Gazelle in its history of production was equipped with many options for power units. So, there were ZMZ, UMZ, and other engine options. Of course, one of the most powerful options was the Cummins Gazelle engine, which was equipped with cars, mainly Business class.

Specifications

The Gazelle Business was provided with a Cummins diesel engine, which proved to be quite good and fell in love with drivers for its simplicity and reliability. But, the installation of Cummins internal combustion engines did not stop there, and with the release of Gazel NEXT in 2013, the tradition continued.

The main technical characteristics of the Gazelle power unit with a Cummins engine:

The device and principle of operation of the motor

It is necessary to start with the fact that the Cummins engine is very unpretentious in terms of fuel. This became available thanks to a new, modernized fuel purification system. The power unit has a new CommonRail fuel supply system. In this case, the fuel is fed directly into the combustion chamber under high pressure.

As for the gas distribution mechanism, everything is very simple and reliable. The cylinder head gasket consists of several steel sheets, which prevents it from burning out quickly, unlike other diesel engines.

A 4-valve gas distribution system is installed on the motor, which is mounted on the Gazelle, which ensures maximum technical characteristics and the necessary power. The timing chain has a tensioner chain, which ensures the reliability of the mechanism and sufficient strength. The camshaft is located according to the classical scheme.

Checking the valve clearances should be carried out every 80,000 km, but the valves must be adjusted every 250,000. The valve clearance rate is: 0.38 mm for intake, and 0.76 for exhaust.

Checking the valve clearances should be carried out every 80,000 km, but the valves must be adjusted every 250,000. The valve clearance rate is: 0.38 mm for intake, and 0.76 for exhaust.

The fuel pump has a rather complex structure, which almost eliminates the possibility of repairing it at home. But, due to its reliability, it continuously provides high pressure, which is 1800 bar.

Also, an electronic controller is installed, which provides quality control of the fuel supplied to the nozzles.

As for the cooling system, it is closed and can be configured for operation in different weather conditions. This becomes quite convenient, since there is a significant difference for engine operation in warm and cold regions.

Power unit repair

Repair of the Cummins Gazelle engine is recommended to be carried out at service technical stations. Although the design is simple, the motor has a number of nuances that the owner of the vehicle may not be aware of. So, the oil pump requires certain equipment in order for the repair to be of high quality. The fuel pump suffers the same fate, during the repair of which it is necessary to clearly set the gaps.

Maintenance of the power unit is carried out every 15,000 km. This process includes operations to replace engine oil, oil filter, as well as fine and coarse fuel filters. Also, maintenance carries out diagnostics of the fuel pump and injectors.

The injection elements are cleaned as they become clogged, but the manufacturer recommends doing the procedure every 50,000 km. This will extend the life of the injectors.

Overhaul also requires some equipment, therefore, in this case, the principle does not work - we repair it ourselves. Although some motorists carry out restoration work with their own hands.

As in any case, you can disassemble the power unit yourself, but it is impossible to bore the block and the crankshaft without special machines. Therefore, most of the owners of Cummins motors turn to car services. Although the motor has a resource of 500,000 km, they are not eternal.

Crankshaft boring is carried out to repair sizes of 0.25 mm, 0.50 mm and 0.75 mm. Further turning of the part weakens the hardness, which in turn increases the risk of breaking the crankshaft under heavy loads. The piston group is mainly bored to a dimension of no more than 95.5 mm, and then a block sleeve is provided, which is quite convenient.

The head of the block lends itself to a bulkhead completely. At the same time, valves, guide bushings and seats are changed. Following the American experience, it is best not to knock out the old guide bushings, but to install K-line bronze bushings that are placed inside the products. This allows you not to carry out a constant boring of the guide bushings and during subsequent repairs, just replace the bronze sleeves.

Conclusion

The Cummins Gazelle engine has established itself as a reliable and easily repairable power unit. The engine size allows not only to get the necessary power, but also to be quite economical with an average consumption of 10 liters per 100 kilometers.

The device of the engine is quite simple, which allows you to carry out repair and restoration work yourself without any problems. As for the oil pump, turbine and injection pump, it is recommended to repair them at specialized service stations, since the design is quite complicated.

The Kamens 2.8 engine (Cummins ISF 2.8L) is installed on vehicles manufactured by GAZ OJSC, in particular on commercial vehicles of the family, GAZelle Business and GAZelle NEXT.

Peculiarities The timing drive is carried out by a single-row chain with an automatic tensioner. The chain is located on the flywheel side (the chain and tensioner are maintenance-free). The injection pump is driven through a gear from the crankshaft to reduce the load on the timing chain. The engine is equipped with devices to facilitate starting at low temperatures. An electric coil is provided for heating the air in the intake manifold. The fuel filter is also electrically heated.

The Cummins ISF 2.8 engine has a very low fuel consumption - at a speed of 80 km / h it consumes only 10.3 liters of diesel fuel, at a speed of 60 km / h, and this is the average urban speed, it reduces diesel fuel consumption to 8.5 liters . Currently, the Cummins 2.8 engine is made in China.

The resource of the Kamens 2.8 engine is, according to the manufacturer, about 500,000 km.

Characteristics of the Cummins ISF 2.8 engine Gazelle Next, Business

| Parameter | Meaning |

|---|---|

| Configuration | L |

| Number of cylinders | 4 |

| Volume, l | 2,781 |

| Cylinder diameter, mm | 94 |

| Piston stroke, mm | 100 |

| Compression ratio | 16,5 |

| Number of valves per cylinder | 4 (2-inlet; 2-outlet) |

| Gas distribution mechanism | SOHC |

| The order of operation of the cylinders | 1-3-4-2 |

| Rated engine power / at engine speed | 88.3 kW - (120 hp) / 3200 rpm |

| Maximum torque / at revs | 297 Nm / 1600-2700 rpm |

| Supply system | with direct injection, turbocharging and charge air cooling |

| Resource | up to 500,000 km |

| Environmental regulations | Euro 3, Euro 4 |

| Weight, kg | 250 |

Design

Four-stroke four-cylinder diesel engine with an electronic Common Rail fuel supply system, with an in-line arrangement of cylinders and pistons that rotate one common crankshaft, with an overhead single camshaft. The engine has a closed-type liquid cooling system with forced circulation. Combined lubrication system: under pressure and spray.

Cylinder block

The Cummins ISF 2.8L cylinder block is made of gray cast iron with milled cylinder liners. This results in less material consumption and greater strength. In case of wear, scuffing, scratches or other damage, the sleeves can be repaired or replaced (possibility of re-sleeving).

cylinder head

The cylinder head is cast iron, 16-valve. A single camshaft is installed in the cylinder head, which actuates the valves in pairs through rocker arms (rocker arms of different shapes: they are short for intake valves, long for exhaust valves). A fuel injector is installed in the center of the cylinder. The cylinder head gasket is made of steel sheets (metal package) and does not require broaching.

Crankshaft

The crankshaft is made of malleable gray iron and balanced. The crankshaft pulley with the crown of the crankshaft position sensor is one-piece.

| Parameter | Meaning |

|---|---|

| Diameter of main journals, mm | 74,0 |

| Diameter of connecting rod journals, mm | 59,0 |

Inlet and outlet valves

All valves are made of heat-resistant steel with chrome-plated stems, have the same design, but are not interchangeable. All valves have a spherical socket, exhaust valves are distinguished by an engraved "C".

Service

Changing the oil in the Kamens 2.8 engine. The oil change interval in the Kamens 2.8 engine on Gazelle Business, Next cars is made every 15,000 km (7-8 thousand km are recommended). The oil is used in the API CH4 standard, viscosity - 10W40. Shell Rimula R5 E 10W40 engine oil is filled from the factory.

The amount of oil in the engine - with the replacement of the oil filter is about 5.7-5.8 liters, the volume of the oil filter is 0.44 liters.

The catalog number of the oil filter for the Gazelle Next with the Kamens engine is LF17356.

Valve clearance adjustment necessary with a run of 150 thousand km (from practice, approximately 80-100 thousand km). Adjustment unit - screw and nut. Intake clearance - 0.25 mm, exhaust clearance - 0.5 mm.

In 2010, the production of a new family of GAZelle vehicles began, which received the prefix "Business" to its name. Among the innovations of these machines is a complete set of American Cummins diesel engines. In this article, we will look at the most popular GAZ-3302 light truck with Cummins ISF 2.8 engine.

Review of GAZ-3302 with Cummins ISF 2.8 engine

In 2010, the Gorky Automobile Plant launched the production of a new family of GAZelle-Business vehicles - old modifications of GAZelles have undergone major changes, they have become more reliable and modern. A few months later, sales of several more GAZelle-Business modifications, equipped with an American-made Cummins diesel engine, started.

All major modifications of GAZelles are equipped with diesel engines - the GAZ-3302 onboard platform (also 330202, 33023, 330232, 33027 and 330273), the GAZ-2705 all-metal van (and 27057) and the GAZ-3221 passenger minibus (also 32212, 32213, 3221 7, 322173, 322132 and 322123). Since 2013, Cummins diesel engines have also been installed on new GAZelle-Next trucks.

In terms of their main characteristics, diesel modifications of GAZelle trucks do not differ from gasoline ones, however, the transmission has been redesigned in them (gearboxes and drive axles have different gear ratios, which is due to the use of a low-speed diesel engine), changes have been made to the electrical equipment, to the cooling system of the power unit, to the system exhaust gases, etc.

To date, diesel modifications of these trucks occupy a significant share in the GAZ model range and are in stable demand from the consumer.

Diesel engine Gazelle Next or the Cummins ISF2.8s4129P, the engine that generations of GAZ small truck and van owners dreamed of. Low fuel consumption and huge torque, perhaps these are the main requirements for buyers of commercial vehicles. 4-cylinder diesel, turbocharged and aftercooled power unit with a working volume of 2.8 liters is quite an interesting option, which we will talk about in more detail.

Cummins engines for Gazelle are supplied from China, where they are assembled at the Beijing plant of the American corporation Cummins. The American manufacturer of diesel engines has quite a few factories around the world. In addition to the 2.8-liter unit, the GAZ conveyor receives a more powerful Cummins ISF 3.8-liter diesel engine for medium-duty trucks and buses.

Once every 15 thousand kilometers, the diesel Gazelle Next requires an oil and filter change. Ignoring the maintenance schedule by a certain manufacturer is fraught with problems in the future. Poor quality fuel and oil can kill the engine pretty quickly. Under normal operating conditions, a Gazelle Next with a Cummins engine can easily cover 500,000 kilometers without major repairs.

First, let's talk about the main technical characteristics of a turbodiesel. With a rather large volume of 2.8 liters, the power of the unit is 120 horsepower, but the torque is an impressive 270 Nm (although there are more powerful versions). A feature of the engine can be considered that the maximum torque is already available from 1400 rpm. That is, there is no need to turn the engine to maximum speed in order to normally drive a gas lorry and still carry a couple of tons of cargo.

Characteristics of the Gazelle Next diesel engine

- Working volume - 2800 cm3

- Number of cylinders - 4

- Number of valves - 16

- Cylinder diameter - 94 mm

- Piston stroke - 100 mm

- Timing Drive - Chain

- HP power (kW) - 120 (88.3) at 3600 rpm in min.

- Torque - 270 Nm at 1400-3000 rpm. in min.

- The order of operation of the cylinders is 1-3-4-2

- Minimum rotation frequency - 750 revolutions

- Fuel type - diesel

- Fuel consumption at constant movement of 60 km / h - 8.5 liters per hundred

- Fuel consumption at constant movement of 80 km / h - 10.3 liters per hundred

Cummins engine device for Gazelle Next

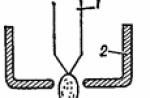

Inline 4 cylinder 16 valve engine with cast iron cylinder block and cast iron cylinder head with overhead camshaft. A single camshaft is installed in the cylinder head, which rotates by means of a chain drive that comes from an intermediate gear. The rotation of the oil pump, high pressure fuel pump is carried out using gears. The main gear sits on the crankshaft and drives the Common Rail injection pump drive gears, plus the timing gear, which transmits torque through the chain to the camshaft. The rotation of the water pump is carried out by a V-ribbed belt, which also rotates the fan through a viscous coupling. The scheme of the gear drive and timing chain in the photo below.

Cummins engine block head for Gazelle Next

The cylinder head has a design with vertically standing valves. At the same time, there are 16 valves, that is, 4 per cylinder. The camshaft transmits the force to open the valves through the rocker arms. The camshaft cams touch the rollers mounted on the rocker arms, driving them.

There are only 8 rocker arms, under their influence two valves come off at the same time. A very important point is the timely adjustment of the thermal clearance of the valve. It is carried out every 120 thousand km. The adjustment unit is elementary, consists of a screw and a nut. All this can be seen in the photo below.

If the valves are not adjusted, then at one fine moment the valve will squeeze a little more than the permissible into the combustion chamber and the valve will meet the piston, and this, as you understand, is a very expensive repair.

By the way, the same Cummins 2.8 engine, but with different settings, can produce 149.6 horsepower with a torque of up to 330 Nm. The increased power unit has been put on some modifications of the GAZelle Next since the fall of 2015. The increase in power was due to new turbo settings and a flashing of the electronic control unit. True, at the same time it was necessary to strengthen the transmission. The ZF Sachs clutch now comes with a larger driven disc diameter, up from 240mm to 280mm. Reinforced bearings and new synchronizers appeared in the gearbox. The design of the rear axle has also been modernized, in particular, the drive gear bearing has been strengthened.

The model of the Gorky Automobile Plant "GAZelle" is well known on the territory of the Russian Federation and abroad. This commercial vehicle has been in great demand since the moment it appeared on the market due to the successful combination of a number of unique technical characteristics and an affordable price.

Relatively recently, these trucks of this brand have been seriously modernized. As a result, an updated GAZelle Next model appeared, which is equipped with both a gasoline and a diesel engine. Taking into account the fact that it is more in demand for commercial vehicles, then we will consider the features of the GAZelle Next diesel.

Read in this article

Upgraded diesel engine for GAZelle Next

As a result, the initial power of this motor has increased from 120 hp. up to 149 "horses". However, it is noteworthy that it also increased markedly (from 270 Newtons to 330 Nm). Thanks to this forcing, acceleration dynamics has improved both in low and high gears, the “shelf” of torque has become more even and longer. The truck was able to overcome steep climbs with a full load, the engine became more elastic.

Acceleration of the GAZelle Next with a modified Cummins diesel engine was reduced by 15% to 60 km/h and to 100 km/h. Also, in increased 5th gear, the car accelerated 30% faster from 40 km/h to 100 km/h. The specified 150-horsepower diesel engine with higher power is installed on all models of the cargo version of the GAZelle Next.

The previous version for 120 hp. can only be found on small buses. At the same time, the cost of updated cars with an upgraded diesel engine does not change compared to previous versions.

Characteristics and features of the Cummins diesel on the GAZelle

Pistons are a compound type solution. The piston skirt is made of aluminum alloy, the upper part is additionally overlaid with heat-resistant material. differs in that it has cemented necks, and the product itself is of increased strength, which excludes the possibility of processing. This means that the shaft in case of wear must be completely replaced. Also, the manufacturer does not provide for the replacement of liners, repair kits are not available.

Why a diesel engine does not need to be twisted like a gasoline engine. Features and differences of diesel internal combustion engines in comparison with gasoline. Optimal turnover.