The tensile strength indicates the stress value at which the screw can fail. Breakage can occur in the shank or thread of the screw, but not under the head. To determine the tensile strength at failure, a tensile test of the entire screw or machined rod is performed. Tensile strength values for A1-A5 stainless screws are always tested over the entire screw (DIN ISO 3506). The tensile strength value can only be accurately determined by testing the screw shank, testing over the entire screw only gives an approximate value, with the exception of stainless screws. However, for practical reasons, testing is often performed on the entire propeller.

Tensile yield strength Re (N/mm 2)

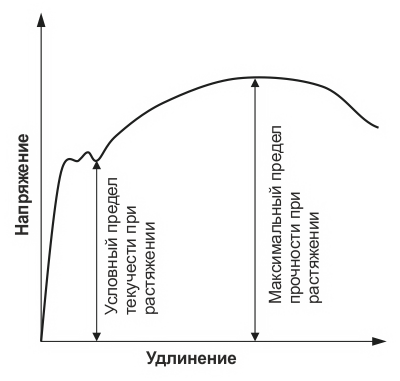

The conditional tensile yield strength indicates at what value of stress the tensile strength remains constant or decreases despite an increase in elongation. In other words, the yield point occurs when there is a transition between the region of elastic and plastic deformation of the metal. The yield stress can also only be accurately determined by testing the screw shaft.

Previously, tensile strength was practically the only basis for classifying steel by strength. The conditional tensile yield strength begins to increasingly supplant the tensile strength, since most of the other criteria for the strength of steel (creep strength, fatigue strength, impact strength, hardness, etc.) correlate better with the conditional tensile yield strength than with the tensile strength when stretched.

Graph of the relationship between stress and elongation for screws of strength class 4.6.

0.2% elongation limit R p0.2 (N/mm2)

This value is used for strong screws, such as strength class 10.9, which, when loaded, show a continuous shear between elastic and plastic deformation. Tensile strength can be difficult to determine because there is no clear plasticity boundary. In this case, the so-called 0.2% limit is used, when the constant elongation is 0.25.

Correlation graph between tension and elongation for screws of strength class 10.9.

Elongation at break A 5 (%)

The elongation at break is important characteristic deformation of the material under tension and viscosity of the material. The elongation at break shows the elongation of the bar under test as a percentage:

A 5 \u003d (L U -L O) / L O × 100%, where

L O - given effective length LO=5×d 0

L U - effective length after stretching

d 0 - diameter of the rod of the tested workpiece (screw before tensile testing)

Hardness and its testing

Hardness is usually defined as the ability of a material to resist penetration by a test object under a specified load. The following three methods are used to measure hardness:

Brinell HB ( ISO 6506) a steel core is used as a test object, the diameter of the imprint is measured. Vickers HV ( ISO 6507) the blunt end of the pyramid is used as a testing object, the diagonal of the imprint is measured. Rockwell ( ISO 6508) HRB hardness for soft materials measured by the depth of the indentation of the core, HRC hardness for hard materials is measured by the depth of the indentation of the pyramidal tip.

| Characteristic | Strength class | ||||

|---|---|---|---|---|---|

| 5.6 | 8.8 | 10.9 | |||

| ≤M16 | >M16 | ||||

| Tensile strength Rm (N/mm2) | nominal value | 500 | 800 | 800 | 1000 |

| minimum | 500 | 800 | 830 | 1040 | |

| Tensile yield strength Re (N/mm2) | nominal value | 300 | -- | -- | -- |

| minimum | 300 | -- | -- | -- | |

| 0.2% elongation limit Rp0.2 (N/mm2) | nominal value | -- | 640 | 640 | 900 |

| minimum | -- | 640 | 660 | 940 | |

| Yield strength Re or 0.2% elongation limit Rp0.2 at high temperature | +100°C | 270 | 590 | 590 | 875 |

| +200°C | 230 | 540 | 540 | 790 | |

| +250°C | 215 | 510 | 510 | 745 | |

| +300°C | 195 | 480 | 480 | 705 | |

| Elongation at break A5 (%) | minimum | 20 | 12 | 12 | 9 |

| Vickers hardness F≤98N (HV) | min…max | 155…200 | 250…320 | 255…335 | 320…380 |

| Max. head value | 250 | -- | -- | -- | |

| Brinell hardness F=30D 2 (HB) | min…max | 147…209 | 238…304 | 242…318 | 304…301 |

| Max. head value | 238 | -- | -- | -- | |

| Rockwell hardness HR | HRB min…max | 79…95 | -- | -- | -- |

| Max. head value | 99,5 | -- | -- | -- | |

| HRC min…max | -- | 22…32 | 23…34 | 32…39 | |

| Impact strength KV (J) | minimum | 25 | 30 | 30 | 20 |

Classification of raw materials used in the manufacture of fasteners.

Carbon fiber Commonly used raw material, performance characteristics which in screw products differ significantly from others. The exception is resistance to impact low temperatures, below -50°C, and resistant to high temperature, above +300°C. Mechanical characteristics ISO 898. Stainless steel A frequently used raw material whose performance in finished screw products differs greatly, such as corrosion resistance, temperature resistance, weldability, magnetization, hardenability. Mechanical characteristics ISO 3506. Non-ferrous metals, aluminium, copper Raw material codes, strength characteristics, test methods and results, and characteristics are given in the standard ISO 8839 / EN 28839. Other materials such as brass and titanium No standards. In some cases, it may be recommended to use mechanical characteristics in accordance with steel screw standards. Plastics No standards.Carbon steel (ISO 898)

Standard ISO 898 is a seven-part standard covering metric bolts, screws, dowel pins and nuts with coarse and fine threads up to M39.

screws

The property class designation format is A.B, where:

A - hundredth of the tensile strength (R m =100×A);

B is the ratio of the conditional yield strength and tensile strength, multiplied by ten (R e =10×A×B).

For example, for bolts of strength class 8.8: R m =800 MPa, R e =640 MPa.

nuts

In the standard SFS-EN 20 298-2 Nuts with standard threads are defined.

In the standard SFS-EN 298-6 nuts with a frequent thread are defined.

The property class code is an integer that indicates the property class of the bolt onto which the nut can be screwed (the first number of the bolt property class). For low nuts, strength classes 04 and 05 are used.

washers

Unlike bolts, screws and nuts, the concept of a property class does not apply to washers. The main strength characteristic of washers is their hardness, measured by the Vickers method (for flat washers), Rockwell (spring washers, grover washers, washers for high-strength bolted joints), Brinell (bronze washers). Specific hardness values are regulated by GOST "s for the corresponding washers.

The properties of stainless steels are described in

The reliability of the structure mainly depends on the quality of the fasteners. After manufacturing, the bolts are subjected to some tests that allow you to determine the quality and possibly permissible loads on fastener.

The tensile test is carried out on tensile testing machines. The test sample is clamped on both sides with split inserts, and gradually stretched with an ever-increasing force. When a certain tension force is reached, the sample breaks. The force required to break the bolt is called the breaking weight. After the tensile test, the sample is examined for elongation, which determines the level of ductility of the metal.

The shear test is carried out by placing the bolt in special device, which consists of a plug and a disk (inserted into the plug). After that, the disk is removed, thereby producing a shear force on the bolt. The cut area is twice the section area, since the cut occurs simultaneously in two planes. Such a test is called a two-axis test. There is also a test for one axis: the bolt is placed in two dies, passing through them, which move in different directions. In this case, the cut plane will be equal to the section plane.

| Bolt diameter | thread pitch | Destructive shear force along one plane, (kg) | Breaking tensile force, (kg) |

|||||||||||||||||||||

| Steel 30HGSA | Steel 30HGSA |

|||||||||||||||||||||||

01.08.13

Steel and fastener strength

Machine-building fasteners can have a different purpose and perform a variety of tasks - from the simple formation of structural integrity to the perception of the main bearing force load on the structure. The greater the load on the fastener, the higher the strength it must have.

Depending on the purpose and field of application, fasteners are made of various strength classes, respectively, from different brands steels. There is no need to use high-strength bolts for fastening, say, a visor on a kiosk, and vice versa - it is completely unacceptable to use bolts of an ordinary, low, strength class in the critical structures of tower or gantry cranes - only high-strength ones are used here - hence the popular name for such bolts "". The desire to save money and use ordinary bolts - cheaper, or "crane bolts" but made from low-strength steels, leads to spectacular news on TV with a falling crane in the spotlight.

For various kinds fasteners (bolts, screws, nuts, studs) use different steels, different strength classes and their different markings.

Let's consider in order.

Bolts, screws and studs

Bolts, screws and studs are made from various carbon steels - different steels correspond to different strength classes. Although it is sometimes possible to make bolts of different strength classes from the same steel, using different ways workpiece processing or additional heat treatment - hardening.

For example, bolts of several strength classes can be made from Steel 35: strength class 5.6 - if bolts are made by turning on a lathe and milling machine: classes 6.6 and 6.8 - obtained by manufacturing bolts by volume stamping on a heading press; and class 8.8 - if the bolts obtained by the listed methods are subjected to heat treatment - hardening.

The strength class for bolts, screws and studs made of carbon steel is indicated by two digits separated by a dot. The approved strength range for carbon steel bolts, screws and studs contains 11 strength classes:

3.6; 4.6; 4.8; 5.6; 5.8; 6.6; 6.8; 8.8; 9.8; 10.9; 12.9

The first digit of the bolt strength class marking indicates 0.01 part of the nominal tensile strength - this is the tensile strength - measured in MPa (megapascals) or N / mm² (newtons per millimeter square). Also, the first digit of the strength class marking indicates ≈0.1 part of the nominal tensile strength, if you measure the tensile strength in kgf / mm² (kilogram-force per millimeter square).

Example: Stud of strength class 5.8: Determine the tensile strength

5/0.01=500 MPa (or 500 N/mm²; or ≈50 kgf/mm²)

The second digit indicates 0.1 part of the ratio of the yield strength (stress at which plastic deformation already begins) to the nominal temporary resistance (tensile strength) - thus for a stud of strength class 10.9, the second number means that a stud belonging to this class , the minimum yield strength will be equal to 90% of the tensile strength value, that is, it will be equal to: (10 / 0.01) × (9 × 0.1) \u003d 1000 × 0.9 \u003d 900 MPa (or N / mm²; or ≈90 kgf/mm²)

Example: Stud of strength class 5.8: Determine the yield strength

500х0.8=400 MPa (or 400 N/mm²; or ≈40 kgf/mm²)

The yield strength value is the maximum allowable working load of a bolt, screw or stud, beyond which an irreversible deformation occurs. When calculating the load on bolts, screws or studs, use 1/2 or 1/3 of the yield strength, that is, with a two-fold or three-fold safety margin, respectively.

Strength classes and steel grades for bolts, screws and studs

| Strength class | steel grade | Strength limit, MPa | Yield limit, MPa | Brinell hardness, HB |

|---|---|---|---|---|

| 3.6 | St3kp, St3sp, St5kp, St5sp | 300…330 | 180…190 | 90…238 |

| 4.6 | St5kp, St.10 | 400 | 240 | 114…238 |

| 4.8 | Art.10, Art.10kp | 400…420 | 320…340 | 124…238 |

| 5.6 | Art.35 | 500 | 300 | 147…238 |

| 5.8 | 500…520 | 400…420 | 152…238 | |

| 6.6 | Art.35, Art.45 | 600 | 360 | 181…238 |

| 6.8 | Art.20, Art.20kp, Art.35 | 600 | 480 | 181…238 |

| 8.8 | Art.35, Art.45, Art.35X, Art.38XA, Art.20G2R | 800* | 640* | 238…304* |

| 8.8 | Art.35, Art.35X, Art.38XA, Art.40X, Art.20G2R | 800…830** | 640…660** | 242…318** |

| 9.8* | Art.35, Art.35X, Art.45, Art.38XA, Art.40X, Art.30XGSA, Art.35XGSA, Art.20G2R | 900 | 720 | 276…342 |

| 10.9 | Art.35X, Art.38XA, S.45, Art.45G, Art.40G2, Art.40X, Art.40X Select, Art.30HGSA, Art.35HGSA, | 1000…1040 | 900…940 | 304…361 |

| 12.9 | Art.30HGSA, Art.35HGSA, Art.40HNMA | 1200…1220 | 1080…110 | 366…414 |

The table shows the most common and recommended steel grades in the hardware industry, but in various special cases other steels are also used when their use is dictated by additional requirements for fasteners.

Icons marked in the table:

* applicable to nominal diameters up to 16 mm.

** Applies to nominal diameters larger than 16 mm.

There are special standards for high-strength bolts for narrow industry applications, which have their own strength gradation. For example, the standards for high-strength bolts with an increased turnkey size used in bridge building - the so-called "": and the Russian standard.

The strength of bolts according to these standards is indicated by the value of the temporary tensile strength (strength limits) in kgf/cm²: that is, 110, 95, 75 etc.

These bolts are available in two versions:

| Bolt thread | Strength class bolts | steel grade | Strength limit, MPa(kgf/cm²) | Relates elongation, % | Impact strength of bolts of execution ХЛ, MJ/m² (kgf· m/cm²) | Max. Brinell hardness, HB |

|---|---|---|---|---|---|---|

| M16...M27 | 110 | 40X Select | 1100 (110)…1350 (135) | minimum 8 | minimum 0.5 (5) | |

| M30 | 95 | 950 (95)...1150 (115) | 363 | |||

| M36 | 75 | 750 (75)...950 (95) | ||||

| M42 | 65 | 650 (65)...850 (85) | ||||

| M48 | 60 | 600 (60)...800 (80) |

In the production of high-strength bolts according to these standards, steels 30Kh3MF, 30Kh2AF and 30Kh2NMFA are also used. The use of such steels allows to achieve even higher strength.

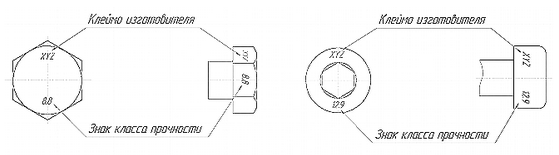

Strength marking of bolts, screws, studs

Metric Fastener Marking System Designed by Engineers ISO(International Standard Organization - International Standards Organization). Soviet, Russian and Ukrainian standards are based on this system.

Bolts and screws with a thread diameter of more than 6 mm are subject to marking. Bolts and screws with a diameter of less than 6 mm do not need to be marked - the manufacturer can apply the marking on his own initiative.

It should be noted that among the screws, only screws with a slot for a hex key are marked, with various form heads: , and . Screws with all types of head, having a cross or slot, are not marked with a designation of the strength class.

It should also be noted that bolts and screws made by cutting, turning (i.e. not stamping) are not marked - in this case, marking of the strength class is possible according to additional requirement Customer.

Marking marks are applied to the end or side surface of the bolt or screw head. If marks are placed on side surface heads, they must be in-depth. It is allowed to mark with convex signs, while the increase in the height of the bolt or screw head should not exceed:

- 0.1 mm - for products with a thread diameter of up to 8 mm;

- 0.2 mm - for products with a thread diameter from 8 mm to 12 mm;

- 0.3 mm - for products with a thread diameter over 12 mm

Bolts and screws with hexagonal and star-shaped heads (including products with a flange) are marked with the manufacturer's trademark and designation of the strength class. This marking is applied on the top of the head in raised or recessed characters; may also be applied on the side of the head in recessed characters. For, if during the production process it is impossible to mark on the top of the head, the marking is applied on the flange.

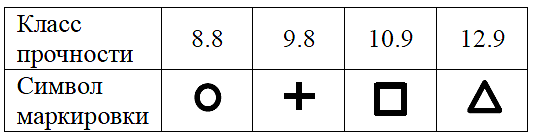

Stud marking

Studs are marked with strength class numbers only with a thread diameter of more than 12 mm. Since it is difficult to mark small diameters of studs using digital stamps, it is allowed to mark such studs with thread diameters M8, M9, M10, M11 using the alternative signs shown in the figure. Signs are applied at the end of the nut end of the stud.

The studs are marked by branding with in-depth marks and the designation of the strength class with the manufacturer's trademark on the threadless section of the stud. Studs of strength classes 5.6, 8.8 and higher are subject to marking.

nuts

Strength class for nuts made of carbon steels, and is denoted by a single number. The approved strength range contains seven strength classes:

4; 5; 6; 8; 9; 10; 12

This number indicates 1/100 of the tensile strength of the bolt with which the nut must be paired in pairs. threaded connection. This combination of bolt and nut is called recommended and allows you to evenly distribute the load in the threaded connection.

For example, a nut of property class 8 must be combined with a bolt whose tensile strength is not less than:

8 x 100 = 800 MPa (or 800 N/mm²; or ≈80 kgf/mm²)

Therefore, bolts of strength classes 8.8 can be used; 9.8; 10.9; 12.9 - a pair with a bolt of strength class 8.8 will be optimal.

Strength classes and steel grades for, and

| Strength class | steel grade | Strength limit, MPa | Brinell hardness, HB |

|---|---|---|---|

| 4 | St3kp, St3sp, St.5, St.5kp, St.20 | 510 | 112…288 |

| 5 | Art.10, Art.10kp, Art.20, Art.20kp | 520…630 | 124…288 |

| 6 | Art.10, Art.10kp, Art.20, Art.20kp, Art.35, Art.45, Art.40X | 600…720 | 138…288 |

| 8 | Art.35, Art.45, Art.20G2R, Art.40X | 800…920 | 162…288 |

| 9 | Art.35X, Art.38XA, Art.45, Art.40X | 1040…1060 | 180…288 |

| 10 | Art.35X, Art.38XA, Art.45, Art.40X, Art.30HGSA, Art.40HNMA | 900…920 | 260…335 |

| 12 | Art.30HGSA, Art.40HNMA | 1150…1200 | 280…335 |

The rule of thumb for matching nuts to bolts is to maintain the integrity of the threads of the nut threaded onto the bolt when the proof test load is applied - simply put, the nut must not "break" from the test load for the selected bolt during testing.

When selecting the strength classes of bolts and nuts mating in a threaded connection, you can use the following table according to GOST 1759.4-87:

| Nut strength class | Matching bolts |

|

| Strength class | Thread diameter |

|

| 4.6; 4.8; 5.6; 5.8; 6.6; 6.8 | ||

| from M16 to M48 |

||

As a rule, nuts of higher strength classes can replace nuts of lower strength classes. This replacement is recommended for bolt + nut connections where the stress will be higher than the yield strength or proof stress of the bolt.

Strength classes and steel grades for

Icons marked in the table:

* for nominal diameters up to 16 mm.

** for nominal diameters over 16 mm.

Together with high-strength bolts for narrow industry applications, which have their own strength gradation, corresponding high-strength nuts are used. For example, with the already mentioned "" according to and, nuts with an increased turnkey size are used according to standards and.

The strength of nuts according to these standards is indicated by the same value as that of a mating bolt - the value of temporary tensile strength (strength limits) in kgf/cm²: 110, 95, 75 etc. Such nuts, as well as bolts, can be produced in two versions:

- Execution U - for climatic regions with the lowest possible temperature up to -40 0 C - the letter U is not indicated in the marking

- Version HL - for climatic regions with the lowest possible temperature from -40 0 C to -65 0 C - is indicated in the marking on the bolt head after the strength class

| Mating bolt thread | Bolt steel grade | Nut strength class | Strength limit, MPa(kgf/cm²) | Nut steel grade | Brinell hardness, HB |

|---|---|---|---|---|---|

| M16...M27 | Art. 40X Select | 110 | 1100 (110) | Art. 35, Art.40, Art.45, Art. 35X, Art.40X | |

| M30 | 95 | 950 (95) | 229...341 | ||

| M36 | 75 | 750 (75) | |||

| M42 | 65 | 650 (65) | |||

| M48 | 60 | 600 (60) |

In the production of high-strength nuts according to these standards, steels 30Kh3MF, 30Kh2AF and 30Kh2NMFA are also used together with bolts from the corresponding steels. The use of such steels makes it possible to achieve even higher strength nuts.

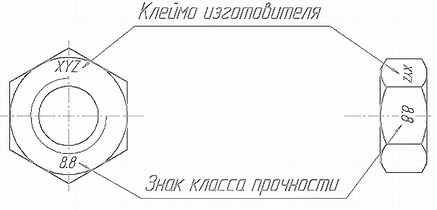

Hex nut marking

Mark nuts with a thread diameter of more than 6 mm. Marking marks are applied to one of the end surfaces. Nuts of the lowest strength class 4 are not marked.

In some technically justified cases, it is allowed to mark on the side surfaces (faces) of the nut.

Signs must be deep.

It is allowed to mark nuts according to the dial system. Such a system is mainly used on small nuts, when there is simply no room for digital signs. With this method, the marking is applied:

- recessed marks on the end surface - a dot at 12 o'clock and risks along the circumference of the side surface

- convex or recessed marks on the chamfers - a dot at 12 o'clock and risks along the circumference of the inclined surface of the chamfers

The correspondence of the marking with the strength class of the nut is shown in the diagram:

The 12 o'clock dot may be replaced by the manufacturer's trademark. In nuts of property class 12, the dot must be replaced by trademark manufacturer to avoid visual blending with a 12-hour mark.

Washer strength

Unlike bolts and nuts, which have strength classes quantified by numbers, based on tensile strength and ductility, washers carry loads in compression, torsion, shear, and are mainly designed to distribute the load in a bolted joint over a large area. In this case, for washers, the determining parameter is surface hardness, and hardness requirements are imposed on all types of washers. If we are talking about the strength class of the washers, then it is the hardness of the washers that is meant.

By analogy with bolts, screws and nuts, many refer to the hardness of washers as their strength class.

The strength class (hardness) of washers can be measured and designated in different units - depending on the method of measuring hardness: measurement methods are Vickers, Rockwell and Brinell. Dimensions, availability protective coating and in without fail hardness determine the scope of washers in various conditions work.

The most common Vickers method - washers can have a Vickers hardness of 100 units to 400, and are designated HV100, HV200, HV300 etc. According to Rockwell, hardness is denoted HRC, according to Brinell HB.