In this article, we will tell you how corrosion appears on a car, how to deal with it, and give tips on removing rust on a car from personal experience.

Why does a car start to rust?

Only iron can rust, which oxidizes when the metal is combined with water. Metal corrosion is an electrochemical process in which electrons are emitted from the anode (its role is played by a metal body) and through the electrolyte (water with a slight admixture of salts) enter the cathode (metal parts). As a result, the iron of the machine is converted into iron oxide - that is, it rusts.If the nature of "household" corrosion is electrochemical, then any chips of paint to metal are potential sites of corrosion damage. As soon as an electrolyte appears there in the form of water, rusting will not keep you waiting.

Understanding the corrosion process provides the tools to deal with it. Because the car body is made of iron, then the anode and cathode will always be found, but we have to do something with the electrolyte. By the way, it is precisely because of the greater saturation of chemical reagents with various salts that utilities use in winter that the car begins to rust intensively during this period.

Ways to fight corrosion

Mankind has come up with barrier protection against corrosion, which does not allow physical contact of the metal with the external environment and is protective. Barrier protection is paint and varnish, everything that protects the surface from the atmosphere.The principle of tread protection is different: the “sacrificial” metal should be oxidized - for example, zinc, which is in direct contact with steel. As a result of the electrochemical reaction, zinc corrodes, not iron. Such a coating is effective even in the presence of defects, and the protection lasts longer, the thicker the zinc layer. We all know about the good corrosion resistance of galvanized bodies, a vivid example is Audi 100 cars, which are in good condition even after 30 years.

Let's talk about the way to combat corrosion. The first way is passive. It is necessary to cover the metal of the body with an insulating coating - i.e. prime and paint. This process is an effective way to prevent corrosion. But it is necessary to constantly monitor the integrity of the protective coating, check for minor damage - cracks, bumps and chips on the body.

Also, this path includes activities related to the cleanliness of the machine - washing (every two weeks) and periodic waxing - water drains faster from the coating along it.

The second path is called active- based on the use of various coatings on the metal. For this, mastics, sealants and anti-corrosion materials are used. Basically, drugs are used on the most corrosive parts of the car - the bottom, thresholds, arches. Additional protection is effective only if applied to absolutely clean and dry surfaces, otherwise water may remain under the protection film, which will continue the corrosion process.

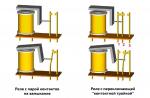

The third way is electrochemical. It is used less frequently due to the high cost and the need for constant power supply of the installed electronic device. Due to the change in the electrode potential, corrosion processes in the car begin to take place only in a certain place. The cathode is not the body of the car, but a special electrode that rusts instead of it.

The third way is electrochemical. It is used less frequently due to the high cost and the need for constant power supply of the installed electronic device. Due to the change in the electrode potential, corrosion processes in the car begin to take place only in a certain place. The cathode is not the body of the car, but a special electrode that rusts instead of it.

All ways to protect the car perfectly complement each other, but sometimes a slip occurs and the process of rust appears in all its brown-red glory. Here you need to act quickly, because. Starting the corrosion process is easy, but getting rid of it is much more difficult.

How to remove yourself?

First things first, you need to carefully remove the rust. To do this, a weak solution of alkaline acid is used, which is used to treat the damaged area, and then removed mechanically (with sandpaper or metal brushes). Carefully follow the requirements of the instructions, because. acid is quite aggressive and corrodes rust from the inside. This process must be stopped in time.Also effective rust converters or modifiers, which, as a result of a chemical reaction, convert iron oxide to iron tannate and are a more stable substance. Quality modifiers contain polymers and act as a primer. Minus - if the metal oxide is not processed in its entirety and remains, then the corrosion process will continue.

In stores, it is easy to find rust converters of various types. The cost is not high. The processing process is simple: first, we sand the damaged area to bare metal, then apply the composition (you can use a brush) and leave it for up to 12 hours, depending on the instructions. Don't be alarmed when the cleaned area turns green - that's the rust modifier at work.

Video. Removing mushrooms from cars

Further, everything is standard - the place from which the rust was removed (or converted) is puttied, primed and painted. Actions are repeated as needed. To prevent the appearance of rust on the car in the future, it is recommended to do anti-corrosion treatment.

How to remove rust from a car body with your own hands? literally every third car owner thinks. Corrosion in the city is a terrible epidemic that mows down cars all the time.

After contact with water and air, all products based on iron (Fe) and its alloys (steel, cast iron) corrode. Corrosion itself is an electrochemical process. During corrosion from the anode (such as a car body), electrons are released by emission through the electrolyte (water with dissolved salts) to the cathode (any metal parts that accept electrons).

Every year humanity loses up to 30% of all metal structures due to corrosion. It is quite possible that artificial iron oxide is the only product that mankind has produced in the largest quantity in its history.

Corrosion and how to deal with it

Since oxidation is a natural process, mankind has not figured out how to deal with rust on a car as efficiently as possible. But in the modern world of a consumer society, this is not necessary. To ensure high rates of industrial production and profit, enterprises make cars with planned aging of components. As a result, such machines cannot last more than 5–10 years, no matter under what ideal conditions they are operated. But older cars were made to last and are operated for 20-40 years, and for them the fight against corrosion is very important.

There are several answers to the answer, how to deal with rust on a car:

- barrier protection using paints and varnishes;

- tread protection - galvanized body (when it is not the metal of the body that rusts, but its coating);

- electrochemical protection (by changing the electrode potential, in the presence of direct current, only a separate part is oxidized - the electrode, and not all cars).

It is important to emphasize that the latter method is the most expensive and is used in exceptional cases. More often it can be found on gas pipelines.

Galvanized protection

In order to successfully remove rust from a car body with your own hands, you must use special diluted acids and an abrasive tool (zero skin). Users order in special car services additional processing of the body of their cars with special mastics or even galvanize the body. However, any of these types of body protection are very expensive and make sense for expensive cars that want to protect against increased corrosion in the winter (our utilities use aggressive agents to remove snow and ice from the tracks). It is almost impossible to do the treatment at home.

Is it possible to remove a small rust by painting it over.

When a car owner is annoyed by rust on a car, do-it-yourself methods of fighting become instantly relevant. It is not necessary to have a perfect car, but no one wants rusty and with holes. Moreover, it is much easier to localize a process that has just begun than a heavily launched one.

Well, if the automaker is worried about reliable, combined protection of the body and other metal parts of the car, but what if not? Then everything falls on the shoulders of the owner.

slow down time

When thinking about how to stop body corrosion, most motorists agree that it is better to wash the car more often (at least once a week) and keep it in well-ventilated areas, garages. To prevent rust from starting its victorious march along the car body, it should not be allowed to mechanically damage it, that is, bumps, scratches, dents and other things.

It is desirable to stop the corrosion of the car body at the initial stage.

Since then it will be much more difficult to do this, because the rusted body element will either have to be completely changed, or it will have to be engaged in a complex and expensive restoration. To prevent corrosion of the car from spreading at a rapid pace, many car owners try to order anti-corrosion treatment of the bottom and other elements of the car body even at the stage of purchase. So you can delay the start of the process for several years.

The easiest way to remove rust from a car body is with a weakly concentrated alkaline acid, but some motorists prefer processing only with emery cloths or electrified tool wheels (with a small abrasive grit).

What processing methods does the car market offer

To remove rust from a car, specialized chemicals can also be used that convert iron oxide to iron tannate, a very stable substance. The disadvantage of this method is the inability to convert the entire oxide, most of it remains, which means that the corrosion process continues.

Also, the fight against corrosion is possible with the use of newfangled polymer-based primers that protect the metal from moisture, and hence from corrosion.

But the most popular among motorists is considered to be full or partial (the most dangerous places) galvanization. With it, rust can be removed from the car body reliably and for a long time. In addition, the practice of the same Germans or Japanese shows that a galvanized body will remain in perfect condition even after 40 years, without traces of rust (examples: Audi 80, 100, Nissan Bluebird, Mazda 626). That is, car treatment with zinc or chromates is a fairly effective method that has proven its effectiveness in practice. If they process even individual elements of the body, you can significantly slow down the aging of the car.

Where protection is most needed

Having bought an inexpensive rust modifier, they begin to process the places most susceptible to corrosion: thresholds, wings, bottom. First you need to carefully sand the place of rust, and then process it with a modifier. The treatment area will turn an unnatural green color, indicating that the rust modification process has been completed successfully. After 12 hours, you can start priming and painting the problem area. It is easier to process on the trunk lid or door surface than under the car, but it is there that most moisture is present, and the bottom rusts much earlier than the rest of the body parts.

To know how to remove rust from a car body, you need to understand at least a little chemistry. A badly sanded problem area or painting over rust does not bring success. Yes, you will mask the rust, but the process will not stop and eventually the car will rot right under the paint. In order to have as little rust on the car body as possible, efforts are needed, and considerable ones.

It is necessary to carefully clean, dry and degrease the place where there was rust, apply a high-quality primer (preferably on a polymer basis) and only then paint.

Corrosion on new cars

Experienced car owners know that the thickness of the metal in modern cars has become much less than it once was. Now a budget car begins to corrode after 2 years of operation.

Now motorists have three main problems:

- rust removal;

- elimination of breakdowns of the chassis;

- adjustment and protection of the engine power supply system.

These problems are caused by the desire of automakers to use low-quality metal for the body, the harsh reality of the state of domestic roads and the poor quality of domestic fuel. And although car corrosion seems to be a long-term problem, after the first winter it becomes clear that this is an erroneous judgment. After all, the main highways of city roads sprinkled with salt literally “eat up” the bodies of our cars. Even those that were with anti-corrosion coating.

Before getting rid of rust, many customers try to order a complete diagnosis and identify all the problem areas of the body. All anti-corrosion treatment depends on how well the service will be carried out. After all, if you do not remove all the rust from the car, you can get significant problems in the future.

Fight against an invisible enemy

Iron oxide, that is, rust, has a specific brown-red color, it is clearly visible, however, only on the outer part of the body, and corrosion processes also occur inside, under the lining of door panels, seats, and in the engine compartment. Rust removal tips are not always helpful or even applicable.

You have to rely only on the automaker and the quality of the brand, since rust can only be removed in accessible places.

Rust becomes one of the factors causing the so-called metal fatigue, when, under various dynamic loads and internal stresses, the metal simply bursts. And it’s good that it wasn’t the steering rack or traction that burst, but the skin part. But often there are more serious breakdowns, which always begin with rust.

When you buy a vintage car, the question of how to remove bugs and other signs of rust is a top priority. So far, the technique allows only the use of various polymer-based paints or putties to level the metal. However, in the case of large-scale corrosion of the body, it will be necessary to use proven means: welding, straightening, puttying and painting work.

Independent work

It is important to understand that not all body work can be done independently, without special equipment. So, you can tint a car a little in the garage, but even painting the body with high quality, most likely, will not work. And there is no need to talk about how to remove rust from a car body completely. This is an almost impossible task. However, it is quite within the power of a novice motorist to solve local problems that spoil aesthetics.

A few videos from YouTube - and you are aware of all the features of this kind of procedure. To remove rust from the car with a minimum investment of time. It is enough to buy sandpaper in a hardware store, car putty, primer paint, and you can completely get rid of rust on the car (in the most prominent places).

Corrosion protection is not only the preservation of the aesthetic appearance, but also the integrity and performance of the car.

Therefore, a large amount of rust on a car cannot be ignored for a long time, as the time will come when this will affect the general condition of the car (literally worsen its technical characteristics). Therefore, it is better to repair all rusty holes in advance.

Buying a used car

When buying a used car, it is advisable to conduct a thorough inspection, as owners often paint over rusty places without proper anti-corrosion treatment of the body. All this leads to the fact that the car begins to rust intensely, despite the fact that the external looks like new.

And if imported cars have factory rust protection, domestic ones come with this option only in the luxury package.

For this reason, in order to get rid of rust on a used car, it is advisable to carry out diagnostic measures in advance (a thorough inspection will reveal all defects). And then the buyer decides for himself whether he needs a car with a rotten body and how much the transaction amount can be reduced.

Experienced motorists know that if you buy an older car in good condition without repair, then the benefit from the purchase will be higher than in the case of a car that has been repaired (often made of poor quality). In addition, until the 2000s, the quality of automotive metal and paintwork was much better than modern ones. And how to deal with corrosion if it covers a new car from the assembly line, and steel has a lot of harmful impurities? No paint will protect against corrosion.

Each car owner has faced or will face such an unpleasant moment as the appearance of rust on the car body. This is a very common problem, which we will cover in this article, as well as give good consistent tips for removing corrosion from metal parts of a car. Note that stopping the spread of corrosion on the surface of the car body is a laborious process, it will be easier to protect yourself from its occurrence in advance and quickly eliminate possible foci. Also, this article will provide detailed videos with a complete process of dealing with corrosion.

The most common causes of rust are minor damage to the paintwork that has not been repaired in a timely manner. These can be small chips from crushed stone or gravel, or scratches of varying degrees of damage. It is in such damage that moisture, dirt and various aggressive chemical elements that are used on roads in winter get into. What creates a favorable environment for the oxidation of the metal and the spread of lesions even under the paint.

Stages of the fight against corrosion on the car body

Thorough washing of the machine to remove all contaminants from the treated surfaces;

Wiping and drying damaged items;

Careful inspection and search for all damage to the paintwork and finding pockets of corrosion throughout the car body. When finding damage, they must be identified in any way so as not to forget about them;

Preparation of damaged parts to remove rust and damage;

Corrosion removal works are being carried out;

Special treatment of cleaned areas for additional protection;

Carrying out puttying and priming works for subsequent painting of the car;

The final stage is painting and polishing the car.

Car wash

Washing a car is a crucial moment in the fight against damage to the paintwork and the elimination of corrosion of metal parts of the car body. On a perfectly clean surface, it is easy to notice all the scratches, chips and cracks. And it is also easy to determine the source of the spread of rust.

To facilitate the process and increase the quality of washing, it is necessary to use specialized car shampoos. They easily cope with most dirt and remove them from deep scratches. The car wash itself can be carried out manually or using high-pressure home car washers. The end result is no different - it's a matter of habit and having the right equipment.

Drying the car after washing

After the car is thoroughly washed and the surface is rinsed with clean water in large quantities. The entire body surface must be free of excess water drops and dried from residual moisture.

After that, you can proceed to the stage of searching for all kinds of damage to the paintwork or the metal base of the part. At the same time, immediately upon detection of a damaged area, it must be identified so as not to be missed during the work. Also, all places that will not be processed should be sealed with masking tape or film so as not to damage them in the process of all work.

How to remove corrosion yourself

To get rid of your favorite car from the manifestation of corrosion, you can apply two fundamentally different ways to deal with rust. For this, a mechanical or chemical method is used. Also, in some cases, you can combine these two methods. That's why. Let's move on to a detailed description of these methods.Mechanical method of rust control

When mechanical cleaning of damaged metal, various manual or electric tools are used. There are also pneumatic analogues of electric tools.To remove the first layer of rust, coarse sandpaper is usually used, or special hard grinding wheels on a grinder. Please note that it is not worth using a “grinder” for this type of work, due to high speeds, you can damage the body part and make further restoration impossible. You can also use special nozzles for a drill or other tool with hard metal brushes, this will also get rid of corrosion deposits.

The most effective way to mechanically combat corrosion is to use a sandblast gun. Which is also used to remove a layer of paint and varnish and strip metal parts to their original appearance. This method allows you to quickly and effortlessly turn any metal into a beautiful shiny detail. The principle of the method is that a jet of sand is supplied to the metal using air or water under high pressure. This jet of sand effectively removes any deposits on the metal itself, while not being able to damage it.

It is worth remembering safety precautions when working with any tool. Always use protective goggles and a respirator. Metal shavings caught in the human eye can cause serious damage, and ignoring those that have already been caught can lead to impaired vision or loss of the eye. Therefore, if metal particles get on the mucous membrane of the eye, you should immediately remove it yourself or go to the hospital for qualified help.

Chemical rust removal methods

The use of chemical rust removers can significantly save time and effort spent on the entire procedure. But in particularly difficult cases, they may not give the full effect. For example, many rust removers are designed for a layer of no more than 1 mm, or in especially deep scratches, the reaction may not be complete.Today, many automotive chemical companies also produce a variety of rust conversion products based on different active ingredients. Also, on sale there are various means for protecting the cleaned metal based on the process of galvanizing parts.

Today, one of the most popular and inexpensive means for cleaning a car body from corrosion is the Rust Neutralizer VSN-1. After applying this substance, a layer of gray matter forms on the surface of the part, which is easily removed. It is interesting that this liquid is not a rust converter - it is a strong neutralizer that completely dissolves all manifestations of corrosion. According to the manufacturer's recommendations, further surface treatment is not required and you can immediately start painting.

But it is worth noting that the composition of this substance was not disclosed, but it can be assumed that the liquid is based on a mixture of various aggressive acids. Which dissolve iron oxide (rust). The composition may include sulfuric, hydrochloric, orthophosphoric and other acids. Therefore, it is worth using the liquid with great care and use personal protective equipment.

Orthophosphoric acid is the most classic way to convert rust. This acid is found in most rust converters. By reacting with iron oxide, the acid removes rust, and the result of the interaction is a thin grayish film that has good properties of protecting the metal from further corrosion.

Another way to deal with rust is the recently popular kits for removing and “galvanizing” the treated surface. In automotive stores, you can now purchase a kit like "Zinkor-auto" or other names with the same principle of operation.

This kit includes a set of two liquids for removing rust and subsequent protection of the car body. Also, in the box there are two special electrodes with an absorbent part and a long wire for connecting to the car battery.

The whole principle is based on electrochemical processes and, according to manufacturers, they form a galvanized layer on the treated surface. For a detailed study of the method, you can watch the presented video, which shows all the steps and the result of processing.

Additional work

Do not forget that the metal part not only needs to be cleaned of rust, but also protected from further formation during operation. Before painting or puttying, it is necessary to treat the surface with a special anti-corrosion or epoxy primer. This will save the metal from interaction with the atmosphere and moisture.Then comes the process of puttying and painting the car, which will bring it to its final form. All stages of preparatory and painting work will be described below.

Puttying and painting car body

In this section of the article, several videos will be offered that describe in detail all the stages of painting work. After carefully reviewing them, each car owner will be able to perform this work at a satisfactory level.After cleaning the part, one or more layers of putty should be applied to level the surface or give the correct shape. Putty is applied in several thin layers, each time creating a more regular geometric shape of the body part. At the same time, after applying and drying the putty itself, the final shape is brought using sandpaper of different fractions.

It is worth taking this stage with all seriousness and attention. This will be the future basis for the paint layer, which is able to show even the smallest scratches. Therefore, the putty surface should be sanded with a constant decrease in fractions on sandpaper, up to “zero”.

Then, the surface of the repaired part is covered with a primer layer and after drying, the car is painted in a pre-selected body color. At the same time, it is worth carefully monitoring the applied layer of paint, as the resulting smudges will further spoil the appearance of the car. On the surface of the car, the paint is applied in at least three layers with a short break between each.

Depending on the type of paint, it may be necessary to apply a coat of lacquer and then buff after the entire body of the vehicle has dried.

Conclusion

Rust on the surface of the car body is a serious problem that can lead to further replacement of the entire part if the corrosion spots appearing are ignored. But it’s worth spending a little of your time, and all fears about the complete “rotting” of car body elements will remain in the past.Stories about the "eternal body" of sellers in a car dealership very often become a legend. Already after several years of operation, you can notice the first "bugs" and corrosion will cost only local repairs. However, if you miss even one scratch, rust will provoke a whole rescue operation to restore the integrity of the body.

Causes of rust on a car body

From a scientific point of view, corrosion is the oxidation of metal layers under the influence of air and water. As a result of the reaction, compounds of hydrated iron oxide appear on the body - a loose red powder.

Generally, rust is affected:

- Design factory solutions. Each body is made of thin sheets of metal and, due to its streamlined shape, involves a large number of joints and welds. The material that the manufacturer chooses must have a minimum resistance to destructive oxidation processes and contain a proportional amount of alloying substances.

- Exploitation. Even the strongest body will not withstand storage in dampness or outdoors, especially in winter. To prolong the life of your car, it is better not to neglect timely technical inspection and careful driving style. Roads in Russia cannot boast of their quality. Gravel and salt scratch the paintwork and primer at high speed, causing moisture to get directly onto the metal layer.

Scientists from Sweden have found that the following are at greater risk of corrosion: thresholds, pillars, spring bases, bottom, doors and spars.

- environmental factors. The inhabitants of the humid climate were not lucky here. A high temperature difference contributes to the formation of condensate in the hidden cavities of the car. Ideally, it flows down the drain holes in the sills and fender pockets. However, as practice shows, in 80% of cases, condensate remains in place due to leaves and other debris in the gutters.

A thin layer of moisture is constantly present on the surface of the body. Depending on environmental factors, different concentrations of aggressive substances remain on the car during the drying of the water. As a result, corrosion develops according to the following scheme:

- Rusting under paintwork.

- Peeling paint on rust spots.

- Through holes in the body.

- Weld damage.

- Destruction of the power parts of the hull.

- Deformation of doorways, thresholds, racks.

- Loss of vehicle control as a result of loss of rigidity of power units.

Types of corrosion on the body and the most common locations

Allocate two types of metal corrosion:

- Chemical. Corrosion centers arise due to the contact of a metal surface with substances that are not electrolytes. For example: oxidation of metals due to heavy contact with exhaust gases, rust in the fuel system due to additives of hydrogen sulfide, elemental sulfur, mercaptans.

- Electrochemical corrosion. Some parts of the body have different electrical potential. A low value becomes the anode, and a high value becomes the cathode. Each pair forms a short-circuited galvanic cell. As a result, when exposed to electrolytes, only the anode areas are destroyed, which leads to the formation of rust.

If corrosion protection is neglected during factory assembly or operation, then with 100% probability rust will “eat” the body. Motorists separate the types of rust according to the places of its localization:

- Non-electrolytes - damage to the fuel and oil systems.

- Gas - exhaust system, muffler, chamfers of plates of exhaust valves of combustion chambers.

- Electrolytes - corrosion due to stagnant water.

- Contact - deformation at the points of contact of the body with different electrical potentials.

- Atmospheric - corrosion due to environmental factors.

- Slotted - in narrow places, gaps.

- Structural - appears in places of heterogeneous composition of the metal.

- In conditions of friction - it affects the nodes of constant friction, under the condition of a corrosive environment.

- Under voltage - covers places of constant voltage.

- Biocorrosion - as a result of the vital activity of microorganisms.

Washing and drying cars to combat fine corrosion

The first step in the fight against rust is washing. The clean surface of the car is a guarantee of getting rid of corrosion, since even a small “bug”, missed through inattention, can cause great inconvenience in the future.

Cleaning from dirt and dust can be done independently or give the vehicle to a car wash, using mechanization. The engine compartment and luggage compartment are subject to mandatory cleaning - for a detailed inspection of the inner surface of the car.

The automotive industry offers various shampoos that not only remove abrasive dust, but also traces of salt and chemicals. A nice side effect will be the protection of the paintwork. The main thing is that the composition of the detergent does not contain toxins, phenols or formaldehydes.

Dry the car immediately after washing. You can get rid of water droplets with a fan heater or a sponge. Drying naturally in the sun can lead to staining.

Separately, it is worth noting that one should not forget to clean the body after traveling in rainy and slushy weather. This will protect microcracks from clogging. The temperature of the water during washing must match the temperature of the air. Sudden temperature changes harm the metal and wear it out. The use of even warm water during the cold period is a danger to the vehicle.

Elimination of corrosion by electrochemical method

The active cathodic protection method is known as the electrochemical method. It is based on the same principle that provokes electrochemical corrosion. Cathodic protection is a method of restoring one metal and destroying another in the process of their mechanical interaction.

To do this, you need an electrolyte, a direct current source and metals with different electrochemical activity relative to iron. First you need to prepare the surface: clean the rust. The electrode is less active than metal and is connected to the charger or to the positive terminal of the battery. The acid must be applied to the electrode or workpiece. When the electrode approaches the surface of the electrolyte, due to the decomposition of ferum hydroxide, seething will begin.

To protect the repair site, a layer of more active metal can be applied to the part and also connected to a continuous current source. When performing the same actions, galvanization is formed on the surface of the hydrolysis object.

After that, you can wash off the remains of electrolytes from the surface, proceed to priming and painting. However, if you don’t want to bother with improvised means, there is a ready-made set of materials on the shelves of automotive stores. It is enough for 1m 2 of the surface of the body.

Mechanical rust removal

For mechanical cleaning it is customary to use abrasives. For example: using an iron brush, you can remove rust on the surface of the body. Disadvantage: It takes a lot of time and effort to manually clean the entire car body. To make your life easier, you can use a grinder. With the help of a grinding disk, it is necessary to clean out the centers of corrosion by 6-8 mm, and then clean it with a fine-grained sandpaper until it is completely smooth.

To clean large metal objects, it is better to use sandblasters - a mixture of sand and water is supplied under pressure to the “infected” area, which effectively fights rust. When working, it is necessary to control the pressure with which the mixture acts on the metal, since if the pressure is too strong, the body can be deformed.

The thickness of the processed walls must be at least 1 cm, otherwise it threatens the appearance of new holes.

You can get acquainted with the technology of removing rust from the surface of the body in the video:

Tools and materials for do-it-yourself rust control

Depending on the method of rust control chosen, a different arsenal of tools will be required. However, be sure to stock up on patience, detergents and clean rags.

Those who do not want to get their hands dirty on sanding discs and understand the hydrolysis process can use innovative methods to combat corrosion. Recently, reagents-converters have been especially popular, which simply turn red dust into gray matter, which are easily washed off the surface of the vehicle.

Work with the body after rust removal: preparation, priming, painting

Immediately after cleaning the corrosion spots, the surface must be thoroughly degreased and primed. However, if the factory primer remains on the metal, there is no need to carry out a new one. The primer, first of all, provides the best application of paint and putty. There are several types: leveler, sealant and epoxy primer.

After complete drying, the body is puttied. It is possible to apply several layers of putty, but each of them must be cleaned to complete smoothness. After that, another layer of primer is applied and the car is sent for painting.

Corrosion prevention and rust protection

It is necessary to begin to resolve this issue even when buying. It is worth remembering that different manufacturers use different types of metals for the manufacture of structures. For example, BMW and Mercedes cars are more resistant to damaging factors, while Opel rusts quickly even in dry weather.

When buying budget cars, it is worth remembering that manufacturers often save on quality and use thin steel in production, which quickly becomes unusable. Therefore, when buying a car, you should focus not on the brand and brand, but on technical characteristics.

During the operation of the vehicle, it is necessary to “look after” it, namely:

- keep in a dry and well-ventilated area;

- do not neglect the car wash using shampoos;

- in case of painting, follow the technology. Corrosion is not formed due to a thin layer of paint, but due to cracks and chips on it;

- carry out regular vehicle inspections. Ideally, this is best done once every 1-2 years;

- use various anti-corrosion agents, wax.

The main enemy of the car is rust. Today there are a lot of ways to deal with rust. However, in order for the iron horse to serve faithfully for more than one year, it is better to prevent the appearance of corrosion. Even the smallest "bug" is capable of provoking major body work.

As practice shows, not all motorists care about the body of their vehicle. But in vain, because even new iron is subject to corrosion. For some reason, people are sure that they can always sell the car to another person when the first problems appear. But practice shows that even foreign cars can rust and it doesn’t matter where the car was made and what its price is. If you are one of those people who are ready to take care of the body of their car, then this article will be very useful.

Where to begin?

First, carefully inspect the bottom of your car. This can be done on a flyover or viewing hole. Pay the most attention to a number of problem areas - thresholds, wings, spars. Most often, so-called pockets succumb to rotting, where water constantly accumulates. Of course, in such places special holes should be provided for the drainage of water, but, as a rule, they turn out to be painted over or clogged with dirt. In this case, you can clean the old ones or make additional holes.

After checking the drain holes, inspect the quality of the anti-corrosion treatment. Pay special attention to the places described above. Very often, anti-corrosion treatment is done poorly and not all places can be covered. In general, it is desirable to cover problem areas with special compounds even before rust appears. Otherwise, you will have to first prepare the surface (remove any traces of corrosion), and only then apply special compounds to the body.

Processing features

There is no particular difficulty in the processing procedure. It is necessary to stock up on a high-quality metal brush, several brushes (the shape and size must be different), sandpaper, rags, white spirit and the mastic itself. Gloves must be worn on hands (skin must be protected). Pay special attention to getting rid of rust on the surface. If this is not done, then all efforts may be in vain. What's more, applying mastic over existing rust can only make matters worse.

To begin with, completely get rid of the dirt that has stuck to the bottom of the vehicle. This can be done with a powerful jet of water. If there is no special apparatus at hand, go to the nearest car wash, where specialists will quickly and efficiently wash the car.

After all the dirt is removed and the bottom is perfectly cleaned, it must be dried or wiped well with a soft cloth. After that, suspicious places should be treated with a special scraper or a metal brush. If rust is found, sand with sandpaper. Check all cavities for dirt and water.

Once the check is completed, the bottom is treated with white spirit. Only then can anti-corrosion materials be applied. Apply the mastic only with a special brush or with your hands (it all depends on its consistency and application features). If the viscosity of the material is low, then processing is best done in several passes. Every centimeter of the surface should be treated with the utmost attention. Otherwise, moisture will begin to accumulate between the mastic and the body, which will accelerate the corrosion process.

The best option is to use bituminous mastic, which has excellent viscosity. It is enough to apply it with a spatula or by hand in one layer to provide maximum protection. Such material is not afraid of frost, so you don’t have to worry about the safety of the car body in winter. As for wax compositions, they are also well suited for body coating. The best option is processing with bituminous and wax mastic. At the same time, remember that even in the case of double processing, 100% efficiency is out of the question. The risk of corrosion always remains.

Another popular anti-corrosion agent is Movil. Its advantage is that the composition can be applied even to an unprepared (not cleaned) surface. Moreover, due to the liquid form of the product, it can be poured into the most inaccessible places, which allows for a complete treatment of the car. Movil is applied using special sprayers. You can buy "anti-corrosion" in a can and greatly simplify your task.

Some details of the process

Remember that you are doing the processing for yourself, so it is better to remove all unnecessary details that may interfere with effective processing. If you cannot find a hole for filling the lubricant in any cavity, then drill new ones (naturally, this must be done wisely, given the design features of your car).

Chromed parts are also worth processing. At the same time, stock up on special formulations designed for these purposes. In the store, be sure to specify that the product is suitable for processing chrome-plated parts. Otherwise, the appearance of the product will be significantly spoiled.

The main types of applied protection

Finally, let's remember what types of body protection against corrosion are used today. There are several of them:

Cathodic - a special type of electrochemical protection, when a special cathodic “protector” is applied to the most problematic area of the body. When moisture gets on the body, it reacts and takes away the harmful effects of rust on itself;

Priming is one of the oldest surface treatment methods. In recent years, it has already lost its relevance and is practically not used by motorists;

Galvanized. In this case, the metal is covered with a special layer (its thickness is about 8-9 microns). One of the most effective rust prevention methods;

Electronic. According to the manufacturers, it provides protection against corrosion for up to 10 years. It looks like a special device.

Conclusion

To protect the body from corrosion and prolong its life, you must monitor the condition of the metal and from time to time carry out anti-corrosion treatment. Otherwise, the car will lose its presentation very quickly. Good luck.