A mixture of air and fuel is fed into the cylinders through the carburetor. From this we can conclude that the carburetor is located between the fuel pump and the cylinder block. Where exactly - depends on the brand of car. For example, in the VAZ-2106, the carburetor is located under the air filter to the right of the cylinder block, when viewed in the direction of the car. In newer models, as a rule, an injector is used instead of a carburetor.

Where is the carburetor located in the engine

The internal combustion engine receives energy by burning strictly measured doses of fuel in the cylinders. In a four-stroke engine, fuel is ignited in four cylinders in turn. Oxygen is needed for combustion, therefore, not pure fuel enters the cylinders, but its mixture with air, which is formed in the carburetor.

In the cylinder block, the ignition of each portion of the mixture must occur at regular intervals, and at the moment when the piston in the cylinders is in its lower position. If these conditions are not met:

- engine power drops

- engine starts to run rough

- the car stalls or roars,

- the amount of carbon dioxide in the exhaust increases.

The moment of ignition of the mixture depends on the ratio of fuel and air in the cylinder, which is formed in the carburetor. By adjusting the carburetor, the desired ratio is achieved experimentally. Of course, the carburetor is adjusted at the factory, but the ignition time also depends on the state of the atmosphere: temperature, humidity, altitude. Therefore, from time to time, you have to do everything with adjustment, for which you need to understand the principle of operation of the carburetor.

How does a carburetor work

The air flow into the carburetor enters through the air filter, the amount of air is regulated by the gas pedal. Each time you step on the gas, more air enters the carburetor.

Fuel enters the carburetor through one, two or, at most, three special sockets. Each socket is responsible for its power: low revs (idling), high revs and, in rare cases, medium.

Needles are inserted into the nests, looking like small screws with pointed ends. The needles are not inserted tightly into the nests: there is a gap between the walls of the nest and the needle, through which fuel enters the carburetor. The further the needle is inserted into the socket, the less clearance remains and less fuel enters. Adjusting the carburetor is to select the correct gap at the appropriate speed.

Inside the carburetor housing is a high speed needle. It regulates the intake of air at all speeds, the overall performance of the engine depends on it, although mainly the fuel mixture for high speeds depends on its position.

Then the low speed or idle needle comes into play. It is usually located inside the carburetor, and it controls the amount of fuel coming after the first needle. Without it, at low speeds, there will be too much fuel in the mixture. With an increase in speed, the needle is removed from the socket, and as much fuel enters the cylinders as the first needle measured out.

A lot of cars run on gasoline. More precisely on a mixture of gasoline and air. Such engines are called internal combustion engines. However, there are two types of internal combustion engines: - these are gasoline engines and diesel engines (read the article for more details -). Today we will talk specifically about gasoline engines, because it is in the structure of a gasoline engine that there is such equipment as a carburetor. The engine itself does not prepare the fuel mixture (air + gasoline) for use, in it this mixture burns out, pushing the pistons. But the device that we will talk about prepares this mixture.

Carburetor – engine attachments, which are designed to make a combustible mixture that is injected into the engine cylinders for further ignition, are usually located on top of the engine.

Principle of operation

Gasoline enters the carburetor through the fuel line and enters the mixing chamber, however, the fuel is sprayed through a system of special carburetor devices called jets, that is, the fuel takes the form of steam. Further, the air passes additional purification through the filter system and is supplied to the same chamber, which contains fuel vapor, mixing in the required proportion, this mixture is supplied to the engine cylinders, where this mixture is ignited with the help of engine spark plugs. The enrichment of the mixture in the carburetor leads to the rapid operation of the engine and vice versa, this is already the work of the accelerator (gas pedal), the driver presses on the gas, the engine shaft rotates faster, the speed picks up, if you release the gas pedal, the engine shaft will rotate more slowly, the speed will drop.

That's all, I think, now it became clear what it is. Read our AUTO SITE

Today, a large number of cars operate thanks to a mixture of gasoline and air. Such motors are generally called internal combustion engines, and it is in the structure of a gasoline engine that there is such special equipment as a carburetor. In this article, we will consider the basic principles of operation and analyze its design in detail.

What is a carburetor, purpose

The carburetor is one of the most complex parts of the fuel concept of any gasoline vehicle. Its purpose is to manufacture a fuel-air mixture (FA) by saturating gasoline with oxygen in the required quantities, followed by feeding the finished mass into the cylinders. Mixing of all components is carried out in the desired consistency, corresponding to the operating modes of the engine.

The fuel supply procedure is carried out exclusively thanks to the carburetor, in which there is such a mechanism as a diffuser. It is designed to narrow the air throat of the mechanism. In other words, during the passage of the atmosphere through this constriction, a pressure drop occurs. Then a small opening is used to supply fuel. Under high pressure, the fuel is squeezed out of the chamber into the carburetor neck, from where the mixture is sent to the outlet channel and then enters the engine cylinders.

Types of carburetors

The process of improving the carburetor entailed the creation of a huge number of types of this device by various manufacturers.

According to the opening time of the dampers of the mixing chambers, the carburetor is divided:

- with alternate opening of the valve flaps of the secondary chambers;

- with synchronous valve opening.

To date, types of carburetors can be divided into three main groups:

- Float - this is the most optimal and common type of carburetors. Against the background of others, it stands out for its special reliability, uncomplicated settings. It consists of float and mixing chambers.

- Membrane-needle - contains several chambers separated by partitions. In the latter there is a piston with a needle that obscures and opens the fuel channel, thereby affecting the valve. The main advantage of this type is simplicity.

- Bubbling - this kind of carburetor involves an externally heated steel cylinder. The coke oven fuel enters a vessel called a bubbler (located at the bottom of the unit) and flows through a layer of heated material. Due to the contact of coke oven gas with the feedstock, self-evaporation of hydrocarbons occurs, after which the gas is saturated with their vapors. Part of the raw material that has not undergone evaporation is removed from the mechanism from time to time.

According to the number of mixing chambers, they are divided into: single-chamber, two-chamber and four-chamber.

Internal organization

Despite the fact that the injector is considered more suitable and perfect, there are still a huge number of cars on the roads whose engine is equipped with a carburetor.

As mentioned earlier, in almost every car there is a float-type carburetor. A simple unit consists of two main chambers: mixing and float. The role of the float is in the dosage and safety of the fuel; a constant fuel supply is maintained under various engine operating conditions.

Inside the assembly there is a recess with a built-in float connected to a needle-type valve, which is located in the fuel pump channel. At the moment of consumption, the float lowers, as a result, the channel opens, and the fuel is pumped into the recess.

The second chamber guarantees mixing of the fuel. For such an action, there is a diffuser - a specially narrowed area; it helps to give acceleration to the passing air flow.

To have a complete picture of what the internal structure of the unit looks like, we recommend watching the video:

Principle of operation

A simple carburetor is not able to provide the engine with a suitable, according to the composition, mixture at all stages of operation. The motorist, in addition to the quantity of fuel assemblies, is obliged to dispose of its quality thanks to the “suction” handle connected to the atmospheric damper.

When the handle is pulled out, the sash closes and less air enters the mixing chamber, and the vacuum is filled with fuel to the greatest extent. This fact is important, especially when starting the engine in the cold, when a rich mixture is needed, which can catch fire at low temperatures.

The creation of a balanced fuel mixture in the mechanism chamber is not complete. Part of the fuel cannot escape and mix with the atmosphere. Drops of fuel that have not had time to evaporate move and settle on the walls of the chamber and exhaust pipes.

The fuel that settles on the walls forms a kind of film that moves at a low speed. In order to evaporate the film of gasoline, the intake pipes are heated during the operation of the engine. Liquid heating or gas heating is more common. We can safely say that the generation of the combustible mixture ends at the end of the engine intake pipe.

Pros and cons of a carburetor

However, not everything is so smooth, because this mechanism needs to be cleaned and adjusted quite often. During the cold season, condensate may accumulate and freeze in the body of the device. In the heat, the mechanism can easily overheat, which will lead to intense evaporation of the fuel and a drop in ICE power. The final argument against the carburetor is the high toxicity of the exhaust, which led to the refusal of its use in current cars.

Possible Carburetor Problems

Now we list the possible problems when working with a carburetor so that you can bypass them:

- If the engine does not start or stalls after starting, this is a clear sign of a lack of fuel in the float chamber or a violation of the composition of the combustible mixture;

- If the engine at idle is unstable or constantly stalls, then the following are possible:

- contamination of channels or idle jets;

- problems in the operation of the solenoid valve;

- breakdowns in the functioning of the elements of the EPHH and BU;

- failure and deformation of the rubber sealing ring.

- In connection with the concept of the first chamber, in the absence of proper revolutions, the possibility of a complete stop of the start of the machine is not excluded. To fix this problem, you need to properly flush or purge the channels, as well as replace damaged parts.

In order to work, the car motor needs power. Unlike electrical equipment, which is powered by the mains, the machine engine needs fuel, so cars have a special power system. It includes a fuel tank, fuel pump, fuel lines, carburetor, air filter, intake and exhaust pipes and a muffler. One of the most important parts of the power system is the carburetor. A combustible mixture is formed in it from the fuel.

How is a carburetor arranged?

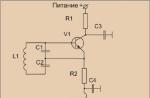

The carburetor consists of two chambers - float and mixing. Fuel first enters the float chamber. When it is filled with fuel to the desired level, the float pops up and closes the valve through which the fuel enters. As soon as its level drops, the float drops and fuel begins to flow into the chamber again. Thus, with the help of a float in the carburetor, the required fuel level is constantly maintained.

From the float chamber, the fuel enters the mixing chamber, where the formation of a combustible mixture takes place. From above, air mixed with fuel enters this chamber. In the mixing chamber there is a spray tube with a jet, a diffuser and a throttle. The jet is a plug that limits the exit of fuel from the float chamber. The throttle is a damper that is connected to the pedal. If you press on it with your foot, the throttle opens and a combustible mixture enters the cylinder. In this case, the speed of the car increases. The spray tube is located in the diffuser, the narrowest point of the mixing chamber.

The principle of operation of the carburetor

During the start of the car engine, a vacuum is created in the mixing chamber, as a result of which fuel sprays from the sprayer. In this case, a stream of air arises, which, mixing with the fuel, carries it into the cylinder.

In addition to the float and mixing chambers, carburetors of modern cars also have a starting device, an idle system, a metering system, an accelerator pump and an economizer. The carburetors of older car models are not able to ensure the operation of the engine well, because, depending on its condition (cold or warm), the composition of the combustible mixture should be different. For example, when starting a cold engine after the car has been standing for a long time, a combustible mixture rich in fuel is needed. And if the engine, on the contrary, is too hot after a long operation, a mixture with a small fuel content is needed. If the driver wants to increase speed or is driving in a heavily loaded car, then a combustible mixture is needed with a high fuel content, the same is required at idle (at low speeds). Of course, a simple carburetor will not cope with this mode of operation.

An accelerator pump is also needed in order to enrich the combustible mixture with fuel. When the driver sharply presses the pedal, then, along with the fuel, an air flow breaks through, the speed of which, as is known, is greater. Therefore, for some time there is not enough fuel in the combustible mixture. The accelerator pump helps to solve this problem, and the engine starts to work faster and more powerfully.

The idle system is necessary so that the engine can operate at low speeds.

In this mode, the engine runs on an enriched mixture, but one metering system cannot prepare it, since the throttle is not fully open at idle. But the idling system of modern carburetors is designed in such a way that the combustible mixture is formed near the throttle, because. in this place, even if it is not fully opened, a vacuum is created necessary for the combustible mixture.

To start the engine, you need a mixture that is well enriched with fuel. For this, a special damper with a valve for air passage is installed in the mixing chamber. There is a special knob on the dashboard with which this valve can be controlled. If the driver pulls out the handle, the valve will open slightly and the amount of air entering the mixing chamber will decrease. The content of fuel from this in the combustible mixture increases. Therefore, even the very first portions of the combustible mixture are saturated with fuel and the engine starts, as they say, with half a turn. With a starting device, the engine will work even at very low temperatures.

The dosing system, which is equipped with carburetors of all modern cars, allows you to prepare a combustible mixture for various engine operating modes. This system allows you to automatically adjust the composition of the combustible mixture when the engine is running at low or medium load. When the engine is running in this mode, fuel for the preparation of a combustible mixture enters through the metering system, but even at full throttle, the fuel supply is sometimes not enough. Therefore, when the throttle is almost fully open, the lever associated with it acts on the economizer actuator rod, which opens an additional passage for fuel from the float chamber. As a result, the engine can run with more power.

As you can see, the carburetor is very important for starting the engine. Its slightest malfunction can not only disable the engine, but also prevent it from starting at all. But the carburetor is not the whole power system. Fuel is supplied to it from the fuel tank, which in a passenger car is most often located in the rear part under the trunk floor or in front. The hole into which you pour gasoline is located outside and is closed with a cork. Only the cork itself is unlikely to be studied seriously, but in vain! Because the power system begins with it. The fuel tank filler cap has a steam valve and an air valve. The first is necessary so that in the heat, when the fuel evaporates, increased pressure is not created in the tank. And the air valve is needed so that a vacuum does not appear in the tank, otherwise the fuel supply will be disrupted.

The device of the car power system

From the tank, the fuel itself will not get into the carburetor in any way, so a fuel pump is needed. Its design is such that the fuel, passing through it, is cleaned in the filter and only after that it passes further into the carburetor. If the engine is not running, and it is necessary to pump fuel into the carburetor, then use the manual priming lever.

Dust constantly settles on the motor parts, which comes from the air that enters them, as well as metal particles formed as a result of friction of the parts. If the device for cleaning the motor from dust was not thought out in cars, then all parts would wear out very quickly. Car engines have a kind of self-protection against dust, i.e. an air filter that purifies the air. Only clean air flows must enter the carburetor, otherwise the engine will quickly fail. The air filter must be cleaned periodically. To do this, it is dismantled, the body is washed with kerosene and fresh oil is poured into the filter, which will absorb all the automotive “impurities”.

Let's follow the fuel path further.

The combustible mixture already necessary for the engine comes out of the carburetor, which passes into the cylinder through the intake pipe.  Exhaust fuel gases exit through exhaust pipes. Another thin-walled pipe is attached to the exhaust pipe, which leads the gases to the muffler. Its name speaks for itself. After all, if there were no muffler, then the exhaust gases would come out with great noise. The operation of the silencer is based on the fact that gases, passing from one pipe to another, gradually expand and lose their speed. They come out of the muffler in a smooth stream and do not cause noise. It also extinguishes the sparks that are formed when the fuel particles burn out. In the power system, failures and malfunctions can also occur. For example, the process of formation of a combustible mixture of the composition necessary for the operation of the engine is often disrupted. Sometimes fuel leaks, the fuel gauge fails, or the carburetor device stops functioning. All these malfunctions must be eliminated in time so that minor breakdowns do not lead to serious consequences.

Exhaust fuel gases exit through exhaust pipes. Another thin-walled pipe is attached to the exhaust pipe, which leads the gases to the muffler. Its name speaks for itself. After all, if there were no muffler, then the exhaust gases would come out with great noise. The operation of the silencer is based on the fact that gases, passing from one pipe to another, gradually expand and lose their speed. They come out of the muffler in a smooth stream and do not cause noise. It also extinguishes the sparks that are formed when the fuel particles burn out. In the power system, failures and malfunctions can also occur. For example, the process of formation of a combustible mixture of the composition necessary for the operation of the engine is often disrupted. Sometimes fuel leaks, the fuel gauge fails, or the carburetor device stops functioning. All these malfunctions must be eliminated in time so that minor breakdowns do not lead to serious consequences.

According to a number of signs, the driver himself will be able to find the reason for the poor operation of the motor and fix the problem. For example, the engine does not start well if the mixture in the cylinder contains few fuel particles. So you need to check the health of the fuel pump. Perhaps the filter, jet is clogged, or the tightness of the connection of parts is broken. When removing and installing the carburetor, you must use special car keys, and you can read what similar tools are needed in the car.

It is very harmful for an engine to run on a lean fuel mixture. From this, it quickly overheats, pops are heard in the air filter. If the mixture is supersaturated with fuel, then most likely the air dampers are not completely closed and fuel enters along with the air flow. The jets may be worn or the fuel level in the carburetor float chamber may be high. In a word, there can be many reasons for the engine to suddenly go haywire. The main thing is to fix problems in a timely manner and not bring them to a major overhaul.

A very clear and useful video on the device and principle of operation of the carburetor is a video filmed back in the USSR, but still relevant in our time.

More articles about ""

Noticed a typo on the site? Select it and press Ctrl + Enter

In this article, you will learn about fuel injection systems. The carburetor is the very first mechanism that made it possible to combine gasoline with air in the right proportion to prepare the air-fuel mixture and supply it to the engine's combustion chambers. These devices are actively used to this day - on motorcycles, chainsaws, lawn mowers, and so on. That's just from the automotive industry, they have long been supplanted by injection injection systems, more advanced and perfect.

What is a carburetor?

A carburetor is a device that mixes fuel and air, delivers the resulting mixture to the intake manifold of an internal combustion engine. Early carburetors worked by simply allowing air to pass over the surface of the fuel (in this particular case, gasoline). But most of them later dispensed a measured amount of fuel into the air stream. This air passes through the jets. For a carburetor, the condition of these parts is extremely important.

The carburetor was the main tool for mixing fuel and air in internal combustion engines until the 1980s, when doubts arose about its effectiveness. When fuel is burned, a lot of harmful emissions are produced. Although carburetors were used in the United States, Europe, and other developed countries until the mid-1990s, they worked alongside more sophisticated control systems to meet carbon emissions requirements.

History of development

Various types of carburetors were developed by a number of automotive pioneers, including the German engineer Karl Benz, the Austrian inventor Siegfried Markus, the English polymath Frederick W. Lanchester, and others. Since so many different methods of mixing air and fuel were used in the early years of the existence and development of cars (and the original stationary gasoline engines also used carburetors), it is rather difficult to pinpoint who is the inventor of this complex device.

Types of carburetors

Early designs differed among themselves in the basic method of operation. They also differ from the more modern ones that dominated for most of the twentieth century. A modern carburetor for a spray-type chainsaw, similar ones are used on modern cars. The very first, historical, so to speak, constructions can be divided into two main types:

- Surface type carburetors.

- Spray carburetors.

Surface carburetors

All early carburetor designs were superficial, although there was a great deal of variety in this category as well. For example, Siegfried Markus introduced something called a "revolving carburetor brush" in 1888. And Frederick Lanchester developed his carburetor-type wick in 1897.

The first carburetor float was developed in 1885 and also patented the float type carburetor around the same time. However, these early designs were surface carburetors that worked by passing air over the surface of the fuel in order to mix them. But why does an engine need a carburetor? And without it, it was impossible to supply the fuel mixture to the combustion chambers (the injector was not yet known in the nineteenth century).

Most surface devices functioned on the basis of simple evaporation. But there were other carburetors, they were known as devices that work due to "bubble" (they are also called filter carburetors). They work by forcing air up through the bottom of the fuel chamber. As a result, a mixture of air and fuel is formed above the main volume of gasoline. And this mixture is subsequently sucked into the intake manifold.

Spray carburetors

Although various surface carburetors were dominant throughout the first decades of the automobile's existence, spray carburetors began to fill a significant niche around the turn of the 19th and 20th centuries. Instead of relying on evaporation, these carburetors actually sprayed a measured amount of fuel into the air that was sucked in by the intake. These carburetors use a float (like the Maybach and earlier Benz designs). But they operated on the basis of the Bernoulli principle, as well as the Venturi effect, like modern devices, such as the K-68 carburetor.

One subtype of aerosol carburetors is the so-called pressure carburetor. It first appeared in the 1940s. Although pressure carburetors only resemble aerosol carburetors in appearance, they were actually the earliest examples of forced fuel injection devices (injectors). Instead of relying on the Venturi effect to suck fuel out of the chamber, pressure carburetors sprayed fuel out of the valves in much the same way as modern injectors. Carburettors became increasingly complex during the 1980s and 1990s.

What does "carburetor" mean?

"Carburetor" is an English word that is derived from the term carbure, translated from French - "carbide". In French, carburer simply means "combine (something) with carbon". Similarly, the English word "carburetor" technically means "increase in carbon content".

The K-68 carburetor works similarly, which was used on scooters of the Tula type (later Ant), Ural and Dnepr motorcycles.

Components

All types of carburetors have different components. But modern appliances share a number of common characteristics, including:

How does a carburetor work?

All types of carburetors work using different mechanisms. For example, wick-type carburetors work by forcing air over the surface of the gas-soaked wicks. This causes the gasoline to evaporate into the air. However, wick-type devices (and other surface devices) have become obsolete over a hundred years ago.

Most carburetors that are used in vehicles today use a spray mechanism. They all work in the same way. Modern carburetors function by the Venturi effect to draw fuel out of the chamber.

Basic principles of operation of carburetors

Carburettors based on the Bernoulli principle have some peculiarities. Changes in air pressure are predictable and directly related to how fast it is moving. This is important because the air passage through the carburetor contains a narrow, compressed venturi. It is needed to accelerate the air as it passes through it.

Air flow (not mixture flow) through the carburetor is controlled by the accelerator pedal. It is connected to the throttle valve located in the carburetor with a cable. This valve closes the venturi when the accelerator pedal is not in use and opens when the accelerator pedal is depressed. This allows air to pass through the venturi. Consequently, more fuel is drawn from the mixing chamber. The operation of the carburetor is based on such principles.

Most carburetors have an additional valve above the venturi (called a throttle that acts as a secondary throttle). The throttle remains partially closed when the engine is cold, which reduces the amount of air that can pass into the carburetor. This results in more air/fuel, so the throttle should open (automatically or manually) as soon as the engine is warm and no longer needs a rich mixture.

Other components of carburetor systems are also designed to affect the air/fuel mixture during various operating conditions. For example, a power valve or metering rod may increase the amount of fuel at open throttle, or it may be in response to low vacuum system pressure (or actual throttle position). A carburetor is a complex element, and the physical basis for its operation is quite complex.

Problems

Some carburetor problems can be solved by adjusting the choke, mixture, or idle, while others require repair or replacement. Often the carburetor membrane wears out, stops pumping gasoline into the chambers.

When the carburetor fails, the engine will perform poorly under certain conditions. Some problems of carburetor systems lead to engine breakdown, it cannot normally idle without outside help (for example, pulling the choke or constant gasping). The most common problems occur during the cold season, when the engine is most difficult to work. And a carburetor that performs poorly on a cold engine may function normally when warm (this is due to problems with coking channels).

It is worth noting that the carburetor for a walk-behind tractor is the same in composition as an automobile one. The difference is in the number of elements and their sizes. In some cases, carburetor problems can be resolved by manually adjusting the mixture or idle speed. To this end, the mixture is usually adjusted by turning one or more screws. They have needle valves. These screws allow you to physically change the position of the needle valves, which means that the amount of fuel can be reduced or increased (rich mixture occurs) depending on the specific situation.

Carburetor repair

Many carburetor system problems can be solved by making changes or other fixes without removing the device from the engine. To adjust the carburetor for a walk-behind tractor, there is no need to remove it. But some problems can only be solved by removing the device and restoring it completely or partially. Rebuilding a carburetor typically involves removing the block, taking it apart, and cleaning it with a solvent designed specifically for this purpose.

A number of internal components, seals and other parts then must be replaced before installation. Only after careful processing is it necessary to assemble the carburetor and install it in place. To carry out quality service, you will need a carburetor repair kit. It includes all the most important design elements.

So, we found out that a carburetor is literally a device that adds gasoline (fuel) to the air and feeds this mixture into the engine's combustion chambers.