The clutch system is designed to connect the vehicle's engine to the gearbox. In general, it can be called a link between these two power units. In this article, we will tell you what the principle of the clutch is, what components the system consists of, and a visual video of the operation of the device.

Device

As mentioned above, the main purpose of the system is the smooth connection of the gearbox pulley and the flywheel of the car's motor during gear shifting and starting the car.

In other words, the clutch acts as a torque switch.

It is also worth noting that the CC (Clutch System) prevents overloading and transmission damage during emergency braking.

There are several types of SS according to various properties:

- by the number of slave disks: single-disk or multi-disk (the first option is the most common);

- according to the principle of operation: “wet” or “dry” (“dry” clutches are the most common);

- according to the principle of turning on the flywheel, the systems can be mechanical, hydraulic, electrical or combined;

- according to the principle of impact on the pressure disk.

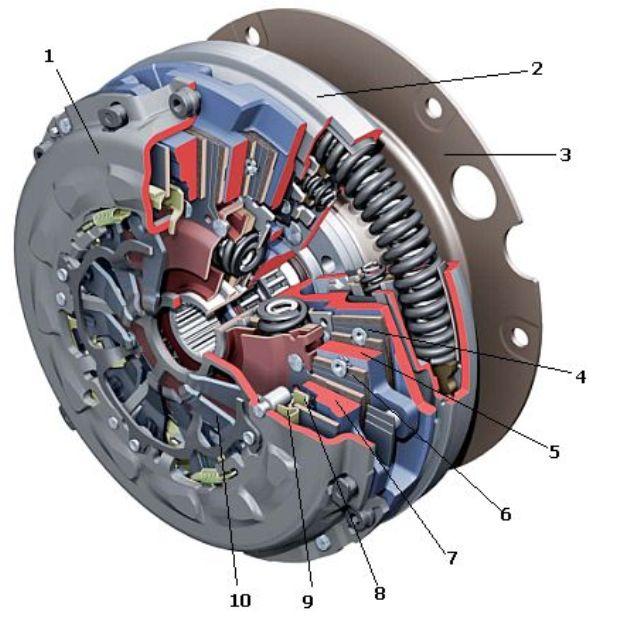

pressure element

This disk among domestic motorists is commonly called a "basket". This component is a rounded device. The springs of the "basket" are connected to the pressure pad, which also has a rounded shape.

driven pulley

In its form, this component is also rounded and consists of several elements:

- metal base of the disc;

- splined coupling;

- carbon fiber pads, which can also be made of ceramic materials or Kevlar - these components are attached to the base of the disc using special devices;

- special thick springs, called damper springs, they are located around the perimeter of the round base. In particular, they are located around the coupling and are designed to prevent vibrations.

release element

Basically it's a bearing. One side of this component is a platform that sits on the primary pulley and attaches to the shaft guard. By the way, the primary pulley protrudes slightly from the gearbox assembly.

The release component of the clutch system is activated at the moment the rim is pressed. According to its principle of operation, the bearing can be:

- push;

- retracting.

Drive unit

The drive system in its design, as mentioned earlier, can be hydraulic, electrical or mechanical. Consider the principle of operation of each of them.

- "Hydraulics" consists of two cylinders: main and working, which are interconnected by means of a high pressure pipe. When you press the clutch pedal with pressure, the master cylinder rod is activated, on one side of which there is a special piston. This piston squeezes out the brake fluid, as a result of which pressure arises in the system, which, in turn, is transmitted to the working cylinder through the pipe. As for the working cylinder, its design is similar: it also has a piston and a rod. As a result of the pressure, the piston actuates the rod, which acts on the release fork.

- As for the electric drive, when you press the pedal, a special electric motor is activated, to which the cable is connected.

- In the mechanical drive system, the force that occurs when you press the clutch pedal is transferred to the release fork using a cable that is located inside the casing.

Pedal

As you know, the clutch pedal system is located to the left of the brake pedal. If your vehicle is equipped with an automatic transmission, then there will be no clutch pedal in it. Nevertheless, the mechanism itself, of course, will be.

How does it work?

If you do not know how the clutch works, then our article will help you understand this issue. Consider the principle of operation of a car clutch in practice.

If the clutch is released, then the driven shaft is clamped between the pressure plate and the flywheel at this time. When the driver presses on the gas, friction occurs in the system, causing torque to be redirected from the ICE flywheel to the vehicle's power speed.

When the driver depresses the CC pedal, the parts of the unit begin to function and interact with each other. As a result of this, the driven shaft is freed from clamping force. To make this happen, the cable of the device comes into operation. The fork of the mechanism is actuated on, as a result of which the bearing begins to move towards the flywheel along the shaft. The bearing then exerts pressure on the compression spring plates.

In the event that the petals of the spring of the mechanism bend towards the flywheel, the spring bends the outer edge away from the pressure plate, thus releasing it. At the same time, the tangential springs release the pressure plate, as a result of which the torque is no longer transmitted from the motor to the gearbox.

If the driver releases the pedal, the pressure plate begins to interact with the driven pulley through a diaphragm spring. It is also worth noting that the pressure plate interacts with the flywheel while the pedal is released. Then the torque begins to be transmitted from the motor to the gearbox as a result of the friction forces formed.

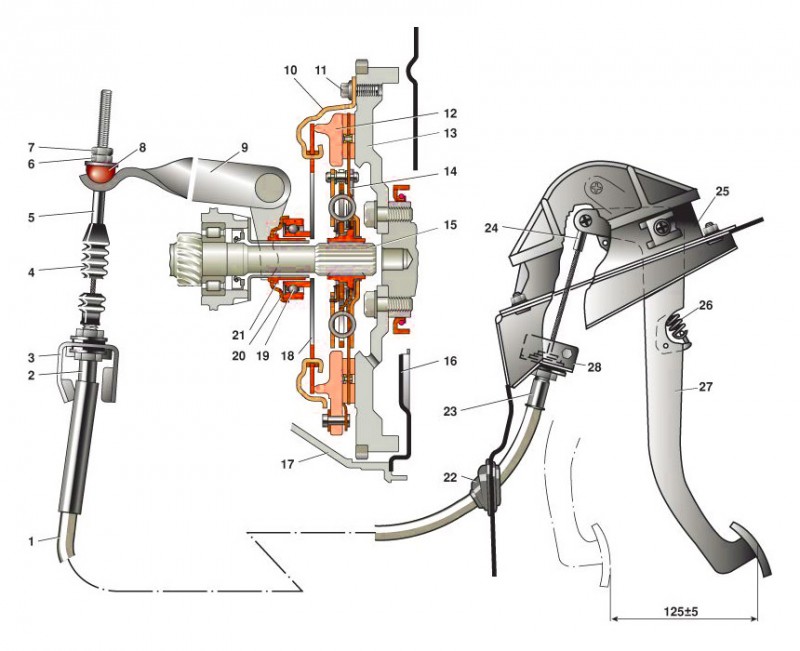

- 1 - directly the sheath of the cable of the mechanism;

- 2 - the lower part of the shell, the tip;

- 3 - pedal cable attachment device;

- 4 - protective cover of the cable;

- 5 - the lower part of the cable;

- 6 - a nut that allows you to adjust the position of the pedal;

- 7 - locknut;

- 8 - cable leash;

- 9 - fork off the mechanism;

- 10 - protective casing of the device;

- 11 - fastening screw;

- 12 - pressure plate;

- 13 - flywheel of the unit;

- 14 - driven pulley;

- 15 - primary pulley of the power unit;

- 16 - the lower part of the crankcase of the device;

- 17 - directly the crankcase of the mechanism;

- 18 - spring pressure device;

- 19 - bearing designed to turn off during gear shifting;

- 20 - coupling flange;

- 21 - clutch sleeve of the release element;

- 22 - sealing gum;

- 23 - upper part of the cable shell;

- 24 - the upper part of the cable;

- 25 - supporting part for fastening the pedal of the device;

- 26 - spring mechanism pedal;

- 27 - directly the pedal itself;

- 28 - thrust plate.