Transfer case serves to distribute the torque between the drive axles. In addition, in the transfer case, an increase in the torque supplied to the driving wheels of the vehicle can also be carried out. As a rule, a device is provided in the transfer case for switching on and off the front drive axle, and sometimes additional units (for example, a power take-off box) are driven from the transfer case.

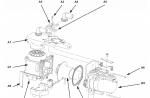

Rice. The device of the transfer case of the KamAZ car:

1 - input shaft flange; 2- input shaft; 3, 4, 8, 13.75, 17, 40 - bearings; 5 - drive gear; 6 - top hatch cover; 7 - power take-off gear; 9 - clutch for switching on the power take-off; 10 - power take-off; 11 - oil collector; 12 - downshift gear; 14 - fitting; 16 - satellite; 18 - drive shaft rear axles; 19 - rear clip of the differential; 20 - epicyclic gear; 21 - drive gear of the center differential; 22 - sun gear; 23 - front clip; 24 - transfer case housing; 25 - overdrive gear; 26 - cover of the crankcase of the transfer case; 27 - cork; 28, 30, 41 - couplings; 31 - drive gear of the sensor drive electric speedometer; 32 - drive shaft front axle; 33 - fork; 34 - spring; 35 - stock; 36 - diaphragm; 37 - switch; 38 - lock; 39 - intermediate shaft; 42 - intermediate gear

To increase the torque supplied to the drive wheels (which is necessary in difficult conditions movement), transfer boxes are usually performed in two stages, and top gear has a gear ratio equal to one (or about one), and the lowest (first) gear is about two. The presence of two gears increases the number of steps and the range of change gear ratio transmission of the vehicle, which increases the possibility of selecting the most advantageous gear in accordance with traffic conditions.

Transfer boxes with a blocked drive are used, when the drives of all axles are constantly rigidly connected to each other and always rotate with the same angular speeds. Such transfer boxes usually have a device to disable the front axle drive, for example, when driving in good conditions(on a hard surface with a high coefficient of adhesion), which allows to reduce fuel consumption, reduce loads in the transmission and tire wear.

In some designs of transfer boxes, a special mechanism is installed - center differential, which distributes the torque supplied from the engine to the transfer case to the drive axles in the required ratio in proportion to grip weight falling on these bridges. The differential also allows the wheels of different drive axles to rotate at different angular speeds, which eliminates the possibility of slippage, reduces transmission loads and tire wear. Use differentials with bevel and cylindrical gears. To increase the cross-country ability of the vehicle, center differentials are sometimes performed with forced blocking or self-locking.

On some fast tracked vehicles install a junction box that allows you to receive various modes transmission operation, for example, simultaneous or separate operation of caterpillar and water movers, separate or simultaneous drive of other units (pumps, winches, etc.).

Rice. Transfer box of a four-axle vehicle:

1 - pallet; 2 - differential assembly; 3 - differential lock clutch; 4 - lower shaft; 5 - support parking brake; 6 - front axle drive housing; 7, 13 - forks; 8 - pneumatic switch; 9 - intermediate shaft; 10 - upper shaft; 11 - transfer case housing; 12 - gear shift clutch; 14 - crankcase cover; 15 - drive gear of the power take-off; 16 - crankcase power take-off; 17- oil pump; 18 - differential driven gear; 19 - rear axle drive cover assembly; 20 - filter; 21 - drain plug

Vehicles with all-wheel drive have a transfer box. There are no such boxes on machines with one drive. This mechanism serves to transmit and share the torque of the running gear. The razdatka is able to provide assistance when driving through impassable places by a vehicle. This device is located right behind the box. variable gears. There are options when the razdatka stands separately or in the same design with the gearbox.

Transfer box device

Many machines have a different design and their own handout features. All have component boxes:

- differential for installation between axles;

- gear / chain torque transmission;

- blocker for center differential;

- drive shafts, which are placed on the axis forward and backward;

- downshift;

- drive shaft.

In such a dispenser, the two used shafts are connected. The drive shaft receives torque through the use of one of possible transfers. There are cars that do not have a differential between the axles and a lowering row. Cars, most often crossovers, not designed for off-road travel, do not have a reduction gear.

Varieties of step-down boxes

In our time, there are three types of transfer boxes:

- By different number of gears. By the number of gears, there are single-stage and two-stage gearboxes. There are models that have a three-speed transmission.

- By location.

- By type of drive axle. Reducing boxes have coaxial and non-coaxial drive shafts.

If we talk about the location of the shafts, then there are differential boxes, as well as blocked ones.

The purpose of the nodes and the principle of operation of the transfer case

Center differential

This part serves to divide the torque for each axle. This is what causes the drive shafts to work with different speed. This feature important when turning or turning the car. Each wheel travels a certain distance, so it requires them to spin at different speeds. In cases where the car does not have a transfer case with a center differential, this problem can be solved by disabling one of the axles. At inexperienced drivers it won't cause any problems.

There are two types of such differentials:

- symmetrical;

- asymmetrical.

They differ in their work in that at the first, the torque is distributed into equal parts, and at the second it is in a certain dependence. Differentials have a high cost, so their repair is expensive.

Center differential lock

In order for the vehicle to feel comfortable in the field, the differential between the axles has a lock. This part is designed to ensure that the wheels rotate at the same speed if necessary. On such a device, you can block the wheels automatically or independently. Blocker repair is a laborious process.

The lock for the center differential very often carries out its activities with the help of. It is a simple and uncomplicated device that allows you to perform blocking functions. The viscous coupling works as follows: it has special disks that are inside special liquid. A certain number of disks are attached to the body, and all the rest with a hub. When the wheels of a car begin to slip, some discs will start moving faster than others, due to this, the temperature of the fluid rises, which ensures the connection of the housing and the hub.

This system gained popularity due to its low price. Cons of the system:

- "Belated" operation, due to which the wheels of the car begin to slip;

- all differential locking cannot be performed;

- if present in the car, the blocker cannot be used due to functional inconsistencies;

- the device overheats during continuous operation.

Torsen differential

The device works by using worm gears. When the car is straight on the road, the differential divides evenly on each side of the axle. But when towing begins, through the use of a worm gear, the torque is transferred to another axis. Drivers note that such devices do not have a large margin of safety, so repairs often have to be carried out. The Torsen differential is installed on crossovers.

Friction clutch with multiple discs

This device represents several discs that have a certain degree of compression. It provides the ability to distribute the torque based on the conditions provided. During normal operation, the torque is evenly distributed. During towing, the clutches are compressed, which causes complete or partial towing differential. In order for the clutch to work, a special drive is attached to it, which can be both electric and hydraulic.

Not many people know that the differential lock is carried out manually using different drives. Some vehicles may be blocked in automatic mode, as well as manually.

Chain transmission

The chain in the transfer case was designed to redistribute torque. Chain transmission is the interaction of two wheels with teeth and the chain itself. There are cases when in a box instead of a chain drive they use gear train. If we talk about reliability, gear is considered better.

Why does the transfer case have such a name

They began to name the transfer case due to the proximity of concepts with the checkpoint. The torque is transmitted at a low vehicle speed, since the transfer case has a demultiplier or a reduction gear. Thus, the machine is able to move in difficult conditions, in the absence of a road. Crossovers do not have such a device due to the fact that they are not designed for off-road use.

The demultiplier helps the machine reduce the speed of rotation of the drive shafts. For this reason, a lot of torque is not lost. The low gear allows the car to have a few more gears. In the case of various traffic situations the driver will have more possibilities correctly determine the required gear ratio.

This device allowed to increase the service life, which saves the car owner's money.

Malfunctions and repair of the transfer case

transfer case enough expensive device, so it is necessary proper care And timely repair to increase service life.

Very often, drivers complain about the inclusion of gears with the expenditure of effort. Most often this occurs when the rods and gear forks are worn out. This problem is often caused by scuffing on the gear wheels of mechanisms. Can't be ruled out bad job fixatives. If the rods and forks are worn out, they must be replaced immediately.

When driving, there is an automatic disengagement of gears. This indicates that the gear teeth are worn and require urgent replacement. It also indicates that the fork mounts may be faulty.

The high noise level during the operation of the transfer case indicates many factors:

- poor viscosity of lubricants;

- damage to gears;

- faulty clutch;

- high level of bearing wear.

You can only replace lubricants on your own, and for everything else you need to turn to specialists. With a small amount of oil, it must be restored to normal.

There are cases when oil flows out of the transfer case. There can be only one reason - worn gaskets. To fix this problem, you need to disassemble the box and replace the gasket. The box needs care. The oil level must be checked periodically and topped up. In case of oil leakage, check all seals and tighten the fasteners.

It is better to entrust the repair of all malfunctions of the transfer case to specialists, since many malfunctions cannot be solved on their own.

A serviceable transfer case works without extraneous noise. It should not overheat when shifting gears. If these conditions are met, then we can safely say that the box is in good condition.

If we talk about the repair of its parts, then you immediately need to understand that this is an expensive procedure. To delay the replacement or repair of the transfer case, it is necessary to regularly inspect and check the entire mechanism. Many drivers who are faced with the repair of a transfer case know that this all requires significant financial investments. Therefore, do not neglect regular visual checks.

All faults are best dealt with early on as this will help reduce future costs and ensure good work boxes.

Transfer box operation

The operation of the transfer box depends on the design features. Considered as a whole, it works in the following modes:

- with a working rear axle;

- with two bridges included;

- with working bridges when blocking the center differential;

- on a downshift, a differential is locked with two axles engaged;

- Both axles work with automatic differential lock.

To select the desired mode, you must use the special buttons and levers.

The role of the transfer case

The razdatka plays a huge role in the operation of vehicles that can be used in off-road conditions. This device is popular among drivers as domestic cars, as well as foreign ones. When bad road conditions, the transfer case can play a decisive role in driving.

The site offers to get acquainted with a detailed video description of the transfer case, as well as with the principle of its operation. This video talks about design features distribution boxes. It also tells and shows the types of boxes with cutaway details.

transfer gearbox called an additional gearbox that distributes engine torque between the drive axles of the car. The transfer case serves to increase the traction force on the drive wheels and increase the vehicle's cross-country ability. It simultaneously performs the functions of a demultiplier, which allows you to increase the range of gear ratios of the gearbox and use the car more efficiently in various road conditions. Depending on the purpose of the vehicles, transfer boxes of various types are used on them.

In addition to general requirements The transfer box is subject to special requirements, according to which it must provide:

The distribution of torque between the driving axles of the vehicle is proportional to the vertical loads on the axles;

The increase in traction force on the drive wheels, necessary to overcome the increased resistance when the car moves along bad roads, off-road and on steep slopes;

Lack of power circulation in the vehicle transmission;

The ability to move the car with a minimum stable speed (2.5 ... 5.0 km / h) when the engine is running at maximum torque.

Transfer boxes with coaxial drive shafts are widely used, as they allow the use of the same final drive (interchangeable) for the front and rear drive axles. However, in this case, the drive gear of the main gear of the front axle, having the left direction of the helix of the teeth, will work for screwing in, therefore, if the tightening of its bearings is loosened, the main gear of the front drive axle may jam. Transfer cases with misaligned driven shafts, unlike transfer cases with coaxial driven shafts, do not have an intermediate shaft. They are more compact, less metal intensive, quieter in operation and have a higher efficiency. Transfer boxes with a blocked drive of the drive axles make it possible to use the traction force, which is full according to the conditions of adhesion of the drive wheels to the road, without their slipping. However, when the vehicle is driven around a curve or on a rough road with the drive locked, wheel slip is inevitable because the front wheels travel a longer distance than the rear wheels. In this case, tire wear increases, fuel consumption increases and transmission parts are overloaded. To eliminate such negative phenomena, the front axle is turned off when driving on paved roads and turned on only on heavy sections of the road. Transfer boxes with differential drive of driving axles eliminate the occurrence of the previously listed negative phenomena. The center differential used in these boxes allows the drive shafts of the drive axles to rotate at different speeds and distribute the engine torque between the axles in accordance with the vertical loads they perceive. If the loads are the same in magnitude, then a symmetrical differential is used, and if they are not the same, then an asymmetric one. With transfer boxes with differential drive, the front axle is constantly engaged. As a result, tire wear is less than when the front axle is switched off. However, the center differential impairs the car's cross-country ability, since when one of the wheels slips in place, the car cannot start moving. Therefore, to increase the patency, the center differentials are made with forced blocking. The most common on off-road vehicles are two-stage transfer boxes.

Two-speed gearbox with direct and downshifts and a blocked drive.

Front axle shafts leading 7, intermediate 8 and front drives 10 and rear 7 axles are mounted on ball bearings in the crankcase 3 and lid 6 distribution box. Rear end drive shaft 1 rests on a cylindrical roller bearing in the undercut of shaft 7. Gear 4 of reduction and direct gears are installed on the splines of the shafts, gear 9 front axle engagement and driven gears 2 and 11 reduction gear and front axle drive shaft. Gear 5 is made together with shaft 7. All gears of the transfer case are spur gears. When direct gear is engaged, the gear 4 is engaged with gear 5 and shafts 1 and 7 are connected directly. When the front axle is engaged, the gear 9 engages with gears 5 to 11. Downshift gear 4 engages with gear 2. Before downshifting, the front axle must be engaged, otherwise the gear will not engage. The front axle can also be engaged without a downshift. The transfer case gear change mechanism has a blocking device (lock) that prevents downshifting if the front axle is off, or axle disengagement if the downshift is on. The locking device protects the drive mechanisms of the wheels of the rear drive axle from overloads. The device consists of two crackers 15 And 16 and expanding springs, which are located in the crankcase between the sliders 14 And 17. Under the action of the expanding spring, the crackers enter the grooves of the sliders. On the slide 14 gear shifting has three notches. In the middle deep recess 7 crackers 15 enters in the neutral position of gear 4, and in the extreme shallower depths of the recess 13 And 20 - when you turn on, respectively, direct and downshifts. Between notches 12 And 13 flattened. Slider 7 has two recesses - deep 18 to enable the front axle and shallower depth 19 to turn off the front axle. The position of the sliders, corresponding to the inclusion of the front axle and direct transmission, is shown in fig. 4.4, 5, and downshift and front axle - in fig. 4.4, V. It is impossible to turn off the front axle when the downshift is engaged, since the gap between the crackers of the blocking device is less than the depth of the recess 18. With the front axle on, cracker 75 from the recess 12 can only be moved to a recess 13 on a flat on a slider 14. The transfer box control drive has two levers. One lever is used to shift gears, it is connected to the slider 14. Another lever is designed to turn off the front axle, it is connected to the slider 17. You can turn on the front axle without disengaging the clutch, since the speed of rotation of the gears 9 and 11 practically the same.

Every motorist, no matter what car he owns, has heard the phrase "transfer case" at least once. But what kind of unit it is, what functions it performs, what “diseases” it suffers from and how to prevent them, few know. Mostly those who have a car equipped with an all-wheel drive system. Today we will learn all about the transfer case. Having mentioned the all-wheel drive system at the beginning of the article, we note that the transfer case is an integral component of this system, playing in it essential role- it is responsible for transmitting torque from the engine and gearbox () to the front and rear axles of the car. It not only distributes the torque to the drive wheels in a given proportion, but can, when the car goes off-road, increase its value on the wheel (s) that rests on a hard surface.

Handout handout - strife

Since there are various systems all-wheel drive (permanent, automatically connected and connected on demand), then the transfer case device differs in them. But there are also common parts for all transfer cases: these are two gears (chain gear and reduction), drive shaft, center differential (includes locks), drive shafts of the front and rear axle. Before moving on to the differences specific to handouts different type, we will understand the functions of their main components.

drive shaft. Based on the name, you can guess that this element of the transfer case takes over the torque from the gearbox and transfers it further to the center differential.

center differential. The differential located between the front and rear axles is responsible for the further transmission and distribution of torque to each axle, angular speeds whose rotations are different. There are two types of center differential - asymmetric (torque is distributed between the front and rear axles in unequal proportions) and symmetrical (torque is supplied to both axles in a 50:50 ratio). The differential lock allows you to completely or partially turn it off, as a result of which both axles are rigidly connected to each other, providing the car with increased off-road capabilities. The differential is blocked, depending on the transfer device, automatically or manually. You can learn more about the design and operation of this node.

chain drive. Its main function is to transmit torque from the center differential to the front axle. Its design uses chain drive, but there is also a variation of this transmission - a gear, when instead of a chain in the drive, two cylindrical gears meshed with each other are responsible for transmitting torque.

Downshift. This transfer case is designed to increase torque when driving on difficult terrain. In modern transfer boxes, the "lower" has changed planetary reductor. We read about the device and function of this transmission.

Drive shafts. These are the end nodes of the transfer case, transmitting torque directly to the front and rear axles. The drive shaft of the rear axle is usually located on the same axis as the drive shaft, and the drive shaft of the front axle is connected to it by means of a chain drive. But there are other options, which we will mention below.

oil sump. The transfer case has its own lubrication system, which includes a crankcase and an oil sump. Having dealt with the mechanisms common to transfer boxes, let's talk about what types of structures of this unit are on all-wheel drive cars mobiles. There are four of them:

- Type one - in this transfer case, the front and rear drive shafts are located on the same axis as the axles.

- Type two - this dispenser is characterized by the placement of drive shafts on different axes with driven shafts.

- Type three - this transfer case has a mechanism for blocking the drive axles.

- The fourth type - the drive from the motor is distributed to the drive axles through the differential.

The transfer case of the first type has only one stage, which ensures the transmission of torque to the drive axles with the same angular speeds. Due to the simplicity of the device, it is quite popular with manufacturers all-wheel drive models cars.

The razdatka of the second type is devoid of an intermediate shaft, due to which it has compact dimensions, light weight and runs almost silently. This type of transfer case is characterized by a high efficiency.

The transfer case of the third type allows you to turn off the front axle when driving on roads with high-quality coverage, and turn it on when driving off-road. Due to this selective switching on / off of the front axle, the car, firstly, can move off-road using the entire engine thrust, and secondly, when driving on normal roads, significantly save fuel.

The transfer case of the fourth type is the most advanced, as it allows you to adjust the angular speed of rotation of the front and rear wheel axles depending on the driving conditions. The presence in the device of this box of a locking mechanism, which is forced by electronics or manually, makes it possible to achieve the transfer of increased torque to the axle that has better grip with the road surface.

The main operating modes of the transfer case

There are five modes of operation of the dispenser. Let's describe them briefly:

- Enabled neutral gear, the drive shaft rotates freely, the torque is not transmitted to the axles

- Overdrive engaged, center differential unlocked (torque is transmitted in a ratio of 1:2)

- Overdrive engaged, center differential locked (most torque is sent to the axle with the best grip)

- Downshift is engaged, center differential is unlocked (torque transmission on the axle is in a ratio of 1: 2)

- The downshift is engaged, the center differential is locked (the front axle is rigidly connected to the rear axle, the torque is distributed to the axle that has the best grip). This mode is used when overcoming the most difficult off-road.

Dispenser malfunctions and ways to prevent them

Many owners of all-wheel drive cars who are faced with a breakdown of the transfer case are familiar with the characteristic hum that this assembly emits when one of its elements fails. Another sign of a box malfunction is a noise of a certain tone, which is heard when the drive wheels turn or slip. So if you hear a howl or noise during the operation of the all-wheel drive system, you should know that it is time to diagnose the transfer case.

Most often, the differential lock fails in the transfer case. As we already know, manufacturers of transfer cases use mechanisms of various designs to block the differential - lockers (allow you to completely and rigidly block the torque transmission mechanism) and self-locking LSDs (allow limited slip of the differential).

Lockers in progress long-term operation the contactor gear may fail, which will not allow the mechanism to lock the differential. To prevent this breakdown, you need to carefully monitor the mode in which the all-wheel drive system operates and prevent long drive with blocking enabled. In addition, the life support systems of the lock can break down - hoses (for pneumatic and vacuum mechanisms), wires (for electronically controlled ones) break. The resource of such blocking is 100-200 thousand kilometers.

Limited slip differentials have their own sores, the most common of which is friction wear when the clutch overheats (due to frequent slipping). To avoid overheating of the clutch, you should not load it during wheel slip, give it a "break" to cool it down. It should also be used to prevent overheating and wear of friction clutches. The resource of such a blockage is 50-150 thousand kilometers.

The second common breakdown of the dispenser is spontaneous shutdown gears. This is due to the failure of the retainer springs, broken gear teeth, wear of the sockets and retainer balls. Gear teeth and detent springs can break due to increased loads on the transmission, and wear of the detent seats and balls is possible due to contamination or a small amount of transmission fluid in the distributor case. If the reason is a small amount of liquid, we sin for tightness oil sump which could crack and leak. In this case, you need to carefully examine it and solder the resulting cracks. The fluid is dirty and needs to be replaced.

Transfer case gear

Transfer case gear

The third reason for the failure of the transfer case is the spontaneous disengagement of the front axle. It can occur due to wear of the transfer case fork, slider groove, gear coupling teeth drive mechanism front bridge. It can also turn off if the front drive shaft bearings are loose and the shaft and clutch teeth are misaligned. The recipe for fixing “sores” is to replace worn parts, tighten loose fasteners.

You can prevent the occurrence of these breakdowns if you properly operate a car with an all-wheel drive system, periodically inspect the transfer case and change the transmission fluid in it in time.

The transfer case (RK) is installed in cars suitable for driving. In other words, it is present in vehicles with all-wheel drive, and in those with front- or rear-wheel drive, there is none.

The purpose of the transfer case is to adjust the torque working in the undercarriage of the machine. She comes to the aid of cars in the passage of complex and landscape routes.

But let's talk about this device in more detail. First, let's figure out where to look for it.

Where can I find a transfer box?

The location of the PK may differ depending on the make and model of the vehicle.

Sometimes the creators of the car put it on, sharing it with this device.

However, you can often find gearboxes that include transfer cases.

What are transfer boxes?

The purpose and design of the transfer case are inextricably linked. Not all vehicles have the same RC. Most often, these mechanisms differ from each other in their type and structure. There are three main criteria by which one such mechanism differs from another.

- Types of drive shafts. In step-down boxes, they can be misaligned and, conversely, coaxial.

- Locations of drive shafts.

- The number of gears available. This number determines the gradation of the box. They are one-, two- and three-stage.

What is the distribution box made of?

The distribution mechanism itself may differ. There are several ways to collect it. However, there are components that a transfer case device cannot do without.

- First, it is the drive shaft. When using one gear, he is responsible for receiving torque.

- Second, there are four drive shaft. They are placed on the axle at the back and front. They are connected in pairs.

- Thirdly, in such a mechanism there is necessarily a gear or chain transmission of torque.

- Most 4x4s also have a low gear. However, we draw your attention to the fact that it is not present in all transfer boxes. So, this link in the chain of the mechanism is absent, for example, in crossovers, which, although they have all-wheel drive, are not designed to drive through difficult landscapes.

- Also in the boxes of some cars with all-wheel drive there is a differential that is installed between the axles, and a lock for the differential.

How does the box work and is it needed?

How does it work?

First, let's figure out how the transfer case works. The principle of operation of the transfer case is that differentials, which are of two types (symmetrical and asymmetrical), divide the torque into axles. The first type of mechanism distributes the torque equally, and the second - not equally, depending on the specified indicators. One way or another, thanks to this device, the drive shafts can operate at different speeds, which increases the maneuverability and stability of the machine when turning and when.

The principle of operation of the dispenser:

Also, a lock can be installed under the differential. This device helps to lock the differential that distributes the torque. After such blocking, the wheels will rotate strictly at the same speed. You can control this function yourself from the inside of the car, or you can set up automatic locking. Such a function is in demand on those machines that have to drive, for example, through long fields.

The transfer box has several modes of operation. It can function:

- with two active axles and differential lock, which is carried out automatically;

- with two active axles, but in a reduction gear with the condition of permanent differential lock;

- with two working axles and with the condition of permanent differential lock;

- with two working bridges;

- provided that only the rear axle is working.

If the box doesn't work

Transfer case malfunctions are different. However, there are several most common ailments of the device:

- Difficult to shift into gear. If you have such a problem, check the rods and plugs of the device. They could wear out as a result long service life. If so, they should be replaced as soon as possible. Also, the cause may be seizures formed on the gear wheels. If none of these reasons applies to you, it remains only to check the latches. Perhaps this problem is caused by their laxity.

- Gears are automatically disengaged while driving. Most likely the gears need to be replaced. Their teeth must have already worn out. If the gears are in order, check the integrity of the fork fasteners. They can jump.

- The box is terribly noisy. First, remember what lubricants do you use? Perhaps their viscosity is not enough and you need to pick up something thicker. The gears could be worn out. Then they need to be replaced. The same reason can be caused by problems with the operation of the clutch or wear of the bearings.

- Oil is leaking from the AC. If you have determined that the oil is flowing from it, just buy new gaskets and ask the master to install them.

Unfortunately, it is almost impossible for an amateur to repair the box on his own. The only thing that a beginner in the repair business can do with his own hands is to produce. For all other procedures, specialist assistance will be required.

Do you need a transfer case?

Like any mechanism, RK has its advantages and disadvantages.

Let's start with the cons. More precisely, from one, but significant minus of the transfer case. The fact is that most of its parts are quite expensive. Therefore, their replacement will be expensive. And those parts that are sold by reasonable prices, are difficult to repair, therefore, they may also require funds from the car owner for the work of the master.

Now the pros:

- When the “razdatka” is operating while the car is moving at low speed, the torque is transmitted to the axles. This increases the cross-country ability of the SUV.

- It is noteworthy that during the operation of the "razdatka" a large torque cannot be lost. This is achieved thanks to the demultiplier. He is an assistant to the machine in reducing the intensity of torsion of the drive shafts.

- Also, the driver of a car equipped with a transfer case has the opportunity to independently determine the gear number.

- When driving in difficult conditions RK will become a friend and assistant to the motorist, helping him " iron horse» overcome terrain obstacles effectively.

- And, of course, one of the leading advantages is that the operation of the transfer case extends the life of the transmission.

But do not forget that no transfer case detracts from the importance of the skill of the driver who decides to drive along difficult areas. After all, even when driving the most “fancy” car, the rider’s inexperience can play a cruel joke on him.