Estimated cost of operation

construction machines and mechanisms

The composition of the estimated costs for the operation of construction machines and mechanisms (EMM)

Regulatory basis for determining estimated operating costs construction machines and mechanisms are:

operating time of construction machines and mechanisms, mash-hour;

the estimated cost of one machine-hour of work of construction machines and mechanisms.

The operating time of construction machines and mechanisms includes:

The time of participation of machines in the performance of technological operations, incl. for vehicles - the time of their movement from the mechanization base (construction site) to the construction site (mechanization base);

Time of replacement of wear parts, cutting tools and interchangeable working equipment;

The time of movement of machines along the front of work within the construction site;

Time of technological breaks in the operation of machines during construction and installation works;

Time of preparation of machines for work and their delivery at the end of work;

Time per shift Maintenance machines;

Breaks in the work of the driver (crew drivers), regulated by labor legislation.

The price of a machine-hour includes the following cost items:

Cm-h \u003d A + R + G + B + E + C + D + P

Operational

One-time costs

A - depreciation deductions on full recovery, rub/mash hour;

P - the cost of all types of repairs, diagnostics and maintenance, rub/machine-hour;

B - the cost of replacing high-wear parts, rub / machine-hour;

Z - wages of workers operating the machine (drivers, drivers), rub / machine-hour;

E – energy costs, rub/mash-hour;

C - the cost of lubricants, rub/mash hour;

G - the cost of hydraulic and coolant, rub / machine-hour;

P - the cost of relocating machines from one construction site (mechanization base) to another construction site (mechanization base), including the installation of machines with commissioning, dismantling, transportation with loading and unloading operations, rub / machine-hour.

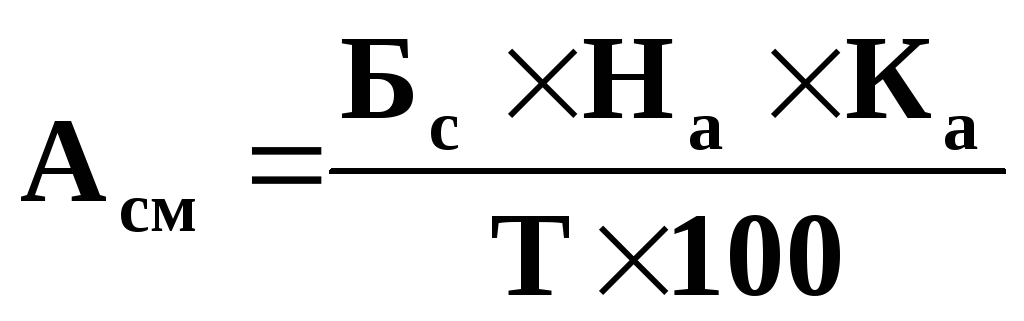

Normative indicator of depreciation for construction machines:

B s - weighted average replacement cost of machines of this size group, rub;

Bs \u003d C + Zd

P is the weighted average price of the FSII, determined on the basis of market prices, rubles;

Zd - the cost of the initial delivery of the car from the seller to the buyer, taking into account the cost of transportation costs, PRR, the cost of TOUR, ZSR, rub.

H a - the rate of depreciation,% per year;

K a - coefficient to the depreciation rate, taking into account the industry and regional specifics of the use of construction machines in the production of construction and installation works, as well as the intensity of their use (operation mode: light, medium and heavy);

T is the annual mode of operation of the machine, machine-hour / year.

The normative indicator of the annual mode of operation of the machine (T) is determined by the formula:

T = × K rs × K s

365 - the number of days in a year;

52 - the number of weeks in a year;

2 - the number of non-working days in a week;

P d - the number of holidays in a year;

M, R, P - the number of all-day downtime in the operation of the machine during the year, associated with: M - meteorological conditions; R - repair and maintenance; P - relocation of the machine from one construction site (mechanization base) to another construction site (mechanization base);

K rs - the standard duration of the work shift, machine-hour / shift;

K c is the coefficient of shift operation of the machine during the year, shift/day. It is defined as the ratio of the time worked by the machine per day, on average, during the year (mash-hour/day) and the standard duration of the work shift (mash-hour/shift).

Recommended indicators of the annual mode of operation of construction machines ( T) according to the main nomenclature of machines are established for the base region (III temperature zone). Correction factors have been introduced for other temperature zones.

For example:

Truck-mounted crane - for the base region T=2300 machine-hours, for the V-temperature zone the correction factor is 0.9.

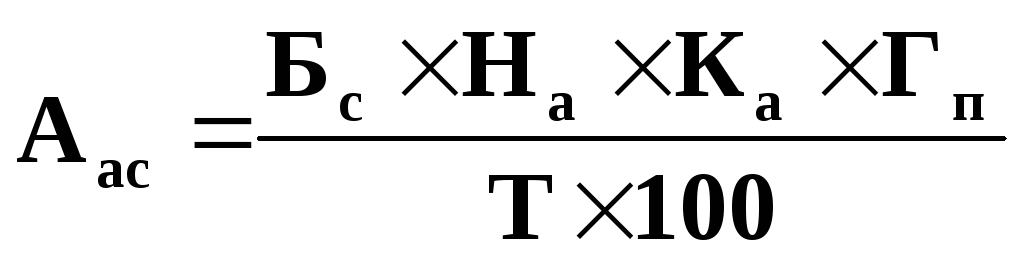

The normative indicator of depreciation deductions for full restoration for vehicles:

Гп - annual mileage auto vehicle, thousand km. This indicator is set on the basis of the calculated indicators of the mileage of vehicles on average per year (excluding unjustified downtime);

H a - the rate of depreciation as a percentage per 100 or 1000 km of run.

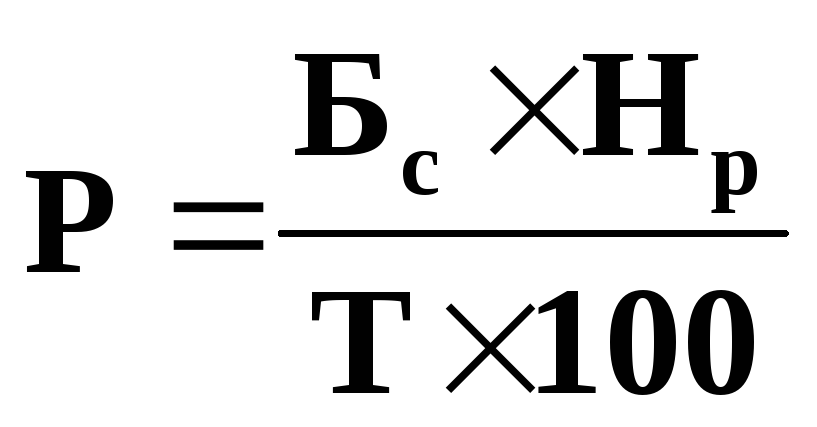

2) The normative cost indicator for all types of repairs, diagnostics and maintenance of machines is determined by the formula:

H p - the rate of annual costs for repairs and maintenance as a percentage of the replacement cost of machines of the corresponding size group. Determined by the formula:

å(Р + ТО) - the sum of the average annual costs for repair (Р) and maintenance (ТО) of machines of a given size group, type or type of machines, rub./year, which include:

the cost of purchasing spare parts and replaceable units, taking into account the cost of their delivery to the consumer, including loading and unloading operations, the cost of containers, packaging, etc.;

the cost of repair materials, taking into account the cost of their delivery to the consumer;

wages of repair workers;

operating costs repair bases in terms of direct costs, including depreciation and operation of technological repair equipment, incl. mobile repair shops;

overhead costs associated with the organization, implementation of maintenance and repair of machines at an individual rate;

profit on the basis of an individual rate, as agreed by the parties.

If there are difficulties in determining the norms of annual costs for the repair and maintenance of machines, the indicators (N p) are recommended to be taken from Table 1.

The indicated data are for reference only and are specified according to the actual average annual data of the construction and mechanization units.

(as a percentage of the book value of machines)

|

Name |

For regions of the Far North and areas equated to them |

For the rest of the Russian Federation |

|

|

motor graders | |||

|

tower cranes, gantry cranes | |||

|

Bulldozers | |||

|

Truck mounted cranes | |||

|

Crawler cranes | |||

|

Pneumatic wheel cranes | |||

|

Loaders | |||

|

Trailed vehicles with internal combustion engines (compressors, mobile power plants, dewatering units, etc.) | |||

|

Manual machines (winches, jacks, hoists, etc.) | |||

|

Self-propelled machines with internal combustion engines (drilling and pile driving equipment, asphalt distributors, motor vehicles, etc.) | |||

|

Scrapers | |||

|

Stationary machines with electric drive (concrete and mortar mixers, plastering stations, painting units, etc.) | |||

|

Excavators |

3) The normative indicator of remuneration for workers operating machines (З) is determined by the formula:

Z= Z m Xt,

З m - wages of a worker of this qualification category, rub / man-hour;

t - labor costs of workers of this qualification category, man-hour / machine-hour.

The number and qualification categories of workers operating machines are established taking into account and on the basis of the following regulatory sources (in order of priority of application):

Guidelines for determining the amount of funds for wages in contract prices and estimates for construction and wages for workers of construction and installation and repair and construction organizations (MDS 83-1.99), put into effect by the letter of the Gosstroy of Russia dated 02.08.99 No. NZ-2618 / 7;

machine operating instructions;

Unified Tariff and Qualification Guide;

current production standards;

In the absence of the necessary data in the listed documents and standards, the number and qualification categories of workers are determined according to the actual operating conditions of the machine.

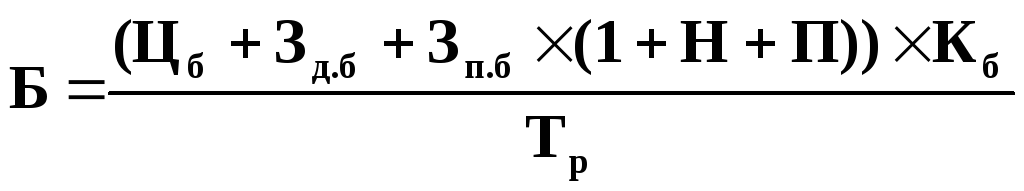

4) The normative cost indicator for the replacement of wearing parts is determined by the formula:

C b - the price of a consumable part of this type of ex-seller, rub / unit;

Z d.b - the cost of delivering wearing parts of this type to the consumer, taking into account transportation costs, including loading and unloading, the cost of containers, props, etc., rub / unit;

З p.b - wages of repair workers, excluding the driver (drivers) of machines of this size group, employed in the replacement of wearing parts, rub / unit .;

K b - the number of wear parts of this type, simultaneously replaced by the machine, units. The indicator (K b) is set according to the instructions for operating the machines of this group;

N + P - individual rates, respectively, of overhead costs and estimated profit in shares of the remuneration of workers employed in the replacement of wearing parts;

T r - normative resource (service life) of a wear part of this type, mash-hour. This indicator is taken on the basis of the manufacturer's recommendations, the data given in the regulatory literature, the actually achieved indicators of the time of use of wearing parts of this type.

|

Types of wearing parts |

Service life, mash-hour |

|

|

Flexible electrical cable: | ||

|

gantry cranes | ||

|

electric excavators | ||

|

Steel ropes (cables) lifting machines: | ||

|

Cable-stayed | ||

|

lifting | ||

|

Boom-lifting | ||

|

Steel ropes (cables) for single-bucket excavators: | ||

|

tipping and pulling for bucket | ||

|

lifting | ||

|

Boom-lifting | ||

|

Steel ropes (cables) of scrapers | ||

|

Conveyor belt | ||

|

V-belts | ||

|

Pump sleeves | ||

|

Chains steel tipping and pulling | ||

|

spray guns and mortar pumps | ||

|

sandblasters and pneumatic tools | ||

|

bulldozers, scrapers and other trailers with hydraulic control |

5) Normative indicators of energy costs are calculated for the following main types: gasoline, kg / rub.; diesel fuel, kg/rub.; electricity, kWh/rub.; compressed air, m 3 / rub.

5.1. Normative cost indicator for petrolfor construction machines(E b) is determined by the formula:

E b = H b X(C b +Z e.b.)

Нb - gasoline consumption rate when the machine is operating in the technological mode in the summer (at a positive outside temperature), taking into account the intra-garage consumption, kg / machine-hour The indicator (Nb) is set on the basis of: passport data; standards given in the technical literature; the actual average level characteristic of the region.

The costs associated with the increased consumption of gasoline when the machine is running in winter time, are to be taken into account in estimated norms ah additional costs in the production of construction and installation works in winter.

C b - current market price for the purchase of gasoline, free-oil base (gas station), rub / kg;

З d.b - the cost of delivering gasoline to a refueling car, rub / kg.

For vehicles formula for determining the standard cost indicator for petrol(e b) has the following form:

H l - linear rate of gasoline consumption during the operation of vehicles in the summer, l. / 100 km;

D b - density of gasoline, kg / l, depending on the type of gasoline, varies in the range of 0.72 ÷ 0.75 kg / l;

T – annual mode of operation of the vehicle, machine-hours/year.

5.2. Normative cost indicator for diesel fuelfor construction machines

E d =H d XTO P X(C d +Z d.d)

N d - diesel fuel consumption rate when the machine is operating in the technological mode in the summer (at a positive outside temperature), taking into account the intra-garage consumption, kg / machine-hour;

K p - coefficient that takes into account the cost of gasoline during the operation of the starting engine, is set on the basis of the manufacturer's recommendations or according to actual costs. In the absence of a starting motor, the coefficient (K p) is not applied;

C d - purchase price of diesel fuel free-loading base (gas station), rub/kg;

Z d.d - the cost of delivering diesel fuel to a refueling vehicle, rub./kg.

For vehicles normative cost indicator for diesel fuel(E e) is determined by the formula:

N l - linear rate of diesel fuel consumption during the operation of vehicles of this size group in the summer, l / 100 km;

D d is the density of diesel fuel, kg/l. Depending on the type of diesel fuel, the density varies in the range: 0.82÷0.85 kg/l;

Гп - annual mileage of the vehicle, 100 km;

T is the annual mode of operation of the vehicle, machine-hour / year.

The costs associated with the increased consumption of gasoline and diesel fuel during the operation of vehicles in the winter are subject to accounting in the estimated rates of additional costs in the production of construction and installation work in the winter.

5.3. Normative cost indicator for liquid fuel(E t) is allowed to be determined by the formula:

E T =R at XM d X(C T +Z d.t)

R y - specific energy consumption per unit of engine power, established and guaranteed by the manufacturer, kg / kW (hp);

M d - nameplate engine power, kW (hp);

(P t + W d.t) is the purchase price of this type of fuel and the cost of its delivery to the refueling vehicle.

5.4. For electrically driven machines normative cost indicator for electricity(E e) is determined by the formula:

E uh =1,1 XM P XTO m XTO V

1.1 - coefficient taking into account the starting torque of the electric motor;

M p - total nameplate power of electric motors installed on the machine, kW;

K m - coefficient of use of electric motors by power (the ratio of the used power to the total nameplate power of electric motors);

K in - coefficient of use of electric motors in time (the ratio of the time of actual operation of electric motors per shift to the standard duration of the work shift).

Indicators K m and Kv are established: by actual data, taking into account the established technological schemes for the production of construction and installation works (according to flow meters); recommendations given in normative (technical) sources.

5.5. Normative cost indicator for compressed air(E c) is determined by the formula:

E V =R V XC V

R in - consumption compressed air, m 3 / machine-hour. The standard indicator is determined by: the manufacturer's instructions for operating the machine; data given in the normative technical literature; actual data.

C in - estimated price for compressed air, rub / m 3; calculated by the formula:

C V =WITH R : P To

C p - estimated price for the operation of a compressor unit of a given capacity, rub / mash-hour;

P c - passport capacity of the compressor unit, m 3 / machine-hour.

In the event that a reliable determination of the compressed air consumption for a given construction machine or a mechanized pneumatic tool is associated with significant difficulties, it is advisable ignore this cost item as part of the estimated price for the operation of a construction machine (mechanized pneumatic tool). At the same time, the costs associated with the consumption of compressed air should be taken into account in the estimate in a separate line, by taking into account the costs associated with the operation of the compressor unit provided for by the project. The operating time of the compressor unit is taken according to the operating time of the machine that consumes compressed air.

6) Standard cost indicator for lubricants for carburetor machines(working on gasoline) (C to) is determined by the formula:

WITH To = (0,035 XC mm +0,004 XC ps +0,015 XC tm)XH b

0.035; 0.004; 0.015 - coefficients taking into account the consumption of lubricants;

C mm, C ps, C tm - market prices, respectively, on engine oils, greases and transmission oils, taking into account the cost of their delivery to the serviced machine of this standard size group, rub / kg;

Nb - the rate of consumption of gasoline for cars of this size group (model) on average per year, kg / machine-hour.

Normative cost indicator for lubricants for diesel machines(C e) is determined by the formula:

WITH d = (0,044 XC mm +0,004 XC ps +0,015 XC tm)XH d XTO P

0.044; 0.004; 0.015 - coefficients taking into account the consumption of lubricants;

Ts mm, Ts ps, Ts tm - market prices, respectively, for motor oils, greases and gear oils, taking into account the costs of their delivery to the serviced machine of this size group, rub / kg;

N d - diesel fuel consumption rate for machines of this size group (model) on average per year, kg / machine-hour;

K p is a coefficient that takes into account the cost of gasoline during the operation of the starting engine. In the absence of a starting motor, the coefficient (K p) is not applied.

Normative indicators of costs for lubricants for electrically powered or compressed air machines, are determined by: passport data; instructions for the operation of machines; recommendations given in the technical literature.

7) Standard cost indicator for hydraulic (working) fluid(D) is determined by the formula:

O - weighted average capacity (capacity) hydraulic system machines of this size group, l. Installed according to the passport data of the machine;

D g - density hydraulic fluid- 0.87 kg/l;

K d - coefficient of topping up of hydraulic fluid, replenishing its systematic leakage during operation of the machine. For domestically produced machines, this indicator is taken on the basis of measurements of the volumes of actual hydraulic fluid leaks. In the absence of the necessary data, the indicator (K d) is taken equal to 1.5.

P g - periodicity complete replacement hydraulic fluid for machines of this size group, once / year, is accepted according to: passport data; instructions for the operation of machines; recommendations given in the technical literature.

Unless otherwise provided by the operating instructions for the machine, the indicator (P g) is taken equal2 , which means the transition during the year from the summer grade of the hydraulic fluid to the winter grade and vice versa;

Cg - purchase price of hydraulic fluid free-loading base (gas station), rub/kg;

W e.g - the cost of delivering hydraulic fluid to the serviced machine, rub / kg, are determined taking into account transportation costs, including loading and unloading operations, the cost of packaging, etc.;

T is the annual mode of operation of the machine, machine-hour / year.

8) Normative indicators of costs for relocation are determined according to the following schemes:

under its own power;

in tow;

on a trailer without dismantling;

on a trailer with dismantling and subsequent installation.

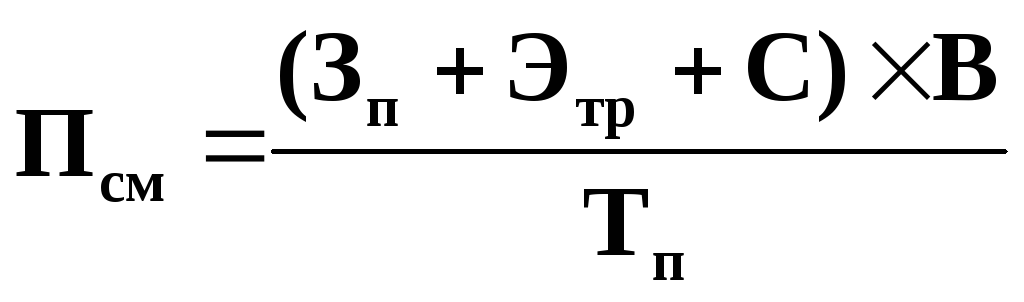

8.1. Relocation costs under its own power, in which the machine to be relocated is occupied (a truck-mounted crane, an asphalt distributor, a concrete pump, etc.) (P cm) are determined by the formula:

Chapter 6

General provisions

These recommendations contain rules for the development and application of prices for the operation of construction machines and are intended for practical guide when setting contractual (contract) prices, as well as for drawing up investor estimates during contract bidding.

The indicators given in the recommendations are of an average nature; various types were used in their calculation. percentages, on the basis of which similar methods were built over the past

10 years. The data of these recommendations can be used to determine the cost of a machine hour both in the central regions and in the regions of the Far North and areas equated to them.These recommendations assume that the overhaul of construction machines is carried out by specialized enterprises. Wage repair workers employed in major repairs is used as the basis for depreciation, overhead and profit.

When establishing the cost of construction machines and mechanisms for depreciation, it is recommended to use data on the selling prices of supplying plants as of the date of drawing up investor estimates or performing calculations of contractual (contract) prices.

An example of calculating the cost of a machine-hour of a bulldozer (B.10.1111-1E 125 kW, 170 HP)

|

Number |

Action |

Rationale |

Count |

Result |

|||

|

Selling price (excluding VAT) |

seller price list |

1260000 rub. |

|||||

|

Shipping costs to the place of permanent dislocations |

1260000 rub. + 40320 rub. |

1300320 rub. |

|||||

|

2260 hours |

|||||||

|

per year |

p. 3 × 14.3% |

RUB 1,300,320 × 14.3% |

185946 rub. |

||||

|

per hour of work |

185946 rub. : 2260 hour |

RUB 82.3/hour |

|||||

|

6.1 |

1514 man-hours/year×20% |

303 man-hours / year |

|||||

|

6.2 |

43.7 rubles/hour |

||||||

|

p. 6.1 × 6.2 |

1514 man-hours/year×43.7 rubles/hour |

RUB 66,162/year |

|||||

|

The cost of spare parts, replacement units, assemblies and repair materials for all types of repairs and maintenance |

RUB 1300320×11% |

143035 rubles/year |

|||||

|

item 6. 1.1×p. 6.2×140% |

303 man-hours/year×43.7 rubles/hour×140% |

18537 rubles/year |

|||||

|

Annual costs |

66 162 rubles/year + 143035 rubles/year + 18537 rubles/year |

227734 rubles/year |

|||||

|

Hourly costs |

227734 rubles/year: 2260 hours |

100.8 rubles/hour |

|||||

|

Accepted by |

rub./hour |

||||||

|

diesel fuel |

lubricants |

40 rubles/kg×(1 + 15%)×(0.063×9.4 kg/hour) |

27.2 rubles/hour |

||||

|

hydraulic fluid |

6.2 rubles/hour |

||||||

|

Amount on line 5 -8 |

82,3 + 100,7 + 112,4 + 27,2 + 6,2 |

328.9 rubles/hour |

|||||

|

10 |

Cost of wearing parts 100×3.5% (100%-3.5%) = 3.6% |

328.9 rubles/hour×3.6% |

|||||

|

11 |

rebase |

328.9 rubles/hour + 11.8 rubles/hour + 40.1 rubles/hour |

380.8 rubles/hour * |

*

An example of calculating the cost of a machine-hour of dump trucks (KAMAZ 55111 g / p 13 tons, 176 kW, 240 hp)

|

Number |

Action |

Rationale |

Count |

Result |

|

Selling price (excluding VAT) |

seller price list |

686000 rub. |

||

|

Delivery costs to the place of permanent deployment |

686000 rub. + 24696 rub. |

7 10696 rub. |

||

|

Annual mode of operation of the machine |

2260 hours |

|||

|

4.1 |

Annual mileage |

40000 km |

||

|

Depreciation deductions |

||||

|

per year |

p. 3 × 14.3% |

7 RUB 10,696 × 0.2% × 40,000 km: 1,000 |

56856 rub. |

|

|

per hour of work |

56856 rub. : 2260 hour |

25.2 rubles/hour |

||

|

The cost of performing routine maintenance and overhaul |

||||

|

The complexity of current maintenance and all types of repairs per year |

2373 man-hours / year × 20% |

475 man-hours/year |

||

|

maintenance worker salary |

43.7 rubles/hour |

|||

|

The cost of current maintenance and all types of repairs for a year, excluding spare parts and materials |

2373 man-hours / year × 43.7 rubles / hour |

103700 rubles/year |

||

|

The cost of spare parts, replacement units, assemblies and repair materials for all types of repairs and maintenance |

RUB 710,696×11% |

78177 rubles/year |

||

|

Indirect costs for capital repairs |

clause 6.1.1×p. 6.2×140% |

475 man-hours/year×43.7 rubles/hour×140% |

29060 rubles/year |

|

|

Annual costs |

103700 rubles/year + 781776 rubles/year + 29060 rubles/year |

2 10937 rubles/year |

||

|

Hourly costs |

2 10937 rubles/year: 2260 hours |

RUB 93.3/hour |

||

|

The wages of workers employed in the management of machines |

rub./hour |

|||

|

Fuels and lubricants and process fluids |

||||

|

diesel fuel |

10.0 rub./kg×(1 + 15%)×7.7 kg/hour×1.04 |

RUB 92.1/hour |

||

|

lubricants |

40 rubles/kg×(1 + 15%)×(0.063×7.7 kg/hour) |

22.3 rubles/hour |

||

|

45 rubles/kg×(1 + 15%)×0.12 kg/hour |

6.2 rubles/hour |

|||

|

Price car tires |

10.6 rubles/hour |

|||

|

10 |

Hourly cost of operating machines without pay for machinists |

25,2 + 93,3 + 92,1 + 22,3 + 6,2 + 10,6 |

RUB 249.7/hour * |

* - must be taken into account in the calculations.

Domestic cars -

11 %;Imported cars - 7%.

5. Indirect costs of the organization during the overhaul "Guidelines for the development of estimated standards and prices for the operation of construction machines and vehicles" MDS 81-3.99 Examples of costing p. 1.2. (Appendix 4).

Costs for fuels and lubricants and hydraulic fluid

1. The selling price for diesel fuel, oil and hydraulic fluid is taken from the supplier's data.

2. The cost of delivering the product to the refueling machine is determined by the specific conditions for the provision of machines of this standard size group. According to their content, they reflect the costs associated with the operation of tankers, with depreciation and operation of an intermediate storage of energy carriers.

According to actual data, the marginal cost of fuels and lubricants and process fluids is:

For central regions - up to 15 %;

For the regions of the Far North and equivalent regions - up to 20% of the selling price of the product ex-oil base.

3. Consumption rates for fuel, oil and process fluids are accepted according to the data of the machine manufacturer or according to the Collection of estimated rates and prices for the operation of machines 4.03-9 1.

4. Consumption rate of lubricants = 0.063×N, where

0.063 - coefficient taking into account the consumption of lubricants;

H is the rate of consumption of diesel fuel.

5. Hydraulic fluid flow rate = (100 l×0.87 kg/l×1.5×2): 2260 h = 0.12 kg/h, where

100 l - capacity of the hydraulic system of the machine;

0.87 kg/l - hydraulic fluid density;

1.5 - coefficient of topping up hydraulic fluid;

2 - the frequency of complete replacement of hydraulic fluid per year;

2260 hours - the annual mode of operation of the machine.

6. For accounting increased consumption fuel during the operation of machines in winter, average annual coefficients are used, differentiated by temperature zones.

|

Temperature zone |

Coefficient |

|

1,01 |

|

|

II |

1,02 |

|

III |

1,04 |

|

IV |

1,06 |

|

1,08 |

|

|

VI |

1,12 |

|

VII, VIII |

1,13 |

Wear parts

Moscow 1994

Clause 2.16.

Extract

The share of costs for the replacement of wear parts in the structure of direct costs for the operation of construction machines, determined according to the prices of Book 4.03-91 is 3.5%. Wear parts include excavator bucket teeth, conveyor belt, cables, ropes, chains, tires, etc. ...

Calculation of the cost of replacing tires for truck(Dump truck KAMAZ 13 t, three-axle)

1. The cost of one tire (brand 280-508R) is 2517 rubles.

2. The cost of the camera and rim tape - 289 rubles.

3. Total set; 2517 + 289 = 2806 rubles

4. Including delivery: 2806×(1 + 15%) = 3226.9 rubles.

5. Including assembly: 3226.9 × (1 + 10%) = 3549.6 rubles.

6. The replacement kit includes 11 tires

7. The cost of the whole set: 3549.6× 11 \u003d 39045 rubles.

8. Full mileage tires before replacement is 65 thousand km

9. The normative annual mileage of the car is 40 thousand km

10. Annual cost of tire replacement: 39045 × 40/65 = 24028 rubles.

11. With a standard annual operating time of the machine of 2260 hours, the indicator for tire replacement will be - 24028/2260 = 10.63 rubles/machine-hour.

Substantiate Entry 7

Indirect costs for major repairs

Indirect costs TOTAL: 40% + 70% + 30% = 140%

The list of machines, the costs of relocation of which are taken into account in the estimates in a separate line:

Bases are pipe welding, field, semi-stationary;

bulldozers with an engine capacity of 400 hp. With. and more;

tower cranes, cantilever-sluice cranes, on caterpillar tracks, on pneumatic wheels, for the construction of cooling tower shells;

copra universal;

dredging and jet-ejector shells;

machines for tunneling works;

heavy dump trucks; belt conveyors; loaders;

scrapers 15 cubic meters;

locomotives;

overburden excavators;

lifts;

pipelayers 50 t;

asphalt concrete plants 50 t/h.

Annex 1

Percentage of the selling prices of manufacturers (sellers) for the initial delivery and relocation during the operation of construction machines and mechanisms during the year.

|

No. p / p |

Selling price of a construction machine ex-factory (seller) in million rubles. before: |

relocation |

Initial Delivery |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Rest of the territory |

Rest of the territory |

Regions of the Far North and areas equated to them |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

0,1 |

16,0 % |

20,0 % |

8,0 % |

10,0 % |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

0,25 |

12,8 % |

16,0 % |

6,4 % |

8,0 % |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

0,5 |

10,4 % |

13,0 % |

4,0 % |

5,0 % |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1,0 |

8,8 % |

11,0 % |

3,6 % |

4,5 % |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

1,5 |

7,2 % |

9,0 % |

3,2 % |

4,0 % |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2,0 |

6,0 % |

7,5 % |

3,0 % |

3,7 % |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

2,5 |

5,0 % |

6,2 % |

2,8 % |

3,5 % |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3,0 |

4,6 % |

5,8 % |

2,6 % |

3,3 % |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

3,5 |

3,9 % |

4,9 % |

2,5 % |

3,1 % |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

4,0 |

3,4 % |

4,3 % |

2,4 % |

3,0 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

11 |

4,5 |

3,2 % |

4,0 % |

2,3 % |

2,9 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

5,0 |

3,1 % |

3,9 % |

2,2 % |

2,8 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

13 |

6,0 |

3,0 % |

3,8 % |

2,2 % |

2,7 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

7,0 |

3,0 % |

3,7 % |

2,1 % |

2,6 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

15 |

8,0 |

2,9 % |

3,6 % |

2,1 % |

2,6 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

16 |

9,0 |

2,8 % |

3,5 % |

2,0 % |

2,5 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

17 |

10,0 |

2,7 % |

3,4 % |

1,9 % |

2,4 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

18 |

15,0 |

2,4 % |

3,0 % |

1,8 % |

2,3 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

19 |

20,0 |

2,0 % |

2,5 % |

1,8 % |

2,2 % |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Engine power in hp before: |

Labor intensity in man-hours per 1 machine-hour |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

25 |

0,25 |

26 |

0,22 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

50 |

0,28 |

48 |

0,25 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

60 |

0,32 |

55 |

0,26 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

75 |

0,35 |

69 |

0,29 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

90 |

0,37 |

86 |

0,32 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

120 |

0,45 |

116 |

0,39 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

140 |

0,52 |

130 |

0,44 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

150 |

0,6 |

156 |

0,56 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

170 |

0,67 |

197 |

0,7 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

10 |

200 |

0,75 |

224 |

0,77 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

11 |

220 |

0,9 |

235 |

0,88 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

12 |

230 |

0,97 |

250 |

0,95 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

13 |

240 |

1,05 |

276 |

1,0 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

14 |

300 |

1,12 |

300 |

1,01 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

15 |

340 |

1,27 |

320 |

1,07 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

16 |

350 |

1,5 |

408 |

1,57 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

17 |

380 |

1,65 |

428 |

1,67 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

18 |

480 |

1,87 |

544 |

Having information about the cost of one machine-hour of vehicle operation, the company has the opportunity to profitably choose a supplier providing services for the rental of machines and mechanisms. We are offering to you detailed algorithm such a calculation. To determine the cost of work transport technology it is necessary first of all to calculate the cost of one machine-hour. This calculation is necessary in the following cases:

To determine the cost of one machine-hour of a certain type of vehicle, the following indicators must be taken into account:

Let's take a closer look at each indicator and give examples of the calculation. Book value of the vehicle- the cost of the vehicle, reflected in the accounting documents, which, when acquiring the vehicle, is equal to the original cost of the vehicle, and after revaluation is equal to the replacement or full replacement cost of the vehicle. Depreciation rate for each item of depreciable property when applying the straight-line method is determined by the formula:

Where K— depreciation rate as a percentage of the original (replacement) cost of the depreciable property; n- term beneficial use of this depreciable property, expressed in months. Note! When determining the useful life of fixed assets, it is necessary to be guided by Decree of the Government of the Russian Federation dated 01.01.2002 No. 1 “On the Classification of fixed assets included in cushioning groups"(As amended on 10.12.2010). Standard indicator costs for all types of repairs, diagnostic and technical maintenance of machines is determined by the formula: where B s — replacement cost of the machine, rub.; H p - the rate of annual costs for repairs and maintenance as a percentage of the replacement cost of machines; T- annual mode of operation of machines, machine-hours / year. Costs for fuel and fuels and lubricants can be determined on the basis of fuel and lubricant consumption rates established in a particular organization. Usually these standards are set and approved at a production meeting in the company. You can also be guided guidelines"Consumption rates of fuels and lubricants for road transport”, approved by the Order of the Ministry of Transport of Russia dated March 14, 2008 No. AM-23-r (as amended on May 14, 2014). Remuneration of the driver, taking into account deductions from wages depends on the form of payment in the company. The most common are piecework and time-based forms of remuneration. piecework form remuneration of labor involves remuneration of labor according to the quantity of products (work) of established quality, taking into account the complexity and working conditions. According to the accepted accounting procedure, the result of the work of each performer individually or the collective (group) result (for the entire group of workers) can be taken into account. With a temporary form labor is paid depending on the time worked at hourly, daily and monthly rates or salaries. This form of payment is used in cases where the output of an individual worker cannot be accurately recorded and expressed in a certain amount of products or work, or when, due to the nature of the work, it is not economically feasible to transfer workers to piecework wages. Example 1 Initial data:

The salary, taking into account personal income tax, will be: 162 × 130 × 1.3 = 27,378.00 rubles. Deductions from wages: 27,378.00 × 0.3 = 8213.4 rubles. ____________________ Overheads accompany the main production, are connected with it. These are the costs of maintenance and operation of fixed assets, management, organization, maintenance of production, business trips, employee training and so-called unproductive expenses (losses from downtime, damage to material assets, etc.). Overhead costs are included in the cost of production, the cost of its production and circulation. Example 2 Suppose that in example 1 industrial construction is considered. In accordance with the regulations, overhead costs should be 90% of the wage fund. Accordingly, overhead costs will be: 27,378.00 × 0.9 = 24,640.20 rubles. ______________________________ Consider an example of calculating the cost for 1 machine hour. Example 3 Let's calculate the cost of 1 machine-hour of operation of a ZOOMLION RT-550 short truck crane with a lifting capacity of 55 tons. For the calculation, we use the following data:

The calculation is presented in the table.

Chapter 6 General provisionsThese recommendations contain rules for the development and application of prices for the operation of construction machines and are intended for practical guidance in setting contractual (contract) prices, as well as for drawing up investor estimates during contract bidding. The indicators given in the recommendations are of an average nature; in their calculation, various kinds of percentages were used, on the basis of which similar methods were built over the past10 years. The data of these recommendations can be used to determine the cost of a machine hour both in the central regions and in the regions of the Far North and areas equated to them. These recommendations assume that the overhaul of construction machines is carried out by specialized enterprises. The wages of maintenance workers involved in major repairs are used as the basis for depreciation, overheads and profits. When establishing the cost of construction machines and mechanisms for depreciation, it is recommended to use data on the selling prices of supplying plants as of the date of drawing up investor estimates or performing calculations of contractual (contract) prices. An example of calculating the cost of a machine-hour of a bulldozer (B.10.1111-1E 125 kW, 170 HP)

* An example of calculating the cost of a machine-hour of dump trucks (KAMAZ 55111 g / p 13 tons, 176 kW, 240 hp)

* - must be taken into account in the calculations. Domestic cars - 11 %; Imported cars - 7%. 5. Indirect costs of the organization during the overhaul "Guidelines for the development of estimated standards and prices for the operation of construction machines and vehicles" MDS 81-3.99 Examples of costing p. 1.2. (Appendix 4). Costs for fuels, lubricants and hydraulic fluid 1. The selling price for diesel fuel, oil and hydraulic fluid is taken from the supplier's data. 2. The cost of delivering the product to the refueling machine is determined by the specific conditions for the provision of machines of this standard size group. According to their content, they reflect the costs associated with the operation of tankers, with depreciation and operation of an intermediate storage of energy carriers. According to actual data, the marginal cost of fuels and lubricants and process fluids is: For central regions - up to 15 %; For the regions of the Far North and equivalent regions - up to 20% of the selling price of the product ex-oil base. 3. Consumption rates for fuel, oil and process fluids are accepted according to the data of the machine manufacturer or according to the Collection of estimated rates and prices for the operation of machines 4.03-9 1. 4. Consumption rate of lubricants = 0.063×N, where 0.063 - coefficient taking into account the consumption of lubricants; H is the rate of consumption of diesel fuel. 5. Hydraulic fluid flow rate = (100 l×0.87 kg/l×1.5×2): 2260 h = 0.12 kg/h, where 100 l - capacity of the hydraulic system of the machine; 0.87 kg/l - hydraulic fluid density; 1.5 - coefficient of topping up hydraulic fluid; 2 - the frequency of complete replacement of hydraulic fluid per year; 2260 hours - the annual mode of operation of the machine. 6. To take into account the increased fuel consumption during the operation of machines in winter, average annual coefficients are used, differentiated by temperature zones.

Wear parts Moscow 1994 Clause 2.16. Extract The share of costs for the replacement of wear parts in the structure of direct costs for the operation of construction machines, determined according to the prices of Book 4.03-91 is 3.5%. Wear parts include excavator bucket teeth, conveyor belt, cables, ropes, chains, tires, etc. ... Calculation of the cost of replacing tires on a truck (KAMAZ dump truck 13 t, three-axle) 1. The cost of one tire (brand 280-508R) is 2517 rubles. 2. The cost of the camera and rim tape - 289 rubles. 3. Total set; 2517 + 289 = 2806 rubles 4. Including delivery: 2806×(1 + 15%) = 3226.9 rubles. 5. Including assembly: 3226.9 × (1 + 10%) = 3549.6 rubles. 6. The replacement kit includes 11 tires 7. The cost of the whole set: 3549.6× 11 \u003d 39045 rubles. 8. Full tire mileage before replacement is 65 thousand km 9. The normative annual mileage of the car is 40 thousand km 10. Annual cost of tire replacement: 39045 × 40/65 = 24028 rubles. 11. With a standard annual operating time of the machine of 2260 hours, the indicator for tire replacement will be - 24028/2260 = 10.63 rubles/machine-hour. Substantiate Entry 7 Indirect costs for major repairs Indirect costs TOTAL: 40% + 70% + 30% = 140% The list of machines, the costs of relocation of which are taken into account in the estimates in a separate line: Bases are pipe welding, field, semi-stationary; bulldozers with an engine capacity of 400 hp. With. and more; tower cranes, cantilever-sluice cranes, on caterpillar tracks, on pneumatic wheels, for the construction of cooling tower shells; copra universal; dredging and jet-ejector shells; machines for tunneling works; heavy dump trucks; belt conveyors; loaders; scrapers 15 cubic meters; locomotives; overburden excavators; lifts; pipelayers 50 t; asphalt concrete plants 50 t/h. Annex 1Percentage of the selling prices of manufacturers (sellers) for the initial delivery and relocation during the operation of construction machines and mechanisms during the year. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||