Almost any rims you like for a car can be installed on your own car. Even if the mounts do not always match, then spacers will come to the rescue to increase the offset of the disc. With their help, it will be possible to correct the installation of the selected wheels.

The widened track of the car in this way will help to increase the stability of the vehicle. Also, these additional pancakes can be an indispensable addition for mounted tuning, when plastic modifiers are hung on a car.

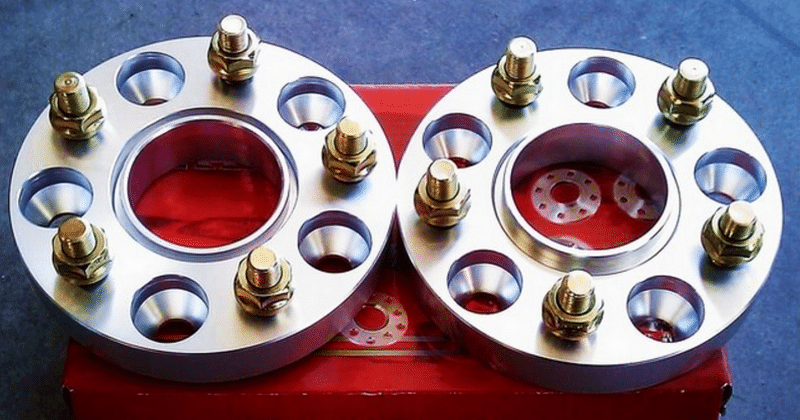

It is customary to distinguish several types of this wheel corrector, which differ from each other in the following parameters:

- part thickness;

- hub mounting method;

- design features of the product.

Pancakes are considered minimal if they are 3-6 mm thick. Small overall dimensions allow them to be installed almost always on regular mounts. The length of the bolt or stud with its threaded part is enough to fix the wheel in its “native” places.

These designs are useful in situations where a non-original overhang is required. After all, if you keep the offset in such wheels, then the caliper will rub against them. Also, it is customary to install a spacer to increase the offset of a rim with a thickness of up to 6 mm during sports tuning of a vehicle.

Medium and large dimensions

The conditional division between these sizes is as follows:

- an interval of 12-25 mm is referred to as an average parameter;

- an interval of 25-50 mm is a large size.

Inserts up to 25 mm thick are manufactured without imbalance. This is due to the centering hub, which is structurally the base surface for processing. It is visually easy to notice cars with such elements. They give a sporty, slightly aggressive look to the car by increasing the track.

You need to know that the installation of wheel spacers is recommended when installing arched expanders and body kits.

Modifying elements with a thickness of more than 25 mm are manufactured with two design features. In the first case, bolts are used to fix this product on the hub of the car. To the fixed washer, and not to the hub, the rim is screwed with standard automotive bolts.

In the second case, the design of spacers with built-in studs is used. This type is appropriate for mounting wheels on hubs with studs and nuts. Such a bar is fixed to the hub through the studs and fastened with nuts. From above, the wheel is hung on the spacer studs and also fixed with nuts. No extensions to stock studs are required.

Installation

You can not install more than one spacer on the hub to increase the disc offset; it is made by hand or bought in a car shop. Otherwise, an imbalance will be created on the hub, which can lead to an accident at any speed.

Homemade wheel spacers

Serious overloads can be experienced by the bearing. In some cases, it can withstand only a few weeks with serious overloads, and then it will fail. At the same time, traction, levers and other suspension elements are overloaded.

Work on installing spacers must be carried out in compliance with the rules for tightening wheel bolts or nuts. First, all fasteners are baited by hand, and then diagonally tightened to the stop. This operation is recommended to be carried out using a torque wrench in order to control the tightness and get rid of imbalance.

How to make the right choice

In addition to making spacers with your own hands, there are products that are made in the factory. Their quality is guaranteed by the factory and confirmed by relevant documents. The most popular companies in this area are foreign trusted firms BIMECC, Schiessler, Hofmann, H&R TRAK+. For home-made products, it is recommended to use blanks from rolled products or after forging.

You need to be aware that cast blanks for the manufacture of spacers can contain a large number of voids with poor quality or low professional casting, which will lead to an imbalance in the final product.

Consequences of low-quality wheel spacers

It is also undesirable to purchase these products from unknown companies, because they can be made using technologies that are not always suitable, for example, powder pressing, which is unable to withstand heavy loads.

If home-made production was used, then it is desirable to balance the resulting product on the stand. It is also impossible to allow a decrease in the number of wheel mounts when using these elements.

Conclusion

When using wheel spacers, it is necessary to strictly observe the safety measures for their installation, because the life and health of the driver and passengers depend on it. At the time of purchase, you need to check the accompanying documents for the products. When the inserts are made independently, then their final work in their place should not lead to a hard increase in load and rapid wear of the suspension elements.