SS20 Racing lower springs is a new addition to the SS20 SPORT product range for drivers who prefer a fast, active driving style. These are springs for those who care not only appearance car, but right job suspension and steering when lowering the clearance, confidence and safety on steep turns.

SS20 Racing lower springs have the following features

- Made from high quality Japanese steel cold winding, which significantly increases the resource of use;

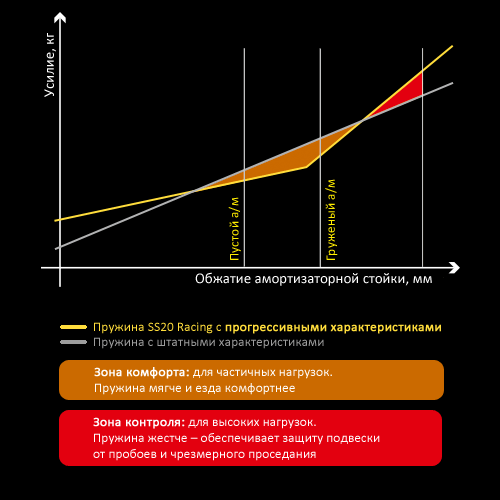

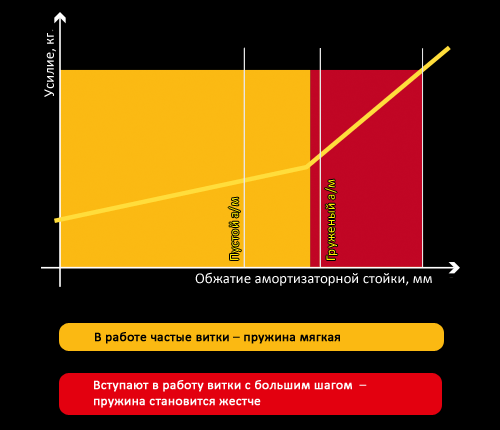

- have progressive characteristics: optimal suspension stiffness at low loads and a proportional increase in stiffness with increasing vehicle load, with roll in a turn or extreme braking;

- matched in pairs with identical characteristics, which ensures an even lowering without body distortions;

- work without shrinkage 2 times longer than hot-rolled springs;

- the weight of the springs is reduced by up to 25% compared to the regular ones (depending on the car model);

- have a durable and resistant powder coating that protects against corrosion;

- have a polyurethane protective braid that protects the coils from damage when closing;

- when fitted with SS20 Racing Series shocks, these springs offer your choice of -30, -50, -70, or -90mm drop.

Or clearance reduction- one of the most modern trends in tuning today. To give their car confidence to drive, stability when maneuvering at a decent speed, and just to make it more stylish and sportier, car owners use different methods.

Someone from a lack of information or finances simply cuts the springs. It is not necessary to expect a super-effect from such economy tuning. But cheap, and outwardly the car looks sporty and stylish. But you have to pay for this with convenience - you drive “like on a stool”, a strong vibration loosens the interior and everything starts to rattle. But even this is not the main thing: when cutting standard springs, it is impossible to achieve their identical characteristics, and this method leads to deformation and weakening of the body, gradual destruction of the front suspension cups, hard metal impacts on the body, and cracks. And this is irretrievable serious losses, which significantly reduce the performance and cost of the car.

Another option - having the financial capacity, you can buy expensive details pendants from the best manufacturers and put it all together. But it is not a fact that after that you will get what you dreamed about. Because to lower the car, you need not only good expensive pieces of iron, but also their coordinated work and the correct calculation of each suspension element. Moreover, it is necessary to take into account the changes made to the suspension geometry, and try to maintain the controllability and comfort of the car, and not disrupt the operation of the brake system.

We hope that the previous arguments were convincing. All this led us to the creation of KITs for lowering (“sets” - translated from English), in which springs play one of the main roles in lowering. Springs - it seems, what could be simpler - a piece of wire twisted into a spiral, that's all. But for some reason, not every manufacturer can produce high-quality, reliable and durable springs that will work stably, not sag over time, and, most importantly, will be made exactly according to the calculated parameters.

Good springs are technologically sophisticated products made of high quality metal. Work load lowered spring significantly higher than normal. Springs with lowering(sport springs) take the same bumps from the road as regular ones, but they are short, and should absorb bumps for less suspension compression travel.

The SS20 Racing lower springs were designed and tested with this feature in mind. As a result, due to special Japanese steel, the use of the method cold winding manufactured with a durable protective coating and a special protective braid to protect the coils from damage when closed, SS20 Racing lowered springs last twice as long as hot-wound springs currently on the market without shrinkage.

At sports springs SS20 Racing progressive characteristics, that is, they provide car understatement without loss of comfort: optimal suspension stiffness at low loads and a proportional increase in stiffness with increasing vehicle load, when leaning in a corner or hard braking.

Depending on the vehicle model and the amount of lowering, the weight of the SS20 Racing springs is reduced by up to 25% compared to the stock springs (except SS30136 and SS30137 springs). Reducing the weight of the springs, together with a decrease in the weight of the shock absorbers, reduces the unsprung masses in the vehicle's suspension, which has a positive effect on driving performance, reduces dynamic loads in the suspension, improves acceleration and braking dynamics and contributes to improved handling.

The energy intensity of the suspension with lowered springs is calculated and maintained due to the increased stiffness of the springs. Thanks to this, the lowered car remains comfortable, shocks to the body are reduced when overcoming bumps.

All SS20 Racing springs are tested on the control stand and are selected in pairs with the same characteristics, so they provide uniform lowering without body distortions, stability and driving safety.

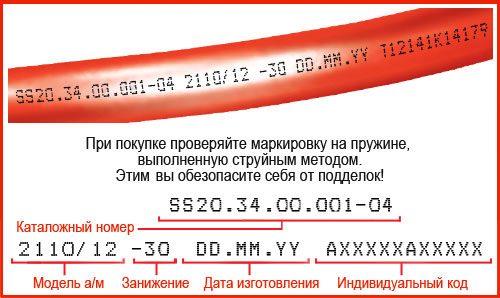

Marking

In addition to lowered springs, SS20 produces classic hot coil springs and variable pitch Gold springs.

Modifications

SS30133 Racing [-30] front suspension cold coil springs (variable pitch)

SS30134 Racing [-50] front cold coil springs (variable pitch)

- VAZ 2108 VAZ 2109 VAZ 21099 VAZ 2113 VAZ 2114 VAZ 2115 VAZ 2110 VAZ 2111 VAZ 2112

- 4 years 2108-2902712, 2112-2902712

SS30135 Racing [-70] front cold coil springs (variable pitch)

- VAZ 2108 VAZ 2109 VAZ 21099 VAZ 2113 VAZ 2114 VAZ 2115 VAZ 2110 VAZ 2111 VAZ 2112

- 4 years 2108-2902712, 2112-2902712

SS30139 Racing [-30] rear suspension cold coil springs (variable pitch)

- 4 years

SS30140 Racing [-50] rear cold coil springs (variable pitch)

- VAZ 2108 VAZ 2109 VAZ 21099 VAZ 2113 VAZ 2114 VAZ 2115 VAZ 2110 VAZ 2111 VAZ 2112 VAZ 1117 VAZ 1118 VAZ 1119 VAZ 2170 VAZ 2171 VAZ 2172 VAZ 2190

- 4 years 2108-2912712, 2110-2912712, 2111-2912712, 11180-2912712

On most cars are coiled coil springs. Despite their simplicity and reliability, they fail over time.

After a long (5–7 years) operation of the machine with a heavy load, they sag due to metal fatigue, while the travel and energy intensity of the suspension are reduced. It starts to work all the way, which accelerates the destruction of body parts. Detect the loss of elasticity of the springs more often unexpectedly. For example, all summer we went to the dacha together, and then we had to capture the guests, and thoroughly load the trunk. The weight is no more than 400 kg allowed for a Zhiguli, and the car is already “crawling on its belly”, catching the asphalt with a muffler.

But not all owners are in a hurry to buy new springs. Someone, having heard enough of other "experts", installs rubber spacers under the springs (or between their coils). The main danger of such a solution is the possibility of the suspension actuating before the coils of the spring close and, as a result, the transmission of almost hard shocks to the body. In the standard design, the suspension makes its full travel until it stops in a soft rubber or polyurethane bump stop, which extinguishes only the remnants of energy. The spacer, replacing the air gaps between the coils of the spring, only limits the suspension travel, turning it from “soft spring” into “oak rubber”.

If you are transporting a ton of cargo per flight on a VAZ-2104, then it is useless to install new springs to replace the sagging ones - and with them the loaded “four” will spread out on the asphalt. And with spacers, the car will look like a “peppy” for another year, until the cracks in the spars disfigure its posture. The fact that the purchase of a new car will have to be taken into account in the estimate of future production costs is not so bad. The main thing is that driving an overloaded car is simply dangerous. But if you use the machine less ruthlessly and rely on it long service, there is only one way out - to put new springs intended for this model.

For inquisitive readers, we will tell you how suspension springs are made on a VAZ. The starting material is a rolled round bar made of spring steel grade 60S2GF. The first operation is the processing of bars on turning lines to the desired diameter, with the removal of the upper decarburized layer. The second is heating and winding with a spiral. Then - hardening and tempering. Then shot blasting: in a special chamber, the springs are fired with a stream of fine steel shot - this is how they are cleaned of scale, strengthen the surface layer and increase fatigue strength. The next stage is a cold draft, or captivity of the springs. They are compressed three times until the turns touch, after which the length decreases by about 18 mm from the original. Now the springs are ready to work for a long time without losing elasticity.

Apply to the finished spring protective covering otherwise, over time, cavities and shells from corrosion will form on the surface of the bar, which will weaken the surface layer and accelerate the breakage of the spring. In addition to the traditional coating - black chlorinated rubber enamel, VAZ uses a more resistant epoxy. For example, for rear suspension springs - only the latter.

The final operation is the control of the static load. 100% of produced springs pass it. Compressing the spring with a certain force, measure its length. For example, the spring model "2101 front" under a load of 435 kg has a nominal length of 232 mm, and with a load of 603 kg - 182 mm. Springs whose length under load turned out to be more or less (out of tolerance) are discarded. Those that fall into the plus tolerance (that is, a little longer than the nominal one) belong to class A, and those who fall into the minus tolerance (slightly shorter) belong to class B.

|

Table 1 |

||

|

Marking of springs for VAZ car suspensions |

||

|

Spring model |

Distinguishing marking color |

|

|

1111 front |

yellow |

green |

After that, the springs are marked by applying a strip of paint to the outer surface of the coils. Depending on the spring model (Table 1), yellow, green, white, blue, brown, blue, black and orange colors.

And yet, despite this sophisticated technology production, all springs in operation sag sooner or later. However, if you use a more expensive material, you can create a spring that retains sufficient elasticity even with prolonged captivity. An example is the mainspring of the UZRGM grenade fuse. Being in a completely compressed state for fifty years, it slightly loses its elasticity and is always ready to work reliably, breaking the primer with a drummer. Of course, such high requirements are not imposed on automobile springs. What is the point of inflating their cost, making them “eternal”, if in a few years more expensive components will require replacement? But the plant is obliged to ensure the preservation of the elasticity of the springs at least during the estimated service life of the machine, and it succeeds. What can not be said about the "left" manufacturers whose springs appear on the market. But there are also conscientious manufacturers who have received VAZ approval for the supply of springs for spare parts. For example: plant construction machines in Slavyansk; Crane plant in Nikopol (both in Ukraine); Soyuz-TMO LLP, Izhevsk and Machine building plant, Perm. The springs of these four factories are marked with the brand of the manufacturer or attached with a tag.

Now about the applicability of springs. Model 2101 (front and rear) - for all rear-wheel drive VAZs with a sedan body. 21012 - made from a larger diameter bar, it is stiffer than 2101. It is installed with right side front suspension "Zhiguli" with right-hand drive (export) to level the car due to the asymmetric distribution of mass. On left-hand drive vehicles, the total weight of the steering gear, pedal assembly, hydraulic brake and clutch units, instrument cluster located on the left side approximately corresponds to the weight of the battery, starter and alternator on the right. With “right-hand drive”, all this is concentrated on one side, which required a reinforced spring on the right. Spring 21012 is also found on both sides of the suspension of "Lada" special configurations with left-hand drive, which require increased energy consumption of the front suspension.

Springs 2102 are installed in the rear suspensions of the VAZ-2102 and 2104 station wagons. Their length is 21 mm longer than that of the usual “zero first”, and it is justified to use such on sedans only to increase the height of the body above the road, for example, if you often have to drive along a country road and touch the bumps with rapids. But this does not mean that springs 2102 can be used to increase the carrying capacity of the machine - premature destruction of the body in this case is inevitable.

Front springs 2108 are installed on all front wheel drive models VAZ, except for the Oka and modifications with a new 16-valve engine. 2108 rear - for all front-wheel drive, except for the VAZ-2110 and Oka families. Owners of VAZ-21099 sedans are sometimes deceived in the markets, offering exorbitantly expensive allegedly scarce "99s" rear springs. Remember: there are none - in rear suspension VAZ-21099 are the usual "eighth" springs. Springs for cars of the VAZ-2110 family are not yet in demand; nevertheless, we report data on their applicability (Table 2).

table 2 |

|||||||

|

Springs for suspensions of VAZ vehicles of the ”tenth” family |

|||||||

|

Spring type |

Automobile model |

||||||

|

VAZ-21102, VAZ-21104 |

VAZ-21122, VAZ-21124 |

||||||

|

Front suspension spring |

|||||||

|

Rear suspension spring |

2110 European |

2110 European |

2110 European |

2110 European |

|||

Some models of springs are also produced in European version - for cars intended for export. They are slightly shorter than usual, so ground clearance there are about 20 mm fewer such machines, and at the same time the compliance of the springs themselves is reduced, which makes it possible to increase the stability of the machine in corners and when driving with high speed. If you decide to put these on your car, keep in mind that you need to change all four springs as a set. Of course, the cross-country ability of the car will decrease significantly, and when traveling on dirt roads more likely to be damaged from below the machine.

Some models of springs are also produced in European version - for cars intended for export. They are slightly shorter than usual, so ground clearance there are about 20 mm fewer such machines, and at the same time the compliance of the springs themselves is reduced, which makes it possible to increase the stability of the machine in corners and when driving with high speed. If you decide to put these on your car, keep in mind that you need to change all four springs as a set. Of course, the cross-country ability of the car will decrease significantly, and when traveling on dirt roads more likely to be damaged from below the machine.

Model 2121 springs are used on all-wheel drive vehicles VAZ of all modifications (2121, 21213, 21218, 2131), and models 1111 - only on Oka.

In conclusion - about the possibility of installing springs on the machine different classes elasticity. General rule, acting on the VAZ, is as follows: all four springs must be of the same class - either A or B. In exceptional cases, it is permissible to install class B springs back if class A springs are in front. But if class B springs are on the front suspension, then set class A springs are not allowed, and the installation of springs of different classes on the suspension of one axle is also unacceptable.

Table 3 |

|||||

|

Brief specifications springs |

|||||

|

Spring model |

Bar diameter, mm |

Outer diameter, mm |

Number of turns |

Spring cover, mm |

|

|

Front suspension springs |

|||||

|

epoxy, black enamel |

|||||

|

epoxy, black enamel |

|||||

|

epoxy |

|||||

|

epoxy, black enamel |

|||||

|

2108 European |

epoxy, black enamel |

||||

|

epoxy, black enamel |

|||||

|

epoxy, black enamel |

|||||

|

Rear suspension springs |

|||||

|

epoxy |

|||||

|

epoxy |

|||||

|

epoxy |

|||||

|

epoxy |

|||||

|

2108 European |

epoxy |

||||

|

epoxy |

|||||

|

2110 European |

epoxy |

||||

|

epoxy, black enamel |

|||||

Characteristics of springs for VAZ car suspensions are given in Table. 3.

It is impossible to accurately determine the parameters of the spring when buying. All checks are approximate, but in many cases they will help to avoid fakes.

Springs in stores are often sold without packaging. However, its presence and information about the manufacturer indirectly indicate its reliability.

Paint marking of the spring class and determination of the total number of turns.

When checking the shape of the spring, not all coils touch the plane - it is better to refrain from buying.

When checking the shape of the spring, not all coils touch the plane - it is better to refrain from buying.

Spring marking ( trademark manufacturer, month and year of manufacture, catalog number), contrary to the OST, Russian manufacturers rarely apply. But there is almost always a mark on sorting into groups (classes), and it should be the same on both purchased springs. If groups (classes) are not marked or their marking does not correspond to the data in the table below, it is better to refrain from buying.

Protrusion of the support coil outward.

Protrusion of the reference coil inward.