A very popular question among motorists is which shock absorbers are better: gas or oil, or gas-oil? And he is interested not only in lovers of a comfortable ride, but also in those who consider themselves to be "racers". In fact, shock absorbers provide many important parameters of the car, and above all - handling and directional stability.

Why do we need shock absorbers in a car, how they are arranged and work, what types of shock absorbers are and what are their advantages and disadvantages - the answers to these questions will help you make the right choice among a large number of manufacturers of these products on the Russian market.

At the end of the article, as usual, you can watch a video in which the author tells and shows which shock absorbers are better to choose (gas, oil or gas-oil) and how they differ from each other.

A shock absorber is an integral part of what provides comfort in the car body (sprung mass in technical terminology). The opposite of this term can be clearly illustrated with an old village cart on wooden wheels with a metal rim. It is easy to imagine how the passengers in such a wagon shake when driving on a rough dirt road.

To smooth out this shaking from potholes and potholes (or in technical terms, to damp vibrations in the vertical plane arising from road obstacles) is the main function of shock absorbers. Schematically, the shock absorber can be represented as a spring located between the wheels of the car (the tire, by the way, is also a kind of spring in this diagram) and the body.

In general, to assess the response to vertical impacts of the road, a car can be represented as a mechanical system consisting of many weights, springs and friction knots, interconnected in a complex way and providing the required smoothness. And shock absorbers play an important role in this scheme.

The principle of operation and the main types of shock absorbers (oil, gas, gas-oil)

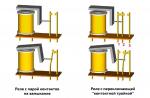

You can illustrate the principle of the shock absorber with a simple example (see the pictures above):

- The lower part of the spring-loaded suspension strut is connected to the wheel through the shock absorber rod, and the upper part is connected to the car body.

- The impact from unevenness through the wheel is transmitted to the rod, which moves the piston inside the cylinder.

- There are two bypass valves in the piston (simplified - holes of different diameters), which allow almost incompressible oil to pass at a higher speed when the rod (and hence the wheel) moves up, and with a lower one - down.

Thus, the hydraulic part of the shock absorber works as a conditionally soft spring for compression, and a hard one for tension (“rebound” in technical terminology).

The mechanical spring in the figure is shown to a greater extent for clarity, but in practice it expands the possibilities of settings and serves as a kind of limiter when the shock absorber hydraulic cylinder fails.

The definition of "oil shock absorber" implies that only hydraulic oil is used as a working material in the cylinder. The dynamics of the oil shock absorber is entirely determined by the work (performance) of the bypass valves.

To expand the dynamic range and adjustment possibilities of oil shock absorbers, a kind of gas “cushion” was invented. The fact is that gases, unlike liquids, are compressed, and non-linearly (not proportional to the movement of the rod). This means that being "attached" to the "oil" part of the cylinder, they will make the dynamics of such a system richer.

The figure below shows a simplified design of a single-tube gas shock absorber.

Scheme of a single-tube gas shock absorber

It is clear that without the lower (gas) part, it becomes oily (only the squeezed out excess must be put somewhere, but more on that below).

And since shock absorbers filled exclusively with gas are not yet found on production cars, it is more correct to call such a design a “gas-oil shock absorber”.

For oil and gas-oil shock absorbers, the working cylinder of the device is usually two-pipe:

- In oil shock absorbers, excess oil comes out into the second (larger diameter) pipe through additional valves during compression, “pressed” in the second pipe by air.

- In gas-oil shock absorbers, a gas cushion (usually nitrogen under pressure) is pumped into the second pipe instead of air.

Sometimes the gas cushion in gas-oil shock absorbers is structurally located on the side of the cylinder.

Main types of shock absorbers

In addition to a narrower range of elasticity characteristics, the cushion of air in the oil shock absorber does not effectively dissipate the heat energy released during intensive work, which sometimes leads to the boiling of the working fluid. In a gas-oil shock absorber, this effect is excluded.

Like any hydraulic technique, shock absorber cylinders require high-precision (precision) machining, a complex system of valves and seals, and for gas-oil shock absorbers this system only becomes more complicated.

Since the gas-filled part of the shock absorber significantly expands the dynamic range of the system, in general, the device assumes a softer response to road bumps than in the "oil" version - it's like a series connection of two springs: soft and hard, which in total gives a softer response than just a hard one. spring.

Interestingly, manufacturers do exactly the opposite and adjust gas shock absorbers to a greater extent for an aggressive driving style and sports cars. More precisely, on well-paved roads, the gas dampers are set to a softer response from vertical influences, and on bad roads with the same settings they become stiffer.

It must be emphasized that in sports driving, smoothness is far from in the first place: parameters such as handling and directional stability are much more important, which gas shock absorbers provide better than oil ones.

The Russian market of shock absorbers for foreign cars with a share of the main players of 10 percent or more, according to the Autoinstruction magazine, is represented by several well-known companies (diagram in the figure above):

- KYB (Kayaba) - 35%;

- Boge (God) - 16%;

- Fenox (Phenox) - 15%;

- Monroe (Monroe) - 14%;

- Bilstein (Bilstein) - 11%;

- Other firms - 9%.

It is interesting that during a survey of service centers conducted by the publication "Kuzov", for the recommendations of professionals on the choice of a manufacturer of high-quality shock absorbers, the picture turned out to be somewhat different.

With firms such as KYB, Bilstein, and Boge leading the way, Monroe is only 5% of the time pros recommend it, even though the firm's market share is nearly three times higher. And they practically do not recommend the Belarusian brand Fenox, the share of products of which is very significant - 15%.

To figure out which shock absorbers are better to put, it is necessary to briefly dwell on the characteristics of the leading players in the Russian market.

- KYB(Kayaba) - the products of the Japanese concern are popular not only in Russia, but also in Europe due to their high quality and reliability at a relatively low price level. Shock absorbers of this company can be found on the conveyors of well-known European automakers. The gas-oil shock absorber of the Ultra SR series is especially popular with Russian sports driving enthusiasts;

- Bilstein(Bilstein) is a world famous German company that has been manufacturing shock absorbers for over 50 years. It was here that the design of a single-tube gas-filled shock absorber was developed. Bilstein products are installed on European premium brands: BMW, Porsche, Mercedes, Ferrari, Maseratti, Jaguar;

- God(Boge) - the brand belongs to the concern ZF Friedrichshafen AG (Germany) - one of the world's oldest manufacturers of shock absorbers. Recently moved to another well-known brand - SACHS and now the same type of products are produced under two trademarks. The concern's products cover more than 90% of the range of world automakers. On the Russian market, a 1-year warranty is provided, regardless of mileage;

- Monroe(Monroe) is an American company whose products are probably the most famous in Europe and are intended for 99% of the world's makes and models of cars. Monroe's latest Sensatrac series gas shock absorbers deliver superior handling performance and instant response to changing driving conditions;

- Koni(Horses) - shock absorbers - this is the only product of the Dutch company for almost 70 years. The main distinguishing feature of Koni shock absorbers is the ability to adjust the stiffness parameters, adapting the car both to external conditions and to the individual characteristics of the driver and the manner of driving the car.

But are all major manufacturers of shock absorbers widely represented on the Russian market? The figure below shows the top six players in this market in the US according to a survey by Ranker.

The first three consists of participants in the Russian rating. But the products of the American fox racing and Swedish Ohlins specific - it is designed for motorcycles, ATVs and SUVs. American Rancho Suspension in Russia is quite well-known and specializes in the supply of products for pickups and large SUVs popular in the USA. A few years ago, Rancho was acquired by Tenneco, which in turn owns the Monroe trademark.

Thus, the first three manufacturers of shock absorbers with a high reputation for Russia are KYB, Monroe And Bilstein.

As for the objective characteristics provided by shock absorbers and affecting the safety, handling and comfort of the car, they look like the following according to the manufacturers themselves.

Braking distance at a speed of 40 km / h:

- Bilstein - 8.0 meters;

- Monroe - 8.5 meters;

- KYB - 9.0 meters.

The differences are quite significant, if you remember that in a critical situation, centimeters of stopping distance are important.

Rear axle drift 90° (tight turn mode):

- Bilstein - 59 km / h;

- Monroe - 52 km / h;

- KYB - 48 km / h.

Tests for smoothness (characteristics closely related to subjective comfort) and directional stability are carried out in relation to each specific car model, therefore, it is possible to compare shock absorbers from different manufacturers only for specific cars.

Interestingly, such tests sometimes give paradoxical results: venerable firms can lose out to outsiders, both in individual indicators and in aggregate test results.

And yet, which shock absorbers to choose? Given the variety of designs, a wide range of loads and significant differences in the characteristics of different models of cars, as well as individual characteristics of the driving style, one should not expect monosyllabic answers to this question.

It is necessary to rely, first of all, on the recommendations of the car manufacturer, both in terms of characteristics and in terms of shock absorber manufacturers. If the owner wants to change the dynamics of the car due to shock absorbers (or there is no way to follow the manufacturer's recommendations exactly), general considerations on how to choose shock absorbers for a car can be formulated as follows:

Selection by type (oil, gas, gas-oil):

- For those who prefer comfort, a quiet ride, reliability and affordable prices, two-pipe oil shock absorbers are suitable;

- If you want comfort requirements combined with improved cornering dynamics, and the cost and reliability of the part are in a reasonable range, then twin-tube gas-oil shock absorbers are the right choice;

- Single-tube gas shock absorbers are designed for aggressive driving enthusiasts who prefer the handling of the car to a smooth ride.

By the way, the age of the car is also an important factor in making a decision. It is hardly advisable to install expensive gas shock absorbers on cars of venerable age with high mileage: the elastic characteristics of the suspension and body strength indicators deteriorate over time, and instead of the expected one, you can get the opposite effect.

Choice by manufacturer (which company shock absorbers are better):

- If the car belongs to the budget segment, and there is no need to test it in sports modes, and funds for maintenance are limited, shock absorbers from the Russian company SAAZ or the Belarusian Fenox may well be suitable;

- Those who appreciate quality and are ready to pay for it (even if the car does not belong to expensive foreign cars) should pay attention to the products of KYB, Monroe and Boge (Sachs);

- The products of Bilstein and KONI (the aristocrats in the world of shock absorbers) are recommended by experts for both sports driving enthusiasts and owners of premium cars.

And, of course, you need to beware of fakes: if the price for Bilstein products in the store is the same as for the Belarusian Fenox, then something is wrong with such a seller (and not with respect to Fenox). And the recipe for verification is the presence of a certificate of conformity, a warranty card and the correspondence of a unique serial number to the data on the official website of the manufacturer.

Differences between gas, gas-oil and oil shock absorbers, their pros and cons

It is hard to imagine how the car would drive and what sensations the driver and passengers in the cabin would experience if the vehicle were not equipped with special devices that could extinguish, or at least minimize the oscillatory movements transmitted by springs, springs, torsion bars. For this purpose, shock absorbers are used, quite rightly they are considered one of the most important elements of an automobile suspension, they are designed to eliminate vertical swaying of the body.

To choose the best shock absorbers for your car, it is advisable to first familiarize yourself with manufacturers that are recognized all over the world.

Koni

Shock absorbers are the only product manufactured by the Dutch company. The main difference is the adjustability of the characteristics of the models, and there is a difference of 100% between the zero and maximum adjustment positions, i.e. there is a real possibility of adapting the device to any type of road, any car model and driving style.

The range of the company is 2500 different models, differing in design schemes. Their cost on the market is the highest, as well as reliability, there is a chance that they will fail along with the car.

Most popular models:

- KONI Load-a-Juster - for a solidly loaded body

- KONI Special - for a smooth ride

- KONI Sport - for lovers of reckless at high speeds

Bilstein

They are installed by manufacturers on cars Lamborghini, Jaguars, Ferrari, which is already evidence of the highest quality.

The most popular models Bilstein Sport, Bilstein Sprint, Bilstein Rally are designed for high-speed, sports cars, they are chosen by fans to show a driving master class. There were no complaints about the quality of Bilstein products.

Kayaba

The products of the Japanese company Kayaba are preferred by world-famous car manufacturers: Renault, Ford, Seat, Peugeot. Kayaba shock absorbers won the sympathy of drivers with affordable cost and quality that meets international standards.

Among the most popular are gas-hydraulic Ultra SR models with high damping characteristics, stabilizing grip on the track surface, with good handling characteristics when using low-profile tires, in the absence of attenuation. This is preferred by lovers of a hard driving style.

BOGE

The main consumers of the products of the German company are the leading European concerns that produce cars BMW, Volkswagen, Volvo, Alfa Romeo, Audi.

The price policy of the manufacturer of shock absorbers is quite affordable for owners who really care about the technical condition of their cars. Installed on a foreign car, BOGE shock absorbers do not adversely affect suspension performance.

Most in demand:

- Boge Pro-gas, gas-filled, for a comfortable ride

- Boge Turbo24, single-pipe, allowing you to ride in off-road conditions on an all-wheel drive car

- Boge Turbo-gas, for sports cars

- Boge Nivomat, maintaining optimal ground clearance even with a significant load on the body

Monroe

The Belgian company is a manufacturer of shock absorbers known throughout the world.

Accurate and instantaneous response is provided by the original design of gas models, it also allows:

- easy to adapt to riding in different, even difficult conditions,

- control comfort,

- adequate vehicle behavior during complex maneuvers at speed

The American company enjoys the best recommendations not only at home, but throughout the world.

A particularly popular product series is Reflex, whose models guarantee maximum contact with the road surface.

TOKICO (HITACHI)

The Japanese company manufactures damper devices for the automotive industry in the United States and Japan. The products are of high quality, with a long service life, the cost is low - the prerequisites are sufficient for popularity.

But when buying, you should be wary of Chinese fakes, there are a lot of them on the domestic market, it is quite difficult to distinguish visually from the original.

It manufactures brake systems, hydraulics and pneumatic equipment for cars, shock absorbers. It has been successfully operating on the market for about 80 years, occupying a leading position. A special merit of the company is the development of a two-tube gas model of a low pressure shock absorber, which has advanced the entire industry as a whole.

Since 2005, TOKICO began to work as part of the HITACHI concern, its products are used in the assembly of sports motorcycles, as one of the most reliable in the world.

SACHS

The German manufacturer specializes in the manufacture of clutches and shock absorbers, the products are universal, high-quality and reliable. Today the company pays more attention to the production of pendants.

The most popular modifications:

- Super Touring - for a comfortable ride on a car of various types

- SACHS Advantage - for a sporty driving style, for a comfortable ride on the roadway of any complexity

KYB

In a relatively short period of existence (about 20 years), the Japanese company managed to gain trust and popularity; Mazda, Toyota, Honda cars are equipped with its products.

Al-KO

The company's products continue to delight motorists with inexpensive but high-quality products for four decades.

Dampers from Al-KO are installed on expensive motorcycles and cars, for the most part they are oil, they are preferred by owners of used vehicles.

DELCO

Manufactured in the USA, mostly used by American vehicle manufacturers. It is almost impossible to meet them on open sale, the main consumers of DELCO products are auto assembly shops.

However, DELCO shock absorbers are well known and highly recommended for their reliability. In off-road conditions, it is irrational to use.

Shock absorber, principle of operation, where installed

And now let's continue talking about shock absorbers, clarify on what principle they work and continue the topic of how to make the right choice of device for your car.

The shock absorber is a damping device that dampens vibrations, absorbs shocks and shocks of moving structural elements (suspension, wheels), body. The action is based on the process of absorbing the mechanical energy of oscillatory movements and converting it into thermal energy.

The interaction of the part with springs, pillows, torsion bars, springs allows you to dampen the free movements of large masses and prevent relatively high speeds of smaller masses associated with elastic elements.

The wheels of the car must be able to move freely up and down relative to the body. The mass of the body must be distributed to the suspension springs, to keep them compressed to a certain extent.

Fulfillment of these conditions will allow maintaining contact between the tire and the road surface, regardless of what will be under the wheel - a bulge or a depression. If shock absorbers are removed from the structure, constant contact will not be possible due to the oscillation of the springs.

For example, a driver can feel a malfunction of a damper device even when driving at a speed of 30 km per hour:

wheels bounce from the slightest bumps

vehicle control is deteriorating

One of the important points is the location of the part. The most efficient operation will ensure the minimum distance of their installation site from the wheel.

Experts emphasize that shock absorbers must be installed strictly vertically, i.e. perpendicular to the suspension plane. Even with minimal deflection, the damping efficiency will decrease.

It is extremely harmful to hold the opinion that this device is simple in principle of operation and primitive in design. In fact, the correct installation of the node and ensuring its excellent operation is a rather complicated science, requiring multifaceted knowledge in the field of physics and mechanics.

What do the main indicators of shock absorbers mean?

Like any other vehicle component, the shock absorber has certain performance characteristics. They play a significant role in the process of driving a car, its obedience to driving, on the comfort of the trip and its safety.

braking distances

The operation of the damping device affects the speed of acceleration and deceleration of the car. If we consider the state of the car at the start, it turns out that when accelerating, the load on the rear wheels first of all increases and decreases on the front wheels, i.e. reduces the strength of their adhesion to the road surface. Braking is accompanied by opposite loads. Ideally, in both situations, the body should maintain its natural horizontal position.

Efforts will be directed precisely at stabilizing the position of the body. But dampers different in design and type of filler will work differently, at different speeds.

For clarity, we can give an example: at a distance of ten meters in front of the car, an obstacle suddenly appears (a cat, a dog jumped onto the road, a person suddenly fell across the road, and little else can happen).

If the car is equipped with oil models, it is unlikely that it will be possible to avoid a tragic outcome. Gas-filled devices will significantly reduce the braking distance. The accident will end safely, and the driver will be able to boast of his experience and excellent reaction.

But even taking into account such reasoning, experts do not recommend installing gas-filled models on used, especially domestic cars - destructive processes in such cars are immediately activated.

the ability of a shock absorber to dampen vibrations on rough roads

We have already mentioned that the most important requirement for shock absorbers is the ability to dampen body vibrations while driving. Those. A high-quality shock absorber should ensure constant contact between the road surface and the wheel surface, this will prevent the possibility of losing control of the car.

In the event of a serious difference in the height of the road surface (bumps or dents), the wheel should go around it as gently and quickly as possible, clearly returning to contact with the road surface.

Since oil-filled devices are slower, it will be difficult for them to provide full damping of vibrations on poor quality roads. Off-road driving with such cars should be avoided, trips on bad roads are fraught not only with discomfort, but also with rapid wear of shock absorbers.

shock absorber stiffness, how it behaves in tight corners

The situation with the displacement of loads, but only on the sides of the car, will occur during the execution of maneuvers by the car, for example, when passing a sharp turn.

Stiffer, gas-filled devices are capable of faster response, with increasing pressure inside the shock absorber, the response speed increases. They give rigidity to the suspension, at high speeds this is expressed by a decrease in body vibrations.

The same is true when making a sharp turn - a hard and fast-acting shock absorber will have time to compensate for the resulting loads and passengers will feel them to a lesser extent.

The installation of such high-speed damping devices is carried out on high-speed cars, such as sports, all-wheel drive and off-road vehicles.

Among the best representatives are the MonoMax series with increased strength and pressure and the adjustable Kayaba - AGX models.

Shock absorbers and working substance

If we take into account the type of working filler, then all models are usually divided into:

- gas

- oil

- gas-oil

If the answer is subjected to a logical analysis, then it will change somewhat, because oils and gases are used as a working substance in shock absorbers.

The cases of gas models are filled with inert gases, more often with nitrogen. It is pumped under a pressure of 2 - 3 atmospheres. The working space of oil-powered models is filled with hydraulic oils and air.

Dampers and number of pipes

In accordance with the design features, shock absorbers are divided into several types: single-tube and double-tube.

oil shock absorbers pros and cons

Let's start with the simplest option - hydraulic two-pipe. Its cost is not high, but it does not differ in stability of work.

This type is distinguished by the location of the working cylinder inside the housing. The body is a cylinder filled with some oil. Working in compression, the piston located inside the cylinder moves down, displacing the oil filler through the valve.

The air at the top of the cylinder is compressed. When the piston rebounds, it makes a reverse movement, the oil returns from the body through the return valve, passes into the working part of the cylinder.

The design and principle of its operation are quite simple, but simplicity does not always guarantee sufficient efficiency - in the process of repaying one energy, another is formed, the compensation of spring vibrations is accompanied by the release of thermal energy, which leads to heating of the oil and a change in its viscosity parameters.

Oil heating is fast and cooling slow, heating and constant oil movement with air access often cause foaming. There are no methods to combat this phenomenon. Sometimes they try to get rid of the problem by filling a new shock absorber "to the eyeballs", i.e. up to maximum occupancy.

But such actions will not lead to anything good, the oil will still look for a way out, as a result, the shock absorber will most likely fail. It turns out that aeration is an incurable disease of oil shock absorbers.

gas shock absorbers pros and cons

gas single pipe

This type is distinguished by a special design that provides for complete isolation of the oil from the gas filler.

These models are made up of:

- corps

- stock

- piston connected to the rod and equipped with reverse and forward stroke valves

- float piston that separates gas from oil

Of the significant differences, the absence of a working chamber should be mentioned, the body acts as its role. Separation into chambers occurs with the help of a float piston.

The lower part of the body is filled with nitrogen under high pressure. In the upper part there is oil, it is in it that the piston moves with the rod.

Since there is no working chamber in the design, the direct stroke valve is located directly near the rebound valve, on the piston.

The design of single-tube models has allowed to increase the volume of gas and oil, while the size of the shock absorber has not changed. Such design improvements saved the device from heating. Exclusion of contact between gas and oil prevents the aeration process, i.e. foaming oil.

Among the shortcomings of such models should be noted:

- change in hardness depending on the temperature of the gas,

- an increase in temperature increases the rigidity of the suspension

- an accidentally formed dent in the body will cause the shock absorber to jam, i.e. he will fail, fortunately, such precedents do not happen often.

gas-oil shock absorbers, pros and cons

Representatives of this species are known as gas-oil. Their design is similar to that of hydraulic models. The difference is that the cavity is filled with gas, usually nitrogen is used.

The gas accumulates pressure and prevents the oil from foaming. But it was also not possible to get rid of the heating problem in this way.

When buying a gas-filled shock absorber, it differs from a hydraulic shock absorber in terms of the stem - gas pressure tends to squeeze it out.

changelings

You should also remember about the shock absorber of a special design, the so-called. changeling. It differs in that it is installed upside down. If conventional shock absorbers are characterized by the direction of the stem strut upwards, then here the stem is directed downwards, its fastening is made to the strut body.

The pseudo-rod has a large thickness, is located on top. Such a device works due to the presence of several plain bearings. Among the advantages of the design, a significant reduction in the vertical and lateral load on the rack should be noted.

Riding style, how it affects the choice of shock absorber

Given the fact that different types of shock absorbers have slightly different characteristics, the choice should take into account the driving style that the motorist prefers.

If the plans include a quiet movement, then you should not bother too much - oil shock absorbers will be enough. Although there is an opinion that such models serve less, no official confirmation of this version has been received.

If the driver prefers an aggressive, sporty style, then it is best to give preference to models from special series, such shock absorbers are distinguished by an increase in compression and rebound forces.

This improvement allows you to get increased stability of the car when driving at high speed, in particular - when cornering. But moving in a calm mode will become less comfortable.

Fans of an aggressive sporty driving style can also use shock absorbers of high rigidity with adjustable parameters. The positive point is that such models have very high strength and reliability.

If the car is used for infrequent and short trips, then buying expensive shock absorbers is not necessary at all. For example, QH or AL-KO, or similar, is quite enough.

How to check the condition of the shock absorber on your car

Experienced drivers claim that the main signs of the health of shock absorbers are:

- obedience to car control

- noise level in the cabin

- no shaking and vibration while driving

At the same time, shock absorbers affect the speed of acceleration of the car, give a smooth ride, braking, cornering, overcoming descents and ascents.

They eliminate vibration, the increase of which can lead to wheel slip in extreme conditions, i.e. their action is aimed at increasing the safety of movement along the highway and minimizing the threat of accidents.

But, unfortunately, any part of the car wears out over time and needs to be replaced. The question arises: by what symptoms can a motorist determine a malfunction of a shock absorber.

It is possible to make a diagnosis yourself:

- determine if there are liquid leaks on the body (they should not be in good condition)

- by pressing on each of the corners of the body, the car should be rocked, as a response, only one return movement should occur, while the car should return to its normal position

- in the event of a malfunction of the shock absorbers, knocks will be clearly heard when the car is rocking

Such a simple test will reveal a malfunction, and therefore the onset of the time to replace it.

In order not to make a mistake when choosing shock absorbers, consider:

- many models are designed for certain brands of cars, so it is advisable to study the catalogs that are available in specialized stores

- type of previously used models

- preferred driving style

- the condition of the roads on which you have to travel in most cases

- cost, especially if the replacement will be carried out on a used car

- replacement of oil shock absorbers with gas ones, or vice versa, must be carried out on both axles at the same time, otherwise there is a risk of significant changes in the behavior of the car

None of the distributors can guarantee the quality and long service life of shock absorbers if they are installed on a car with a faulty suspension, without anthers and fenders, and the installation itself is carried out in violation of technology.

The question of choosing shock absorbers for a car is a very popular topic among motorists. The huge variety of models on the market causes a variety of opinions and is the cause of many disputes. We can say one thing: replacing the shock absorber completely changes the nature of the movement of the car. There are three types of shock absorbers on the market today. These are gas, oil, and also gas-filled. Each of them has its own properties and characteristics. Let's try to figure out which is better - an oil or gas shock absorber.

Functions and device

The work of shock absorbers is to reduce the amplitude and number of oscillations of the spring. As for the algorithm of action, it is no different from the principle of the oil pump. The small cylinder is installed in the large one.

When the suspension oscillates, it thereby causes the shock absorber rod to move. The rod, in turn, drives the piston. The latter compresses the gas or oil in the cylinder. Oil escapes through small holes into the second cylinder, which is larger, thereby slowing down the movement of the piston and suspension. There are different types of these elements. You can buy a shock absorber gas or oil. Which one is better? Feedback on a particular design will be in the course of the story.

Types of shock absorbers for a car

So, they can be classified according to different factors. According to the type of working substance, gas, oil and gas-oil products are distinguished.

Also, these elements are distinguished by the number of pipes. There can be one- and two-pipe systems. How are they arranged? The first shock absorber is a single tube. This design is most often used on oil and gas-filled devices. Doubles are less common.

Depending on what type of shock absorber is installed on the car, it can move as smoothly as on an expensive executive car, or hard as on a sports car. We will try to figure out which is better - an oil or gas shock absorber.

Features of oil devices

Inside such an element is a special oil. Flowing from one cylinder to another, this almost incompressible fluid dampens suspension vibrations when the car is moving. Inside the device is not only oil. There is air in the compensation chamber. It is needed so that the oil does not flow too quickly from one chamber to another. The dynamics of the device is completely determined by the performance of the bypass valves.

These mechanisms have the simplest possible design. Therefore, they practically do not fail. The weak point of these devices is fast driving on rough roads. Pistons can move unexpectedly and oil can often foam. Because of this, the liquid will not be able to move through the holes in the transfer valves as quickly as it should. The shock absorber works in the mode of increased loads.

If you ask an experienced car enthusiast what is better - a gas or oil shock absorber, then he will choose gas models. Many motorists do not like hydraulic devices. Reviews say that the liquid in the cold season loses its properties and becomes thicker. Until the oil warms up, driving on rough roads will not be very comfortable. If you often need to ride on bumps, air can get into the oil. This will not only adversely affect the operation of the shock absorber, but can also cause the product to fail.

The oil shock absorber also has its advantages. Reviews note the low price and availability in any bridge. These are serious advantages. If the driving style is calm or if the comfort of movement is important, then the choice is obvious. Next, we will consider other types of shock absorbers and decide which is better - gas or oil.

Gas

As the name implies, a special gas is used here as a working substance. More often it is nitrogen pumped under pressure. There is also oil inside the device. It is separated from the gas chamber by a special floating piston that prevents the two substances from mixing.

Also, as already noted, there are no completely gas products for sale. There is still oil, but there is much more gas. Structurally, they differ significantly from oil models. The gas shock absorber is always single-tube.

If the oil element is soft and suitable for a comfortable ride, then the suspension on gas shock absorbers is the stiffest. In addition to high rigidity, the products are distinguished by a high price. Reviews say that this is the choice for those who prefer a sporty driving style.

The gas shock absorber in the absence of comfort and rigidity improves the grip of the wheel with the road. In addition, with such a suspension, rolls are completely excluded. Significantly increased controllability.

Subtotal

So, now you can sum up and decide which is better - a gas or oil shock absorber. For those who prefer a quiet ride on city roads, hydraulic products are the best choice. For those who like to move fast on the trails at high speeds and want better handling, hydraulic elements are the choice. As you can see, it is impossible to clearly say that some product is better.

They have different characteristics, and they suit someone more, someone less. When choosing a gas model, it must be borne in mind that when replacing, other suspension elements must also be changed.

Gas-oil products

Here, both gas and oil are used in one design. The greater the pressure force of the substances, the better the controllability and the higher the rigidity of the device. The advantage of the design is that the oil will never foam here. You can move confidently even on rough roads without fear of loss of control or failure of the shock absorber.

Gas, oil, gas-oil systems - which is better?

This is a rather difficult question. And now, knowing the advantages of gas-oil products, it is difficult to say which shock absorber is better - gas, oil or gas-oil. Hydraulic devices are of outdated design. And due to this, ride comfort is very doubtful. There are all risks of breaking the shock absorber when driving on bad roads. In addition, handling leaves much to be desired.

And now, it would seem, a solution has been found - a gas shock absorber. But this is the choice of street racers who like to drive fast on smooth highways without potholes and potholes. But since the stroke of the rod is small, there will be constant shaking in the cabin. This vibration can cause various parts of the car to fail earlier.

So what to choose for a car enthusiast who wants to get good handling, relative comfort, service life and reliability? Should I choose a gas or oil shock absorber? What's better? Reviews say that a compromise option is gas-oil products. They combine all the advantages of both devices.

Two-pipe

Oil or gas-filled devices of this design are the most popular. You can always find them for sale. Structurally, these are the simplest options. Feature - in the presence of two containers for oil. So, it can flow from one chamber to the second through special transitional valves.

Among the advantages of this design, comparative reliability and affordable cost are distinguished. There are more disadvantages. Reviews often note boiling oil. As a result, there is a violation of the efficiency of work. Another disadvantage, judging by the reviews, is a lot of weight. If you have to choose which shock absorber is better for a VAZ - gas or oil, then experts recommend installing two-pipe hydraulic structures. They are also suitable for family cars, whose drivers often drive in a calm manner. A twin-tube oil shock absorber is not suitable for installation on a sports car, crossover or SUV.

Gas single pipe

Since these products use gas as a damping agent, there is no particular need for a second pipe. I must say that due to the characteristics of the device, the shock absorber can be installed at any angle - even upside down.

You also need to know that the greater the pressure inside the gas cylinder, the faster the reaction to suspension movements will be. These options are considered the most effective, judging by the reviews. Now you can buy a shock absorber gas or oil. What's better? If you want reliability at the expense of comfort, then it is better to choose gas-filled models.

With or without regulation?

If you need to go fast on the highway, and after a while move off-road, then it is better to purchase an adjustable option. Its settings are very easy to change. The price is higher than the cost of gas models. But efficiency is also on the level.

About choice

So, we need Which is better to buy - gas or oil? For bad roads and a calm driving style, the latest products are suitable. For good and smooth roads - gas-filled.

Question " what's better”, perhaps one of the most frequently asked questions on the Internet. We, people, tend to doubt the choice of this or that product, thing, and anything ... Drivers are people too, so we have no less doubts than a simple layman. We constantly make some kind of choice, starting with the choice of a car, ending. Moreover, every day we imperceptibly make hundreds of vital decisions, for example, performing a complex maneuver, on the correct implementation of which more than one human life sometimes depends...

Structurally, a shock absorber is a cylinder with a piston, on which there are valves with different flow area and different throughput. In the case of oil shock absorbers, it passes through the valve holes, when compressed, it quickly passes through the holes, and the back valves limit the rate of fluid passage, thereby preventing the shock absorber from quickly stretching.

Shock absorbers with gas chambers are called gas shock absorbers. Gas shock absorbers have only one cylinder, in which the pressure is approximately 25 bar. The floating piston separates the gas from the oil, preventing them from mixing, due to this high gas pressure, the oil is not able to foam. As a damping element in gas shock absorbers, the same chambers are used, only instead they use a special gas. According to a non-linear law, the stiffness of a gas shock absorber increases with tension or compression, which, by the way, is not typical for oil shock absorbers.

The main differences between gas-oil shock absorbers

We have already figured out how gas and oil shock absorbers work and what they consist of, the question remains - what kind of "such a beast" gas-oil shock absorber. In a nutshell, the gas-oil shock absorber is a kind of compromise between gas and oil shock absorbers. The gas-oil shock absorber has almost the same design as the oil shock absorber, it also consists of two cylinders. The upper part is filled with nitrogen, the cylinder itself is under a pressure of 2.5-5 bar, which increases the effectiveness of the shock absorbers. The principle is as follows - the higher the gas pressure on the oil, the faster the response of the shock absorbers, while the car's suspension will be stiffer.

Summing up

Oil shock absorbers softer, since they use only oil, which, like all liquids, is almost not subject to compression, as a result, the stroke, as well as the shock absorber force, will directly depend on the check valves in the piston of the shock absorber cylinder. In terms of travel, the oil damper will be softer and more energetic.

Gas shock absorbers can be called more rigid, since the second working medium of the shock absorber is gas, which itself is able to compress, despite the fact that it is under high pressure. As a result, the gas will also take part in softening the ride of the car and the force on the shock absorber rod. All this makes the shock absorber more rigid and less inertial in relation to the movement of the rod. The main "chip" of the gas shock absorber is its ability to change the stiffness properties depending on the road, by means of a gas chamber, which dampens vibrations due to its non-linearity during operation. The gas shock absorber is less soft and less elastic, therefore, during the passage of uneven sections, the suspension with gas shock absorbers can seem very stiff and extremely uncomfortable. However, rigidity is at the same time a plus of this type of strut, since for a frisky ride or maneuvers, a large stroke of the rod and increased softness are simply unacceptable.

So which shock absorbers are better - gas or oil, or is it still gas-oil?

This issue is quite controversial, so it’s impossible to say for sure that this one is better, and that one is worse. Everyone must decide for himself what is more priority for him, based on what is written above. In addition, it is necessary to follow the recommendations of the automaker, it is the manufacturer who knows for sure which shock absorber can provide the necessary resistance, and a comfortable ride for passengers. Another thing is when manufacturers install shock absorbers of a "budget" sample in order to save money, but this does not suit you, in which case you can install your own version. However, those devices that you are going to install should have the parameters as close as possible in order not to disturb the driving performance of the car.

Service life and price of shock absorbers

As you know, gas shock absorbers have a more complex design, primarily due to additional damping chambers filled with gas. In addition, due to the use of seals for working with gas. For the manufacture of such devices, a more radical approach is needed, and the seals themselves must have a more rigid design.

As for the service life, it will primarily depend on the shock absorbers themselves, as well as the roads on which the vehicle will be operated. If the shock absorber is of high quality, it may well serve 60,000 km, or even more. However, if we compare resource of oil and gas devices, under equal operating conditions and quality, the oil shock absorber will last longer due to the simplicity of its design. In addition, the cost of oil shock absorbers will be about 20-30% lower compared to gas ones.

It is one of the elements of the car's suspension that affects its behavior while driving and is closely related to safe driving. Therefore, if the question is which shock absorbers are better to put, then you need to focus not on the company or price, but on the tests and recommendations of the automaker.

Exactly the same situation with the choice of the type of amortization - gas or oil - is recommended put only those that are provided at the car factory. Others can influence the behavior of the machine and not always for the better, deviating from the desired result.

From this article you will learn:

Weighty indicators of the choice of shock absorbers

When considering what to look for when choosing the best shock absorbers, the first thing to do is emphasize on:

- Braking distances, as strange as it sounds. After all, shock absorbers resist rocking, which greatly affects the speed of stopping the car during emergency braking. That is, the softer the shock absorber strut, the greater the amplitude of oscillation during braking of a car with an ABS system.

- Sagging on sharp turns. Due to the centrifugal force, body roll is created when the car enters a turn at speed and, as a result, adhesion to the road surface deteriorates, which, in turn, threatens to lose the trajectory of movement. The stiffness of the shock absorber is also responsible for this indicator.

- Stability on broken roads depends on the ability of shock absorbers to quickly dampen vibrations when passing bumps. The resistance of the shock absorber is responsible for this indicator.

controllability vs. smoothness graph

An unbiased comparison of the three most famous shock absorber manufacturers led to the following subjective conclusions:

- shock absorbers Bilstein will be a good choice for fast and sharply controlled driving, but at the same time you will have to endure shaking and stiff suspension work;

- with not fast and comfortable driving, installation of shock absorbers Monroe- the best option;

- for mixed cycles of movement recommend the installation Kayaba.

Choosing the best shock absorber for your riding style

Which shock absorber is best for your car depends largely on the intended purpose, the quality of the roads, the stiffness of the tires and your inherent driving style. Therefore, the same car can hold the road well at speed, but will be annoying shaking even on small bumps, and another car, which behaves inertly and sluggishly when cornering, will perfectly hold even deep potholes. And all because the characteristics of shock absorbers depend on the type and serviceability.

When deciding which shock to put on, you need to decide which indicator you prefer: fast handling or soft comfort. After all, unfortunately, when one indicator increases, the other falls.

If there are no special requirements for operation, then it is advisable not to be smart and follow the recommendations of the automaker when buying regular shock absorbers. Their technical indicators are compatible with the normal operating conditions of a car - they have reliable stability, controllability, take into account the characteristics of the suspension and the strength of the body.

Too powerful shock absorbers can tear out the attachment points to the body or suspension.

When the car is often and heavily loaded or there is an additional cylinder from gas-balloon equipment in the trunk, it is recommended to buy and install percent racks 30-40 stronger. And drivers who like to press down on the gas pedal put on shock absorbers with increased resistance in order to reduce body roll.

All shock absorbers divided into types according to these two parameters:

- the composition of the working substance (it can be oil, gas or gas-oil);

- number of pipes (2-pipe or single-pipe).

How driving style affects shock absorbers

Discussion of the eternal question "Which shock absorbers are better"

Gas or oil shock absorbers - which is better to put

As we already know, car shock absorbers are divided into three types according to the type of working substance. Next, consider in what situations they show themselves from the best side.

Install oil shock absorbers are better if:

- the budget is limited, because due to the main disadvantages, such as poor efficiency on rough roads and unstable operation in the cold season, the price of such shock absorbers is much lower than others.

Choose gas-oil shock absorbers are better if car owner:

- prefers a calm driving style;

- not ready to frequently repair the suspension of the car.

As a rule, it is precisely such shock absorbers that the bulk of drivers install.

Their design is similar to conventional hydraulic ones, but due to the fact that they use nitrogen gas instead of air, they last longer, provide better cushioning and more efficient performance in high-speed conditions on the track.

Put gas shock absorbers are better if:

- the car is often used in racing;

- an instant reaction to a change in the mode of movement of the wheels is necessary;

- need improved vehicle handling in all weather conditions (they do not tan in the cold and protect the car from aquaplaning);

- the need to confidently maintain traction at high speed is more important than comfortable driving.

Main lack of such shock absorbers in that, due to the small stroke of the rod, you will not only feel shaking on bumps, but also more frequent suspension repairs, since some chassis nodes will wear out faster.

Operating a vehicle with gas struts on rough roads will accelerate the failure of other suspension components.

When choosing the best shock absorbers, you can be guided by different criteria: both the driving style and the operating conditions of the car, or based on the stiffness and comfort index. But in any case, you need to monitor the health of each type of shock absorber, because when one or more shock absorbers fail, the quality of tire adhesion to the road surface deteriorates significantly, and this will negatively affect the stability and braking distance of the car.

In addition, there is also significant wear on such suspension parts - levers, steering tips, tires, springs and brakes, no matter what firms they are. That is, from all of the above, we can conclude that for the average car owner on his car it would be better to put gas-oil shock absorbers. It remains only to decide on the manufacturer.

Choosing the best shock absorber company - TOP 7

Manufacturers often make shock absorbers that can be installed on most cars, even those designed for different driving styles. At the same time, each of the companies still tries to place more emphasis on one particular specification, which is why one or another company has to be preferred, depending on the operating conditions of the car. Next, we present an overview of such popular companies as: KONI, Bilstein, Boge, Sachs, Monroe, Tokico and KYB, producing shock absorbers that have successfully proven themselves in practice.

shock absorbers Bilstein and KONI are the most expensive and reliable. If the conversation concerns a company KONI, then the manufacturer gives a guarantee for the entire service life of the car. Their shock absorbers are applicable to any car and for any driving style. The type of KONI shock absorbers must be selected depending on the suspension design and operating conditions. With such shock absorbers, the suspensions of Mazerati, Lamborghini, Ferrari cars go. Before packing them, the manufacturer tests the shock absorbers for strict compliance with the specified characteristics.

The German Bilstein will be a little worse because they only have the “coolest” sports series (Sport, Sprint and Rally). Suspension with their single-tube gas shocks will be very stiff.

God also German quality. The shock absorbers of this company, which, by the way, is now owned by Sachs, are installed on conveyor cars of the VAG, BMW and Mercedes concern. The cost is much cheaper than the previous ones, and the technical characteristics of foreign general-purpose cars do not change. They produce shock absorbers with the expectation of 3 basic needs: for a comfortable ride (Pro-gas, Automatic), for sports cars (Turbo-gas) and capable of withstanding increased loads (Nivomat, Turbo24).

shock absorbers Sachs will stand only half a step higher than Kayaba or Tokiko, as they are designed for general accessibility and applicability. Although they are from the same unit along with God, there is no clear distribution according to purpose and operating conditions, depending on the suspension (both for a jeep and for a passenger car are the same). Saks are available in several versions: SuperTouring, Advantage and Sporting Set.

Japanese shock absorbers KYB And TOKICO more or less reliable. Kayaba can be found on cars from the assembly line of Honda, Toyota, Mazda, Ford, Renault and many others, because their plants are located in more than 10 countries around the world, but TOKICO is designed exclusively for the Japanese and slightly American automaker. But there are no fakes either, which cannot be said about Kayab.

KAYABA are available in the standard gas-oil and reinforced gas shock absorbers. There is a separate line for all-wheel drive jeeps - MonoMax, sports - Ultra SR and standard operation - Exel-G.

Firm shock absorbers MONROE designed for the aftermarket. Their reliability corresponds to the price, and the service life will be close to 20 thousand km. A car with such racks will sway slightly on a rough road, but will begin to collapse on a turn. The Belgian manufacturer presents its shock absorbers in a wide range. They offer one and two-pipe racks. Previously, they were quite popular and of better quality, but recently they began to take positions. But still, they are somewhat more reliable than Profit or Optimal. Monroe is a normal economy option.

As you can see, the choice is great, and you should not give unambiguous preference to shock absorbers of one or another company. Rather than just asking people which shock absorbers are best, it’s more about making a choice for reasons of expediency - almost every manufacturer offers its own type of shock absorber that is suitable for any conditions and methods of operation. So, if you have a domestic car, then it makes no sense to buy expensive Koni, Belshtein or God, and Sachs or Monroe would be ideal. But a brand new foreign car of the middle class is better to put God or Kayaba.