Its main purpose is to distribute, change and transmit torque, and if necessary, to ensure the rotation of two consumers with different angular velocities.

Axle differential is a differential designed to drive the drive wheels, but if it is installed between the drive axles in an all-wheel drive vehicle - the center interval.

As a rule, the differential of the car is located in the following places:

- Driving axles in an all-wheel drive vehicle - in transfer case

- Driving wheel drive in an all-wheel drive vehicle - in the crankcase of the rear and front axle

- Driving wheel drive front wheel drive car- in the gearbox

- Driving wheel drive rear wheel drive car- rear axle housing

The differential is based on a planetary gearbox. The type of gear used in the gearbox conditionally divides the differential into the following three types:

- Worm

- Cylindrical

- Conical

Worm gear is the most versatile differential and can be installed both between axles and between wheels. The cylindrical type, as a rule, is located in cars between the axles. The conical type is mainly used as an interwheel.

There are also asymmetrical and symmetrical differentials of the car. The asymmetric type is installed between two drive axles and allows the transmission of torque in various proportions. The symmetrical type, as a rule, is installed on the main gears and allows the torque to be transmitted to two wheels of equal value.

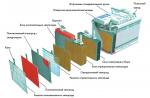

Automobile differential device

The main elements of the differential are:

- Side gears

- Pinion gears

- Frame

Diagram of a front-wheel drive car differential:

1 - driven gear of the main gear; 2 - a fragment of the main gear; 3 - axis of the satellites; 4 - satellite; 5 - differential case; 6 - right flanged shaft; 7 - stuffing box; 8 - conical roller bearing; 9 - side gear; 10 - left flanged shaft; 11 - a fragment of the gearbox housing.

Satellite gears, in their principle of operation, resemble a planetary gearbox and serve to connect the housing and side gear to each other. The latter, in turn, are connected by splines to the drive wheels. Various designs use four or two satellites, in cars the second option is more commonly used.

Differential cup or housing - its main purpose is to transmit torque from the main gear to the side gears through the satellites. Inside it are the axis for the rotation of the satellite.

Sun gears or semi-axial gears - designed to transmit torque with the help of semi-axes to the drive wheels. The left and right gears can have either the same or different number of teeth. In turn, the gears different number teeth are used to form an asymmetrical differential, and with the same number - for a symmetrical one.

The principle of operation of an automobile differential

The differential works as follows: by rotating one of the driving wheels of the car, the second will begin to rotate in the opposite direction, but the immobility condition must be met cardan shaft. IN this case stellites rotate in their axes, playing the role of a gear.

If you start the engine and engage the clutch and any of the gears, it will begin to rotate cardan shaft, transmitting its torque through the cylindrical and bevel gears of the differential box.

Thus, while the car is moving along a curved trajectory, one wheel slows down, while the second, on the contrary, increases it. As a result, slipping and slipping of the wheels are eliminated and each of them rotates at the speed that is necessary for safe movement.

When the car is moving in a straight line, nothing much happens and the differential transmits torque to both wheels in the same ratio. The semi-axial gears rotate with the same angular velocity, since the satellites in this case are in a stationary state.

When moving to slippery surfaces differential has one significant disadvantage- it can cause a side skid of the car, since the slipping wheel has low adhesion to the coating and it starts to rotate at idle.

The simplest car differentials have another drawback. When dirt or other third-party elements get between the splines, the torque can be transmitted in a different ratio, even 0 to 100. Thus, one wheel will remain in a completely static position.

Modern models are practically devoid of this drawback. Their device is different manual or automatic more rigid. Moreover, in many cars modern machines stabilization systems are installed and exchange rate stability, allowing to optimize the distribution of torque depending on the trajectory of the car.

How the differential works - video:

That's all, now you know the differential device.

In construction modern cars there are a number of components and assemblies that are mandatory for all their brands, models, types and types. These include, first of all, the engine, gearbox, brake system. The list also includes a differential.

There is a differential in any car, and in some cars there are several of these nodes. Experienced motorists are well aware of what a differential is in a car, what role it plays and what varieties it can be. For those people who are still just novice motorists, it will certainly be useful to know about this.

The conical differential of the car: 1 - cardan shaft; 2 - axle shaft of the drive wheel;

The differential is a mechanism by which the same torque is transmitted to the wheels of the same axle, rotating at different speeds. In addition, the differential is used to evenly distribute torque between several drive axles.

The basis for the design of any automotive differential working principle planetary gear. Depending on what type of rotary motion transmission is used, there are such types of differentials as:

- Conical;

- Cylindrical;

- Worm.

Between wheels mounted on the same axle, a bevel differential is almost always installed. The cylindrical differential is usually used as a center differential, and the worm gear is distinguished by the versatility of its application. The most widely used differentials of the conical type, which are installed on almost all vehicles as cross-axle. All their main elements are also available in cylindrical and worm differentials.

The housing of the bevel differential (often referred to as a bowl) receives torque from the main gear and transmits it to the gears of the axle shafts through the so-called satellites. They perform the functions of planetary gears, and as for their number, then, depending on the design features of a particular bevel differential, they can be from two to four.

If the car is moving along a straight path, the resistance of each of the wheels to the road is the same. In this case, the rotation of the satellites does not occur, and the rotation of the semi-axial gears is carried out with equal angular velocities. At the time of the turn, one of the wheels, that which is on the inside of the turn, meets more resistance from the road, the rotation of its side gear becomes slower, the satellites begin to rotate. As a result of this, the speed of rotation of the outer wheel increases, but the torque remains the same as on the inner wheel.

When moving along slippery road when one wheel spins and moves at a slower speed, the situation is similar to the situation with a turn, as a result of which the car often simply cannot move. In order to increase the torque on one or the other wheel, a differential lock is used.

Varieties of automotive differentials

In addition to bevel, cylindrical and worm, the following types of differentials exist and are successfully used: complete blocking, Thorsen differential, Quaif differential, viscous coupling.

Full lock differential

This type of differential is most commonly used on trucks and SUVs. Their blocking is turned on and off directly from the passenger compartment using a special key by the driver. They are used to increase the cross-country ability of vehicles.

Differentials Thorsen

The design of Thorsen differentials was developed German company Siemens. In fact, they are combinations of bevel and worm differentials. Thorsen differentials are different high efficiency However, they are quite difficult to manufacture and maintain.

Quaif differentials

A distinctive feature of this type of differentials is that the satellites in them are located parallel to the axis of rotation of the body (bowl), and in two rows. In addition, during the operation of these units, friction forces are formed, which, if necessary, automatically block, increase the cross-country ability and traction force of the car. Most often, Quaif differentials are used for tuning cars and SUVs.

viscous coupling

The operation of this type of differential is based on the same principle as the operation of a torque converter. Most often, viscous couplings are used in cars with all-wheel drive and are used to ensure the connection of the front wheels with the rear ones according to the following principle: if one of them slips, then the torque is transmitted to the others, due to which the problem of slippage is solved. Structurally, a viscous coupling is a cylinder in which there is a package of perforated metal disks immersed in a viscous liquid and connected to the shafts (both driving and driven). Depending on the temperature, the viscosity of the liquid changes, on which the principle of operation of this unit is based.

The use of differentials, their advantages and disadvantages

In those vehicles that have only one leading axle, one differential is installed. Vehicles with two or more driven axles are equipped with differentials installed in each of them. In vehicles with cross-country ability, having two leading axles, three differentials are installed: one for each of the axles and one between them. In the same vehicles that have more than two driving axles, so-called inter-bogie differentials are used.

When the car moves in turns, the wheels of the drive axle travel a path of different lengths. In order for the tires not to slip, the wheels must rotate at different speeds. Consider: what is a differential and the principle of its operation, what are the varieties.

What it is?

The differential is a mechanism that allows the wheels of the drive axle to rotate at different speeds and the same torque supplied to them. In a transmission with one drive axle, the differential is installed between the wheel drives (cross-axle). IN all-wheel drive cars it can be located between the leading axles (interaxle).The product of the traction force and the radius of the wheel gives the torque that the differential must transfer to the wheels. When traction is poor or one wheel is out, there is very little or no torque and traction at the wheel, and the vehicle will not be able to continue driving. This is a feature of the bevel gear differential, which has become widespread. This type of differential is called symmetrical, as it equally distributes torque between the wheels.

This is because the satellite works as an equal-arm lever and transmits only equal forces to the gears of the axle shaft, and, accordingly, to the drive wheels. If one of the wheels has little traction pavement, then the effective torque on it is small, respectively, a symmetrical differential will bring the same force to the other wheel. That is, if one wheel is slipping, the traction force on the second is zero, which negatively affects the patency.

To improve it on cars, full or partial differential locks are used, the degree of which is estimated by the locking coefficient.

Blocking coefficient (Kb) - the ratio of the torque on the lagging wheel to the moment on the running wheel. Its value for a symmetrical differential is always 1, for limited slip differentials from 1 to 5. The more Kb, the better patency car. That is, at Kb = 3, the moment on the lagging wheel will be three times greater than on the slipping one. But the moment on the wheel in this second will be possible from 20 to 70%, depending on the possibility of the blocking mechanism.

There are several types of differentials.

Full lock differential

Forced differential lock is used mainly on SUVs and trucks to improve off-road capability. Turns on with a key in the cabin, as needed. It is very important to disable the lock when driving on dry ground, in order to avoid breakage of the axle shafts. An example is a center differential lock on a VAZ-2121. It is forced into action by the driver. The angular velocities of the wheels are always equal here, which contradicts the conditions for the car to move along a curve, leads to rubber wear and deterioration of controllability on a hard surface.

An example is a center differential lock on a VAZ-2121. It is forced into action by the driver. The angular velocities of the wheels are always equal here, which contradicts the conditions for the car to move along a curve, leads to rubber wear and deterioration of controllability on a hard surface.

viscous coupling

Viscous coupling is a multi-plate clutch in which transmitted torque increases with an increase in the difference between the speeds of the driving and driven shafts. It is used in simplified permanent all-wheel drive systems and as a locking mechanism for differentials.The principle of operation of the viscous coupling is based on the special properties of a special silicone fluid: when the temperature rises, its viscosity does not decrease, as, for example, with oil, but increases. The viscous coupling is a cylinder filled with silicone fluid. Inside it is a package of perforated discs connected through one, respectively, to the drive and driven shafts.

IN all-wheel drive transmission at normal conditions shafts rotate at approximately the same speed: the input shaft is driven by torque from the main drive axle, and the output shaft rotates the wheels to which it is connected. When slipping the wheels of the main drive axle input shaft rotates faster than the output (the machine is practically stationary), the fluid heats up from friction against the discs, and the clutch begins to transmit greater moment to the output shaft.

IN all-wheel drive transmission at normal conditions shafts rotate at approximately the same speed: the input shaft is driven by torque from the main drive axle, and the output shaft rotates the wheels to which it is connected. When slipping the wheels of the main drive axle input shaft rotates faster than the output (the machine is practically stationary), the fluid heats up from friction against the discs, and the clutch begins to transmit greater moment to the output shaft.

A significant drawback of the viscous coupling is that it takes time for the clutch to actuate, and it is difficult to find its optimal characteristic. Therefore, many manufacturers refuse to use viscous coupling in favor of electronically controlled multi-plate clutches.

Thorsen

From English. TORQUE - torque and "SENSING" - sensitive, that is torque sensitive. The satellites are located in the housing perpendicular to its axis, connected to each other in pairs by means of a spur gear, and connected to the side gears by a worm gear. In turn, the semi-axial gear connected with the lagging wheel turns the satellite that engages with it, which, in turn, rotates the second satellite and the axle gear. Such a rigid kinematic connection provides the wheels of the car with the ability to rotate with different speed. The friction forces arising in the worm gear from the difference in the moments on the wheels carry out the differential lock. The disadvantage of the design is the complexity of manufacturing, assembly of the unit as a whole and repair.

Such a rigid kinematic connection provides the wheels of the car with the ability to rotate with different speed. The friction forces arising in the worm gear from the difference in the moments on the wheels carry out the differential lock. The disadvantage of the design is the complexity of manufacturing, assembly of the unit as a whole and repair.

quief

The satellites are arranged in two rows parallel to the body rotation axis. Moreover, they are not mounted on axes, but are located in the openings of the body closed on both sides. The right row of satellites (there can be from 3 to 5) engages with the right gear of the axle shaft, the left row with the left one. In addition, the satellites from different rows are engaged with each other through one. When one of the wheels begins to lag behind, the semi-axial gear associated with it begins to rotate more slowly than the differential housing and turn the satellite that engages with it. It transmits the movement to the satellite associated with it, and that, in turn, to the side gear. This ensures different wheel speeds in a turn.

When one of the wheels begins to lag behind, the semi-axial gear associated with it begins to rotate more slowly than the differential housing and turn the satellite that engages with it. It transmits the movement to the satellite associated with it, and that, in turn, to the side gear. This ensures different wheel speeds in a turn.

Due to the difference in torque on the wheels, friction forces arise that block, which increases the traction force of the car, increasing its cross-country ability. Differentials of this type have received most widespread in tuning.

Let's start with what this car itself means technical term in a language that the common man can understand. An automobile differential is what makes up the transmission and what makes it possible for the wheels to spin asynchronously, that is, each wheel is independent of each other and rotates separately.

In scientific terms, (from Latin differentia - difference, difference) a car differential is a device that divides the incoming energy (torque) supplied to the input shaft between the output shafts. A simple and understandable explanation expands horizons. Girls are also interested in the work of machine mechanisms.

Reason for use in car designs

During the turning of the car, the leading drive wheels rotate at the same speed and as one wheel of the car makes a turn in a long arc, and the other in a short one, slip occurs, which is bad and is accompanied by tire wear and causes discomfort to the driver due to a decrease in the quality of the car's dynamics.

Purpose of the differential

- allows the drive (driving) wheels to rotate at different angular speeds

- serves as a separate additional gear paired with the main gear. main gear- This gear mechanism transmission of the car, which transmits torque to the drive wheels.

- continuously transmits torque from the engine to the drive wheels.

At front wheel drive cars main gear and differencial are located directly in the gearbox.

At front wheel drive cars main gear and differencial are located directly in the gearbox.

If more than one engine is installed on the vehicle, one engine per wheel, then the differential is not required. But they don't usually do that. Install 4 engines, one for each wheel, only on Belaz dump trucks. These motors are electric.

In the device of racing karts, a differential is also not installed, since the frame design is flexible, which allows you to slightly raise the rear drive wheel with inside turn without lifting the front wheels.

in figure a) - the wheels rotate at the same frequency, in figure b) - the movement of the wheels on a turn

1 - axis of satellites, 2 - driven gear, 3 - side gears, 4 - satellite,

5 - drive gear, 6 - axle shafts.

On racing cars differencial rallies are usually welded, hard-blocked and tightly connected to the wheels on the drive axle. This is used because such cars when driving, all turns pass with a skid.

How the differential works

Operating principle. The main gear transmits torsional energy through the gear to the housing and satellites, which are engaged with the gears of the axle shafts.

When the speed of rotation of the wheels is the same, the satellites sit motionless (see pictures below).

When the angular speeds of the wheels change, for example, when turning or slipping due to uneven roads, and so on, the satellites rotate. Satellites are used to compensate for the difference in wheel speeds.

Consider an example - a car slips on ice. Here, one wheel is slipping, because there is no grip on the ice, which means there is no torque. And since the free blocking device distributes traction equally to the wheels, if there is no torque on one wheel, then it disappears on the second.

The way out of this situation is to create an opposing force on the opposite wheel. And that's what blocking does. It is necessary to block the slipping opposite wheel and then there will be an opposing force for the opposite wheel.

How a differential works on a four wheel drive vehicle

On jeeps, sedans, hatchbacks and station wagons 4x4, if a free symmetrical differential is installed, the following situation occurs. While driving without slipping, 25% of the torque energy is distributed equally to each wheel.

But if one wheel is slipping, for example on ice, the torsional energy is reduced to zero because the wheel cannot grip the smooth surface of the ice. In such a situation, if one wheel is left without rotation, then the energy of rotation disappears on the opposite neighboring wheel, because in this example installed symmetrical center.

But if one wheel is slipping, for example on ice, the torsional energy is reduced to zero because the wheel cannot grip the smooth surface of the ice. In such a situation, if one wheel is left without rotation, then the energy of rotation disappears on the opposite neighboring wheel, because in this example installed symmetrical center.

It turns out that one axis was left without rotation, and therefore the torque on the second axis also disappears, since the differencial center axle is symmetrical. The result is no rotation on all 4 drive wheels.

A differential is a device that controls the distribution of torque from the input shaft to the output, while the speed of each individual element may differ. The mechanism is widely used in the automotive industry.

Differentials differ according to the installation location, purpose and design features:

- In cars with a drive on one axle, only one differential is used, called the cross-axle. Its necessity is caused by the fact that the outer and inner wheels travel different distances when turning the vehicle.

- Cars with 6×6 or 8×8 drives contain an additional bogie differential in the design.

- In all-wheel drive models, as many as three differentials are installed: two interwheel and one interaxle.

We will talk about how the center differential works, and what kind of center differentials can be in general, we will talk in more detail later.

The purpose of the center differential

The center differential is designed to distribute torque between the driving axles of the car and allows them to rotate at different angular speeds. This need is caused simple condition movement of vehicles on uneven surfaces, when the own weight of the structure presses on the axle, which is in a lower position. So, when driving downhill, a significant part of the moment is fed to rear wheels. And, vice versa, in the case of descent.

The center differential device is installed, as a rule, in the transfer case of the car. The center differential can be symmetrical or asymmetrical. The first distributes the torque between the axles equally, and the second - in a certain ratio.

In addition, there is an interaxle differential without a locking mechanism that allows the axles to rotate at different speeds, as well as a self-locking differential or with a manual locking mechanism that forcibly distributes torque between the drive axle shafts, depending on road conditions. Wherein forced blocking center differential implies a complete or partial shutdown of the differential, providing a rigid connection between the front and rear axle shafts.

Most often for full implementation all-wheel drive capabilities of the car, a self-locking differential is used, which can have three types of designs and different principles work accordingly.

Designs and principle of operation of a self-locking center differential

So, there are three types of self-locking center differential:

- viscous coupling;

- lock type Torsen;

- friction clutch.

Center differential with viscous coupling

The scheme of the center differential with viscous coupling is a planetary symmetrical scheme on bevel gears. This design assumes the presence of a viscous coupling control element, which consists of the following elements:

- frame;

- housing shaft;

- drive shaft;

- driven shaft;

- disks;

- side gear;

- seals.

The coupling in its design has a hermetically sealed cavity filled with an air-silicone oil mixture. The cavity is kinetically connected with two disk packs, which are connected to both axle shafts.

Principle of operation:

When moving in a straight line on a flat surface and with constant speed the center differential transmits the engine torque to the front and rear drive axles in a ratio of 50 to 50. If one of the disc packs starts to rotate faster than the other, then pressure increases in the hermetic cavity of the clutch, and it begins to mechanically slow down (i.e. block) this pack, thereby equalizing angular speeds rotation.

The following examples can easily explain why a viscous center differential is needed:

- In case of departure vehicle on a slippery surface, which leads to a strong slip of the front wheels, due to a significant increase in pressure in the clutch. As a result, much more torque is delivered to the rear wheels.

- Distribution of moment in favor front wheel drive occurs when the vehicle accelerates rapidly on a slippery surface. In such a situation, the center of gravity shifts forward, and the front axle becomes the leading one.

The design with a viscous coupling has become widespread due to the simplicity of the design and its low cost. The disadvantages include the lack of a manual blocking function, the possibility of overheating during long-term operation, incomplete automatic blocking, and the conversion of a significant part of the kinetic energy into thermal energy.

Center differential with lock type Torsen

The design of the working drive of this system consists of the following units:

- frame;

- right side gear;

- left side gear;

- satellites of the right and left side gears;

- output shafts.

It is worth noting that the Torsen differential has the most advanced design.

Principle of operation:

Torsen interaxal locking differential consists of driven and driven worm wheels, otherwise called semi-axle and satellites. In such a system, blocking occurs due to the peculiarities of the functioning of the gears. of this type. In the normal state, they are given a certain gear ratio. If the wheels are good grip with the surface and move smoothly, the differential works in exactly the same way as a symmetrical one. But as soon as there is a sharp increase in torque, the satellite tries to start moving in reverse side. The side worm gear is overloaded and the output shafts are blocked. In this case, the excess engine torque is transferred to another axis. The maximum degree of torque redistribution for Torsen differentials is 75 to 25.

The most famous variation of this system is Torsen Audi Quattro. This is one of the most popular mechanisms in the designs of modern four-wheel drive vehicles. Its undeniable advantages are a wide range of torque transfer, instant response speed and the absence of a negative effect on brake system. But the disadvantages include the complexity of the design with all the attendant consequences.

Center differential with friction clutch

The slip-clutch lock is far superior to the designs described above because both automatic and manual differential locks are available. Structurally, it is very similar to a viscous coupling and differs only in the main working elements.

- frame;

- housing shaft;

- drive shaft;

- driven shaft;

- friction discs;

- seals.

Principle of operation:

The principle of operation of the center differential of this kind is quite simple. With uniform smooth motion, the angular velocities are distributed equally between the axes. If one of the semi-axes begins to rotate at an increased speed, the friction discs approach and slow it down due to friction forces.

However, due to the complexity of the design and maintenance friction differentials not used by manufacturers stock cars despite its obvious advantages. In addition, a significant disadvantage of such a system is rapid wear working elements, which means a small resource of its work.

Haldex locking system

But it is worth saying that on the basis of the design of the center differential with a friction clutch, back in 1998, the Swedish plant Haldex produced its own alternative system. It was based on the operation of an electro-hydraulic bundle of elements. Ta old version The system was more of a failure than a success, but gave rise to several modifications, the last of which became quite popular.

Haldex 4th generation, released in 2007, was a real breakthrough. The main working planes of the system are friction discs. Through them, the torque from the engine is transmitted to the axle shafts. One of the innovations was complete failure manufacturer from being used as a working drive hydraulic pump. It was replaced by a powerful all-electric pump.

But the most interesting change was the transformation of the system into a fully electronic one. So, the inclusion of the clutch and the blocking of the axle shafts no longer depend on the speed of rotation of a single wheel. The operation of the system is controlled through the electronic unit control, which receives all the necessary information from motion sensors. In addition, one of the main signals for engaging the clutch in operation is pressing the gas pedal. Acceleration is almost always accompanied by a certain amount of slippage, so locking is most welcome.

Haldex 4 is called by many the most modern system for vehicles with all-wheel drive. Especially often Haldex is installed on modern SUVs With center differential Asian production. Its main advantages are simplicity of design, reliability and operation throughout the entire driving time. And here main disadvantage– the impossibility of transferring more than 50% of the power to rear axle rotation.