Automakers are trying to make their products as safe as possible, for this in sedans, hatchbacks, crossovers, etc. additional systems and nodes are installed. These modules include ABS, which allows to ensure the straightness of the vehicle during heavy braking on difficult road surfaces.

With frequent use, individual elements wear out, and it is necessary to carry out diagnostic work to identify breakdowns. Let's figure out how to check the ABS sensor with a tester in various cars, because it reads electronic pulses transmitted to the ECU (electronic control unit).

The sensor functions in tandem with a special toothed comb, and is an induction coil. The information is analyzed in the ECU, and as a result, the pressure on the brake cylinders is adjusted through the hydraulic system.

The most common malfunctions that occur in these nodes are associated with an open circuit between the control unit and the sensor itself. Also the unit may fail due to mechanical or electrical damage, in this case, the impulse is incorrectly transmitted to the computer.

ABS sensor

Possible malfunctions are signaled by a special light sensor on the dashboard. For more accurate diagnosis, it is necessary to use special devices.

troubleshooting

Checking the ABS sensor with a tester is carried out independently after the indicator lights up. You will also need an instruction manual for the car and an assistant. Contacts with the necessary PIN connectors are preliminarily output.

The work is performed in the following sequence:

- the car is lifted with a jack or hung out on a special lift;

- for ease of access to the sensor, the wheel is dismantled;

- fasteners are unwound from the back of the hub, fixing the necessary knot;

- we get rid of the casing on the ABS unit and open the connections with the controllers in it;

- we put a repair cable with PIN contacts on the tester, and connect the other end to the sensor socket;

- measure the resistance at the contacts and compare the readings with the factory parameters specified in the car's operating instructions;

- conduct a “ringing” of the wiring for the absence of a short circuit with ground.

After these works, we scroll the wheel by hand, while measuring the resistance. This operation requires someone's help. As the wheel speed changes, the data on the multimeter should also vary and respond to that speed.

The resistance of the ABS sensor is usually in the region of 1 kOhm (1000 Ohm). It depends on the specific model of car, since the sensors are different for everyone. So, for example, for one model, 600 ohms will be considered the norm, and for another, 1350 ohms.

Carrying out a voltage test

Monitoring the performance of sensors can be carried out using the "voltmeter" mode on the multimeter. The operation is carried out on each of the sensors in turn. To do this, you must perform the following algorithm:

- alternately jack up the required side with the wheel;

- PIN-cable connectors connect with the tester;

- the wheel will need to be rotated with the most accurate frequency of 1 rpm.

The multimeter should show readings in the range of 0.25-1.20 V. As the speed increases, there should be a noticeable tendency to increase the voltage reading on the tester screen.

Alternative verification methods

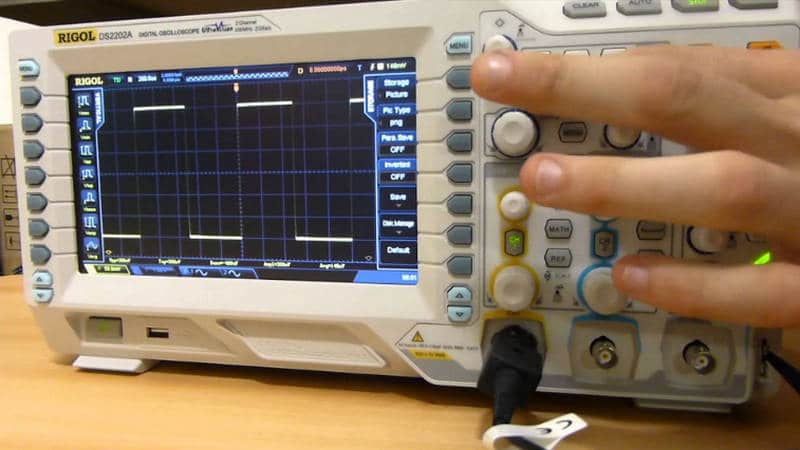

In addition to the multimeter, testing can be carried out using a more informative device for this, for example, an oscilloscope. It forms a graph on the monitor, the amplitude of which determines the resistance level. However, this device is quite expensive for home use and requires qualified service by a specialist.

An oscilloscope can be found at specialized stations professionally engaged in car diagnostics.

Many ABS systems in modern vehicles have a self-diagnostic function. By activating this function, the driver will receive a special error code on the on-board computer monitor, encrypted using numbers and letters. The instruction manual for this car model will help you figure out the decoding.

Oscilloscope operation

You can replace a faulty sensor yourself. Before the procedure, you must order this element from an authorized dealer.

The updated sensor must be tested on a flat stretch of road, braking from a speed of 20-40 km / h. To do this, the brake pedal must be sharply squeezed to the floor. With proper operation, a slight vibration transmitted from the working unit will be felt on the pedals under the driver's foot. You should also hear the characteristic sound of braking pads. If necessary, the wiring is also replaced. As a result, the system test results should be the same.