should be borne in mind that the battery should not have a short circuit of the plates, in which case the consequences can be unpredictable. Recovery is carried out by reverse current, for which we connect the plus of the transformer to the minus of the battery, and the minus to the positive terminal of the battery.

Restoring using this method will require a high-capacity power supply. For example, a welding transformer is suitable for this (not to be confused with an inverter). This source must have an output voltage of at least 20 volts, and a current of more than 80 amperes. It should be borne in mind that the battery should not have a short circuit of the plates, in which case the consequences can be unpredictable. Recovery is carried out by reverse current, for which we connect the plus of the transformer to the minus of the battery, and the minus to the positive terminal of the battery.

Charging the battery The plugs of the renewable power supply must be inverted and the electrolyte level correct. Charging is turned on for 30 minutes, while abundant gas formation and abundant heat generation are formed, electrolyte can even splash out of the necks of the cans. Therefore, security measures must be observed impeccably. At the end of charging with reverse current, the electrolyte is drained, washed with distilled water and a new sulfuric acid solution of the required density is poured.

Next, charging is carried out with a conventional charger of the correct polarity minus to minus, plus to plus. At the end of charging, several control and training cycles can be carried out. It should be remembered that these works do not guarantee recovery and may lead to the final failure of the battery.

This method, like the previous one, should be carried out on a battery, which, in case of failure, will not be a pity to dispose of. The battery is charged to the maximum, the electrolyte is drained and washed with distilled water. A solution of sodium ethylenediaminetetraacetic acid is poured into the empty container. For its preparation, it is better to use a chemical laboratory.

This method, like the previous one, should be carried out on a battery, which, in case of failure, will not be a pity to dispose of. The battery is charged to the maximum, the electrolyte is drained and washed with distilled water. A solution of sodium ethylenediaminetetraacetic acid is poured into the empty container. For its preparation, it is better to use a chemical laboratory.

The time it takes to desulfate the battery is 40 to 60 minutes, with abundant gas evolution and heating of the container. At the end of gas evolution, the solution is drained, washed 2-3 times with distilled water, a new electrolyte is poured in and the battery is charged. If you are lucky, the restored battery will last for some time.

CORRECT USE OF THE VEHICLE BATTERY

And in order not to have to wonder how to restore a car battery, it is worth adopting a few useful tips about caring for this device.

- At intervals of once every two to three months, check the level and density of the electrolyte;

- In severe frosts, it is worth raising the density of the electrolyte to 1.40 g / cc.

- It is necessary to charge the battery with a current ten times less than its capacity. For example, if the battery capacity is 60 A / h, charging should be carried out with a current of 5 amperes;

- If the air temperature is below -25 'C, do not leave the car overnight for open parking. At this temperature, the electrolyte in the battery can freeze, causing the battery to fail.

Subject to these simple tips, you will be able to significantly extend the life of the battery and do not have to wonder how to restore the car battery.

As unfortunate as it may be, everything has its own lifespan. It is believed that the battery has a life of about three years, after which the battery is sent to a landfill, and a new battery takes its place in the car.

However, do not rush to say goodbye to the old battery ahead of time, as there are several ways to resuscitate it. It is with them that I would like to introduce you today.

The most common and favorite methods for resuscitating batteries by most car owners include:

1. Continuous charge of the battery with low current.

2. Battery charge in distilled water.

3. Maximum battery discharges by low currents.

Agree, the names of recovery methods give only superficial ideas about their essence. For achievement excellent result you need to get acquainted with these methods of resuscitation of the battery closer.

Continuous battery charging with low current

Using this simple method, you can restore life only to a battery with a slight and not chronic sulfation of the plates.

In order to give a second life to a battery, you need to:

1. Fill the battery with distilled water slightly above the level.

2. Turn on the battery for charging with a current of normal value (0.1 battery capacity).

3. As soon as gas formation in the battery becomes noticeable, the charge should be turned off for 20-30 minutes.

4. After a break, the battery must again be connected to a current, only this time reduced by ten times in comparison with the original, i.e. 0.01 of the battery capacity.

5. Having noticed increased gas formation on the plates of both polarities, it is necessary to disconnect the battery from the current and take a break for 15-20 minutes.

The fourth and fifth battery recovery steps should be repeated several times. Sometimes, in order for the battery to come to full combat readiness, it is necessary to repeat these procedures for several days in a row before starting to operate the battery at full capacity.

To avoid the inconvenience associated with battery operation, we recommend periodically checking the electrolyte level in the battery (the height of its layer should not be less than 5 mm above the upper edges of the plates), and if necessary, you can add distilled water. Make sure that no foreign matter gets into the battery. traces of oxidation on battery terminals and wires must be carefully removed.

Battery charge in distilled water

If the sulfation of the battery is deep, but not old, then you can try to restore the battery in the following way.

1. We discharge the battery to a voltage of 9 V.

2. Drain all the electrolyte solution and fill the battery with distilled water. We are waiting for about an hour.

3. After a pause in operation, turn on the battery for a charge. In this case, the voltage at each battery terminal must in no case exceed 11.5 V.

4. Gradually increase the charge. After the specific gravity of the solution has been increased to approximately 1.1-1.12, it is necessary to bring the charging current to a value equal to 0.1 of the battery capacity.

5. The battery should be charged in this way until a uniform gas evolution is noticeable on the plates of both polarities.

6. After that, it is necessary to discharge the battery for one and a half to two hours with a current equal to 0.2 of the discharge current, corresponding to a ten-hour battery discharge mode.

Steps 5 and 6 of battery recovery should be repeated several times. After the specific gravity of the solution does not stop increasing, the electrolyte level should be brought to normal and the battery is ready for use.

It is worth noting that this method is quite time-consuming, it can often take weeks to give the battery a second life.

Resuscitation of the battery by the method of maximum discharges with low currents

The battery recovery method, which will be discussed now, is suitable for batteries with old sulfation. Obviously, the process will be long and laborious, but worth it.

1. First of all, you need to charge the battery with a current equal to 0.2 * Q (where Q is the battery capacity).

2. After the voltage has reached 12V, the charging current should be reduced to the value calculated by the formula 0.05*Q.

3. The charge should be stopped when both the voltage and the weight of the electrolyte have reached stable values.

4. Let the battery rest for half an hour to an hour. Then again charge it with a small current until it “boils”.

This step should be repeated several times. You will understand that it is time to stop the procedure when the electrolyte starts to boil a few minutes after the start of charging.

After that, you should repeat the first stage of work, and after a couple of hours, continue to charge the battery in the indicated way. To restore battery performance, you may need to repeat the entire cycle of work up to 8 times.

Of course, restoring the battery on your own is a rather long and laborious process, but with a little effort you can significantly extend the life of the battery and save a significant amount.