Where does the air come from in the cooling system, if all the clamps are well tightened, the antifreeze level is always normal, there are no leaks, the thermostat and pump work fine.

I think the reason is that a steam outlet pipe was made from the radiator to the expander tank, and this is where an air lock forms. The radiator cools faster and warm antifreeze from the expansion tank begins to evaporate air into the system. It takes a lot of effort to drive air down by squeezing antifreeze in the tank, but back under pressure to drive air into the radiator and create bubbles in the upper pipes of the system - this is very likely easy to do.

How does airing of SOD occur during normal operation of a car with a normal coolant level, tightly tightened clamps, sealed radiators and serviceable stopper RB?

Let's take a look at the drawing of the SOD in photo 2. Steam vent hose No. 6 is never completely filled with coolant. If it were transparent, then we would see in the process ICE operation that inside it areas with liquid alternate with areas of air. The surface tension prevents the liquid from settling at a certain level. In addition, in our RB, the “MAX” level mark is approximately 60 mm higher than the fitting for the steam outlet of the radiator of engine No. 11. At ICE cooling, and consequently the coolant poured into it, atmospheric air is drawn into the upper part of the radiator, from where it enters the thermostat through the inlet hose No. 9, which has a slight slope. In the morning, we turn on the internal combustion engine, the coolant pump of which draws the trapped air into the heater radiator through the supply hose No. 2 and into the internal combustion engine through the supply pipe No. 3 hose. But don't think that the very next morning you will get a problem with SOD. No. This happens gradually, day after day, and depends on the outside temperature. First of all, we hear different sounds from under the instrument panel. Waterfall, gurgling, overflowing water, murmuring... In the cold period of the year, a decrease in the heat output of the heater radiator is added to this. It's cold in the cabin. And only when the internal combustion engine temperature "creeps" along the instrument panel to the red zone, and the internal combustion engine radiator fans do not stop for a long time we start scratching our heads. Worst of all, if we learn about the problem with the SOD by the puffs of steam from under the hood.

From this situation, I found such a way out - it is necessary that the steam outlet pipe drown in antifreeze at the bottom of the expander tank. I took the system from a medical dropper, stuffed the needle with the tube from the dropper into the branch pipe of the dilator, then put this pipe with the tube inside from the dropper back onto the tank and clamped it. That's it, now the back pressure from above into the system through the radiator cannot be created in any way, there is no reverse air flow into the radiator.

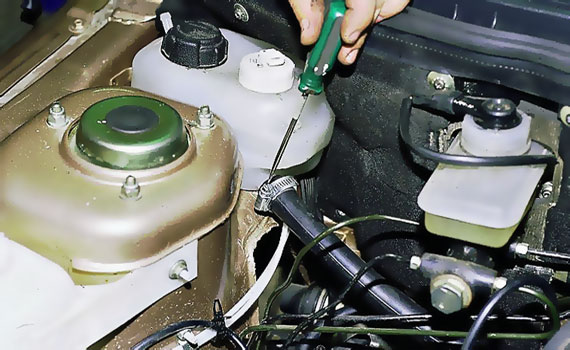

How to make a water seal?

photo 3

We cut off somewhere 15-20 cm of the tube from the dropper. At one end we put on the tip of the needle. As strongly as possible we bend the tube onto the fitting from the needle. The needle itself can be broken off initially. Next, we push this entire structure into the expansion tank fitting, and cut off the excess part of the needle fitting, as shown in the photo. In order for the dropper hose to push through a 90-degree angle in the Republic of Belarus, you need to cut the end of the tube to a bevel - this way it will be easier to push through there. Next, we put on the RB pipe and clamp it. That's it, the water seal is made, there is no reverse air flow from the RB to the radiator.

The cooling system of a car engine requires increased attention both in the warm season and in winter period. Therefore, proper and timely maintenance of the cooling system will help you get rid of many problems with the machine, most often due to non-compliance with elementary rules.

The automotive cooling system is quite complex. reliable performance which is possible only if all its components and assemblies are in good condition. Ideally, system maintenance should come down to just two things:

- Flushing - instructions for flushing the engine cooling system;

- Replacing the coolant - instructions for replacing antifreeze.

But ideal conditions do not exist, therefore, during the operation of the car, it is important to monitor the tightness of the cooling system and what you pour into it. In this article, we will tell you what you need to pay attention to when servicing the engine cooling system to prevent malfunctions.

For details on how the engine cooling system works in a car and the features of its maintenance, see the video at the bottom of the page.

First, let's remember what is poured into your cooling system? Not so long ago, it was quite common to find cars with water in the engine cooling system instead of antifreeze. Fortunately, the use of water as a coolant has become the exception rather than the rule these days. It is usually used in emergency situations when something needs to be poured into the system, but there is no antifreeze at hand.

If we compare the characteristics of water and a special coolant (antifreeze), then the latter has a lot of advantages - this is more heat boiling, and low temperature freezing, and the presence in the composition of softening and anti-corrosion additives that prevent the formation of scale and rust in the engine cooling system.

We have decided on this issue - no water in the engine cooling system! But it should be borne in mind that the durability of the system largely depends on the quality of the coolant. You should not buy the first canister that comes across with the inscription "Antifreeze" or "Tosol", you need to give preference only to products from reliable manufacturers that have all the necessary certificates.

Most counterfeit fluids contain aggressive acids, which over time corrode not only parts of the cooling system, but also lead to the appearance of "shells" even in the engine cylinder head! Therefore, we do not advise you to save on antifreeze.

We wrote in great detail about the types of automotive coolants, their differences from each other, and how to choose antifreeze for your car in this article, we strongly recommend that you read it!

Also one of important criteria The quality of the coolant is the presence in its composition of special fluorescent additives that help detect leaks in the engine cooling system. Since the system must be sealed, leaks in it are unacceptable.

Checking the cooling system for leaks

Checking the engine cooling system for leaks milestone in her service. The fact is that in a sealed system, antifreeze boils at a temperature of 130 ° C, and under normal conditions it boils at only 108 ° C. Therefore, the slightest crack, for example, in a cooling radiator, a rubber hose or an expansion tank, breaks the tightness and the engine boils.

To facilitate the search for microcracks in the engine cooling system, special fluorescent additives that are part of modern antifreeze help - thanks to them, it glows in the rays of an ultraviolet lamp.

But, unfortunately, not every motorist has such a lamp. Therefore, in the process of maintaining the engine cooling system, we recommend that you follow a few simple rules:

- To check the fluid level on the expansion tank, there are MIN marks and MAX. With a cold engine, the antifreeze level should be between these two marks.

- If the coolant level in the expansion tank is constantly decreasing, then this indicates a leak, that is, a violation of the tightness of the engine cooling system.

- Carefully inspect your radiator and pipes for leaks and smudges, tighten the connecting clamps if necessary and make sure that the radiator cap is closed all the way.

The presence of air in automotive system cooling (the so-called "air locks") can also disrupt its operation. Below we will reveal to you the easiest way, how to bleed air from engine cooling system.

The presence of air in the cooling system is checked as follows:

- Open the expansion tank cap,

- Turn on interior heating for full power and let the engine run idling two or three minutes

- If there is air in the cooling system, then bubbles will appear in the expansion tank.

In order to remove air from the engine cooling system, the car must be tilted so that the "front" is slightly "pulled up" to the top. Further, the sequence of actions will be as follows:

- Open the radiator cap and start the car.

- Turn on the stove and let the engine run for a few minutes to allow air to escape from the system.

- After that, the engine can be turned off and the radiator cap closed.

And now let's look at a few more nuances that you should pay attention to when servicing the engine cooling system to prevent the occurrence of malfunctions or eliminate them.

What should I pay attention to when servicing the engine cooling system

To prevent malfunctions of the engine cooling system, it is necessary to regularly perform the following maintenance operations:

- Coolant Density Check. The density of antifreeze is checked with a hydrometer. For high density, dilute your fluid with distilled water, and for low density, dilute with a similar coolant.

- Tension drive belt . One of the most common causes of car engine overheating (especially with mechanical drive fan) is a weak drive belt tension. Belt slip reduces the performance of the pump and, accordingly, the speed of rotation of the impeller.

- Cleaning the engine cooling system. Also don't forget to check external state motor and radiator. Both the radiator and engine need regular cleaning as dirt and debris get in the way normal cooling motor. Often the radiator is clogged with dirt, dust, poplar fluff and other muck. All this debris is easily removed with a strong jet of water or a powerful vacuum cleaner. Oil leaks on the engine and dust adhering to them should also be washed off regularly.

- Thermostat check. An important element cooling system is a thermostat, which maintains the optimum operating temperature of the motor, as well as fast warm-up engine immediately after starting. We wrote in detail about how a car thermostat works and methods for diagnosing it in an article about the device and principle of operation of a car thermostat.

- Engine cooling fan. Another element that requires attention when caring for the engine cooling system is the fan. On most modern cars electric cooling fans are installed, which are controlled by a thermoelectric sensor screwed into the radiator. When the set temperature is reached, the sensor contacts are closed, and the fan starts to work, cooling the surface of the radiator.

If the fan does not turn on when the engine warms up, the reason for this may lie in the temperature sensor. The operability of the sensor is determined very simply, for this you just need to close its contacts:

- if the fan is running, then the sensor is faulty,

- if not, the reason is either in the fan motor, or in electrical circuit his nutrition.

Video about the features of servicing the engine cooling system

The cooling system of each car is a rather complex device with many various nodes included in its composition. And the most common malfunction is an air lock. In this article, we will focus on this particular breakdown, the causes of its occurrence, the consequences, ways to eliminate it, as well as about preventive actions.

The condition of the cooling system must be monitored as carefully as the most important systems auto. Photo: lr-club.com

What is an airlock and symptoms of manifestation

Some novice motorists have often heard the expression "air lock", but not everyone knows what it is and whether it is dangerous for the operation of the car. An air lock is the entry of air into the coolant circulation system. As a result of the occurrence of such a malfunction, the correct circulation of the coolant through the system will be disrupted, which in the future can lead to costly repairs.

The main symptoms of the manifestation of airiness are as follows:

- Lack of heat in the car. Due to the fact that air has entered the cooling system, there is no coolant supply to the heater radiator, and, therefore, there is no heat.

- Engine overheating internal combustion(ICE). If the system is air-filled, then the coolant cannot move freely and, as a result, the motor overheats. You can determine this by the temperature indicator, which is located on the dashboard;

- Reduced engine power.

If such defects are found, an inspection of all components included in the system should be carried out.

Now it is worth considering the reasons why this problem occurs.

Reasons for the airiness of the cooling system

There are many reasons why air can get into the cooling system, but it is worth considering the most common:

- Damage to the cylinder head gasket (cylinder head). If cylinder head gasket damaged, then coolant leakage is possible, it will manifest itself as follows: seething in the expansion tank, liquid entering the oil pan, and white steam from the muffler.

- Depressurization of the water pump (pump). If the pump is depressurized, it can pick up air and then an air lock is formed.

- Depressurization of elements of the cooling system. Air can enter the system through a seal failure at the junctions of nozzles, fittings and tubes. While the coolant will pass through the pipe or tube, air may be sucked in from the outside at the site of damage.

- Expansion tank cap broken.

The plug of the expansion tank works like a valve and relieves excess pressure. In the event of a breakdown, reverse process and it starts pumping air into the system.

- Radiator damage.

Another common cause of air locks is air entering the system during coolant replacement or topping up.

What can cause air in the cooling system

The consequences can be different, from minor to critical, everything will depend on at what point the motorist discovered the malfunction. Photo: mail.ru

Some of the minor impacts include:

- failure of various sensors. As a result of a breakdown of the sensors, incorrect data on the operation of the car will be received;

- partial or complete absence of heat in the car;

- increased fuel consumption;

- increased wear of engine parts.

If the air in the cooling system is not detected and eliminated in time, this can lead to a breakdown of the internal combustion engine.

Materials and liquids expand when heated, if there is no proper cooling, this can lead to a modification of the engine components, and as a result, to the death of the motor. And then to expensive and time-consuming repairs. Now it is necessary to consider the ways in which the air lock is eliminated.

Methods for eliminating air lock

There are several ways to eliminate air lock in the cooling system. All of them are quite simple and there is no need to visit a service station.

The first way looks like this:

- the plastic protection is removed;

- then use a screwdriver to loosen the clamp and remove the upper or lower branch pipe throttle valve;

- then the plug of the expansion tank is unscrewed and a clean rag is placed on the neck;

- now you have to blow with all your might expansion tank, the procedures should be performed until the coolant flows out of the removed pipe;

- install the pipe back into place and tighten the clamp, and also put the protection in place.

Second way:

- drive the front wheels onto the lift or overpass in such a way that top point the radiator cap has become in the cooling system;

- unscrew the caps from the expansion tank and the cooling radiator;

- start the engine and bring to operating temperature 90 degrees;

- then you should turn off the gas and gradually add coolant to the expansion tank. Top up until there are no more bubbles in the reservoir.

The third way.

- it is necessary to bring the engine to an operating temperature of 90 degrees and turn off the engine;

- now, with the help of a screwdriver, the clamp for fastening the throttle valve pipe is loosened, and the pipe itself is directly removed;

- then you should wait until all the air that has entered the system comes out of the pipe, as soon as the coolant runs, you should quickly put it in place.

In such ways, you can get rid of the air congestion with your own hands. It is worth noting that of all the methods, the first one is 100% effective.

Also, if you follow some simple rules, which will be discussed below, you can avoid problems with the cooling system.

You can find a video instruction on how to bleed the cooling system here:

What will reduce the risk of air lock

If you follow the rules for operating a car, you can significantly reduce the risk of an air lock in the car. These recommendations look like this:

- compliance with regulations service book for the passage of maintenance (TO);

- checking the coolant level at least once a month;

- fill only recommended and high-quality coolant. Very often, if low-quality coolant is used, then airing of the system occurs.

Outcome

It's time to take stock. The cooling system in every vehicle plays a major role in ensuring required cooling and maintaining the required internal combustion engine temperature, and is also responsible for heating the cabin. If you carry out scheduled maintenance on time and monitor the coolant level, then there will be no problems in the operation of the engine. After all, if you do not notice and do not eliminate the airing of the system in time, this can lead to serious problems, in some cases to overhaul ICE.