Many car owners are looking for ways to save fuel. A hydrogen generator for a car will radically solve this issue. Reviews of those who have installed this device for themselves, allow us to talk about a significant reduction in costs in the operation of transport. So the topic is quite interesting. Below we will talk about how to make a hydrogen generator on your own.

ICE on hydrogen fuel

For several decades, the search has been going on to adapt engines internal combustion for complete or hybrid work on hydrogen fuel. In Great Britain, back in 1841, an engine operating on an air-hydrogen mixture was patented. The Zeppelin concern at the beginning of the 20th century used internal combustion engines running on hydrogen as the propulsion system for its famous airships.

The development of hydrogen energy was also facilitated by the global energy crisis that erupted in the 70s of the last century. However, with its end, hydrogen generators were quickly forgotten. And this despite a lot of advantages compared to conventional fuel:

- ideal flammability of the fuel mixture based on air and hydrogen, which makes it possible to easily start the engine at any ambient temperature;

- a large release of heat during the combustion of gas;

- absolute environmental safety - exhaust gases turn into water;

- 4 times higher combustion rate compared to gasoline mixture;

- the ability of the mixture to work without detonation at high degree compression.

Basic technical reason, which is an insurmountable barrier to the use of hydrogen as a fuel for cars, has become the inability to fit enough gas to vehicle. Size fuel tank for hydrogen will be comparable to the parameters of the car itself. The high explosiveness of the gas must exclude the possibility of the slightest leakage. In liquid form, a cryogenic installation is required. This method is also not very feasible on a car.

Brown gas

Today, hydrogen generators are gaining popularity among motorists. However, this is not quite what was discussed above. Through electrolysis, water is converted into the so-called Brown's gas, which is added to the fuel mixture. The main problem that this gas solves is complete combustion fuel. This serves as an increase in power and a decrease in fuel consumption by a decent percentage. Some mechanics have achieved savings of up to 40%.

The surface area of the electrodes is decisive for the quantitative gas output. Under the action of an electric current, a water molecule begins to decompose into two hydrogen atoms and one oxygen. Such a gas mixture during combustion releases almost 4 times more energy than during the combustion of molecular hydrogen. Therefore, the use of this gas in internal combustion engines leads to more efficient combustion of the fuel mixture, reduces the amount harmful emissions into the atmosphere, increases power and reduces the amount of fuel consumed.

Universal scheme of hydrogen generator

For those who do not have the ability to design, a hydrogen generator for a car can be bought from craftsmen who put on stream the assembly and installation of such systems. Today there are many such proposals. The cost of the unit and installation is about 40 thousand rubles.

But you can assemble such a system yourself - there is nothing complicated in it. It consists of several simple elements connected into one whole:

- Plants for electrolysis of water.

- Storage tank.

- Moisture trap from gas.

- Electronic control unit (current modulator).

Below is a diagram by which you can easily assemble a hydrogen generator with your own hands. Blueprints main plant that produces Brown's gas are quite simple and understandable.

The scheme does not represent any engineering complexity; anyone who knows how to work with a tool can repeat it. For vehicles with injection system fuel supply, it is also necessary to install a controller that regulates the level of gas supply to fuel mixture and associated with on-board computer car.

Reactor

The amount of Brown's gas obtained depends on the area of the electrodes and their material. If copper or iron plates are taken as electrodes, then the reactor will not be able to work for a long time due to the rapid destruction of the plates.

The use of titanium sheets looks ideal. However, their use increases the cost of assembling the unit several times. The use of high-alloy stainless steel plates is considered optimal. This metal is available, it will not be difficult to acquire it. You can also use your spent tank from washing machine. The difficulty will be only cutting the plates of the desired size.

Installation types

To date, a hydrogen generator for a car can be equipped with three electrolyzers that are different in type, nature of work and performance:

The first type of construction is quite sufficient for the set carburetor engines. No need for complicated installation electronic circuit gas productivity regulator, and the assembly of such an electrolyzer itself is not difficult.

For more powerful cars the assembly of the second type of reactor is preferred. And for engines running on diesel fuel, And heavy vehicles use the third type of reactor.

Required performance

In order to really save fuel, a hydrogen generator for a car must produce gas every minute at the rate of 1 liter per 1000 engine displacement. Based on these requirements, the number of plates for the reactor is selected.

To increase the surface of the electrodes, it is necessary to process the surface with sandpaper in a perpendicular direction. This treatment is extremely important - it will increase the working area and avoid "sticking" of gas bubbles to the surface.

The latter leads to the isolation of the electrode from the liquid and prevents normal electrolysis. Do not forget that for the normal operation of the electrolyzer, the water must be alkaline. Ordinary soda can serve as a catalyst.

current regulator

The hydrogen generator on the car in the process of work increases its productivity. This is due to the release of heat during the electrolysis reaction. The working fluid of the reactor is heated, and the process proceeds much more intensively. A current regulator is used to control the course of the reaction.

If you do not lower it, the water may simply boil, and the reactor will stop producing Brown's gas. A special controller that regulates the operation of the reactor allows you to change the performance with increasing speed.

Carburetor models are equipped with a controller with a conventional switch for two operating modes: "Route" and "City".

Installation safety

Many craftsmen place the plates in plastic containers. Don't skimp on this. You need a stainless steel tank. If it is not available, you can use the design with plates open type. In the latter case, it is necessary to use a high-quality current and water insulator for reliable operation reactor.

It is known that the combustion temperature of hydrogen is 2800. This is the most explosive gas in nature. Brown's gas is nothing more than an "explosive" mixture of hydrogen. Therefore, hydrogen generators road transport require high-quality assembly of all components of the system and the availability of sensors to monitor the process.

temperature sensor working fluid, pressure and ammeter will not be superfluous in the design of the installation. Particular attention should be paid to the water seal at the outlet of the reactor. It is vital. If the mixture ignites, such a valve will prevent the flame from spreading into the reactor.

Hydrogen generator for heating residential and industrial premises, operating on the same principles, differs by several times greater reactor productivity. In such installations, the absence of a water seal is a mortal danger. Hydrogen generators on cars are also recommended to be equipped with such a check valve in order to ensure safe and reliable operation of the system.

Until conventional fuel is indispensable

There are several experimental models in the world that run entirely on Brown's gas. However technical solutions have not yet reached their perfection. Such systems are not available to ordinary inhabitants of the planet. Therefore, while motorists have to be content with "handicraft" developments that make it possible to reduce fuel costs.

A little about trust and naivety

Some enterprising businessmen offer a hydrogen generator for cars for sale. They talk about laser treatment of the surface of electrodes or about the unique secret alloys from which they are made, special water catalysts developed in scientific laboratories around the world.

It all depends on the ability of the thought of such entrepreneurs to fly scientific fantasy. Credulity can make you at your own expense (sometimes not even small ones) the owner of an installation whose contact plates will collapse after two months of operation.

If you have already decided to save money in this way, then it is better to assemble the installation yourself. At least there will be no one to blame later.

Unique invention

Today, people are paying more and more attention to the environment, namely, this factor is directly affected by human activity, as well as its offspring. For example, cars. Representatives of this type of transport emit an incredible amount of exhaust into the atmosphere every day. These harmful substances greatly affect the state of the planet as a whole. Everything in the world becomes every minute more cars, respectively, and emissions too. Therefore, if this pollution is not stopped now, it may be too late tomorrow. Realizing this, Japanese developers started producing ecological engine, which would not affect the state of the environment in such a detrimental way. And so, Genepax introduced the world to the brainchild of modern environmentally friendly production - an internal combustion engine on water.

Advantages of the engine on the water

The state of the environment, as well as the shortage of gasoline, forced the developers to think about a simply unimaginable concept - creating an engine on water. The very thought already called into question the success of this project, but scientists from Japan were not used to giving up without a fight. Today they proudly demonstrate how they work. this engine which can be filled with river or sea water. “It's just amazing! - say experts from all over the world with one voice, - which can be refueled plain water, while the harmful ones are equal to zero. According to Japanese developers, only 1 liter of water is enough to drive at a speed of 90 km/h for an hour. At the same time, very important detail is that the engine can be filled with water of absolutely any quality: the car will drive as long as you have a container of water. Also, thanks to the internal combustion engine on the water, it will not be necessary to build large-scale stations to recharge the batteries that are in the car.

How the new device works

The engine on the water was called the Water Energy System. This system has no special differences from the hydrogen one. The engine on water is built exactly on the same principle as its counterparts, which use hydrogen as fuel. How did the developers manage to get fuel from the water? The fact is that Japanese scientists invented new technology, which is based on the splitting of water into oxygen and hydrogen using a special collector with membrane-type electrodes. The material that makes up the collector enters into a chemical reaction with water and splits its molecule into atoms, thereby providing the engine with fuel. We could not find out all the details of the splitting technology, because. developers have not yet received a patent for their invention. But today we can already safely say that this engine on water is capable of making a real revolution in the world of automotive industry. In addition to the fact that this unit is completely environmentally friendly, it is also durable! Unique technology The use of water makes the apparatus practically indestructible.

Forecasts for the future

Will soon be invented new car with internal combustion engine on the water in the city of Osaka. This will be done so that developers can patent their invention. According to preliminary estimates, scientists say that the assembly of such a device currently costs 18 thousand dollars, but soon, due to mass production, the price will be reduced by 4 times, that is, up to 4 thousand dollars for one engine on water.

This is just an amazing invention that is designed to save our world from:

- petrol crisis.

- Global warming due to atmospheric pollution

We hope that soon the engine will go to mass production, and more and more automobile factories will use it in their models.

From TV screens we are told that the amount of oil is rapidly decreasing, and soon gasoline cars recede into the distant past. That's just not entirely true.

Indeed, the number of proven oil reserves is not very large. Depending on the degree of consumption, they can last for a period of 50 to 200 years. But these statistics do not take into account hitherto unexplored oil production sites.

In fact, there is more than enough oil on our planet. Another question is that the complexity of its extraction is constantly increasing, which means that the price is also growing. In addition, the environmental factor cannot be discounted. Traffic fumes pollute the environment and something needs to be done about it.

modern science created many alternative energy sources up to the engine of nuclear fission in your machines. But most of these technologies are still concepts without the possibility of real application. At least that was the case until recently.

Every year, engineering companies produce everything more cars working on alternative sources nutrition. One of the most effective solutions in this context is a hydrogen engine from the Toyota brand. It allows you to completely forget about gasoline, making the car an environmentally friendly and cheap vehicle.

Hydrogen engines

Types of hydrogen engines and their description

Science is constantly evolving. New concepts come up every day. But only the best of them come true. Now there are only two types of hydrogen engines that can be cost-effective and productive.

The first type of hydrogen engine runs on fuel cells. Unfortunately, hydrogen engines of this type still have high prices. The fact is that the design contains expensive materials like platinum.

The second type includes hydrogen internal combustion engines. The principle of operation of such devices is very similar to propane models. That is why they are often reconfigured to work under hydrogen. Unfortunately, the efficiency of such devices is an order of magnitude lower than those that operate on fuel cells.

On this moment it is hard to say which of the two technologies for creating hydrogen engines will win. Each has its pros and cons. In any case, work in this direction does not stop. Therefore, it is quite possible that by 2030 a car with a hydrogen engine can be bought at any car dealership.

Principle of operation

The hydrogen engine works on the principle of electrolysis. This process occurs in water under the influence of a special catalyst. As a result, hydrogen is released. Its chemical formula is as follows - HHO. The gas is not explosive.

Important! Inside special containers, the gas is mixed with the fuel-air mixture.

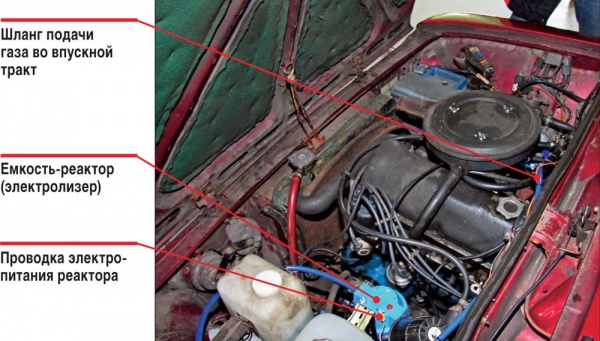

The generator includes an electrolyzer and a reservoir. The current modulator is responsible for the gas generation process. To provide best results an optimizer is installed in injection hydrogen engines. This device is responsible for regulating the ratio fuel-air mixture and Brown gas.

Characteristics of catalysts

The catalysts used to create the desired reaction in a hydrogen engine can be three types:

- Cylindrical banks. This is the most simple design, running on a rather primitive control system. The performance of a hydrogen engine operating with this catalyst does not exceed 0.7 liters of gas per minute. Such systems can be used on cars with a hydrogen engine up to one and a half liters. Increasing the number of cans allows you to exceed this limit.

- Separate cells. It is believed that this type of catalyst is the most efficient. The performance of the system is more than two liters of gas per minute, the efficiency is maximum.

- Open plates or dry catalyst. This system designed for long term work. Productivity fluctuates in the range from one to two liters of gas a minute. The open position provides the most efficient cooling.

The efficiency of hydrogen engines is growing every year. Now starting to be put into operation hybrid devices operating on hydrogen and gasoline. In turn, designers do not stop looking for the most efficient catalyst model that provides even greater performance.

DIY hydrogen engine

Generator

To create an efficient hydrogen engine for a car with your own hands, you need to start with a generator. Simplest homemade generator- this is a sealed container with a liquid in which the electrodes are immersed. For such a device, a 12 V power supply is sufficient.

The fitting is installed on the cover of the structure. It removes a mixture of hydrogen and oxygen. Actually, this is the basis of the generator for the hydrogen engine, which is connected to the internal combustion engine.

To create complete system you will also need an additional drive and battery. It is best to use a water filter as a housing, or you can buy special installation. In the latter, cylindrical electrodes of increased productivity are used.

As you can see, isolating the right gas for the reaction is not so difficult. It is much more difficult to produce it in the amount needed for a hydrogen engine. To increase the efficiency it is necessary to use copper electrodes. In extreme cases, stainless steel is also suitable.

During the reaction, the current must be supplied with different strength. Therefore, without electronic block not enough. In addition, there must always be a certain amount of water in the tank so that the reaction takes place in normal conditions. The automatic feeding system in the hydrogen engine solves this problem. The intensity of the electrolysis provides a sufficient amount of salt.

Important! If the water is distilled, there will be no electrolysis at all.

To make water for a hydrogen engine, you need to take 10 liters of liquid and add a tablespoon of hydroxide.

Hydrogen engine device

First of all, you need to take care of additional tanks and pipelines. The hydrogen engine needs a water level sensor, which is installed in the middle of the cover. This will prevent false triggering when moving up and down. It is he who will give the command to the automatic recharge system when needed.

The pressure sensor plays a special role. It turns on at 40 psi. As soon as the internal pressure reaches 45 psi, the pumping is turned off. Above 50 psi the fuse will trip.

The hydrogen engine fuse must consist of two parts: a valve emergency reset and burst disk. The rupture disk will activate when the pressure reaches 60 psi without causing any harm to the system.

To remove heat, you need to use the coldest candle. Candles with platinum tips are not suitable. Platinum is an excellent catalyst for the reaction of hydrogen and oxygen.

Important! Take Special attention creation of crankcase ventilation for a hydrogen engine.

Electrical part

Important role V wiring diagram the hydrogen engine is played by a 555 timer. It acts as a pulse generator. Moreover, it can be used to adjust the frequency and pulse width.

Important! The timer has three frequency ranges. The resistance of the resistors is within 100 ohms. The connection takes place in parallel.

The hydrogen engine board must have two 555 pulse timers. The first one must have capacitors larger capacity. The output from leg 3 goes to the second generator. He actually turns it on.

The third output of the second pulse timer hydrogen generator connected to 220 and 820 ohm resistors. The transistor amplifies the current to the desired value. The diode 1N4007 is responsible for its protection. This provides normal work the entire system.

Results

Now the hydrogen engine is no longer a figment of the imagination of scientists, but a very real development that you can do yourself. Of course, in terms of characteristics, such a unit will be inferior to the factory model. But the savings for the internal combustion engine will still be noticeable.

Hydrogen engines not only help to reduce gasoline consumption, but are also completely safe for the environment. That is why already in the first quarter of the sale hydrogen car Toyota brands broke all records in Japan.

The resulting gas is called hydrogen, Brown's gas or water gas. The engine on the water was created in order to protect the environment, because modern machines emit a lot of harmful substances into the atmosphere exhaust gases. An internal combustion engine converts 15 percent of the energy of gasoline into mechanical energy, while a water engine will increase these percentages by several times. The laws of thermodynamics will not be violated if the Brown system works in the car. It consists in the following - the gas begins to burn and dry water vapor is formed, which in turn improves heat transfer between the valves and the seat. Steam cleans the valve-piston system from carbon deposits. A water-powered engine has more mechanical energy than a gasoline-powered engine. It is more economical, because the mileage of the injectors and the interservice mileage increase. You can drive up to 40 hours on a liter of water.

Creating an engine on water at home is not easy, but possible, because water needs to be decomposed into gas, and this will require catalysts and electrodes. You also need to stock up on distilled water. The simplest Brown generator design would be 5mm plexiglass, 316 stainless steel wire, vinyl tubing (4mm diameter) and 6 x 700ml jars. The wire will need 20 meters. When working, use rubber gloves. You need to get a certain amount of gas. If the engine is 1.5 liters, then gas should be formed from 0.7 to 1.5 liters per minute. This process will depend on the voltage created on the electrodes. The electrolyte will heat up to 60 degrees in two hours if you supply power at 12 V. This is too much, so it is better to use a supply of 6 V. Unfortunately, the engine has not yet been created purely on water, so you need gasoline to start the engine.

Next, 2 electrodes are created from wire and stainless steel plates and attached to the lids of the jars. Fittings are made on the covers, into which gas will escape, and bolts that will hold the electrodes. The lids must fit tightly, and the electrodes do not close together. Now, half a liter of distilled water is poured into 6 cans with the addition of half a teaspoon of KaOH. After turning the ignition key, gas will begin to be produced. The tube is mounted in the duct near the filter. When producing hydrogen and oxygen, the mixture passes through the car's manifold and mixes with gasoline from the fuel tank and burns in the engine, as it should. At the same time, gasoline itself burns very economically and the engine does not wear out so quickly. Such a water engine system should work on any car, if everything is connected correctly and the correct voltage is applied.

Automotive experimenters are also interested in Pantone's GEET reactor. (GEET stands for Global Green Energy Technology.) It is simpler to build and does not require a specific voltage to be applied. Its essence is that the exhaust gases pass through a pointed rod. It becomes statically charged, so the water molecules in the gas are split into hydrogen and oxygen. Exhaust gases have high temperature, which is also involved in the splitting process. Further, in the reactor, the hydrocarbon molecules are separated into carbon and hydrogen. Formations are obtained from oxygen, carbon and hydrogen. Oxygen does not oxidize because gases contain carbon dioxide and nitrogen. When doing experiments with such an engine on water, a mixture of 20 percent gasoline and 80 percent water is needed. Then it will be economical and able to withstand long distances.

Those who conducted the experiments noticed that often the ratio is 50 to 50, not 20 to 80. But those who drive a car and try to save on fuel that is expensive in our time will be happy with 10 percent savings, this is obvious. The disadvantage of the Pantone reactor is difficult way out exhaust connections, because there is a lot of resistance. In addition, the reactor is single-mode. The Pantone GEET-reactor began to be installed all over the world on lawn mowers, gasoline generators. A lot of experiments were carried out and crude oil and even food waste were poured into the reactor. Based on this reactor, they tried to create another GEET-muffler device. It works using steam, soot and hydrocarbons. The main mechanism is a cyclone. In it, the splitting of components occurs when exposed to centrifugal force and throttling.

The muffler consists of a catalytic reactor in which a chemical catalyst creates hydrogen from exhaust gases. The reaction can start at a temperature of 400 degrees. While the Pantone reactor required a temperature of 500-600 degrees. You can work at temperatures below 400 degrees, but then, in order for hydrogen to appear, you need to install a reactor with electric heating elements. For this, a glow plug is often used. diesel engines. An engine on water using a GEET-muffler device will also require gasoline, but its consumption will be from 20 to 30 percent of the total liquid. Maximum 50 in some car models. But this is a significant savings in the family budget. The device is convenient in that it is compact and water, so that the muffler works, is taken not from a separate tank, but from exhaust gases. This means that the driver does not need to control the process of filling the car with water.

The water engine is a new technology developed by scientists to clean the air from harmful emissions into the atmosphere. After all, not only gasoline-powered cars pollute it. Plants and factories destroy the ozone layer, which can lead to irreparable consequences and completely change the climate of the entire globe. Nature has been sending signals for a long time to make people think about using new developments.

It would seem that fuel from water and nothing else - what could be simpler and at the same time more ingenious? External energy is needed only to start the engine cycle: a certain force acts on the water molecules so that they decay into two hydrogen atoms and one oxygen atom each. Then hydrogen, as we were taught, with a barking sound burns in oxygen. As a result, water is formed. Part of the energy goes into pushing the pistons of the engine, and part goes into a new reaction. Would have turned out perfect car: environment does not pollute, and it does not require so much water.

However, physicists are very skeptical about such inventions: the very idea of a perpetual motion machine contradicts the second law of thermodynamics. Recall: "It is impossible to spontaneously transfer heat from a body that is less heated to a body that is hotter." As applied to our hypothetical fuel from H 2 O, it can be reformulated as follows: more energy will be spent on the splitting of water than will be obtained as a result of the combustion of hydrogen.

However, the inventors are sure that a mistake crept in somewhere. And there is a way to split water with the least amount of energy.

1. The most conspiratorial model

Some claim that American inventor Stan Mayer (on the picture) invented his water engine at the end of the last century. And even managed to get a patent for it. But the scoundrels from the fuel corporations (or from the World Government - as you like) killed the self-taught mechanic so that his invention would never go to the masses. In March 1998, the inventor ate dinner at a restaurant, walked to the parking lot, and died in his car. He was only 48 years old. The alleged cause of death is poisoning, and according to the official version, an aneurysm of cerebral vessels.

So, Mr. Mayer's engine was arranged as follows. The main thing in the device is a certain "water fuel cell". It is in it that water, by means of electrolysis, decomposes into hydrogen and oxygen, forming the so-called explosive gas, HOH (hydrogen hydroxide).

It was this thing that Mayer installed in the buggy engine, also replacing the spark plugs with special injectors that inject explosive gas into the cylinders of the internal combustion engine. The inventor assembled the machine back in 1990 and demonstrated it to a reporter from the Ohio state television channel. According to him, just 83 liters of water would be enough to make the journey from New York to Los Angeles. And this, neither more nor less, almost five thousand kilometers.

The history of the invention is rather sad. Stan sold the buggy patent to two investors for $25,000. And in 1996, after eminent experts from Queen Mary University of London and the Royal Academy of Engineering of Great Britain investigated the buggy, the court found him guilty of forgery and ordered him to return the money to investors.

2. Air and water

In 2008, the world was shocked by yet another news about an engine that runs only on air and water. This time, the good news came from Japan: Genepax Corporation said that their engine requires only water and air to run. Like Stan Meier's version, Genepax's internal combustion engine runs on hydrogen, which is released from water. And all the salt of the device is in the special design of the electrodes, which, in fact, split water into hydrogen and oxygen. The Japanese called this invention MEA - Membrane Electrode Assembly (membrane electrode device).

It works like this: a metal hydride reacts with water, and the result is hydrogen. True, with the help of the new device, this reaction lasts longer - while the engine is running. This means that there is no need for a special tank to transport highly explosive hydrogen. According to representatives of the company Genepax, catalysts are needed for the reaction - for example, platinum.

Recently, nothing has been heard about the water engine - either there is no revolution in the discovery, or resource companies do not give unique car become massive.

3. Pakistan rids itself - and the world along with it - of a fuel crisis

It was with this message that the government of a Muslim state, deprived of resources, decided to invest in the work of one engineer who announced the creation of a unique water engine. Agha Waqar Ahmad created special device, which splits water into hydrogen and oxygen by electrolysis and can be installed on any internal combustion engine. Which, by the way, was demonstrated to Pakistani scientists and experts from the Ministry of Energy.

A Pakistani mechanic's invention won't take your car completely off the hydrocarbon needle. However, after connecting it to the standard cylinders of a gasoline or diesel engine the car's fuel consumption is drastically reduced. And the fuel itself burns out almost completely - which means that emissions are reduced. harmful substances in atmosphere.

The development of a water-gasoline engine is still ongoing. In complete secrecy, of course.