It is unlikely that anyone will deny the fact that a radio-controlled car is the most interesting and appropriate gift for a child and many adult men. But it often happens that even expensive models turn out to be unreliable and show low speed. And even in this case, there is a solution. In this article, we will look at ways to make a radio-controlled car in order to fully enjoy control. racing car along the trajectory you have planned.

How to assemble a radio controlled car?

So, for self-assembly of a radio-controlled car, you will need the following items:

- model of absolutely any car, you can use the simplest one, any production - from Chinese to domestic, from American to European;

- VAZ solenoids for opening doors, 12 volt battery;

- radio control equipment - AGC, but do not confuse with Automatic gain control, because the abbreviation is exactly the same;

- batteries with chargers;

- radiator;

- electrical measuring units;

- a soldering iron along with solder, as well as a metalwork tool;

- a piece of rubber, which is necessary in order to strengthen the bumper.

An example of assembling a radio-controlled car

Well, now let's go directly to the scheme, in other words, to the process of creating a high-quality model of a RC machine:

- At the very beginning, assemble the suspension - that's why we needed the base model, as well as a 12V battery.

- After that, take the VAZ solenoids, plastic gears and assemble the gearbox.

- On the body and studs, cut the thread so that you can hang the solenoids and gears.

- Now connect the gearbox to power, be sure to check. If everything is in order with its functionality, install the gearbox itself directly into the machine.

- Install a heatsink to protect the circuit from overheating. By the way, you can fix the radiator plate securely enough with the help of bolts.

- After you install the heatsink, install the radio control and power driver ICs.

- After installing the chips, fully assemble the body of your car.

Now you can safely proceed to the test races of the car.

So, you have a radio-controlled car in your arsenal. What needs to be done to make it more reliable and maneuverable?

Do not overload the model with unnecessary systems and details. All sound signals, high beam, low beam headlights, opening doors - that's all, of course, it looks pretty nice, believable. Creating a radio-controlled car is already quite a difficult process. You should not complicate it even more, because this can have a very negative impact on the main running indicators of your model.

The most important thing to focus on is to make a quality suspension, to ensure excellent signal transmission. Well, to improve maneuverability, optimization speed indicators fine-tuning the system during test runs will help you.

Important! Even the most interesting radio-controlled car may not be the child's only hobby on for a long time. So that he does not get bored and learns everything new with interest, and you waste your nerves less, correcting the consequences of the leprosy of a little crumb, use a selection of our interesting ideas:

footage

Now you can make a radio-controlled car and enjoy the toy for as long as you have the excitement, because it's so exciting.

It must be said that on modern market radio-controlled cars today are overabundant, but it is filled with models, as a rule, Chinese made, although among them you will find a product for almost every taste. However, there are always craftsmen who are not satisfied with the current proposals or they believe that a radio-controlled car, assembled with their own hands, will always be better than even good conveyor copies. It is for beginner craftsmen that our article today is written. Let's start with the necessary tools, and then we will describe the workflow and give some useful tips.

How to build a radio-controlled car: tools

So we need the following:

- model of any car, even the simplest one, any production - even Chinese, even domestic, American or European;

- VAZ door opening solenoids, 12-volt battery;

- radio control equipment - AGC (not to be confused with Automatic Gain Control, since the abbreviation is the same);

- batteries with chargers;

- radiator;

- electronic measuring equipment;

- soldering iron with solder and metalwork tool;

- a piece of rubber (needed to reinforce the bumper).

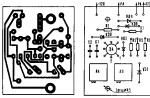

Scheme of a radio-controlled car

Well, now let's move on to the scheme, that is, to the process of creating a high-quality model of a RC machine. To begin with, we assemble the suspension - for this we need a basic model and a 12 V battery. It will look something like this:

Now we take VAZ solenoids and plastic gears and assemble the gearbox. We cut the threads on the studs and the body so that the gears and solenoids can be hung. Everything should look like this:

Now we connect the gearbox to the power supply and check, after which we install the gearbox in the car if it passed the test. We install a radiator in order to protect the circuit from overheating. The radiator plate, by the way, can be very securely fastened with bolts. After that, we install the power driver and radio control chips. You can see them well in this photo:

Well, then we completely assemble the body of our car. After that, you can proceed to the test runs of the car. And now a few tips.

So, you have a radio-controlled car, how to make it agile and reliable? First, don't overload the model unnecessary details and systems. Sound signals, luminous headlights, opening doors - all this, of course, is good and beautiful, but creating a radio-controlled car is already quite a difficult process, and its even greater complication can negatively affect the basic "driving" qualities of your model. Therefore, the main thing to focus on is to make good suspension and provide reliable transmission signal. Well, in improving maneuverability and optimization speed characteristics fine-tuning systems during test runs will help you. As for specific schemes, it is simply not possible to describe even a hundredth of them in this article, so I refer you to

This article is a modeler's story about the manufacture of a homemade radio-controlled model of an all-wheel drive car range Rover of plastic model. It reveals the nuances of manufacturing axle drives, installing electronics and many other nuances.

So, I decided to make a car model with my own hands!

I bought an ordinary bench model in the store range rover a. The price of this model is 1500 rubles, in general it is a little expensive, but the model is worth it! Initially I thought about making a hammer, but this model is much more suitable in design.  I had electronics, well, I took some parts from a trophy called "cat" which I had not needed for a long time and was disassembled for parts!

I had electronics, well, I took some parts from a trophy called "cat" which I had not needed for a long time and was disassembled for parts!

Of course, it was possible to take other prefabricated models as a basis, but I wanted just such an off-road jeep.

It all started with bridges and differentials that I made from copper pipes and soldered with a regular 100w soldering iron. The differentials here are ordinary, the gear is plastic, the rods and drive bones are iron from the trophy.

These tubes can be purchased at any hardware store.

I took the differential gear from a regular printer. I didn’t need him for a long time and now I decided that it was time for him to rest.  Everything turned out pretty reliably, but it’s rather inconvenient to work with a soldering iron!

Everything turned out pretty reliably, but it’s rather inconvenient to work with a soldering iron!

After I made the differentials, I had to close them with something, I closed them with pill caps.  And painted it with regular car paint. It turned out beautifully, although beauty is hardly needed for a trophy.

And painted it with regular car paint. It turned out beautifully, although beauty is hardly needed for a trophy.

Then it was necessary to make steering rods and put bridges on the frame. The frame was included and to my surprise it turned out to be iron, not plastic.

It was not easy to do this, since the scale of the parts is very small and it was not possible to solder here, I had to bolt it. Steering rods I took from the same old trophy that I dismantled.

All parts of the differentials are on bearings. Since I made the model for a long time.  I also ordered a gearbox with a reduction gear, the gear will be switched on by a microservo machine from the remote control.

I also ordered a gearbox with a reduction gear, the gear will be switched on by a microservo machine from the remote control.

Well, in general, then I installed a plastic bottom, cut a hole in it, installed a gearbox, cardan shafts, a home-made gearbox, an ordinary collector engine for such a small model, it makes no sense to put a bc and the speed is not important to me.

The engine is from a helicopter, but in the gearbox it is quite powerful.

The most important thing is that the model does not move in jerks, but smoothly without delay, the gearbox was not easy to make, but I had a heap of details, the main thing is ingenuity.

The most important thing is that the model does not move in jerks, but smoothly without delay, the gearbox was not easy to make, but I had a heap of details, the main thing is ingenuity.

The reducer was screwed to the bottom, it kept perfectly, but to attach the bottom to the frame I had to tinker.

Then I installed electronics, shock absorbers, battery. At first I installed the electronics rather weak and the regulator and the receiver were a single unit, but then I installed everything separately and the electronics were more powerful.

Then I installed electronics, shock absorbers, battery. At first I installed the electronics rather weak and the regulator and the receiver were a single unit, but then I installed everything separately and the electronics were more powerful.

.1390645053061.prev.jpg)

And finally, painting, installation of all the main components, decals, headlights, and more. I painted everything with regular plastic paint in 4 coats then painted the fenders brown and sanded the parts to give a shabby and worn look.

The body of the model and the color are completely original, the color was found on the Internet and the photo real car everything was done according to the original. This color combination exists on real car and in this color they were painted at the factory.

The body of the model and the color are completely original, the color was found on the Internet and the photo real car everything was done according to the original. This color combination exists on real car and in this color they were painted at the factory.

Well, here are the final photos. I will add a video with the test a little later, and the model turned out to be very passable, the speed was 18 km / h, but I did it not for speed. In general, I am satisfied with my work, and it is up to you to evaluate it.

The machine is not big size the scale is 1x24 in size and there is the whole point of the idea, I wanted a mini trophy for myself.

The machine is not big size the scale is 1x24 in size and there is the whole point of the idea, I wanted a mini trophy for myself.

The model is not afraid of moisture! Germetil himself simply varnished the electronics, very reliably, no moisture is terrible.

Servo machine micro park from the aircraft for 3.5 kg.

Servo machine micro park from the aircraft for 3.5 kg.

The battery lasts for 25 minutes of riding, but I will install more powerful electronics and a battery, because this one is not quite enough.

Even the bumpers are the same as on the original. And fastenings on them too. The drive on it is not 50-50%, but 60-40%.

In general, the Range Rover turned out in a rustic style, I didn’t even think that it would turn out to be so high-quality to paint because I really don’t know how to paint, although there’s nothing difficult! .1390645295252.prev.jpg)

I forgot to add for the sake of beauty, I also installed a roll cage and a full spare tire. Spare wheel and frame were included with the kit.

More about radio-controlled models:

Misha comments:

Tell me how it works four-wheel drive, inside the bridge, what besides the razdatki be? There must be rounded fist after all.

Psychologists say that doing something interesting together brings children and parents closer together. A father for a boy is always and in everything an example. Unfortunately, fathers do not always understand what to do with their child, except for watching TV. We offer you to learn how to do This activity will appeal to both "boys": both the son and the father. In this process, the mother, most likely, will not be able to intervene. Simply because of their ignorance in the radio business.

Activity for dad and son only

Sometimes it seems that only mothers take care of raising a child, and fathers only earn money. However, the role of the father in the formation of the character of the baby, especially the son, is no less than that of the mother. It happens that a tired father has no time to play with his child in his noisy and cheerful games. However, you need to remember that there may come a time when the son simply stops looking for opportunities to communicate with dad if he constantly does not find time for this. In the end, there is a misunderstanding between dad and son, which is already quite difficult to overcome in adolescence. A ready-made kit or an independent attempt to figure out how to make a car on the control panel will help the father and child strengthen their relationship and mutual understanding.

What is the reason for the father's removal from his son? Sometimes this is a common inexperience, a kind of fear that young dads have, especially if the mother practically does not let the father near the baby.

Where can you start collaborating?

The easiest option (if you do not take into account the usual purchase finished model) - a machine-designer assembled according to the instructions. The kit contains all the necessary parts, you just need time and effort. A couple of evenings after work - and the radio-controlled toy is ready. And how much joy both son and dad will get when the model goes!

Another, more complex option is to invent and assemble a car from scratch. In this case, it will take more time, and the details will have to be looked for, and general labor, the joint business will bring more emotions.

What to choose: a copy or just a car without a brand

Some advanced craftsmen create and collect exact mini-replicas real cars. It happens like this:

- firstly, the machine on the remote control is carefully assembled with his own hands, moreover, by family efforts;

- secondly, the model may not be made of the same materials as the original;

- thirdly, some minor minor details may be omitted.

Everything else, down to the engine and fuel, is done with meticulous precision. Some masters are engaged in assembling collectible models, which are exact copies of real, real cars.

On the control panel? You can collect a semi-copy, that is, a copy that resembles appearance selected original. And you can come up with a model "on a free theme", without focusing on any particular form. The size of the machine, in principle, does not matter. They also make small homemade models, jeeps or cars, and real radio-controlled mini-cars. It all depends on the desire, the allocated time and finances. Any activity that the son and father are engaged in together will strengthen the authority of the father in the eyes of the child.

What spare parts to prepare for the model to go

How to make a car on the remote control? Everything starts with a project. To work, you need to prepare not only a list various parts and components, but also all the necessary tools. This will make the process more fun and organized. So, what you need to assemble the machine:

- a motor (from a hair dryer, from a small fan) or a gasoline mini-engine;

- frame;

- body;

- a set of rubber wheels;

- what real cars call "shaft";

- suspension or chassis;

- 2 axles for mounting wheels;

- antenna;

- thin connecting wires;

- rechargeable batteries to power the electric motor or gasoline (if the engine is an internal combustion engine);

- signal receiver;

- control panel (transmitter or radio unit).

Of the tools you will need pliers, a soldering iron, various screwdrivers and small wrenches, electrical tape, superglue, bolts, washers, nuts and other fasteners. All missing tools, parts and components are either made independently or bought in specialized stores.

How is this done and what will be the end result?

While preparing the parts according to the plan of how to make a remote control car, you may find that some of them need to be bought. The frame and body can be adapted from an old toy. Surely there are several boring or broken children's cars at home, from which you can take some of the missing parts.

The motor must be checked in advance for performance. Its power must correspond to the weight of the future little car. Weak engine will not pull heavy model. All work can be reduced to zero. Batteries must be fresh or rechargeable. The build sequence is:

- The frame is assembled first.

- The motor is fixed and adjusted.

- Batteries or accumulator are installed.

- The next step is to fix the antenna.

- The wheels are mounted so that they can easily rotate with the axle. If this is not done, the machine will not be able to turn, it will only drive straight: forward and backward.

It is preferable to take rubber tires, as they move better not only on the floor of the apartment, but also on the open ground. If you like the process and you manage to figure out well how to make a car on the control panel, you can build several different copies, teach neighbor dads and boys and arrange mini-races over rough terrain right in the yard.

This article provides guidelines for building a car model for beginners, as well as lists common mistakes that modelers usually make when building their first model. Here you will find those tips that, as a rule, are not in the instructions.

Much has been said in previous articles about choosing and buying the right chassis for you. But, as already mentioned, radio-controlled cars are sold in two versions. The first one is a kit for self assembly, the second is a factory-assembled RTR (Ready To Run) kit. If you are the owner of the second option, then you can safely proceed to the last paragraph of this article. But the owners of the self-assembly kit will first have to assemble their car, and assemble it correctly!

Before starting assembly

Before you start assembling, you should carefully read the material below and make sure that you understand everything and stock up on everything you need to successfully build the model.

Read the instructions carefully

To begin with, carefully read the instructions and make sure you understand everything that is written in it. If you do not understand any foreign words, then be sure to translate them before starting the assembly. This will save you time (and your money) in the future and prevent incorrect assembly of nodes. The instructions may also be accompanied by inserts with updates and corrections to some parts of the instructions. If there are, then they should be read first.

What to look out for

Length of bolts and screws, their location. This is very important - if you, for example, screw a shorter screw into the gearbox cover, then there is a risk that during further operation the torque passing through the transmission will simply tear out the top layer of the thread, and the gears will begin to "walk" inside the gearbox.

Where is the “left”, “right”, “front” and “rear” of the car. Sometimes they simply forget about it and try to set the front levers to rear gear, confuse fists and so on. With such mistakes, the picker's nerves suffer most of all ("Well, why doesn't she get up?!").

Choose the right workspace. For successful build you will need a well-prepared workplace. This can be any table with dimensions of at least 80x80 cm with good lighting (preferably a lamp with a power of at least 60 watts). I also recommend laying a white towel on the table. This is very convenient, since it is easier to see any small detail on a white background, which will prevent the loss of screws. Screws tend to roll off uneven surfaces, and when they fall, they usually bounce off a hard table and fly far away. A towel on the table eliminates all of the above problems. Even when assembling it is very useful to have small box with small compartments in which you can lay out the same fasteners and other parts (often they use boxes for fishing baits). Workplace should be away from small children, pets, and anything that poses a threat (and the possibility of losing parts) to your unassembled model.

Find the right tool

- Screwdrivers- ordinary screwdrivers with a cross and a slot of small and medium sizes.

- Pliers- small

- Side cutters- also small

- Model knife or scalpel- preferably with replaceable blades.

- Hexagons- are applied (as the main ones) not in all models. So when buying, you should clarify what the model is going to be on (slotted screws or screws with an internal hexagon).

- Calipers- used to measure and accurately set the lengths of the suspension rods.

Assembly

So you have all essential tool, prepared the workspace and studied the instructions. Now the only thing left is to assemble your car model! But even here there are subtleties, which I will now tell you about.

Cutting parts from the printed circuit board. Parts should be cut off from the printed circuit board using side cutters and then carefully cut off the burrs from them with a model knife or scalpel. Take your time because this operation is quite dangerous for your fingers.

Screwing bolts and screws. Try not to overtighten them. Tighten them tightly, but carefully, paying attention to the material from which the part is made into which you screw the screw. ABS plastic can be quite flimsy, so the risk of turning a screw is much greater compared to graphite plastic. Driving screws in ABS plastic is quite easy, but in graphite it is sometimes very difficult, especially for the first time in new parts. To make it easier to screw into similar situations(and to prevent the slot in the screw from breaking off), you simply need to lubricate the screw being screwed in with a small amount of soap.

thread-lock(literally translated from English means "threaded lock") is used to prevent self-loosening of screws and screws in critical and vibration-loaded areas of the structure. Usually the instructions say where to apply the thread-lock, but if you feel that something can unscrew (for example, shock absorber mounting points), then it is better to immediately apply this composition to the thread. As a rule, thread-lock is applied to all connections (on a thread) with a bolt-nut, and on all connections (on a thread), when two metal surfaces- metal to metal. Superglue can be used as a thread-lock (but it contains less cyanoacrylate, so it holds weaker).

Places where thread-lock is most often applied:

|

|

With frequent changes of shock absorber mounting points, the plastic breaks and the shock absorbers begin to unscrew, so it is better to use thread-lock. |

|

|

From the constant change of attachment points of the upper suspension rods, the plastic breaks. In order for the rods to be securely fastened, it is necessary to apply a thread-lock. You should also fix the screws that are screwed into the aluminum motor mount and hold the top bracket and carbon plate. |

|

|

The ball mounts of the rods also begin to unscrew over time. There is only one way out - thread-lock. |

Gear lubrication. If you want your car's transmission to last for a long time, then you will have to spend a certain amount of time lubricating it. There are several subtleties here.

Never lubricate bare parts- cardans, gears, etc., as dirt will immediately stick to the lubricant, which, during further operation, will erase the part like a file. For effective lubrication, take a regular small plastic tie and use it to evenly apply grease to each of the teeth of all gears. Lubricate the bushings in the same way (if any).

Set the gap in the main pair. Main couple- these are two gears, one of which is located on the motor (leading), and the other transmits torque directly to the transmission (driven). To ensure optimal clearance during installation, it is necessary to lay a piece of paper between them, which should then be removed by rotating the gears. The paper should contain distinct imprints of gear teeth. If the prints are indistinct, and you feel that the gap between the gears is too big, then this operation should be done again, but with a large clamping force between the gears.

Installation of radio equipment

The servos must be centered before installation. Set the trims to neutral and turn on the transmitter and then the receiver with the servos connected to it. They will immediately accept central position. If this is not done, then it is likely that the first time the machines are turned on, they will take their central position, which will turn out to be the extreme left or right for the wheels.

Install the receiver as far away from electrical circuits as possible. To avoid interference, try to install the receiver as far as possible from the ESC, battery, and power wires. This also applies to the antenna wire. A common mistake is to twist the antenna wire, if it is too long, around the base of the antenna straw attachment. Under no circumstances should this be done. Aluminum straw mounts should be avoided.

Onboard food. Before you buy or make a bunch of batteries for on-board power, be sure to check how many volts the servos you plan to use are rated for. They come in 4.8, 6.0, and 7.2 volts, so be careful not to mix up the number of cans.

Bonding rubber

Be sure to degrease the rubber before gluing. Rubber is always sold with a factory preservative that must be washed off before gluing. In places of gluing, wash the rubber with soap and rinse with warm water.

Be sure to put marks on the rim of the disc. In order for the rubber to stick well, it is necessary to apply risks to the rim (at the gluing point) with some kind of abrasive material (sandpaper, metallized washcloth for washing pans, etc.) If the wheels are chrome-plated, then chrome should be completely removed at the gluing points.

Pay attention to which direction this or that wheel rotates. If you have directional tires, then be careful not to confuse the direction of rotation.

For RTR models

I suggest to the happy owners of RTR cars to completely disassemble their models and then reassemble them, taking into account the above material. Why do it? I'll explain now.

Poor factory build quality. Unfortunately it is so. At the factory, screws and screws are often not tightened properly, in right places they don’t put thread-lock, poorly lubricate the gears, fill the shock absorbers poorly, etc.

Knowledge of your model. Since the model came assembled from the factory, many can only guess how it works inside. When sorting, you will learn a lot of new things, find design flaws and its vulnerabilities. You will be more prepared for further repairs and maintenance.

That, in fact, is all. If you followed the manufacturer's instructions and looked at this article along the way, then you should have succeeded. The next stage is running-in models. But more on that in the next episode...