particulate filter Features of the operation of the particulate filter in urban conditions.

If the car does not accelerate to the required temperatures, depending on the brand, someone has 30 km / h, someone has 50 km / h, there is no stable speed above a certain threshold, the particulate filter does not go into regeneration mode. This is due to banal safety: since there is a certain amount of carbon in the filter, which, when oxidized to carbon dioxide, will release temperature.

In this situation, there is a risk that the particulate filter housing will heat up to a critical temperature and may damage anti-corrosion coating bodywork, etc. In the future, anticorrosive under the bottom will begin to smoke.

Therefore, most brands have a limitation that the filter is burned through only in certain engine operating modes in motion.

How to guarantee the cooling of the particulate filter

When we are standing in city traffic jams, especially in winter, the particulate filter does not go into burn-through mode. The control unit reads signals from ABS sensors, sees that the speed is not sufficient, and the particulate filter accumulates soot. Fine soot particles accumulate in pockets, as shown in the figure below.

Read more about the particulate filter device.

With a certain frequency, a certain number of them accumulate, the resistance of the exhaust filter increases, and it reaches a certain value at the inlet and outlet, in this situation, you need to put a backpressure sensor in front of the filter and modern engine will enter the regeneration mode.

In this case, the injectors give an additional injection of one more portion of fuel at the moment of the working stroke. As a result, the fuel flares up when the exhaust stroke begins. That is, when the piston throws all the burning substances into the exhaust. In fact, a burning torch flies into the particulate filter from the cylinder. It raises the temperature inside the particulate filter, soot under the influence of platinum begins to oxidize to carbon dioxide, and in gaseous form, substances seep through the porous ceramics, as shown in the picture, and the particulate filter is operational again.

The resistance is reduced to the desired threshold, the regeneration mode is turned off, the car drives on.

How does a particulate filter get clogged in traffic jams. Regeneration does not occur

There are certain restrictions in traffic jams, and it is in this situation that the following happens: accumulation is on, but the mode is not activated, over time, soot accumulation will occur above a certain threshold, after which the car’s control unit will inform that it’s time for the owner to go to a car service. Namely, it will show that the particulate filter is clogged, regeneration is no longer possible above a certain limit, and all that remains is to go to the service.

Diesel particulate filter replacement and its cost

There are several solutions to this problem. If the clogging of the particulate filter has reached such a level and the owner immediately reacts to the sensor and comes to the service, then with special. appliance dealers, you can activate the regeneration mode. At the same time, there will be a characteristic, smoky carbon dioxide exhaust, under the supervision of specialists, the engine will work in desired mode so as not to overheat the bottom of the car.

If you start this problem, and not immediately go, but with a delay, then the degree of clogging of the particulate filter can step over the second critical border, where even from the dealer scan there will be a burnout ban. And then any official dealer will say that you only need to replace the particulate filter.

Recall that the main element this filter- This is platinum, so the cost of the device is very high. Well, for example, if you take the filter of a medium-sized passenger car, then the cost can reach from 1000 euros.

What to do in such a situation if you do not want to buy a new soot, or simply, as they say, there is nothing.

Let's consider several options:

1. Removing the particulate filter. But at the same time, not for all cars, it is possible to make the control unit work in the case of a particulate filter replaced by a flame arrester. Because they catch both the pressure drop and the drop in the content of certain substances, with these components, the control unit will not allow the car to move. Basically, it is possible to deceive the system with older generation models. Newer and more modern will no longer succeed.

The one who cannot be deceived will have to live with him throughout the entire operation of the car. And sooner or later it will have to change. At a minimum, do not stand in traffic jams for a long time, especially in winter. After each stop, let the system regenerate, drive a certain number of kilometers along the highway at a certain speed, so as not to let it completely clog.

2. There is a second decent and fairly economical option, in addition to replacing it. It will be an interesting option for both the car owner and the car service. This is the maintenance and cleaning of the particulate filter.

Diesel particulate filter diagnostics and problem solving

Let's look at an example and a possible way out of the situation. If during diagnostics such an inscription appears as in the figure: "The particulate filter is full" - this situation taken from VAG.

It is necessary to work on this problem. You have a choice.

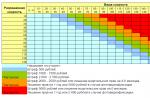

As you can see in the figure, the difference in cost reaches 10 times. Cleaning the filter for both the owner and the service costs less. When servicing the particulate filter, it will retain its performance, it will not damage anything, and the owner will not have to worry about replacing and overpaying money.

How to clean and how, we will talk in the next article. And consider products such as particulate filter cleaner, cleaning fluids, and preventive additives to reduce device clogging during vehicle operation.

Read an interesting article

Currently, the Euro-6 standard is in force in Europe, and the less stringent Euro-5 standard is in force in Russia, regulating exhaust standards harmful substances in atmosphere.

The above documents fix the limits on emissions of harmful substances for all types of passenger cars running on combustible fuels (diesel, gasoline), so in our article we will dwell in more detail on DPF particulate filters for cars using diesel (diesel oil) as fuel.

Ignition and burning cycle diesel fuel significantly different from the combustion of gasoline. If high-octane mixtures burn out almost completely, then the diesel leaves a trace in the form of soot. This is what the particulate filter should remove from the exhaust.

Diesel particulate filters may have different names that vary from country to country and from brand to brand.

- So, DPF is an abbreviation for English. designations Diesel Particulate filters,

- FAP is an abbreviation that came from France - Filtre a Particules,

- And RPF is from RubPartikelFilter, from Germany.

Diesel particulate filter has one main purpose - to clean the exhaust gases of a diesel engine internal combustion from soot, which comes in the form of small mechanical particles ranging in size from 10 nm to 1 micron. At detailed analysis it can be seen that these particles are compounds of carbon with water, heavy metals, sulfur and other elements.

Physically, the filter element can be made in the form of a separate housing installed in the exhaust system exhaust gases immediately after the catalytic converter. IN individual models cars, the particulate filter and the catalyst are combined into one housing.

The filter element is most often a hard material with a crystalline porous structure, for example, a ceramic matrix (silicon carbide or other compounds).

The ceramic matrix, which is responsible for cleaning exhaust gases from soot impurities, accumulates it in its pores.

This, over time, worsens its filtering properties, makes it difficult for exhaust gases to escape, which in turn creates an additional load on the engine, since the combustion chamber is not completely cleaned of combustion products.

Exhaust system with diesel particulate filter modern car

Exhaust system with diesel particulate filter modern car For this reason, it is required regular cleaning of the DPF filter(FAP or RPF) - the so-called regeneration.

The level of contamination of the particulate filter is monitored by special sensors.

- The most common method for assessing the contamination of a particulate filter is to analyze the pressure difference between the inlet and outlet of the assembly. The higher the difference, the higher the degree of contamination (gases have difficulty passing through the grate, which causes an increase in pressure at the inlet and a decrease in the outlet).

- Another type of sensors is oxygen, they monitor the level of oxygen in the exhaust mixture, respectively, the use of two sensors at the inlet and outlet of the particulate filter allows you to assess whether the content of other impurities has decreased or not, that is, whether purification has occurred or not.

On your display dashboard vehicle will show the corresponding error.

Most modern cars self-regenerating filters are used. They need a certain mode of engine operation to start the self-cleaning process.

When the machine is driven predominantly short distances without regularly warming up the particulate filter, this can cause it to become irreversibly filled with mechanical soot particles. In this case, without visiting the point Maintenance or even salon official dealer can not be dispensed with, since the error code can only be eliminated at the official service center.

Shutdown and regeneration

There are two types of regeneration particulate filters:

- Passive.

- Active.

The first type of regeneration is possible only on filters with a catalytic coating. Due to the fact that normal chemical reactions for burning soot require temperatures above 600 ° C, so-called catalysts are used to accelerate and facilitate the oxidation (combustion) reaction (substances that change the conditions for the occurrence of chemical reactions without their own consumption).

Thus, the use of a platinum-coated particulate filter reduces the temperature of soot burning to the level of 300 ° C. That is, the combustion of soot using a catalyst (catalytic coating) occurs during the natural operation of the engine, completely imperceptible to the user. There is no need to run any cleaning procedure.

Active type of regeneration involves modifying engine operation or adding special additives to the fuel in order to increase the temperature of the exhaust gases at the inlet to the particulate filter by up to 600 ° C. That is, this type of regeneration requires the participation or any active actions of the owner diesel car mobile ( manual start cleaning procedures or addition of additives).

Built-in sensors analyze the current level of contamination of the filter element, and, if necessary, signal the user about a malfunction that has occurred (indication can occur on the dashboard or through the display on-board computer, depending on the model of the machine and its equipment).

Upon seeing the signal of a clogged particulate filter, the user can start the regeneration procedure in manual mode.

Procedures in various models cars and different manufacturers may differ in the sequence of actions, but the bottom line is that by changing the cycles of exhaust gases, their temperature rises, which in turn warms up to desired indicator ceramic filter grate and burns soot.

If the procedure regeneration in manual mode for some reason does not clean the filter (simple wear of the equipment is possible, severe clogging of the ceramic matrix, frequent driving for short distances around the city, without a full warm-up of the exhaust system, when the filter cannot clean itself, etc.), the system may change the error status. Now only an authorized service center can remove it.

The specialists of the technical service point, in turn, can offer to carry out a professional filter cleaning procedure (using chemicals, etc.) or completely replace the unit with a new one.

Due to the high cost complete replacement, some service stations offer a cheaper filter removal procedure with the installation of equipment that deceives the pollution sensor (the error can also be removed by software). This, of course, increases the emission of harmful substances into the atmosphere. We will leave the legality of the procedure on the conscience of the service station and car owners.

Should I remove the particulate filter?

On the one hand, removing the particulate filter is a one-time procedure that allows you to save on periodic replacement or cleaning of the unit, engine power increases slightly with the filter missing (since there is no resistance to exhaust gases). On the other hand, emissions are growing, and the likelihood of passing a regular state technical inspection is reduced to zero.

The car will be able to drive with an error on the display. But it is worth bearing in mind that a clogged filter increases the resistance in the exhaust pipe.

Incorrect hardware removal of the node can cause an error due to which the engine refuses to start.

It is worth leaving the particulate filter or removing it completely - it is up to each owner to decide on their own. However, one should not lose sight of the fact that in the event of a negative result during the inspection, it may be necessary to install a new unit, which means that the removal procedure is an extra unjustified expense that only delayed the inevitable replacement procedure.

What is a particulate filter and why you need it, you can read in one of our articles - link

On this page we will try to describe the main symptoms indicating a malfunction of the particulate filter system. diesel vehicles(the manufacturer is not important - consider common problems, inherent in all cars with EURO-4 standards and higher). After all, operating a modern diesel car in our modern conditions, especially within the city, particulate filters often fail already at a range of about 70-90 thousand km, and problems with them sometimes begin earlier, already at 40-60 km. run.

Why particulate filter fails so quickly:

Here it is just worth remembering the device of the filter itself and its principle of operation. The filter is always installed behind the exhaust manifold, in close proximity to the engine and the exhaust gases pass through the filter before entering the rest of the exhaust system and further into the atmosphere. The main filter element of the particulate filter is a ceramic matrix, usually made of silicon carbide. It has a cellular mesh structure inside and porous channel walls that act as filters and trap soot particles from engine exhaust gases. Over time, the filter begins to become clogged with soot, but the system provides for the possibility of cleaning the particulate filter (called regeneration). This function is controlled by the engine-ECU, which interrogates a number of sensors (differential pressure sensors before and after the particulate filter and temperature sensors) and based on their readings, the ECU turns on regeneration.

I would like to note that poor quality fuel also strongly affects the resource particulate filter and the engine as a whole. The amount of soot directly depends on the sulfur content in the fuel, and with its overestimated parameters, the filter clogs faster. get worse.

There are two types of regeneration - passive and active.

Passive regeneration is more effective and usually occurs when driving for more than half an hour in an extra-urban cycle at engine speeds of about 2500 rpm. At passive regeneration soot in the filter is oxidized by the catalyst and high temperature exhaust gases (passive soot regeneration occurs only when constant temperature 350-550°C). Such regeneration is more efficient and if the car is operated in suburban conditions, there is no doubt that the particulate filter will last much longer.

In city conditions and heavy traffic, it is almost impossible to warm up the particulate filter to such a temperature during normal driving, therefore, when the filter is clogged, the ECU uses active regeneration, injecting excess diesel into the engine (at the same time, from the exhaust pipe to idling there is smoke white color and the speed can be slightly overestimated) in order to warm up the particulate filter to a temperature of 600-650 ° C. When this temperature is reached, the soot particles in the filter react with oxygen to form harmless carbon dioxide. But such regeneration is less effective, so often a "city" diesel car already has problems with the filter at very low mileage. In addition, the car may not include regeneration at all for a number of reasons - an active error in the ECU, an incorrectly closed tank cap, a malfunction of the USR valve, etc.) and then the particulate filter will become unusable very soon and the ECU, based on the readings of the sensors and calculating the limit clogging of the filter will register a permanent indelible error on it and the car will move only in emergency mode(up to 3000 rpm without turning on the turbocharger). In this case, the filter will need to be replaced with a new one or particulate filter software removal and its physical removal.

Of course, one should not forget about the quality of fuel, often sold at gas stations in our country, especially diesel, because the quality of diesel fuel is very important factor for all modern diesel engines high pressure With direct injection fuel.

The main disadvantages when operating a vehicle with a faulty particulate filter:

power loss

increase in fuel consumption

due to severe clogging of the filter, the exhaust gas recirculation (EGR) system "cokes" much faster, which leads to the failure of an expensive valve, and in some cases, a turbocharger

the engine runs in emergency mode "for wear", the turbocharger does not turn on and the speed develops up to 3000 rpm. - as a result of this, the automatic transmission receives insufficient torque from the engine and controls packages with increased load (shocks when switching)

if the clogging of the filter is close to critical, and the car continues to be used, then the engine may fail

Symptoms indicative of possible malfunction particulate filter and its clogging and the need particulate filter removal :

The appearance of increased fuel consumption, frequent regeneration ( White smoke when parked at idle indicates ongoing active regeneration)

Reduced engine power and thrust

H erratic engine operation And increased smoke at work

W whistling sound when engine is running

Behind elevated level engine oil in the engine(subject to the norm)

Engine transition into emergency mode(up to 3000 rpm without normal operation of the turbocharger).

Dashboard display:

part of the car on the instrument panel has particulate filter indicator- usually it lights up or starts flashing when there is a malfunction, sometimes the CHECK-ENGINE indicator flashes.

All the signs indicated here are not one hundred percent the cause of a defect in the particulate filter system, and in order to fully identify the problem, before proceeding with any intervention in the car, it is necessary to make a qualified car diagnostics. After identifying the problem by a specialist, you will understand whether it is necessary to this case change or remove particulate filter

.

In the photo: A worn out and clogged particulate filter, cut transversely.

AUTUMN PROMOTION!

When chip tuning a diesel car software removal particulate filter for free! Call us. The offer is limited.

We produce particulate filter software removal cars Audi, Bmw, Volkswagen, Mercedes, Nissan, Mitsubishi, Toyota, Mazda, Chevrolet, Subaru, Honda, Acura, Mini, Peugeot, Renault, Citroen, Hyundai, Kia, Daihatsu, Rover, Mini and others.

A device such as a particulate filter has been available in all diesel cars manufactured since 2011 (as well as on a number of models manufactured after 2000 - then it was not yet a mandatory element, but was already used by some car manufacturers) in the territories of countries included in WTO (Euro-5 standard adopted by the Customs Union).

New particulate filter  Particulate filter after working out

Particulate filter after working out

The main task of such an element is to clean exhaust gases as much as possible from harmful gases. environment impurities.

The use of particulate filters has reduced the content of soot particles in the exhaust of diesel cars by almost 100% - more precisely, by 99.9%.

What is a car particulate filter and how does it work?

At the moment, two types of soot cleaners are used in cars:

soot DPF filter(an abbreviation for the words Diesel Particulate Filte) for a diesel car captures soot particles up to 1 micron in size, which are formed as a result of fuel combustion. Such a filter is simple in design, but it requires regular cleaning (regeneration) actions.

The FAP type filter (an abbreviation of the French expression Filtre A Particules) is a more complex device that does not require regular intervention. Regeneration (purification) occurs here automatically.

The location of the particulate filter (see Fig. 1) is in the exhaust system, beyond catalytic converter. In some cases, it can also be combined with a converter, and then its location is directly behind the exhaust manifold.

This is the place where the exhaust gases have the highest temperature. In this embodiment, the device is called a "catalytic coated particulate filter".

The average resource of particulate filters is designed for a mileage of 150 thousand km. But this is the European standard. On Russian fuel, according to reviews of owners and employees of car services, this figure is reduced by almost three times.

At the moment when the on-board computer gives an error indicating that the particulate filter is clogged, the car owner will need to make one of the following decisions:

- Complete particulate filter replacement. A very costly undertaking. Of course, the price depends very much on the make and model of the car, but in any case, this action is much more expensive than all the items listed below. For example, on a BMW, replacing a particulate filter will cost approximately 1,500 euros.

- Physical removal of the particulate filter. The procedure is also not cheap, and has several disadvantages. It is not enough just to take and cut out the filter, replacing it with a pipe section. A number of on-board computer procedures are tied to the data coming from the particulate filter sensors, which means that it will be necessary to replace its firmware. Replacing the firmware does not always go smoothly, in some cases errors occur (false indications, other problems with the on-board computer).

- Diesel particulate filter sensor cheat. It consists in installing a separate device that emulates normal work sensors (fakes signals) or software removal of the particulate filter from the electronic control unit system. This procedure does not relieve the owner of the car from cleaning the filter itself. However, it significantly extends its life or allows you to easily remove the particulate filter with the least errors in the operation of the on-board computer.

- Regeneration. Most correct procedure, because removing the filter increases emissions of harmful substances into the atmosphere, despite the fact that even without given element European cars successfully pass technical inspection according to Russian standards. At the same time, the cost of filter regeneration remains acceptable in comparison with the same removal or replacement, although they require periodic repetition.

VIDEO INSTRUCTION

Types of regeneration - cleaning methods

In fact, a particulate filter is a container filled with a substance with a porous structure (ceramics is most often used). When exhaust gases pass through these "honeycombs", soot and fumes settle on the pores of the filler.

Over time, the pores become clogged and the passage of exhaust gases becomes difficult, which leads to an increase in fuel consumption and a decrease in engine power, and the risk of various problems increases.

To restore the properties of the filter, a regeneration procedure is performed, which can be of two types:

- Active. The pores are cleaned by raising the temperature inside the filter to 600-1000 degrees Celsius. At this temperature, the soot burns completely.

- Passive. Here, the removal of soot also occurs due to its combustion, but combustion occurs at a temperature of about 350 ° C (this normal temperature diesel exhaust gases). Soot oxidation requires a special catalyst that lowers the reaction temperature - for example, platinum in filters Volkswagen(the same catalytic coated particulate filters that were mentioned earlier).

Active regeneration requires the implementation of special procedures on the part of the car owner, and passive regeneration occurs without any participation of the driver of the car.

If regeneration does not have the desired effect, then you can always simply rinse the filter. Flushing the particulate filter performed after removing it from the vehicle. The unit is placed in a special chemical composition for a while, and then pass the same composition through a filter under pressure.

How to start particulate filter regeneration

Raise the temperature inside the particulate filter to complete combustion soot can be done in one of the following ways ( active regeneration):

- Introduction to fuel mixture special additives (most often based on cerium), which, when passing along with exhaust gases continue to burn. In this case, the removal of the vehicle assembly itself is not required. disadvantage this method is his low efficiency- the method can give positive effect only at the initial stage of pollution (no more than 2000 - 3000 kilometers from the moment the error indicator was triggered on the on-board computer panel).

- Starting a special engine operation procedure through the block electronic control auto. In this case, the air supply is reduced, the fuel is injected on the exhaust stroke (that is, it enters the exhaust system unburned). In some car models, original technologies are used, for example, an additive is additionally introduced, or the outflow of burnt gases is reduced, etc.

If regeneration does not help, it is necessary particulate filter repair.

It will be removed, disassembled and cleaned by hand or completely replaced in the workshop. Of course, this can be done with your own hands, but it is better to trust the experts.

The regeneration procedure starts most often without user intervention:

- The sensor for increasing the level of soot in the filter is triggered.

- During the movement, the control unit will independently increase the speed, reduce the air flow and clean the particulate filter.

But, if cleaning attempts are unsuccessful, or the soot level is critical, then the control unit will refuse cleaning attempts and display an error.

In this case, you can try to start the procedure yourself through the service menu of the electronic control unit (ECU) and follow the instructions of the system (if not supported auto mode turnover management).

It all depends on the car model and EBP firmware. In some cases, it may be necessary to know service codes or connect external diagnostic devices.

What liquid will help to regenerate a diesel particulate filter

If you have not become the owner of a car with a particulate filter with a catalytic coating or an integrated automatic procedure regeneration, you can always resort to the use of special additives.

You can try to restore the particulate filter, for example, using universal tools:

- Regeneration Catalysts from ARDINA – Diesel Particulate Filter Regeneration Aid (poured into the fuel tank as an additive).

- Liqui Moly Pro-Line Diesel Partikelfilter Reiniger is a cleaner that requires forced injection, after application it must be neutralized with another solution (Pro-Line Diesel Partikelfilter Spulung).

- Liqui Moly Diesel Partikelfilter Schutz is another additive that acts as a catalyst.

VIDEO DESCRIPTION

If the car uses an original additive (for automatic supply from a special tank in the particulate filter regeneration mode), then it should be ordered from authorized dealers.

On cars with a diesel engine, a particulate filter has been used as part of the exhaust system since 2000. With the introduction of Euro 5 standards in January 2011, the use of a particulate filter on passenger cars with a diesel engine is mandatory.

The diesel particulate filter (in the English version Diesel Particulate Filter, DPF, in the French version Filtre a Particules, FAP, in the German version RubPartikelFilter, RPF) is designed to reduce the emission of soot particles into the atmosphere with exhaust gases. The use of a filter makes it possible to reduce soot particles in exhaust gases by up to 99.9%.

In a diesel engine, soot is formed when fuel is not burned completely. Soot particles have a size of 10 nm to 1 µm. Each particle consists of a carbon core, to which hydrocarbons, metal oxides, sulfur and water are connected. The specific composition of soot is determined by the mode of operation of the engine and the composition of the fuel.

In the exhaust system, the particulate filter is located behind the catalytic converter. In some designs, the diesel particulate filter is combined with an oxidation-type catalytic converter and is located immediately after the exhaust manifold where the temperature of the exhaust gases is maximum. It's called a catalytic coated particulate filter.

Main constructive element The particulate filter is a matrix that is made of ceramic (silicon carbide). The matrix is placed in a metal case. The ceramic matrix has a cellular structure consisting of channels of small cross section, alternately closed on one side and the other. The side walls of the channels have a porous structure and play the role of a filter.

In cross section, the cells of the matrix have a square shape. More perfect are the input cells of the octagonal shape. They have a larger surface area (compared to exit cells), allow more exhaust gases to pass through and provide longer term particulate filter service.

In the work of the particulate filter, two successive stages are distinguished: filtration and regeneration of soot. During filtration, soot particles are captured and deposited on the filter walls. Small soot particles (from 0.1 to 1 µm) are the most difficult to capture. Their share is small (up to 5%), but these are the most dangerous emissions for humans. Modern particulate filters retain these particles as well.

Soot particles accumulated during filtration create an obstacle for exhaust gases, which leads to a decrease in engine power. Therefore, periodically cleaning of the filter from accumulated soot or regeneration is required. A distinction is made between passive and active regeneration of the particulate filter. IN modern filters As a rule, passive and active regeneration are used.

Passive particulate filter regeneration is carried out due to the high temperature of the exhaust gases (about 600 ° C), which is achieved when the engine is running with maximum load. Another way of passive regeneration is the addition of special additives to the fuel, which ensure the combustion of soot at a lower temperature (450-500°C).

Under certain engine operating conditions (light load, urban driving, etc.), the exhaust gas temperature is not high enough and passive regeneration cannot occur. In this case, active (forced) regeneration of the particulate filter is carried out.

Active particulate filter regeneration It is carried out by forcibly raising the temperature of the exhaust gases for a certain period of time. The accumulated soot is oxidized (burns out). There are several ways to increase the temperature of the exhaust gases during active regeneration:

- late fuel injection;

- additional fuel injection on the exhaust stroke;

- usage electric heater before the particulate filter;

- injection of a portion of fuel directly in front of the particulate filter;

- heating of exhaust gases by microwaves.

The design of the particulate filter and the systems that ensure its operation are constantly being improved. Currently, the most popular particulate filter with a catalytic coating and particulate filter with a system for introducing additives into the fuel.

Particulate filter with catalytic coating

Diesel particulate filter with catalytic coating applied to automobiles Volkswagen Group and a number of other manufacturers. In the operation of a catalytic coated particulate filter, a distinction is made between active and passive regeneration.

During passive regeneration, soot is continuously oxidized due to the action of the catalyst (platinum) and the high temperature of the exhaust gases (350-500°C). The chain of chemical transformations during passive regeneration is as follows:

- nitrogen oxides react with oxygen in the presence of a catalyst to form nitrogen dioxide;

- nitrogen dioxide reacts with soot particles (carbon) to form nitric oxide and carbon monoxide;

- nitric oxide and carbon monoxide react with oxygen to form nitrogen dioxide and carbon dioxide.

Active regeneration occurs at a temperature of 600-650°C, which is created using the diesel control system. The need for active regeneration is determined based on an assessment bandwidth particulate filter, which is carried out using the following sensors of the diesel control system: air flow meter; exhaust gas temperature before the particulate filter; exhaust gas temperature after the particulate filter; pressure drop across the particulate filter.

Based on the electrical signals of the sensors the electronic unit control system produces additional fuel injection into the combustion chamber, and also reduces the air supply to the engine and stops exhaust gas recirculation. In this case, the temperature of the exhaust gases rises to the value required for recirculation.

Diesel particulate filter with fuel additive system

A diesel particulate filter with a system for introducing additives into the fuel is a development PSA concern(Peuqeot-Citroen). Since the pioneers in the use of additives for regeneration are the French, the name FAP filter (from the French Filtre a Particules) has stuck to the filter. A similar approach is implemented in particulate filters from other automakers (Ford, Toyota).

The system uses an additive containing cerium, which is added to the fuel and ensures the combustion of soot at a lower temperature (450-500°C). But even this exhaust gas temperature cannot always be reached, so the system periodically performs active regeneration of the particulate filter. The diesel particulate filter is usually installed separately after the catalytic converter.

The additive is stored in a separate tank with a capacity of 3-5 liters, which is enough for 80-120 thousand kilometers (filter service life). Structurally, the tank can be located in the fuel tank or outside it. The additive level in the tank is controlled by a float-type sensor. The additive is supplied to the fuel tank by means of electric pump. Additive supply is carried out at each refueling fuel tank proportional to the amount of fuel supplied. The start and duration of the additive supply is regulated by the engine control unit (in some designs, a separate electronic unit).

A side effect of using the additive is that during combustion it settles in the form of ash on the filter walls and is not removed from it, which reduces the life of the device. The service life of a modern diesel particulate filter is 120,000 km. Manufacturers declare release in soon filter with a resource of 250,000 km.

Due to the high cost of exhausted particulate filters, car owners, as a rule, are not replaced, but removed, followed by a flashing of the engine management system.