The instructions for the car of any manufacturer always indicate that it is compatible with this machine. Of great importance is the composition of the brake fluid. The chemical components of the fluid can affect the brake system in different ways. Incorrectly selected brake fluid can deform the parts of the system and disrupt its operation, up to brake failure.

What is the composition of the brake fluid?

High-quality brake fluid is the key to the perfect operation of the brake system. The main parameters by which quality is determined are:

Boiling temperature. Brake fluid should not boil at relatively low temperatures, because a lot of heat energy is generated during the operation of the brake system. If the liquid boils easily, the resulting vapor bubbles are compressed and interfere with the braking force. And this means that the brakes may stop working.

Viscosity. At low temperatures, the properties of the brake fluid are also very important. It should circulate well through the system. Frozen liquid blocks work, too viscous slows it down, and excessive liquid increases the possibility of leakage;

The main characteristics of the brake fluid are the boiling point, viscosity and hygroscopicity.

Hygroscopicity. The less moisture the brake fluid can absorb, the better. After all, excess moisture is a rapid boiling of a liquid, thickening at low temperatures and another change in its properties. A liquid with changed properties no longer performs its functions and needs to be replaced.

In addition to these characteristics, the anti-corrosion and lubricating properties of the fluid are important - they provide a long life for pistons, cuffs and cylinders. Also, the liquid should not deform the rubber parts of the system.

Can you mix?

It is possible to mix with each other or fill in a new liquid without first cleaning the system in only one case - when glycolic liquids simply belong to different classes (DOT 3, DOT 4 and DOT 5.1). But still, manufacturers recommend mixing liquids of the same class, and even better - of the same brand.

Mineral and glycol fluids do not combine with each other; if they are mixed, the rubber cuffs of the hydraulic drive are deformed. Liquids in which silicone is present are categorically incompatible with any other. Chemical reactions in the case of mixing such fluids with others are aggressive to the details of the system and completely change the properties of the brake fluid.

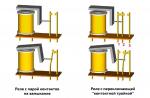

Why should the choice of brake fluid be taken as seriously as possible? The fact is that the smooth operation of the brake system and, accordingly, the safety of the car largely depend on it. When the driver presses the pedal, the brake fluid, which is under pressure in the system, transfers force to the caliper piston, and the piston to the pads. The brakes are applied and the car stops. But due to the friction that occurs in this case, the liquid is heated. If it boils, it will lose its important property - incompressibility. In this case, the system will practically stop responding to pressing the pedal and it will be very, very difficult to stop, since the force is not transmitted to the brake pads.

Basic properties of brake fluid

Brake fluids have a number of characteristics that directly affect their performance. This:

- hygroscopicity;

- pour point;

- aggressiveness.

The ability of a liquid to absorb moisture depends on the level of hygroscopicity. The lower this figure, the better. This is due to the fact that moisture, getting into the brake fluid, worsens its properties, in particular, lowers the boiling point.

The aggressiveness of the brake fluid determines the extent to which it has a negative effect on gaskets and other elements of the system made of rubber or plastic.

The pour point is an extremely important parameter. In severe frosts, the brake fluid can become extremely thick, it stops circulating in the system. In this case, it is difficult for the driver to press the brake pedal, and he may have serious problems with driving safety. In Russia, which is famous all over the world for its cold winter, it is necessary to use a liquid that retains its properties even at low temperatures.

Types of fluid for the brake system

There are several classifications of brake fluids, but the most popular today is the one developed by the US Department of Transportation (USDOT). According to it, all products belonging to this category are divided into several classes, from DOT-1 to DOT-5. The most important thing to know about them:

- DOT-1 and DOT-2 fluids are practically not used today;

- DOT-3 is a glycol-based brake fluid, relatively aggressive towards paintwork and rubber products, with a high level of hygroscopicity, with a boiling point of 205 degrees Celsius (provided that moisture has not entered it);

- DOT-4 - this category includes glycol-based brake fluids that corrode paint, but do not adversely affect rubber products; they are less hygroscopic than DOT-3 products and boil at 230 degrees Celsius (provided they have not absorbed water);

- DOT-5 is a more modern type of brake fluid, which uses silicone with a package of additives as a base, due to which it practically does not absorb water, is safe for paintwork and rubber parts, and boils at a temperature of 250 degrees Celsius;

- DOT-5.1 is a glycol-based brake fluid with a relatively high level of hygroscopicity, aggressive towards paintwork, but safe for rubber parts, boiling at a temperature of 275 degrees Celsius (provided that it has not absorbed water).

Within each category, there may be products with improved characteristics, although the official classification does not provide for them. For example, in addition to DOT-4 brake fluid, you can find DOT-4.5 and DOT-4 SUPER. Also, each type, except for DOT-5, is divided into two groups:

- for cars with ABS (in this case, the marking looks like this - DOT-4 / ABS);

- for vehicles without ABS.

Brake fluids belonging to different classes, as a rule, have a different color. This allows the driver to visually determine which product he is dealing with, avoiding mistakes or accidental mixing:

- DOT-3, DOT-4, DOT1 - yellow (from light yellow to light brown);

- DOT-5 - red or pink.

Since DOT-3, DOT-4 and DOT-5.1 brake fluids are glycol-based, they can in principle be mixed. However, different manufacturers may use different additive packages; therefore, according to experts, it is allowed to combine products created by one manufacturer. For example, you can mix Liqui Moly brake fluid with other similar products from the same company. Accordingly, silicone-based DOT-5 products are not compatible with DOT-3, DOT-4, and DOT-5.1.

DOT-3 brake fluid is considered the most versatile and affordable in terms of cost today. Most often it is used in cars and trucks of early years of production, which are not used very intensively.

DOT-4 is a versatile but slightly more expensive product. It is suitable for almost any vehicle with disc brakes, and due to its high viscosity, it works well in systems with a high degree of wear, allowing you to not be afraid of leaks.

DOT 5.1 is a rather expensive product that is well suited for vehicles with low mileage and vehicles that operate in high and even extreme humidity conditions.

When choosing a brake fluid, you must be guided by the following parameters:

- manufacturer's recommendations;

- mileage, condition of the brake system,

- type, weight, power characteristics of your vehicle.

In the proposed article, we will tell you why a car is so important, what properties it has and when it needs to be replaced.

Brake fluid actuates the hydraulic drive. Namely, pressure is transferred from the main brake cylinder, which obeys the brake pedal, to the wheel brake cylinders. The latter, thanks to the brake pads, slow down the movement. Now imagine what the consequences could be if this whole process does not take place efficiently, and the car stops moving later than necessary?

Brake Fluid Requirements:

- firstly, it must perform its functions at any temperature: be it minus 30 or plus 150 (the temperature in the brake cylinders at the time of intense braking);

- secondly, it must react well with both metals and rubber sealing parts of the hydraulic system;

- thirdly, the brake fluid must have high lubricating properties. This condition is very important for brake cylinders, namely for their internal surfaces;

- fourthly, the properties of the brake fluid should not depend on the operating conditions.

Based on the above requirements, it is created, which includes 92-98% of the base and special additives.

Types of brake fluid.

Depending on what is included in the basis, such types of brake fluid:

Mineral. It has low cost, high lubricating properties. Its aggressiveness to rubber is very low. Main disadvantages:

- at temperatures below minus 20 it is quite viscous;

- boiling point is quite low.

Used this type of brake fluid only in older cars because it is neutral to rubber seals.

Glycolic. It contains ethers and polyglycols. This base is very popular due to its high performance properties. Increased hygroscopicity is its main disadvantage.

Silicone. The most modern and completely non-hygroscopic. It is used very rarely because:

- incompatible with other types of bases;

- poorly compatible with rubber parts;

- has increased requirements for the quality of pumping;

- pretty expensive.

The main properties of the brake fluid.

Boiling temperature. When a liquid boils, vapor is released, which is compressed. This process leads to the fact that the pedal "fails" and there is no braking. Often such a problem is observed when they often slow down. It is in this situation that the heat from friction is not removed from the brake system in time, and the overall temperature increases.

Viscosity at various temperatures. Critical cases: thickening at low temperatures or increased fluidity at high temperatures.

How often is the brake fluid changed?

Experts recommend making brake fluid replacement every two to three years. Because due to the difference in operating temperatures, the brake fluid easily absorbs moisture from the air and even when condensed. This ability results in low lubrication in the warm season and thickening in the cold season. And the most terrible thing is that it is enough to dissolve only 3% of water in the brake fluid in order to reduce the boiling point by 70 degrees. This fact is the main reason for the replacement.

Change brake fluid you can do it earlier if you find impurities, or notice that the transparency has decreased. However, it is quite difficult to objectively assess the state of the liquid, because it does not mix in the system. Consequently, different properties of the brake fluid are observed in the reservoir and in the working cylinders.

What brake fluid should be filled in?

The most important condition is to follow the manufacturer's requirements, since the braking system is designed for certain parameters. brake fluid. Do not forget that quite often the manual prescribes how often it needs to be replaced.

To mix brake fluid or not to mix?

Mixing is strictly prohibited. brake fluids different classes! Since there is a possibility of additive incompatibility, it is also not advised to mix fluids from different manufacturers, even if they are within the same class. Use only the brake fluid specified by the manufacturer.

How to add "brake" correctly?

Everything is very simple here, the main thing is to remember which one was previously filled in the car. Buy the same and add to the brake reservoir. Be sure to keep it at the "max" mark. As practice shows, with a working brake system, it has to be topped up once a year.

Brake fluid (TF) is a technical component of hydraulic systems that transfers pressure from the master brake cylinder to the drum or disc brake pads. The chemical composition of the brake fluid determines the physicochemical and performance properties of the product. Consider the main components of this composition and its purpose.

Brake fluid - percentage composition

High fluidity, thermal stability, lubricity and anti-corrosion properties are provided by 3 components:

- Solvent

It is a mixture of polyesters of glycolic and boric acids. Provides uniform distribution of chemical compounds in a 3-component mixture. The percentage is 60–90%.

- The basis

Consists of polyglycols (polymerization products of dihydric alcohols with oxides of ethylene, propylene). Reduces friction of rubbing mechanisms and prevents abrasion of metal surfaces of brake pads. Content - up to 30%

- Additives

To improve the technical properties, additives with a mass fraction of 2–5% are added to the brake fluid. Anticorrosive additives prevent oxidative destruction of copper, steel, brass coatings. Antioxidant reagents inhibit the breakdown of polyglycol ethers and reduce the formation of degradation products (acids and resins). Bisphenol A (diphenylolpropane), azimidobenzene and triazoles are used as such additives. The introduced additives prolong the service life of the product.

For acid-base stability, a buffer solution is additionally added to the finished mixture - sodium or potassium salt of boric acid with a fraction<1%.

The composition of brake fluids of different types

The qualitative and quantitative content of the components differs depending on the scope of the TA. Allocate mineral, glycol and silicone compounds.

Mineral compositions- technical liquid of brown color. Castor oil of the general formula C 3 H 5 (C 18 H 33 O 3) 3 is used as a lubricant. The chemical properties of such oils are characterized by temperature lability, a tendency to form coke deposits on brass and copper surfaces. Such qualities were partially leveled by the introduction of benztriazole, trimethylborate and other antioxidant and anticorrosion additives. Due to temperature instability, mineral compositions were used in hydraulic systems with drum-type pads.

Glycolic liquids- traditional compositions containing polyglycol ethers and boric acid polyesters. Glycol TFs are better known by their DOT 3, DOT 5 markings. The ratio of polyglycol ethers and lubricants in combination with environmentally friendly additives meets international quality standards.

silicone fluids- polyorganosiloxanes, which are polymeric organosilicon components, are used as a base. The introduction of a fundamentally new lubricating agent made it possible to achieve complete indifference of TJ in relation to rubber and metals, as well as high fluidity regardless of temperature.

Application rules

Brake fluid produced by various manufacturers has a number of specific requirements, which are indicated in the operating recommendations. There are general rules for the use of TJ. Silicone-based DOT 5.1 formulations are not compatible with glycol counterparts. It is possible to mix different types of TJ provided that the bases are identical. The brake fluid is replaced within the time specified by the manufacturer.

Brake fluid is an important component of the braking system. Its main purpose is to transfer force from the master brake cylinder to the wheel cylinders.

Since most liquids are practically incompressible, the pressure will be transmitted through the liquid, and after a negligible time will be the same in the entire volume occupied by this liquid. That is, a liquid conducts pressure in much the same way that wires conduct electricity. And since the wires are not made from the first material that comes across, but from the one that is suitable, so the liquid must have certain properties in order to be a good conductor of pressure.

In brake systems with a hydraulic drive, the following brake fluids are mainly used: BSK, Neva, Tom, Rosa - in domestic cars, SAE J 1703ISO 4925, DOTZ, DOT4, BOT4 +, DOT5.1, DOT5, Racing Formula DOT 6 - in foreign cars.

Basic properties of brake fluid

1.BOILING POINT

The main parameter of the brake fluid is its boiling point - the higher it is, the better for the brake system. Boiled brake fluid bubbles and the effectiveness of the brake system is reduced.

The higher it is, the less likely it is that a vapor lock will form in the system. When the car brakes, the working cylinders and the fluid in them heat up. If the temperature exceeds the allowable temperature, the TJ will boil and vapor bubbles will form. The incompressible fluid will become “soft”, the pedal will “fall through”, and the car will not stop in time.