People who have a country or private house feel the need to transport bulky goods, so a towbar will be needed in this case. And do it yourself and save money.

This article is intended for persons over 18 years of age.

Are you over 18 already?

Many car owners, not wanting to overpay for cargo transportation services, decide to make a towbar with their own hands. It may be needed in many cases. In the modern world, it is quite difficult to live without a trailer, having a car. Everyone sooner or later makes repairs in their homes, and for the transportation of building materials you have to overpay and order delivery. Those who own a country house or dacha, at the end of each season, puzzle over how to transport the crop to their city dwelling. Residents living near the seas transport their boats and boats to the water by the beginning of the season. In general, a towbar is an indispensable thing that should be on every car, if in your garage, in addition to a passenger car, there is also a truck.

Towbar, if it is not on your car, you can buy it at the car market or make it yourself. It is not difficult to make a tow hitch for a car with your own hands.

But the first thing to know - before you take up the materials, be sure to go for registration with the traffic police, otherwise the installation of the towbar will be illegal, and you will have to pay a fine.

Tow hitch for car

Tow hitch for car

Necessary materials

To make a part with your own hands, you will need the following tools and equipment:

- welding machine;

- Sander;

- drill and drills of the required diameter;

- a steel ball, made independently or bought ready-made;

The do-it-yourself towball ball must be absolutely round and have a diameter of 50 mm. This is the standard diameter used for European and domestic machines. In American cars, the ball diameter ranges from 50.8 mm to 53.975 mm.

Materials required for work:

- one and a half meter steel pipe with a diameter of 50x50;

- sheets of steel, the thickness of which is 5 mm, measuring 300 by 70, and two sheets of 200 by 70;

- bolts M10 and M12. The first will require two, the last - six pieces;

- socket;

- insulated wires and electrical tape (or heat shrink);

- screws with nuts, about 40 mm long.

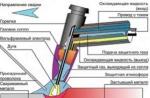

Semi-automatic welding

Semi-automatic welding

As you can see, not so many consumables are required to make such a useful device in everyday life.

Preparatory work

In order to decide how to make a towbar with your own hands, you should understand what the maximum load will be for the device and set the type of mount that is suitable for a particular car.

The load must not exceed the total weight of the machine. Do not miss this moment, it is very important.

Ideally, it is recommended to install factory-made towbars, but there is nothing to worry about if you make it yourself. It is not difficult and it will serve you for as long as the factory one, if everything is done technically correctly and all the nuances are taken into account.

Most often, home-made towbars are installed on vehicles of domestic production. Do-it-yourself towbar on the Oka can be of different types: welded, flanged and collapsible. Installation is carried out using general rules.

Dimensions

The dimensions of towbars are selected individually for each car, taking into account the design features and size of the vehicle. The expected load and type of fastening are taken into account. Do not miss the appearance of the car after attaching the part.

The dimensions of the towbars are selected individually for each car.

The dimensions of the towbars are selected individually for each car.

Drawings and templates

In the era of computer technology on the Internet, you can easily get any information and download any drawing. The same applies to the do-it-yourself towbar drawings.

There are several design options:

- stationary hitch;

- removable;

- quick release.

You should choose the one you need, taking into account the design features of your vehicle. They have a common scheme, but the types are different - depending on the method of attachment to the body.

Fixed, or as it is also called, stationary, is attached in such a way that the towbar with the car body is one piece and cannot be removed.

Removable parts are preferred by those drivers who do not want to spoil the appearance of the car with this device and after use, dismantle it.

With the help of a flange mount, which is also removable, the towbar is fixed to the frame or power bumper using bolts for this. This method is used in order to be able to transport heavy loads.

Fixed hitch

Fixed hitch

The flanged towbar is the most versatile, its only drawback is that even if the part is dismantled, the bar will still be visible. Nevertheless, it fits absolutely all vehicles, and it is possible to adjust it in height.

Manufacturing process

So, how to make a tow hitch with your own hands? The first thing to start with is to get a ball with eyes. It doesn't matter if it's new or used.

First, remove the bumper of the car, cut off the eyes and use a drill to make holes. Using a pipe of the selected diameter and up to one meter long, we connect the fasteners. This must be done with a welding machine. At a right angle, we fix another pipe in the center of the first one using the same welding. After completion of welding work, the structure should be primed and painted.

To strengthen the langeron, it is recommended to insert a small piece of a corner with nuts welded to it. The result should be a semblance of a removable towbar. This structure can be connected to electricity through the headlight, while the socket can be made through the connector.

We figured out how to make a towbar, the next question that arises for car owners is how to attach it to the vehicle body.

The method for each car will be different. For example, you will need to drill holes in order to install the manufactured towbar on Lanos with your own hands. The manufacturer does not provide special holes.

Making a towbar with your own hands

Making a towbar with your own hands

Tow bar installation:

- For installation, you need to place the car on a lift or use a viewing hole. So it will be more convenient to work without crawling under the car.

- Turn off all electronics. The car must be de-energized.

- Remove the contents from the trunk and dismantle the upholstery.

- We attach the design of the towbar to the car and wonder if everything is done correctly. The help of a friend will not be superfluous at this stage.

- Using a drill, drill the holes necessary to secure the part. The drill should be 12.5 mm in diameter. Bolts with nuts are inserted into the drilled holes and tightened with a wrench.

- From the side of the trunk and at the bottom of the langeron, we drill two additional holes. In this case, a reinforcing overlay should be applied. Bolts are also inserted into the holes.

- Another hole is drilled in the bottom of the trunk. It will be required to connect the wires and sockets. Remember to take into account the colors of the wires, and carefully mark the locations before drilling holes to avoid mistakes.

- The final step is to connect the wires and connect them to the outlet.

The simple process of installing a product such as a do-it-yourself trailer hitch can be considered complete.

By adhering to certain rules and doing the work in good conscience, you will get an excellent towbar and be able to solve the problem of transporting goods yourself.

It is very important to remember that absolutely all drilled holes in the body of your car must be treated with anti-corrosion compounds. Since the part is located at the bottom of the machine, all bolts are treated with anticorrosive.

The current legislation contains a rule according to which all devices at the rear of the trailer must exactly duplicate the operation of the car's lighting devices. Do not forget about this, otherwise a fine and emergency situations cannot be avoided.

To paint the towbar, do not forget that this is the same metal part as any other on the car body. Painting work should be carried out in strict sequence, starting with cleaning the surface.

Towbar painting

Towbar painting

Carefully monitor the reliability of the design. No one wants to lose a trailer while driving. Such an incident can cause a lot of trouble.

When carrying out welding work and manipulating the grinder, do not forget about safety precautions and work with safety glasses.

By installing a towbar on a passenger car, you will be able to transport a standard trailer. After reading the article, you will find out what types of towbars are, how they are installed and connected to the car's on-board network.

How to choose a hitch

Most passenger cars are not equipped with a towbar, therefore they are unable to transport goods. Installing a towbar allows you to use the car as a towing vehicle, which is especially useful when traveling to the country, transporting building materials and other work. The permitted weight of a loaded trailer is half the weight of an average vehicle. If you subtract the weight of the trailer itself from this value, then you will be able to transport up to half a ton of cargo without increasing the load on the chassis of the car.

The stores sell various types and options of towbars - non-separable, removable, welded from pipes or assembled with bolts. In addition, it is easy to make a towbar yourself by finding drawings on the Internet or buying a used one inexpensively. When choosing a towbar, it is necessary to consider for which car it is made. A towbar for small and light cars is not suitable for heavy minivans or SUVs, because the actual loads will be higher than the calculated ones. In addition, the towbar installation kit is made for a specific car. Installation in another vehicle is only possible if the width between the mounting holes of the body is exactly the same. Otherwise, a serious alteration of the device will be required.

A towbar with a fixed hook is a danger to the car. If your car is hit from behind, the bumper will not be able to absorb the force of the impact, because the tow bar protrudes behind it and has high rigidity and strength. As a result of even a small collision, the towbar frame will transfer the impact energy and break the geometry of the body. Therefore, a towbar with a removable or retractable hook is preferable, because it allows you to transport goods, and when folded, does not deprive the car of the protection provided by the bumper and body metal.

By purchasing a towbar in a store, you get a guarantee under which you can repair or replace it if any defects are found. When buying a towbar from your hands, you act at your own peril and risk, because there can be no question of any insurance. Therefore, carefully approach the choice of device. Trying to save a few thousand dollars can cause the trailer to come off the car. If this happens while driving on the highway at high speed, then unpredictable consequences are possible. In addition, a towbar designed for a particular car is attached to the holes provided for by the design of the car, which do not reduce the strength of the body. If you are going to drill holes for it, then do not forget, there is a small chance that the hole will weaken the body.

If you get into an accident on such a car, you will lose the right to compensation, because unacceptable changes have been made to the design of the vehicle.

Tow bar installation tools

For work you will need:

- pit, overpass or lift;

- towbar installation kit;

- drill and a set of drills for metal;

- a set of keys;

- Screwdriver Set;

- means for anticorrosive processing of openings;

- pliers;

- side cutters;

- wires;

- insulating tape.

Do-it-yourself towbar installation - Video instruction

Roll the car onto a pit, overpass or lift. It is undesirable to install the towbar from jacks, because there is a high probability of their tipping over due to side loads. Before starting work, carefully read the article. The information in this article will help you avoid injury and damage to your vehicle. Read the instructions for the hitch. There are many different ways to install this device, depending on its design. If the towbar is made for your car, then you don’t have to drill anything. If you are using a towbar designed for another machine, prepare a grinder with a metal disc, a welding inverter, a drill with a set of drills and a means to protect the holes from corrosion.

Disconnect the battery, unload all the contents of the trunk, remove the mat and remove the spare tire. After that, find the holes for installing the towbar. They are located in the side members in the trunk area. On frame SUVs, the towbar is always attached to the frame. On cars with a monocoque body, they are mounted above or below the trunk floor. Sometimes, in addition to spars, holes are located in the bottom of the trunk. Regular holes can be found by plastic or rubber plugs. Pull out the plugs, attach the towbar frame to the holes and make sure that the holes on the mounts and the body match. If any holes do not match, mark and drill them on the towbar frame. Then the frame. When the frame is dry, it is attached to the body using bolts and nuts from the installation kit. You may have to remove the bumper for this operation (depending on the model and how the towbar is attached).

If you are installing a tow bar that is not designed for your car, then put it in place to check if it fits into any holes or not. If there are no holes in the body or side members at the attachment points of the towbar, they will have to be drilled independently. The diameter of the holes should be 1-1.5 mm greater than the thickness of the fixing bolts. Replace the towbar frame to make sure the holes line up. After that, it is necessary to carefully treat the holes with an anti-corrosion agent. After it dries, put the frame in place and secure with bolts and nuts. Having installed the towbar, it is necessary to carefully check the tightening of all bolts.

Forkop socket connection - diagram

Most often, a standard seven-pin socket is installed on the towbar, although other options are possible. The socket is connected either to the wires of the corresponding bulbs (directly or through a relay), or to the signal socket of the car. If you connect the outlet to the wires, then the connections must be soldered and protected with heat shrink tubing.

- To do this, the wire at the point of contact is cut and protected from both sides at a distance of 0.5-1 cm. The wire going to the outlet is stripped at a distance of 1-1.5 cm.

- Then all the stripped ends of the wire are tinned, a heat shrink tube is put on any of the cut wires.

- Then they are soldered to each other so that the conductor going to the outlet connects both ends of the cut wire. The tube is pushed over the solder and heated with a hair dryer or lighter until it completely seals the wires.

- After that, you need to check all connections to avoid a short circuit, then connect the battery and use a tester or a light bulb to check that the connector pins are connected correctly. To do this, connect the light bulb to the appropriate connectors and turn on the desired mode (turn, dimensions, braking, number plate lighting).

Hello, our dear motorists! Today we will try to figure out the purpose of such a car part as a tow bar. For those who have forgotten what it is, I remind you: - a special device designed to hitch a trailer with a car.

Its extreme part, mounted on a passenger car, is a ball on a hook that protrudes beyond the rear bumper and can be easily seen. This hook is attached to a special beam installed under the bottom of the body, which can be called the second part of the towbar, hidden from prying eyes.

If the cargo that needs to be transported does not fit into the interior and trunk of your car or it is too heavy, you will need such a part. It should be noted that not all machines are equipped with it, but you can install it separately if you wish.

Currently, there are three types of towbars: welded, removable and flanged. Welded is considered the most reliable and relatively cheap, but it has one drawback - it cannot be removed. It will be possible to install a flanged towbar only if your car is already equipped with a special platform for it.

In order not to make a mistake with the choice of a towbar - be sure to consider not only the make and model of your car, but also the year of manufacture. The ideal option would be to consult a professional. To do this, you just need to drive your car to a service station or the nearest service center, where a specialist, taking into account all the nuances, will be able to select a suitable towing device. When buying a towbar, do not forget to check for its certificate, otherwise you risk getting a low-quality part, which can create problems in the future.

The most popular, recently, towbars are used among hunters, summer residents, tourists and fishermen. With its presence, it becomes possible to use a trailer, and this is a very valuable addition to the car, especially if you often have to transport equipment, equipment, crops or other bulky things. Let us consider in more detail all the advantages of a towbar.

Why do you need a towbar

In our time, when the car has become more of a necessity than a luxury item, it has become possible to effectively use it in various areas of human life. Modern cars are equipped with more and more new parts designed to provide driver comfort. As for the towbar, this is by no means a new device. I'm sure many of you remember the inconspicuous hook that barely peeped out from under the rear bumper of grandfather's Zhiguli, which means that this device has been around for decades.

In those days, almost all towbars were welded and could not be removed, and in order to close the hook ball, rubber toys were often put on them. I don’t know about you, but I often paid attention to rabbits, bears and dogs sitting almost on the rear bumper of the car, and over time I even recognized all my neighbors by them. But let's not deviate from the topic. Let's see what exactly a useful towbar can be and is it needed at all?

People who travel often or simply lead an active lifestyle very often carry various things with their car. One of them fits freely in the trunk of a car (small things), and the second, which may include more massive structures, often has to be transported by a separate vehicle - a truck or bus. The presence of a towbar in the car greatly facilitates this task, as it allows you to attach the trailer to the car and load everything you need onto it.

People who travel often or simply lead an active lifestyle very often carry various things with their car. One of them fits freely in the trunk of a car (small things), and the second, which may include more massive structures, often has to be transported by a separate vehicle - a truck or bus. The presence of a towbar in the car greatly facilitates this task, as it allows you to attach the trailer to the car and load everything you need onto it.

In principle, one of the main functions of this device lies in the transportation of additional cargo. But they use a towbar not only to attach a cargo trailer to a car. Also, if you decide to relax with your family outside the city, you can use it to tow a residential trailer (such as a "house on wheels").

Some drivers think that the presence of a towbar (even in the absence of a trailer) is already a positive addition to the car. This opinion is based on confidence in the protective function of this device in the event of an accident, supposedly in a collision (and suddenly someone drives into you from behind), it will be able to take the brunt of the blow. But such a statement is wrong.

Some drivers think that the presence of a towbar (even in the absence of a trailer) is already a positive addition to the car. This opinion is based on confidence in the protective function of this device in the event of an accident, supposedly in a collision (and suddenly someone drives into you from behind), it will be able to take the brunt of the blow. But such a statement is wrong.

Directing the entire force of impact in one place will do more harm than distributing this force over the entire area of the bumper, so the towbar must be removable and not expose the car to unnecessary danger. This is the opinion of the inhabitants of many countries in which driving with a towbar without a trailer is prohibited by law.

towbar mount

It is quite possible to attach a towbar to your car without the help of specialists. Perhaps it will be a little longer than in car workshops, but if you follow certain rules, as a result you can be sure of its reliability.

First of all, responsibly approach the issue of choosing a towing device: it must fully correspond to the model of your car and perform not only a practical, but also an aesthetic function.

Also, when buying a device, do not forget that all towbars can be either removable(if you want, you can easily detach the hook from the beam), or fixed(hook with a beam - a single unit). The first option, from the point of view of ease of use, is, of course, more interesting, since if it is not necessary, the hook can be removed so that it does not affect the general appearance of the car.

Also, when buying a device, do not forget that all towbars can be either removable(if you want, you can easily detach the hook from the beam), or fixed(hook with a beam - a single unit). The first option, from the point of view of ease of use, is, of course, more interesting, since if it is not necessary, the hook can be removed so that it does not affect the general appearance of the car.

The load capacity of the towing device is another criterion for its selection. It is clear that stronger structures designed to transport large loads are more expensive, but it is not worth saving in this matter: transporting cargo that exceeds the permissible towbar load capacity threatens with the possibility of serious consequences for road users.

And so, let's assume that after reading the listed recommendations for choosing a towbar, you took them into account and purchased the desired device. Now it remains only to install it on the car.

And so, let's assume that after reading the listed recommendations for choosing a towbar, you took them into account and purchased the desired device. Now it remains only to install it on the car.

As with any other part, the tow hitch comes with instructions that clearly describe the installation process, you just need to have a set of screwdrivers and a wrench. Leading manufacturers of such devices ( BOSAL, THULE, Westfalia) cooperate with manufacturers of well-known car brands, thanks to which, when installing the towbar, it is not necessary to drill additional holes in the body (provided that the model is suitable for your car).

Regardless of the make and model of the machine, the procedure for installing the trailer hitch can be divided into these are the main steps:

Preparatory stage, including the dismantling of the rear bumper and the dismantling of the bumper amplifier. Dismantling the rear bumper, which is fastened on modern cars with a few self-tapping screws and plastic caps. On some models, before removing the bumper, you will have to unscrew the rear lights, since it is under them that the self-tapping screws holding the bumper are located.

The dismantling of the bumper amplifier is irrevocable. In its place, in the future, there will be a towbar beam.

The stage of direct installation in each individual case is individual and, as a rule, is described in some detail in the instructions attached to the model. If we consider the points common to all models, then the setup will look like this:

tow bar beams and its side brackets must be attached to the body side members in accordance with the installation scheme shown in the instructions;

attach the socket box to the beam and insert the wiring harness of the device through the hole in the rear panel of the body, before attaching it to the beam with plastic bundles;

do the wiring. On most cars, the connector for it is provided for by the design, it remains only to find it guided by the vehicle diagram and connect the two pads;

Note! During the fastening of the beam of the machine to the elements of its body, all threaded connections must be tightened in good faith.

Install the parts removed from the vehicle in reverse order. Also be prepared for the need to slightly trim the rear bumper of your car in accordance with the template provided in the instructions. If you are not ready for such a measure, pay attention to this when buying: usually such a requirement is indicated in the installation manual.

Towbar reliability is the basis of safety

Any car requires careful attention, and not only because it can break down or rust, but also because it is responsible for your safety while driving. It is much easier to drive a car without a trailer than with it, and if it is also seriously loaded, then the driver’s vigilance and accuracy should increase significantly.

Any car requires careful attention, and not only because it can break down or rust, but also because it is responsible for your safety while driving. It is much easier to drive a car without a trailer than with it, and if it is also seriously loaded, then the driver’s vigilance and accuracy should increase significantly.

All the subtleties and nuances of the operation of the towing device are described in the user manual, which is directly attached to each individual model. There are also tips common to all models that allow you to thoroughly reduce the risk when using a towbar and protect its mechanism from frequent breakdowns.

Tip 1

Try to keep an eye on the tow ball, it must be constantly lubricated in order to ensure the correct operation of the device (the exception is the use of special clamps made of ferrod alloys).

Tip 2

Put protective caps and plugs on the ball. This will keep the hook lubricated and protect you from dirt stains on your clothes while using the carrier.

Tip 3

The tow ball, like any other part subject to friction, tends to wear out, so from time to time, in order to avoid the risk of the trailer jumping off, you need to check its diameter (should be 50 mm). If it decreases even by a millimeter, replace the ball.

Just imagine what can happen if the ball wears out: the trailer head disconnects from the towbar at high speed and the uncontrolled trailer, with an unpredictable trajectory of movement, for some time continues to move next to you and your car with all its passengers, and there is still the risk of a rollover, in which case other road users are also at risk.

Tip 4

For replacement, you should choose only original balls from the same manufacturer as the previously purchased towbar, since not all types are suitable for different car models. The design of the ball, depending on the car and on the permissible load, is always different.

Tip 5

Every 1000 km, check the reliability of fastening of all bolts of the towbar and their tension. You can do this both independently and with the help of employees of the nearest service center. To facilitate such work, the instruction (if the tightening standards for threaded connections are indicated) and a torque wrench will help you.

Tip 6

Despite its apparent simplicity, the tow hitch is a rather complex mechanism, which usually has a single installation option and is designed for a narrow range of models, and sometimes even for only one model. Based on this, install the towbar clearly following the requirements of the attached instructions. Violation of the installation rules prescribed by the manufacturer threatens with the possibility of an early breakdown of not only the towing device itself, but also the load-bearing elements of the machine to which it is attached.

Despite its apparent simplicity, the tow hitch is a rather complex mechanism, which usually has a single installation option and is designed for a narrow range of models, and sometimes even for only one model. Based on this, install the towbar clearly following the requirements of the attached instructions. Violation of the installation rules prescribed by the manufacturer threatens with the possibility of an early breakdown of not only the towing device itself, but also the load-bearing elements of the machine to which it is attached.

Tip 7

Under no circumstances exceed the vertical load capacity of the ball! Its maximum permissible limit must be indicated on the identification plate of the towbar and in the quality certificate.

Tip 8

Pay special attention to the maximum load and speed of the car with a fixed trailer when driving on dirt roads. In such cases, the speed should not exceed 30 km/h, and the maximum load capacity is reduced by 50%.

Tip 9

Trailer tow hitches with two axles spaced more than 1 meter should be used with extreme caution.

Tip 10

If you want to increase the carrying capacity of the towbar, in no case do not make changes to the factory towing mechanisms, you can simply ruin the device. In addition, welding parts of it, making additional holes or removing parts, you are unlikely to achieve the desired result.

Calculating the maximum load, the manufacturer from the very beginning laid down the necessary parameters of the beam, hook and bracket, and also determined the data on the permissible loads of the car structure and offered regular (main) and alternative methods of its fastening.

Today, many motorists install a tow bar on their car in order to be able to carry various loads on a trailer. This is really very convenient, because an ordinary car turns into a reliable assistant with advanced payload capabilities. But installing a towbar requires knowledge of some of the nuances, which we will definitely mention in this article.

So, the main task for a motorist before performing work is to draw up all the necessary documents for the trailer and calculate the required mass of the latter. If this is done, you can start installing the towing device (this is what experts often call the towbar). A modern towbar for cars has the most uncomplicated device. So, it is enough to mount the bracket to the body, on which the hook with the ball is located. It is on this ball that the trailer coupling head is thrown.

Which hitch to choose?

Previously, it was customary to weld the hook to the bracket, without the possibility of subsequent dismantling. It is quite natural that many experts call this approach blasphemy. The only plus of this method is low cost, and for most people this factor is decisive (especially in Russia). If the driver has at least a modicum of consciousness, then it is still better to purchase a towbar, where the hook can be unscrewed and folded under the bumper if desired.

Many motorists drive with a protruding hook, forgetting that they create additional danger for themselves in the event of an accident. It is believed that only those who are behind will have problems. But it's not. The towbar is fixed to the power parts of the body, namely the spars. If there is a strong impact during an accident, then this will definitely lead to damage to them. But aligning a bent element is a huge problem. Much more than just changing the bumper, whose task is precisely to absorb the main blow.

DIY installation

Trailer power supply - connection diagram

But screwing the towbar is not enough - you need to bring a socket to it to power the main electrical equipment of the trailer. Most often, this procedure takes a minimum of time, because you do not need to pull the wiring through the entire machine. There should be a harness in the trunk near the rear lights, to which the connection is made. You can install the towbar yourself or rely on specialists who most often take about 3-4 thousand rubles for such work.

But there are several nuances. In particular, in a number of modern car models, it is not so easy to connect the trailer's electrics to the existing electrical network. You have to install the so-called adapter (matching unit). The cost of such a device can be different - from 5 to 9 thousand rubles. The installation will also cost a certain amount - from 1 to 3 thousand rubles. By the way, on some cars, such electronics have already been installed, but it is better to clarify this point right away.

Another important aspect is the type of connector. For example, the American version has thirteen contacts, while the European version has only seven. But here everything is simplified by the presence of an adapter, with which you can easily switch the European and American type of wiring.

And most importantly - you do not need to save money when buying a towbar, it will cost you more. It is best to give preference to proven and high-quality drawbars from companies such as Westfalia, Bosal, Auto-Hak and so on. You should not completely trust Chinese products, because they do not always have the proper quality.

Installation steps:

Video about installing a towbar on Logan with your own hands:

Installing the trailer hitch on a BMW 3 (F30):

Of course, it’s different for everyone, but for sure, at least once in a lifetime, any person had to transport goods, move, pick up crops from a summer house, and you never know what else ... It’s good when a truck is hidden in the garage for these purposes, but what if you have a car one, and it is intended for all occasions? That's right - get a trailer, or, in extreme cases, borrow it from a neighbor. Only bad luck - the trailer is not so easy to attach. You need a special device - a towbar. There are two options here: seek help from professionals or take matters into your own hands and install the tow bar yourself. But first, it would be useful to find out in more detail what a towbar is and why exactly it is needed.

This is how the installed hitch looks like

Almost all modern, and most non-modern cars are not equipped with towbars from the factory. Therefore, car owners, if necessary, have to install such a device on their own. But before proceeding with the purchase and installation, you should decide which towbar is right for you. Towbars are:

- fixed (fixed by welding or bolts) - the cheapest and most practical solution, but many car owners are confused by their appearance;

- removable - in terms of reliability, such devices are often not inferior to fixed ones, but at any time it can be removed from the car (the minus of such a towbar is the price, it is almost twice as high as that of a fixed towing device);

- flanged (for 2 or 4 holes) - for their installation, the car must be equipped with a special platform.

Buy ready-made or make your own

You can buy a towbar ready-made or spend a lot of time (but save money!) And make such a device yourself. Nevertheless, most of those who want to install a towbar are inclined towards the option of buying a factory product. And that's why:

Finished factory hitch

- Due to the fact that such products are now being developed and designed using special computer programs, the manufacturer can accurately calculate what load the towbar can withstand and put a certain strength resource into it.

- Factory products are subject to careful control for defects, compliance with standards, tolerances, etc. Control takes place at all production stages.

- In addition, the manufacturer bears warranty obligations to the buyer and in the event of a towbar breakdown due to the manufacturer’s fault (for example, a factory defect), he will be forced to replace the product with a quality one or return your money. However, do not flatter yourself - it will not be easy to prove that the failure of the product is not caused by improper installation. That is why many recommend ordering the installation from the same company that produced the device, of course, if such a service is provided.

What you need for self-installation

So, if you still decide to install the towbar on your own, you first need to take care of where the work will be carried out (ideally, a garage with a pit or a lift, in the worst case, an overpass). The entire installation process will take several hours of your time. For those who decide to go by purchasing a ready-made device, there is almost no cause for concern - all additional parts, such as bushings, mounts, sockets, wiring, etc., are included in the towbar kit. Those who decide to make a towbar on their own will be forced to purchase all the necessary parts separately.

To install the tow hitch, you will need the following items and tools:

- the device itself;

- a set of fasteners for it;

- wires for supplying electricity to the brake light unit of the trailer or trailer;

- drill with drills of various sizes;

- set of wrenches;

- you may need a special tool to remove the bumper.

Preliminary work consists in marking the place for future attachments of the tow hitch. It is most convenient to perform such work with a regular marker. In order for the holes to turn out to be of high quality, experts recommend using a drill slightly larger than the size of the bolts used.

Remember! To prevent corrosion in places where holes for fasteners are drilled, these areas should be treated with a special anti-corrosion compound. Only after this procedure can the towbar be finally mounted.

And if everything is quite clear regarding the installation of the towbar itself, then connecting the electrics of the towbar with your own hands can drive even an experienced motorist into a stupor. However, do not get upset in advance. Let's try to understand in more detail.

Connecting a towbar

According to current legislation, a trailer attached to a car must completely duplicate all the signals given by the car while driving. That is why the standard wiring of your trailer must be connected to the vehicle's on-board electrical network.

The appearance of the socket for connecting the towbar

Attention! Before you start connecting the towbar electrics, you should carefully study what types of connectors and contacts are responsible for what.

Most factory towbars come with detailed installation instructions. If you strictly follow the manufacturer's recommendations, and also do not forget about the elementary rules for connecting electricians in principle, then installation problems should not arise. If the towbar is connected correctly, the trailer completely duplicates all the light signals of the car to which it is connected. So, let's talk about the installation in more detail.

Tow hitch installation

Usually, installing a towbar does not cause any particular difficulties for the car owner. You probably won't even have to remove the rear bumper and/or drill holes in it. For example, we will show the process of installing a towbar on a Lada Largus car.

We carefully clean the bottom of the car, preparing it for the installation of the tow hitch

We carefully clean the bottom of the car, preparing it for the installation of the tow hitch  Armed with a screwdriver, remove the plugs in regular places

Armed with a screwdriver, remove the plugs in regular places  We go around the locker of the device and insert the bolts into the provided holes

We go around the locker of the device and insert the bolts into the provided holes  To firmly fix the towbar under the bumper, carefully tighten all the bolts

To firmly fix the towbar under the bumper, carefully tighten all the bolts

After that, we conduct a control check of the reliability of the connection between the car and the towbar. Now you can connect the towbar electrics with your own hands.

Electrical connection

For each specific tow hitch, the manufacturer provides a connection diagram for the towbar socket. Connect the wiring only according to this diagram. A special module is installed on the towbar - a socket for connecting the car's electrics with the trailer's electrics. The most common are seven and 13-pin sockets. Russian cars equipped with towbars from the factory often have exactly seven-pin connection sockets. Thirteen-pin sockets can often be found on Korean, Chinese and European cars, as well as on cars made in the USA. “Extra” contacts are needed to connect various specific equipment on the trailer, which domestic designers considered unnecessary.

The decoding below applies to both 7-pin and 13-pin connectors. After the dot, the most common colors used in the installation of wires are indicated (be careful - colors may vary).

- Turn signal (left). Yellow color.

- Fog light (rear). Color - blue.

- Grounding pins 1-8. White color.

- Turn signal (right). Green color.

- Dimensions (left side) and license plate light. Brown color.

- Feet. Color - red.

- Dimensions (right side) and license plate light. Black color.

- Reverse. Pink colour.

- Voltage 12V with battery. Orange color.

- Voltage 12V with the ignition on. Color - gray.

- Grounding contact 10. Color - white with black.

- Signal wire. Color - blue with white.

Approximate socket connection diagram

If the connector installed on the vehicle does not match the one that the selected trailer is equipped with, special adapters should be used.

Network integration

When the connector is selected, we connect it to the vehicle's on-board network. It is more convenient to do this through the technological hole in the rear brake light block. In modern foreign cars, when connecting, malfunctions can occur, mainly caused by the fact that in such cars the electrician is designed for a certain voltage. The problem is solved easily - by installing an adapter with a high resistance. Domestic cars in this sense are less problematic - their electrical system is able to withstand heavy loads. When installing the towbar connector, we connect the wires by color. It will be correct to insulate each wire separately, and then check them for operability.

Now more and more motorists are trying to equip their cars with towbars. This is not surprising, because having a faithful and reliable passenger car in everyday life, it is pleasant to think that, if necessary, it can carry bulky cargo or help tow another car. As you can see from this article, installing and connecting a towbar is a simple task. The main thing is to follow our recommendations and advice from the manufacturer.