Winter tuning wheels

Tire chains are a type of removable tread that converts an ordinary highway wheel into a rubber with improved flotation. From the point of view of the design, the chains on the wheels are a connected wire with reinforcement, evenly wrapping around the entire circumference of the tire. The composition of such chains includes two longitudinal cables located on the circumference of the wheel inside and outside. To connect them to each other, transverse elements or special "lugs" made of reinforced rubber are used.

The use of snow chains can significantly increase the cross-country ability of the vehicle by increasing grip characteristics tires. This is true when driving on surfaces such as ice, mud, loose or wet snow etc. For example, when traveling outside the city, the first 100 km of the path may lie along ordinary road covered with asphalt, while then you need to turn onto a dirt track, which is an "impassable" off-road.

In this case, anti-slip chains are put on the wheels and continue on their way. Otherwise, the risk of getting stuck in impassable mud increases significantly, as a result of which you will have to look for a tractor or other vehicle for towing a car. In addition, snow chains greatly facilitate the passage of such sections as steep slopes covered with ice, which are quite difficult to overcome even with studded tires.

Types of wheel chains

Different types of protective circuits

There are two main types of snow chains: soft and hard. In soft chains, rubber “lugs” act as crossbars, while hard chains are connected using link elements. In addition, there are two types of chain pattern: “ladder” and “diamond” (another name is “honeycomb”). In the case of the "ladder" pattern, the connections between the longitudinal cables are made in the form of straight lines located across, similar to a rope ladder. Diamond or honeycomb chain connections are made diagonally, resulting in an interlaced design.

Snow chains are also classified according to the following criteria:

- size;

- the shape of the links or "lugs";

- production material: steel, aluminum, titanium, fiberglass with reinforcement and so on.

In some cases, additional reinforcement of wheeled chain structures is performed using metal spikes. It is quite difficult to unequivocally answer the question of which kind of chains should be preferred, since individual characteristics largely depend on the planned operating conditions. In particular, hard chains are better than soft chains for driving in heavy off-road conditions such as loose snow or dirt.

At the same time, certain limitations are associated with rigid structures, since at speeds exceeding 40 km / h, there is a risk of damage to the transmission. In the case of soft snow chains, optimally suited for icy or slightly muddy sections of the road, you can accelerate to 80 km / h. At the same time, rubber wear is significantly reduced compared to rigid chains.

The situation is similar with the size of the chains: an increase in the links increases the cross-country ability, but at the same time the mass of the structure also increases, and the movement of the car on flat sections of the road becomes more difficult and unpleasant. In addition, the transmission is more heavily loaded and the wear of rubber is accelerated.

Self-manufacturing

Everything you need to make an accessory

It also happens that you need to drive off-road, but there is no ready-made snow chain at hand. In such a situation, you can try to make snow chains with your own hands, using the available tools and materials. To do this, you will need the following details:

- tension devices;

- a chain with a wire diameter of 4-5 mm;

- carabiners with a diameter of 5 mm;

- hooks.

We cut the chain into pieces of a certain size. For the manufacture of longitudinal sections, four pieces will be required, each of which has 83 links. The transverse sections will be made from sixteen 13-piece pieces. The first transverse section is attached to the sixth link of the longitudinal chain, the last - to the twelfth. The remaining transverse chains are fixed at intervals of 10 links. Hooks or rings are used to connect the transverse and longitudinal links. After the fourth transverse chain, a five-link segment is attached on one side. Carabiners are installed at the ends of the links located along. The tensioner is placed on the fixed end of the carabiner, the hook on the other. On this, the chain can be considered ready and suitable for testing on the wheels of a UAZ car.

Every motorist needs to have snow chains in the trunk. They will help out in the most difficult road conditions. How to make snow chains with your own hands and how to use them correctly, we will consider below.

What are snow chains for?

Anti-slip chains will make an all-terrain vehicle out of an average car off-road. They increase grip vehicle on any road surface. With such chains to the car not afraid of any obstacles: no dirty slurry, no slippery ice, no high snowdrifts.

The main advantage of such devices is that they can be used in case of urgent need. For example, you went fishing. At first they moved along an asphalt road, and then moved out onto a country road. Then an unexpected obstacle arose - the road was washed away by rain. In this case just get itput them on wheels. Now you can go.

Always store in trunk machine data device to apply their emergency. They will be useful to owners not only jeeps and SUVs, but also ordinary cars.

Carefully: Use chains in exceptional situations when it is necessary to increase the cross-country ability of the car. Do not use such devices on an ongoing basis - this negatively affects the condition of the car.

Types of anti-slip chains by type of material

Anti-slip equipment available for sale various kinds , it is also possible do chains on the wheels with their own hands. They differ in the types used for manufacturing. materials and by characteristic drawing the chains themselves.

soft chains

Soft chains for wheels are made rubber, polyurethane and other plastics. They are a grid, along the entire perimeter of which there are metal spikes.

The most popular soft anti-slip chains are made from polyurethane. They possess high resistance to wear and tear, very elastic and resistant to chemicals.

Rubber in its properties is much inferior to polyurethane.

cost pretty expensive, but they are operated in urban conditions without damaging the road. Besides speed when driving with such chains on wheels, you can keep quite high - up to 80 km/h. For the strong off-road and ice such devices not effective.

Rigid chains

This type of chain is made from solid materials - steel, aluminum or titanium. They are inexpensive but very reliable. Ideal even for heavy ice and off-road. With classic chain devices, it is not recommended to drive faster than 50 km/h.

Anti-skid bracelets

This equipment is different lack of longitudinal elements. Bracelets are attached across around the entire circumference of the wheel at the same distance. Easy to install but less effective off-road.

Types of anti-slip chains according to the drawing

Depending on the weave pattern chain links, there are several species devices. Their properties are different so be careful when choosing.

Ladder

This two circles chains connected to each other transverse segments. They got this name because from the outside, these devices are very similar to a ladder.

This is the most inexpensive and simple in the manufacture of a variant of snow chains. They also have some flaws:

- less effective when driving on snowdrifts and ground;

- automobile moves in jerks, and this overloads the transmission;

- car throws to the side across the movement.

Rhombus

In such devices chained circles connected by segments not in a straight line, but diagonally crosswise. This results in a characteristic diamond-shaped drawing.

These traction control chains are ideal for moving around. wetlands or deep snow. They are very durable and provide good grip with surface.

Perfect for SUVs and off-road vehicles . In many times increase permeability vehicle.

Deprived of almost all the shortcomings of the "ladder" counterparts.

honeycombs

Such drawing is obtained by combining chained hexagons each other at the corners. There are hexagons in the center, and pentagons on the edges. Such devices have all the advantages of diamond-shaped, plus add more great lateral stability.

DIY materials and tools

To make snow chains with your own hands, required:

- a piece of steel chain of the required length (section not less than 5 mm);

- carabiners or hooks for connecting transverse segments (2 pcs for each segment);

- Bulgarian;

- vise;

- roulette;

- chain tensioner.

We make snow chains with our own hands

To make homemade chain equipment, it is necessary to perform the following actions:

- Measure measuring tape circumference of the tire. Cut 2 pieces from the chain equal to this measurement minus 20-30 cm. The finished segments, closed in a ring, should lie approximately on the tire tread line. Connect them in 2 circles using carabiners.

- For cross sections measure the distance between two rings from the chain external side of the tire (here you need to take into account the length of the connectors).

- cut off right amount cross chains- they should be at least 8 pcs.

- At the ends of the resulting segments attach carabiners or hooks. They can be made from reinforced wire or use chain links, but be sure to fix them by welding.

- Now attach the cross pieces circles at equal distances.

- To adjust the tension, you need to make suitable system. Can it be done from a piece of chain, supplemented with a regulator with two screws. It is also possible to use metal springs or rubber bands. At the ends of the regulators too attach carabiners.

- Best to use 2 tensioners: from the outside and from inside wheels. If necessary, you can tighten the system with one regulator.

On anterior and rear wheel drive cars equipment is put on drive wheels only. By car With all-wheel drive "dressing in a shell" is necessary whole set of wheels.

How to properly put chains on wheels

Expand the chains on a level surface in front of each wheel. Moving on minimum speed, stop by on prepared devices so so that the wheels are completely on them. Fasten all carabiners and put on the tension adjusters.

When there is not enough space it is possible to “shod” the wheels in turn in anti-skid equipment using a jack.

Necessarily check circuits for damage and twisting.

What is the danger of using anti-slip chains

At constant use snow chains, the following Negative consequences:

- The load on the steering gear is increased.

- Suspension wears out quickly.

- The chains make a lot of noise while driving.

- Increased tire wear.

- Unable to keep high speed.

- Not comfortable to move around.

Do not use these devices rigid type when driving on paved roads- this leads to damage to the roadway.

Observe speed mode : for hard - no higher than 80 km / h, for soft - no higher than 50 km / h. Use such equipment only in emergency situations to increase permeability.

In the life of a car owner, situations arise when he overcomes impassability or snow drifts. There will be no problems if the car is an SUV, and studded tires are installed on it. As for regular cars, then attempts to drive through mud or snow in winter end unsuccessfully.

Anti-skid chains. Purpose, advantages and disadvantages

To boost off-road qualities vehicle, snow chains or traction control chains are used. The purpose of these accessories is to increase the patency of the car. They play the role of universal lugs.

After installing them, the driver receives:

- good performance on snowy roads;

- the ability to overcome climbs and descents with less chance of loss of control;

- improved car handling on icy surfaces;

- increased rowing properties when overcoming mud.

Thanks to the anti-skid chains on the wheels, the car overcomes serious off-road conditions. But we note that the patency in this case depends on the clearance.

Disadvantages of snow chains:

- Increased load on the steering mechanism, transmission elements.

- The impossibility of fast movement (it will not be possible to drive at speeds over 40 km / h).

- Intensive tire wear.

- Strong sound effect.

Chains for a car will help in off-road or snow drift, But long-term operation Not recommended.

Varieties of chains

Despite the negative qualities, snow chains increase the patency of the car.

These tools differ from each other in terms of:

- material of manufacture;

- drawing geometry.

These differences affect the car's behavior on the road and off-road performance.

Production material

According to the material of manufacture, the chains are divided into:

- Rigid.

- Soft.

Initially, such means of increasing patency were made of metal - rigid chains on wheels. The material of manufacture was steel, aluminum, titanium. At the same time, the strength of such a product is affected by metal, the dimensions and thickness of the links. The more links, the higher the cross-country performance.

Video: ABC off-road. Anti-skid chains

The advantages of a rigid structure are improved cross-country ability of the car and improved traction control and anti-icing performance on ice. Such a chain in the form of a bracelet “rakes out” better from under the wheels. At the same time, they make a lot of noise and accelerate tire wear. Such bracelets on wheels have a speed limit of 40 kph. A product with large links has a significant mass, and far from all cars, the space of arches allows them to be used.

Structurally, they can be completely made of a metal chain, without a rigid base to which the transverse elements are attached.

Soft chains are distinguished by the fact that non-metallic materials are used to create them:

- rubber;

- plastic;

- polyurethane.

For the strength of such accessories, reinforcement is used. They are th and less. For them speed limit is already 80 km / h, while they do not have a strong noise effect. Their disadvantages include indicators when driving on ice.

For urban driving winter period it is better to choose soft traction control chains, for example, rubber ones. But when leaving the city, where there is a high probability of getting into a mud area or ice, they use a hard type.

Drawing geometry

As for the geometry of the pattern, three types are available:

- "Ladder".

- "Rhombus".

- "Honeycombs".

The "ladder" consists of a base - two longitudinal branches, and it is located along the circumference of the wheel on both sides. For fastening on the wheel, locks are installed on the base. Working elements are attached to it perpendicularly. Externally, the straightened chain looks like a rope ladder, hence the name.

"Ladder" is the simplest type of cross-country vehicle, so such products are inexpensive. But such a chain has a number of disadvantages:

- working elements are parallel to each other. Because of this, contact with the road for such a chain is variable, due to which a car on loose soil or snow can “burrow”;

- "Ladder", due to the peculiarities of the location of the working elements, is good only for longitudinal movement, while the lateral stability of such lugs is low;

- due to variable contact, a high load on the transmission elements.

Better in terms of operational chain type "rhombus". Their design uses longitudinal branches, the working elements form a diamond-shaped pattern.

In “honeycombs”, the rhombuses formed by transverse branches also have a periodic arrangement, while they are additionally connected to each other by a linear connection.

Unlike the "ladder", in the "rhombus" and "honeycomb" the contact of the working branches with the coating occurs constantly, which reduces the negative impact on tires and transmission. They provide resistance to lateral impacts, that is, the car blows less to the sides.

What to consider when choosing

When choosing snow chains, pay attention to the material of manufacture, the geometric pattern and the dimensions of the chain. It should fit tightly around the wheel. Therefore, when choosing, be sure to find out the diameter and width of the wheel.

Pay attention to the dimensions of the links themselves. small constituent elements provide patency in snow or ice conditions, but cope worse with mud - it needs large links.

How to put chains on wheels?

You need to mount on wheels in advance, before leaving for the problem area. If the car is already stuck in mud or a snowdrift, it is problematic to put them on the wheels.

To put chains on wheels you need:

- In front of the wheels of the drive axle on the ground, we lay the chains longitudinally to the movement and straighten them. Fixing elements (hooks, locks, carabiners, etc.) must face the direction of travel.

- We run the wheels on the chains so that 20-30 cm of the product remains in front of the wheel.

- We throw on the wheel the part located behind the wheel.

- We connect the fixing element first with the internal longitudinal branch, and only then with the external one.

- If there is a chain tensioner, use it.

- We drive 20-30 meters by car so that the product normally sits on the wheel and straightens.

Video: How to put a chain on a wheel without running over and without a jack

And only after that we try to overcome impassability. At the same time, you need to do this in low gear and with increased turnover engine so that the wheels can "rake" out from under them. In urban conditions, we move on chains in the usual mode, but before that it is better to do a test run to determine the behavior of the car, and this should be done on the road with different conditions- snow, ice. And most importantly - you must not exceed the speed limit, otherwise you will lose control or break the chain.

How to make your own wheel chains

The choice of snow chains on the market is very large now, but it is not necessary to purchase them, since they are not difficult to manufacture and it is quite possible to do it yourself. But at home we make only a rigid chain.

First of all, let's define the geometry of the picture. The simplest will be a "ladder", but if you wish, you can also make a "rhombus", although it is more difficult to manufacture. From the materials you will need:

- a metal chain whose links are connected by welding. At the same time, we immediately determine the size of the links;

- fastening;

- stretching device.

Video: Making CHAINS on wheels

As for the tools, you will need:

- angle grinder machine with a cutting wheel ("Bulgarian");

- welding machine;

- measuring tool;

- vise.

With that, let's get to work:

- We take measurements. First of all, you should measure the longitudinal branches along the wheel, both of them should be the same length.

- We cut off the required sections with a grinder.

- We measure the length of the transverse elements and cut them in the right amount (the more cross members, the better).

- In the end links of the transverse branches at the place of the weld, we make a cut and unbend a little. We do this with all the prepared elements.

- We lay the longitudinal branches on the ground and, by cutting the links of the crossbars, we hook to them. We make sure that the crossbars are perpendicular to the bases and at the same distance from each other.

- Using a welding machine, we weld the cuts made.

- We attach hooks or carabiners to the front ends of the longitudinal branches in the same way.

- If necessary, on the branch that will be located on the inside, we install a tensioner.

- We install the manufactured product on the wheel and check how it sits (if necessary, we increase or shorten the longitudinal branches).

Can be used for assembly bolted connections crossbars with longitudinal branches, but weld more reliable.

Frequent car trips winter time can turn around backfire for drivers, as a result of which it is necessary to call a tug to help. Unpleasant weather conditions such as snow, ice and rain reduce the car's cross-country ability. Especially for snow-covered sections of the tracks provided special equipment, which is called snow chains. When there is an obstacle ahead in the form of a section of a snowy track, chains put on wheels will help to increase the efficiency of overcoming such a distance. Such products can be bought at any auto shop, but not every driver can afford their cost. There is only one way out - to make snow chains with your own hands.

Purpose of snow chains

The cost of high-quality snow chains starts from 5 thousand rubles. Moreover, this does not require special knowledge and experience, since if you have the instructions indicated in the material, you can make products yourself.

Anti-skid chains (lugs) are products that are put on the drive wheels, increasing the cross-country ability of the vehicle. By installing such products on wheels, the driver receives the following benefits:

- High performance on snow-covered roads.

- Overcoming climbs and descents on sections of tracks with ice with a low probability of loss of control.

- Improving the quality of driving in snowy and icy areas pavement.

- Improving the rowing properties of the car when passing through muddy sections of the road.

It is important! Snow chains are installed on the wheels only when it is necessary to overcome a difficult section of the road. It is not recommended to use them constantly, as this negatively affects the vehicle.

The negative impact is due to the following factors:

- Increased load on the steering mechanism, as well as transmission elements.

- Impossibility of fast travel.

- Increased tire wear.

- Lack of comfort.

- Extraneous noise.

- Negative impact on the suspension elements.

In addition to everything, it is forbidden to operate a car with hooks on asphalt, as this contributes to the destruction of the coating. The products in question should always be in the trunk of the car in order to be able to use them if necessary. This applies not only to cars of the crossover and SUV class, but also to light mono-drive vehicles.

Varieties and how they differ

Many drivers, having familiarized themselves with the shortcomings of lugs, make a negative decision to purchase or manufacture them. However, sooner or later there comes a situation when the presence of chains does not hurt. Grousers are divided into several varieties. The main distinguishing parameters are: the material of manufacture and the geometric pattern of the chain product on the tire.

This is interesting! The above parameters have a corresponding effect on the vehicle and its off-road performance when driving.

Depending on the material of manufacture, lugs are divided into the following types:

- Rigid.

- Soft.

Rigid lugs

Hard types include products from the following types of metals: titanium, steel, aluminum. The strength of the product depends not only on the material, but also on the thickness of the links. How larger size s links, the higher the car's cross-country ability. However, the indicators of the negative impact on the car are also higher.

On the one hand, thick chains increase the cross-country ability of the car, on the other hand, they negatively affect the suspension and steering rack.

The disadvantage of rigid products is high rate noise effect, and accelerated wear tires. On chains of this type, it is impossible to reach speeds above 40 km / h. In addition, the massiveness and heaviness of the chains adversely affect the vehicle. Not in all types cars rigid chains can be used due to the small space between the wheel arches.

Soft lugs

Soft lugs are made from non-metallic materials such as rubber, polyurethane, and even plastic. To increase the strength of products, a method such as reinforcement is used. Soft Options lugs for cars are more forgiving, as they contribute to rubber wear to a lesser extent, and they are also almost silent. A car on such lugs can reach speeds up to 80 km / h, while quality grip with pavement.

Soft chains can hardly be called “chains” in the truest sense of the word, but they do the job when driving around the city just as well

Like hard chains, soft lugs have disadvantages that are clearly manifested when moving on ice. Soft chains perform well when moving around the city, without having a negative impact on the road surface. However, they are not able to ensure the effective passage of snowy areas and mud, so in such situations, only rigid chains should be used.

Varieties of lugs according to the geometric pattern

Depending on the geometry of the pattern, there are three types of snow chains:

Each option has its advantages and disadvantages, so let's look at them in detail.

"Ladder" is a base in the form of longitudinally arranged branches. These branches are evenly distributed around the entire circumference of the wheel. To fix the chain on the wheel, the appropriate type of locks are used. Outwardly, this type of lug resembles a ladder, from where the name came from.

This option lug is one of the most popular, effective and in demand. Of the disadvantages of this type of chain, it is worth noting:

- parallel arrangement of chains on the wheel, so the car will dig in when overcoming snowy or soil areas;

- low rate roll stability, which is also due to the parallel arrangement of the branches of the chain;

Despite the high raking properties, ladder-type chains are practically useless on snow-covered ground.

Chains of this type are recommended to be used only when it is necessary to overcome a risky section of the route. This option is one of the cheapest, so when the need arises, most drivers prefer this option without delving into its features.

The rhombus design of the lugs is a modernized design of the Ladder. For this, there are longitudinal branches that form a diamond-shaped pattern, excluding all the negative factors that are characteristic of the Ladder.

The geometric shape in the form of a rhombus is intended for the use of lugs when it is necessary to overcome a snowy or swampy area. The diamond shape is shown in the photo below.

Diamond-shaped chains have increased strength and high performance clutch

The diamond-shaped form of snow chains is popular among SUVs and crossovers, since this type of pattern on the lugs increases the passable qualities of the car several times. This is especially true for snowy and icy road sections.

An analogue of a rhombus are “honeycombs”, which have transverse branches similar to a rhombus, however, they are additionally connected by straight connectors. Rhombus and honeycombs are improved types of lugs, when using which the contact of products with the road surface occurs constantly. This is a big plus for both rubber and transmission, so when making lugs, it is recommended to pay attention to the last two models.

"Honeycombs" provide constant contact with the road, because they give the car high level roll stability

It is also worth noting that when buying snow chains, you must consider their size. Grousers manufactured in production are divided not only in size for wheels, but also depending on the type of car.

Anti-skid chains and bracelets: which is better

The analogues of chains for cars are bracelets, which are a pair of segments of chains fixed on wheels with belts. The chain is located on top of the bar, and the belt is located in the hole between the disc. At the same time, the bracelet, unlike the chain, is firmly tightened on the tire, which allows the chain to be located in one place.

To increase efficiency, it is recommended to attach at least three anti-skid bracelets to one wheel

Usually three bracelets are installed on one wheel, which is enough to reach a hard surface, while creating friction and repulsion of the car. Unlike chains, bracelets have the following advantages:

- Speed and ease of installation. If chains are recommended to be installed only before overcoming a snowy or swampy area, then the bracelet can be installed even when the car is stuck.

- Compact, as they do not take up much space in the trunk, unlike chains.

- No need to jack up the wheel.

- Versatility. If the chains are designed for a certain wheel diameter, then the bracelets are suitable for any wheel size.

- Unlike chains, bracelets are several times cheaper.

- Long service life.

Like chains, bracelets are divided into hard and soft. Some of the cheapest bracelet options are plastic products. They are suitable for any type of car: from small cars to SUVs, so every driver can afford them.

Bracelets, like chains, are divided into hard and soft

What is the difference between chains and bracelets? Numerous observations of drivers show that the chains have a better grip on the road surface, which has a positive effect on the patency parameters. Chains can be used to overcome snowy and icy areas until they end. Bracelets can only be used for short-term use up to 5-10 km.

It is important! If one link breaks on the chain, then this poses a threat to the car body. Possible damage paintwork, which ultimately contributes to the formation of a corrosion zone.

When it is known what chains and bracelets are, we can conclude:

- If you plan a long road through swampy, snowy and icy terrain, then it is recommended to use chains.

- Bracelets are used only when rare trips are planned around the city or outside it in bad weather. Even if during the trip you forget to wear a bracelet, you can do it at any time, even if the car gets stuck.

Making snow chains: sequence of actions

Many motorists value their work, so they resort to solving the problem with the lack of lugs on their own.

Necessary tools and equipment

Before performing the corresponding work, you must first make sure that the appropriate materials and tools are available. You can watch the process of making snow chains on the video, but the disadvantage of the videos is the lack of information about the necessary equipment.

To make a simple Ladder chain, you will need the following materials:

- Steel chain. The thickness of the reinforcement must be at least 5 mm.

- Carabiners with a clutch and a thread. Products with latches are not suitable for the manufacture of a lug.

- Chain tensioner.

- Bolts, nuts and washers.

- Hooks.

For the manufacture of snow chains, carabiners with a clutch and a thread are required

The main material is a chain, the length of which for two medium wheels with a diameter of R15 must be at least 15 meters. Buying a chain separately and making a lug out of it yourself is much cheaper than buying a finished product.

To make lugs, you will also need a set of tools:

- Vise;

- Bulgarian with a circle for metal;

- Roulette;

- Hammer;

- Wrenches for tightening bolts and nuts.

As you can see, the stock of materials and tools is insignificant, so after preparation, you can start making snow chains.

Step-by-step instruction

The manufacturing procedure involves the following steps:

- Tire circumference measurement. This is necessary in order to make two rings from a chain of the appropriate diameter. Here alone important point: The length should be such that the chain lies on half the width of the bar, as shown in the photo below.

To determine the length of the chain, it is necessary to close the chain on the imaginary middle of the wheel

- The required chain length is cut off, after which the chain segment is connected using threaded carabiners. The second segment of the chain is prepared of the same length.

- Manufacturing of cross links. Using a tape measure, a measurement is taken, after which a decision is made on the required number of links. How more quantity such links, better patency, but even this will require a large chain length. The number of links is also determined depending on the size of the wheel. Their optimal amount is 8 pieces.

To determine the width of the transverse links, it is necessary to take a measurement with a tape measure

- All links must be the same size. At both ends of the links you need to fix a carabiner. Bolts, nuts and washers can be used instead of carabiners.

In the absence of carabiners, the links can be fixed with bolts, nuts and washers

- The length of the links should be such that the chain on the wheel is well tensioned. If the length is longer, then they can fly off.

- When required amount links will be ready, you can start assembling. The assembly must be done so that each link is located at the same distance from the previous one.

For efficient use of chains, the distance between adjacent links should be approximately the same.

- When the product is assembled, you can try it on the wheel. To put snow chains on the wheel, you will need metal springs or rubber. The springs can be terminated with hooks to facilitate installation of the product.

To simplify the installation of chains, rubber bands with hooks at the ends are used.

- Instead of springs and rubber, other elastic materials can be used as tensioners. The main condition is that the products must securely fix the snow chain on the wheel. The result is a product of the following form:

With proper observance of the instructions, the following circuit design should be obtained

Such homemade device does not take up much space in the trunk, and it will take no more than 2 hours to make it. By analogy, a chain is made for the second wheel. For all-wheel drive SUVs chains must be put on all wheels. On mono-drive vehicles, the chains are located exclusively on the drive wheels.

Features of installation on a car

Making chains is only half the battle. Now you need to properly install them on the car. There are several ways to do this. The first of these involves jacking up the car. To do this, the driver must perform the following manipulations:

- Before an obstacle, you must stop on a hard surface, then set the car at first speed and squeeze the handbrake;

- Using a jack, you need to hang out the part of the car on which you plan to install the chain;

- As soon as the wheel is hung out, you should proceed with the installation of the lug;

- This process usually takes about 10-15 minutes for one wheel. In this case, you need to make sure that the chain is securely fastened.

Similarly, the product is installed on the second side and, if necessary, for all four wheels. The second option involves installing a chain without raising the wheels:

- You need to stop, and then place chains on both sides in front of the wheels.

- Run on the chains to the middle of their size.

- Fasten the product from the inside with a hook or carabiner.

- Straighten each link, then connect the tension adjuster.

In the absence of a jack, it is possible to run into chains lying on the ground

This option seems simple, but in reality it is not. After installing the chain on the wheel, you need to drive a few meters, and then adjust the tension. Then you can storm the obstacles.

Snow chain test

The manufactured device must be tested in operation to ensure its reliability and effectiveness. It is worth remembering that the effectiveness of the product depends not only on the number of links available, but also on the size of the chain used. The larger the chain size, the higher the quality of the car's patency.

To test the snow chain, it is enough to wait for bad weather, and then rush to an area where there is no traffic. After installing the chain on the drive wheels, it is necessary to overcome various obstacles in the form of snow slides, icy sections of the road surface, as well as swamps. After overcoming each obstacle, it is necessary to check the features of the location of the product on wheels.

It is important! During testing, damage to chain links may occur, so be sure to check their condition regularly.

If after testing the results are pleasing to the eye, then you can try to overcome obstacles without chains on wheels. The result is sure to amaze, and snow chains will become an indispensable attribute in the trunk of your car.

As a conclusion, it should be noted that snow chains are not installed at all in order for the car to stand out on the road. In addition to improved cross-country ability, the chains ensure the safety of the driver and passengers on the road in case of negative weather conditions. With the presence of such devices on the wheels of a car, you have a chance to overcome an obstacle or escape from a snow drift.

Snow chains are designed to significantly increase the car's patency both on ice and in snowfall and other off-road conditions. How to make your own snow chains hands will go speech in this article.

Anti-skid chains - structurally, they are a structure made of reinforced wire or a chain connected so that it evenly braids the tire around the entire circumference. Such a structure consists of two longitudinal cables - external and internal, passing along the circumference of the wheel, which are connected transverse elements or rubber "grousers".

There are 3 types of snow chains:

snow chains in the form of a ladder;

anti-skid chains in the form of a rhombus;

anti-skid chains in the form of honeycombs.

Each has its own advantages and disadvantages, but it is easier to make snow chains in the form of a ladder. Therefore, we take them as a basis:

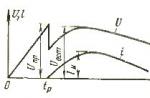

Ladder-shaped snow chains consist of longitudinal and transverse branches, tail branches, locking hook, locking hook and locking ring. The connection of the chain elements occurs with the help of connecting rings (Fig. 1)

Fig.1 Scheme of the anti-skid chain (ladder)

1 - transverse branch, 2 - longitudinal branch, 3 - tail branch, 4 - locking hook, 5 - locking hook, 6 - locking ring.

To make a snow chain with your own hands you will need:

Chain with a bar diameter of 4-5 mm - 15 meters;

Hooks - 32 pieces;

Tensioner - 2 pieces.

We cut 4 pieces of chain of 83 links for longitudinal chains.

We cut 16 pieces of 13 links for transverse chains.

We fix the first transverse chain on the 6th link of the longitudinal chains, and all the rest, except for the last one, on every 10th link from the previous one, we fix the last one on the 12th.

We fasten the longitudinal links with the transverse ones using hooks or rings.

After the 4th transverse chain, we fix a segment of 5 links on one side, and on the ends of both longitudinal links we put on such carabiners with a diameter of 5 mm.

On the side where the segment of 5 links is fixed, we fix the tension device on the carabiner.

Attach a hook to the other end.

We put chains on the wheels.

We test the chains on our car .....

Mounting the snow chain

Snow chains are mounted on the driving wheels of the car. The snow chain can be installed in two ways:

1 - without jacking up the car;

2 - with jacking up the car.

The mounting method is chosen by the driver depending on skills and road conditions. It is advisable to install snow chains before entering a difficult road section.

1st method - without jacking up the car:

Carefully straighten the snow chain (chain links must not be twisted);

Spread snow chains on the road surface and run over them with driving wheels;

Fix the car in a position that excludes spontaneous movement on the road;

Put the chains on the tire in such a way that the locking hook (pos. 4) with the locking ring (pos. 6) is on the outside of the wheel;

Hook the locking hook (pos.5) on the inner side of the wheel for one of the links of the tail branch (pos.3);

Spread the transverse branches (pos.2) evenly around the circumference of the wheel;

Thread the locking hook (pos.4) into one of the end links of the tail branch (pos.3);

Turn the locking hook towards the locking ring (pos.6);

Insert the locking ring into the groove of the locking hook;

If necessary, make an additional tension of the chain (reattach the locking hook and the hook for the following tail links).

Longitudinal and transverse branches should grip the tire tightly. Removing the tool from the wheel is carried out in the reverse order.

2nd method - with jacking up the car:

Install stops under the front wheels of the car;

Set the car to the handbrake;

Jack up the car by hanging the wheel above the road to a height of 20-30 mm;

Put on the device in the same way as in the 1st method.