The main unit of any car is its engine, which is used as an engine internal combustion(ICE). Depending on the fuel used, the types of engine power systems, which are very important for normal operation motor.

Types of engine power systems

Depending on the applied fuel fluid motors, and, consequently, power systems can be divided into three main types:

- gasoline;

- diesel;

- operating on gaseous fuels.

There are other types, but their use is very small.

In some cases, the classification of power systems is made not by the type of fuel, but by the method of preparing and supplying the combustible mixture to the combustion chamber. In this case, the following types are distinguished:

- carburetor (ejector);

- with forced injection (injector).

Carburetor system

This system is used for gasoline engines. It is based on education air-fuel mixture due to the vacuum created by the movement of the piston. Air is passively sucked in, mixed in a diffuser with atomized fuel and enters the cylinder, where it is ignited using a spark plug. Such mechanical way has a number of disadvantages, for example - high flow fuel and design complexity.

forced injection

This system became a logical continuation of the first and replaced it. The work is based on the forced supply of a metered amount of fuel through the nozzle. Depending on the number of nozzles, injection types of engine power systems come with distributed (the number of nozzles and cylinders is equal) and centralized (one nozzle) injection.

The diesel engine has distinguishing feature: fuel is supplied through the nozzle directly into the cylinder, where air is separately sucked in. The ignition takes place due to high pressure created by the piston, so candles are not used.

Regardless of which system is used on your car, the main malfunctions of the engine power system are usually associated with either insufficient fuel supply or a violation of the regulation of its supply. Therefore, to ensure reliable operation needs to be done on time Maintenance. For these purposes, all the necessary details and Consumables you can purchase online at the store website at favorable prices. Save time and money with us!

in a carbureted engine gasoline is used as fuel. Gasoline is a flammable liquid that is obtained from petroleum by direct distillation, or cracking. Gasoline is one of the main components of the combustible mixture. At normal conditions combustion working mixture there is a gradual increase in pressure in the engine cylinders. When using fuel over Low quality than required technical specifications car engine, the speed of combustion of the working mixture can increase by 100 times and be 2000 m / s, such a rapid combustion of the mixture is called detonation. The tendency of gasoline to detonate is conditionally characterized by an octane number, the higher octane number gasoline, the less prone it is to detonation. Gasoline with a higher octane rating is used in automobile engines with a higher compression ratio. To reduce detonation, ethyl liquid is added to gasoline.

In the cylinders of an automobile engine, the working process proceeds quite quickly. For example, if crankshaft rotates at a speed of 2000 rpm, then each cycle takes 0.015 s. To do this, it is necessary that the speed of combustion of the fuel is 25-30 m/s. However, the combustion of fuel in the combustion chamber is slower. In order to increase the rate of combustion, the fuel is crushed into tiny particles and mixed with air. It has been established that for normal combustion of 1 kg of fuel, 15 kg of air is needed, a mixture with such a ratio (1:15) is called normal. However, this ratio does not complete combustion fuel. For complete combustion of fuel, more air is needed and the ratio of fuel to air should be 1:18. Such a mixture is called lean. With an increase in the ratio, the combustion rate decreases sharply, and at a ratio of 1:20, ignition does not occur at all. But highest power engine is achieved at a ratio of 1:13, in which case the combustion rate is close to optimal. Such a mixture is called enriched. With this composition of the mixture, complete combustion of the fuel does not occur, therefore, with an increase in power, fuel consumption increases.

When the engine is running, the following modes are distinguished:

1) cold engine start;

2) work at low speed crankshaft(idle mode);

3) work at partial (average) loads;

4) work at full loads;

5) work with a sharp increase in load or crankshaft speed (acceleration).

In each individual mode, the composition of the combustible mixture must be different.

The engine power system is designed to prepare and supply a combustible mixture to the combustion chambers, in addition to this supply system regulates the amount and composition of the working mixture.

Supply system carburetor engine

includes the following elements:

1) fuel tank;

2) fuel lines;

3) fuel filters;

4) fuel pump;

5) carburetor;

6) air filter;

7) exhaust manifold:

8) intake manifold;

9) exhaust silencer.

On modern cars instead of carburetor power systems are increasingly used fuel injection systems. On engines cars a distributor fuel injection system or a central fuel injection system can be installed single point injection fuel.

Fuel injection systems have a number of advantages over carburetor power systems:

1) the absence of additional resistance to air flow in the form of a carburetor diffuser, which contributes to better filling of the combustion chambers of the cylinders and obtaining higher power;

2) improving the scavenging of cylinders by using the possibility of more long period overlapping valves (with simultaneously open inlet and outlet valves);

3) improving the quality of the preparation of the working mixture by purging the combustion chambers with clean air without the admixture of fuel vapors;

4) more accurate distribution of fuel over the cylinders, which makes it possible to use gasoline with a lower octane number;

5) more accurate selection of the composition of the working mixture at all stages of engine operation, taking into account its technical condition.

In addition to the advantages, the injection system has one significant disadvantage. injection system fuel injection has more a high degree the complexity of manufacturing parts, and also this system includes many electronic components, which leads to an increase in the cost of the car and the complexity of its maintenance.

Distributor fuel injection system is the most modern and perfect. The main functional element of this system is the electronic unit control (ECU). The ECU is essentially on-board computer car. The ECU provides optimal control of the mechanisms and systems of the engine, provides the most economical and efficient work engine with maximum protection environment in all modes.

The fuel injection system consists of:

1) air supply subsystems with throttle valve;

2) fuel supply subsystems with injectors, one for each cylinder;

3) afterburning systems for modified gases;

4) systems for capturing and liquefying gasoline vapors.

In addition to the control functions, the ECU has self-learning functions, diagnostic and self-diagnosis functions, and it also stores in memory the previous parameters and characteristics of the engine, changing its technical condition.

Central single point fuel injection system differs from the distributor injection system in that it does not have a separate (distributive) gasoline injection for each cylinder. The fuel supply in this system is carried out using a central injection module with one electromagnetic nozzle. Feed adjustment air-fuel mixture performed by a throttle valve. The distribution of the working mixture over the cylinders is carried out, as in the carburetor power system. The remaining elements and functions of this power supply system are the same as in the distribution injection system.

Today, the term "diet" in the field of healthy eating is one of the most used, it has become something fashionable and popular. Almost every one of us follows some kind of diet, but in most cases doing it wrong, which further harms our precious health. After all, a diet is, first of all, a healthy diet, the rules for eating food that is healthy for the body. Therefore, this concept should not be confused with a restriction in food, because correct system nutrition is the most important and necessary process for the normal functioning of the whole organism.

Fasting days

Everyone who cares about their health just needs to know about the benefits of fasting days. Many are mistaken that such preventive measures are designed to get rid of the kilograms gained in weeks. Unloading days really contribute to weight loss, but only if you follow a diet or a proper diet. Nutritionists recommend unloading no more than 1-2 times a week, but at the same time provide the body with the necessary portion of calories on the remaining days. In no case should you turn fasting days into a long hunger strike.

Nutrition by blood type

Separation of blood groups began only at the beginning of the twentieth century. Differences in the properties of the blood of individual groups were first discovered by the Austrian scientist Karl Landsteiner and the Czech physician Jan Jansky. Explore Features different types blood continues to this day. As a result of special studies, it turned out that for each blood group there are separate recommendations regarding nutrition and physical activity. This theory was put forward by the American doctor Peter D "Adamo and even developed a nutritional technique for each group.

Health food

Without facing diseases, we are not attentive to our diet. However, as soon as we touch on these problems, we are looking for methods and ways to restore the body. The simple path of taking pills or other miracle cures is often temporary and carries with it a host of negative side effects. One of the effective and not difficult to use means can be considered clinical nutrition, especially since its effect can have a preventive function. Simultaneous use of various means of restoring the body in combination with therapeutic nutrition increases the effectiveness of treatment, because the vast majority of diseases are the result of improper and unlimited nutrition.

Vegetarianism

For each of us, this concept has its own meaning. Some adhere to a vegetarian way of eating based on ethical and moral views, others for health reasons, some thus strive to maintain a figure or simply follow a fashion trend. Even experts do not provide an unambiguous interpretation. However, it is true enough that vegetarianism is a diet that excludes or restricts the intake of meat and animal products. This lifestyle must be treated with caution, responsibly, and also know and follow the basic rules so that the vegetarian food system really serves for the benefit of health, and does not destroy it.

raw food diet

A raw food diet is a fashionable trend today regarding a diet in which only raw foods are consumed. The raw food nutrition system promotes the idea of a healthy lifestyle without harming the environment, cleansing the body and fighting excess weight, treating various chronic diseases, prolonging youth and life expectancy. However, around the popular ideology of the raw food diet revolves a lot of heated discussions. Is this way of eating really useful or is it just harmful to health?

Healing fasting

It is worth practicing fasting solely for the sake of health and, according to most nutritionists, only in this case a long refusal of food is justified. Fasting can help cure many diseases, in particular gastritis, hypertension, arthrosis, allergies, diabetes mellitus, eczema, etc. It is recommended to use healing fasting as a method of losing weight only under the supervision of specialists so as not to develop serious illnesses due to ignorance of various subtleties complex process fasting.

Individual nutrition

First of all, speaking of individual nutrition, we are talking about the exclusion of certain foods from the diet of a certain person. Since ancient times, questions of the individuality of our organisms in terms of biochemical functioning have worried people.

Meals for the seasons

The eastern principle of dividing products according to the seasons - this is dividing them into male and female nature - yin and yang, helps to understand the properties of food products and their impact on human life as much as possible. In the countries of the East, traditionally, the year was divided into pores, with one amendment: in addition to winter, spring, summer and autumn, there is also an off-season. We are talking about the transitional time between the dominant seasons. Each season corresponds to the activity of certain functions of our body.

Fractional nutrition

Initially, the fractional nutrition system was invented by doctors in order to contribute to the treatment of gastritis, stomach ulcers and other diseases of the digestive tract, as well as in preventive measures. Today, this nutrition system is also used in the fight against excess weight. The essence of the fractional diet is to eat food in small portions, but often, every 3-4 hours throughout the day.

Functional food

The concept of "functional food" implies in its composition the presence of valuable and rare elements that positively affect the body's immunity, prevent diseases and strengthen the general physical and emotional background in the body. The main emphasis in this system is placed not so much on the composition and nutritional value of products, but on their biological value for our body.

Balanced diet

One of the few systems that does not require significant effort and restrictions. Main principle– create a clear meal schedule and consume only energy-rich and nutritious foods. The concept of "energy value of food" means useful calories (proteins, fats, carbohydrates, vitamins, minerals and other important enzymes), which, after digestion, give the body the necessary energy for normal functioning. A balanced diet system is designed not only to improve overall health, but also to significantly contribute to weight loss or maintaining a normal weight.

Supply system power unit participates directly in the formation of the air-fuel mixture. Supply system gasoline engine includes enough elements that have different functions and purposes.

Types of power supply systems for gasoline engines

Among all possible gasoline engines, there are two fundamental power supply systems for the power unit - injection and carburetor. The first is equipped with most modern vehicles. The second one is considered obsolete, but to this day it is used in the operation of old cars, such as VAZ, Volga, Lawns, etc.

They differ in the trigger mechanism for pumping fuel into the intake manifold and cylinders. At carburetor system- this function is performed by the carburetor, but in the injector - electronic system fuel injection with injectors.

Batteries and their functions

Structurally, there is standard set elements fuel system gasoline power unit. The difference is directly in the fuel injection system into the manifold or cylinders. Consider all the elements of the injection and carburetor engines.

Fuel tank

An essential element of any vehicle. It is in it that fuel is stored, which enters the combustion chambers. Depending on the design features vehicle, the volume of the fuel tank may be different. Manufactured given element steel, stainless steel, aluminum or plastic.

Pipelines

Fuel lines serve transport system between the fuel tank and the injection system. They are usually made of plastic or metal. On older cars, you can find them copper. Adapters, connectors or other elements can be used to connect with other elements of the fuel system.

Fuel filter

Due to not particularly quality fuel, a fuel filter is used for filtration. This element can be located in the fuel tank, engine compartment or under the car, built into the fuel lines. A different element is used for each group of vehicles.

Each car manufacturer uses its own filters. They vary in shape and material. The most common are fibrous or cotton. These elements are the best at retaining third-party elements and water that clog cylinders and nozzles.

Some motorists install two different filters into the fuel system for more effective protection. It is recommended to replace the element every second maintenance.

The fuel pump is the pump that pumps fuel throughout the system. So, they are of two types - electrical and mechanical. Many seasoned car enthusiasts remember that on the old Zhiguli and Volga gasoline pumps of mechanical action were installed with a foot, which could pump up the missing fuel to start. This element was located on the cylinder block, often on the left side.

All modern gasoline power units are equipped with electric gasoline pumps. The elements are often located directly in the fuel tank, but it also happens that this element is located in the engine compartment.

Carburetor

On old vehicles carburetors were installed. This is the element that mechanical actions supplied fuel to the combustion chambers. For each manufacturer, they had a different structure and structure, but the principle of operation remained unchanged.

The most memorable for the domestic motorist were the OZONE and K series carburetors for Zhiguli and Volga.

Injectors are part of the fuel system of an injection gasoline power unit, which performs the function of metered supply of gasoline to the combustion chambers. Injectors are different in shape and type, it is individual for each car.

These elements are located on fuel rail. Maintenance of nozzles should be carried out regularly, because if they become too clogged, they may already be cleaned out, it will not be possible and the parts will have to be changed completely.

Conclusion

Fuel system petrol car has a simple structure and construction. So, the fuel that is stored in the tank, with the help of a gasoline pump, enters the cylinders. At the same time, it is cleaned in the filter and distributed using a carburetor or nozzles.

Ministry of Education of the Russian Federation

Saint Petersburg State University

service and economy

Vehicles

"Design and operation of the gasoline engine power supply system"

Completed by a 3rd year student

Specialty 100.101

Ivanov V.I.

Saint Petersburg

Introduction

1. The operation of engines on the working mixture

2. The power supply system of the carburetor engine

3. Design and operation of the carburetor engine power system

4. The power supply system of a gasoline engine with fuel injection

5. Safety

List of used literature

Introduction

The power system is a set of devices and devices that supply fuel and air to the engine cylinders and remove exhaust gases from the cylinders.

The power supply system is used to prepare the combustible mixture necessary for the operation of the engine.

combustible is called a mixture of fuel and air in certain proportions.

1. The operation of engines on the working mixture

Working called the mixture of fuel, air and exhaust gases formed in the cylinders during engine operation.

Depending on the place and method of preparing the combustible mixture, car engines may have various systems nutrition (Fig. 1).

Rice. 1. Types of engine power systems classified according to various criteria

The power supply system with the preparation of a combustible mixture in a special device - a carburetor - is used in gasoline engines, which are called carburetor. For the preparation of a combustible mixture in a carburetor, a spray method is used. With this method, droplets of gasoline, falling from the atomizer into an air stream moving at a speed of 50 ... 150 m / s in the mixing chamber of the carburetor, are crushed, evaporate and, mixing with air, form a combustible mixture. Received combustible mixture enters the engine cylinders.

The fuel system with the preparation of a combustible mixture in the intake manifold is also used in gasoline engines. To prepare a combustible mixture, finely atomized fuel is injected from the injectors into the rapidly moving air stream in the intake manifold under pressure from the nozzles. The fuel is mixed with air, and the formed combustible mixture enters the engine cylinders.

The power supply system with the preparation of a combustible mixture directly in the engine cylinders is used in both diesel and gasoline engines. The preparation of a combustible mixture occurs inside the engine cylinders by injection of finely atomized fuel from nozzles under pressure into the air compressed in the cylinders. At the same time, if self-ignition of the formed working mixture occurs in diesel engines from compression, then in gasoline engines, the working mixture in the cylinders ignites forcibly from spark plugs. The fuel injection system provides better filling of the engine cylinders with a combustible mixture and better cleaning of exhaust gases. At the same time, fuel injection allows you to increase the compression ratio and maximum power for gasoline engines, reduce fuel consumption and reduce exhaust emissions. However, fuel-injected power systems are more complex in design and maintenance in operation.

2. The power supply system of the carburetor engine

Fuel. Gasoline is the fuel for gasoline car engines. various brands- A-80, AI-93, AI-95, AI-98, where the letter A means automobile; I - method for determining the octane number of gasoline (research); 93, 95, 98 - octane number characterizing the resistance of gasoline to detonation. The higher the octane number, the higher the compression ratio of the engine can be.

Detonation - the process of combustion of the working mixture with the explosion of its individual volumes in the engine cylinders with a flame propagation speed of up to 3000 m / s, while during normal combustion of the working mixture, the flame propagation speed is 30 ... 40 m / s. Combustion during detonation becomes explosive. The shock wave propagates in the engine cylinders at supersonic speed. The gas pressure rises sharply and the performance of the engine in terms of power and efficiency deteriorates. There are ringing knocks in the engine, black smoke from the muffler, and the engine overheats. At the same time, the parts of the crank mechanism quickly wear out and the valve heads burn.

To improve the anti-knock properties, tetraethyl lead, an anti-knock TES, is added to gasolines. Such gasolines are called leaded, they have a distinctive designation and color - AI-93-ethyl (orange-red) and AI-98-ethyl ( of blue color). Leaded gasolines are very poisonous, and care must be taken when handling them - do not use for washing hands and parts, do not suck in the mouth when pouring, etc.

The use of leaded gasolines for vehicles in major cities forbidden.

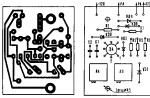

3. Design and operation of the carburetor engine power system

The power supply system of the car engine consists of fuel tank, fuel pump, air filter, carburetor, fuel lines, intake and exhaust pipes, muffler pipe, main and additional mufflers (Fig. 2).

Fuel from tank 6 is supplied by pump 7 through fuel lines 5 to the carburetor 4. Through the air filter 1 air enters the carburetor. The combustible mixture prepared in the carburetor is fed into the engine cylinders through the inlet pipeline 2. Exhaust gases are discharged from the engine cylinders to the environment through the exhaust pipe 3, pipe 8 mufflers, main 10 and additional 9 mufflers.

Rice. 2. Engine power system:

1 - air filter; 2,3 - pipelines; 4 - carburetor; 5 - fuel line; 6 - tank; 7 - pump; 8 - pipe; 9, 10 - mufflers

A filter is often installed in the engine power system fine cleaning fuel. The fuel tank is connected by a hose to a separator ( special device), which serves to condense gasoline vapors, and a drain pipe with a carburetor. Separator hose and drain line are fitted with check valves. One valve prevents fuel from draining from the tank through the carburetor when the car rolls over, and the other valve connects the internal cavity of the tank with the atmosphere. Fuel is supplied to the system with part of it drained back from the carburetor (through a calibrated hole) into the fuel tank, which ensures constant fuel circulation in the system. Constant circulation of fuel eliminates air locks in the system, improve its performance and promote additional cooling engine.

Fuel tank serves to store the fuel supply required for a certain vehicle mileage. Vehicles use welded, stamped steel fuel tanks coated with lead to prevent corrosion, or plastic. A tank filled with gasoline provides a vehicle mileage of 350 ... 400 km.

The fuel tank (Fig. 3) is welded from two trough-shaped halves 1. In the upper part, the tank has a filler neck, consisting of a receiving 13 and bulk 10 pipes with seal 8 and rubber connecting hose 11. The filler neck is closed with a threaded hermetic plug 6 with gasket 7. At the bottom of the tank is drainer with screw plug 14. The amount of fuel in the tank is controlled by a pointer, a sensor 3 which is installed inside the tank. Fuel is taken from the tank through the fuel receiving tube 2, which has a strainer, and through the hose 4 and fuel line 5 enters the fuel pump. Communication of the internal cavity of the tank with environment and its ventilation is carried out through the air 12 and ventilation 9 tubes.

Rice. 3. Fuel tank:

1 - half a tank; 2, 9, 12 - tubes; 3 - sensor; 4, 11 - hoses; 5 - fuel line; 6, 14 - traffic jams; 7 - gasket; 8 - sealant; 10, 13 - pipes

In the fuel tanks of cars, there are often special baffles to increase rigidity and reduce fuel fluctuations when driving inside. In addition, an anti-drainage device is placed in the lower part of the tank, made in the form of a glass with a diameter of 150 and a height of 80 mm. This device is designed to prevent interruptions in the operation of the engine and its stop during a sharp start or hard braking, as well as when driving a car on high speeds on the turns.

The shape of the fuel tank largely depends on its placement on the vehicle. The tank can be located under the body floor, in the trunk, under the rear and behind back seat, i.e. in places more protected from impacts in collisions. The fuel tank is attached to the car body.

Fuel pump serves to supply fuel from the fuel tank to the carburetor. Self-regulating, diaphragm-type fuel pumps are installed on car engines.

IN fuel pump(Fig. 4) between the top 7 (with cover 9) and lower 1 diaphragm block is installed by parts of the body 3, which is connected to the stem 11. The rod is covered by the forked end of the balancer 15 lever 16 pump drive. A spring is installed on the stem 2 diaphragm block. At the top of the pump housing are the suction 10 and delivery 4 valves. The pump is driven by a pusher from the eccentric of the drive shaft oil pump. Under the influence of the eccentric, the pusher presses the upper part of the lever 16, and the balancer 15 through stem 11 moves the aperture block 3 down. At the same time, the spring 2 shrinks. The volume of the cavity above the block of diaphragms increases, and the fuel under the action of vacuum from the tank enters the pump through the suction pipe 8, strainer b and suction valve 10. The discharge valve of the pump is closed. Up the diaphragm unit moves under the action of a spring 2, when the balancer 15 does not hold stock 11.