Each car owner must keep the braking system in perfect condition. The safety of all road users depends on the quality of its work. Therefore, the question of why the front brake discs are heated is quite relevant for drivers with different experience.

Any vehicle must be obedient to its owner, especially the braking system. So, let's look at the possible causes of overheating and how to eliminate them.

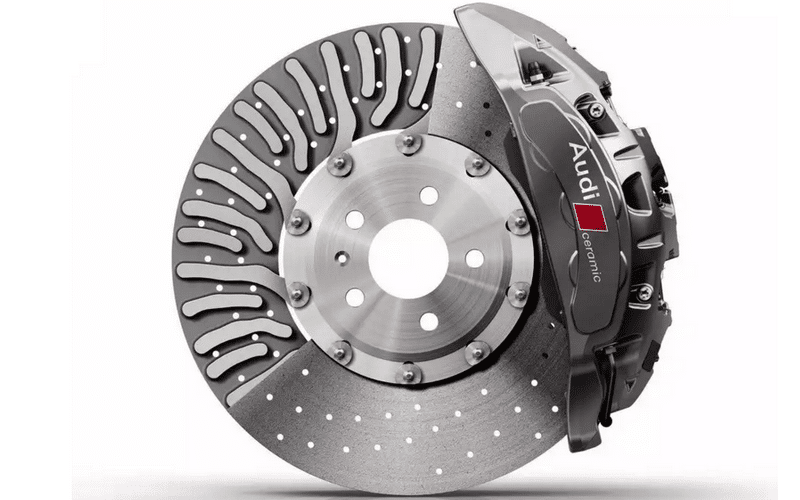

One of the popular brake systems is the disc design. The effectiveness of this model has been proven in practice and adopted by most popular auto companies. There are several design options in which the disc material can be different:

- cast iron;

- forged steel;

- cermets;

- carbon fiber.

The last two varieties are more expensive to use, so they are used less often, although they are highly effective. Most often they can be found on sports models.

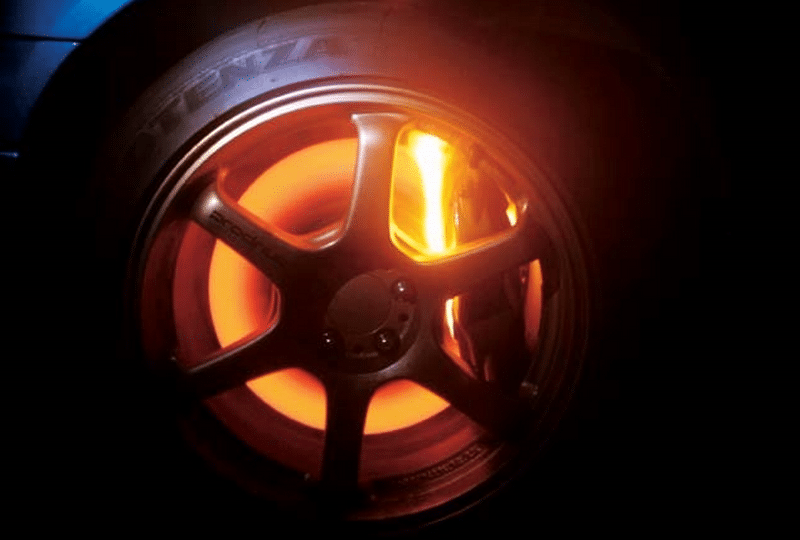

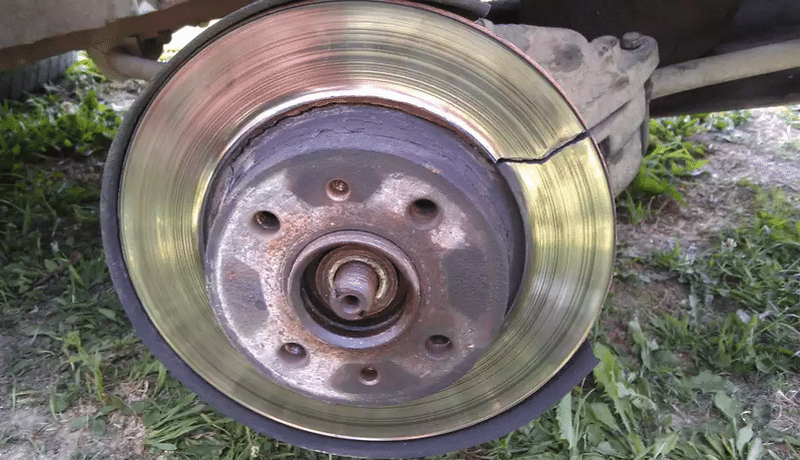

Initially, let's figure out whether the brake discs on the car should be heated or not. In short, yes, they should. When braking, the brake pads press on the disc from both sides, and a friction force arises between the materials, as the disc rotates and the pads are rigidly fixed in the caliper. In this case, the kinetic energy (movement) of the car is spent on overcoming the friction of materials and goes into heating the brake discs and pads. It is important to understand that the heating of the brake mechanisms is absolutely normal, but it should not be excessive. It is also not the heating itself that is important, but the degree of deformation after it. During prolonged braking, for example, on a serpentine downhill, severe overheating of the brake discs can occur and, as a result, they warp, which will later cause a beating when the brake pedal is pressed. And if you also get into a puddle at the same time, then a sharp temperature drop can lead to a crack in the brake disc.

Carbon brake discs

For ceramic-metal or carbon-fiber products, the heating temperature reaches 1200-1400 C. At the same time, the coefficient of friction is significantly higher, and they are also not subject to thermal deformation. The main disadvantage is their price, so these materials are not used in the broad masses.

The cost of production of metal discs is low, so they are widely used, but the limiting temperatures are 500-600 C. Significant overheating leads to loss of geometry and failure due to thermal deformation.

Metal brake disc

Note: a sharp temperature drop can be detrimental to discs, so in no case should you pour water on them, especially immediately after overheating!

Also, do not wash the car after intensive use of the brakes to prevent water from getting on the discs.

The occurrence of overheating

Overheating of the brake discs

As we have already found out, a slight heating is considered normal, however, a significant increase in temperature without intensive use of the brake pedal should alert the driver. There will be either structural or operational fault. After all, individual driving style is also included in the list of reasons for heating brake discs. Frequent and sharp pressing of the brake increases the temperature of the mating elements of the system.

The main reasons why overheating occurs, and how to get rid of them:

- wedge brake caliper guides, the pads cannot evenly clamp the disc (it is necessary to check the condition of the rubber seals and the presence of lubrication on the guides, the absence of sand and dirt on them);

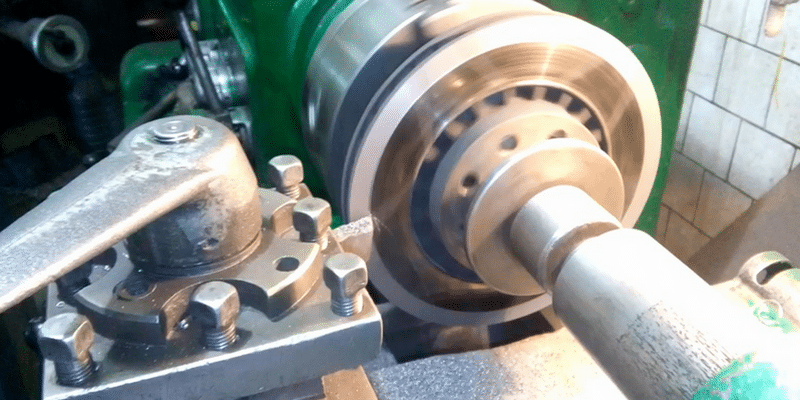

- disc warped, and the pads are pressed unevenly over the entire plane (requires a disc groove or a complete replacement);

- friction linings have worked out their resource and do not provide a satisfactory coefficient of friction (low-quality linings need to be replaced);

- different braking systems in front - disc, and in the back - drum lead to overheating of the front part, due to design features (installation of ventilated brakes or correction of driving style).

Visually, overheated metal surfaces can be distinguished by the residual color after exposure to temperatures.

warped disc

The parameters will be approximate, but they will give an idea of the characteristics of overheating, which can lead to dangerous deformation:

- appeared yellowish tinge- a sign of overheating up to 160-280 C;

- bluish color speaks of an increase to 300-450 C;

- blackening surface possible at 450-500 C.

If such colors were noticed, then it is necessary to carry out, in addition to visual diagnostics, a more serious check at the station or on your own at the inspection hole. Sometimes it is enough to use a jack.

Problem with new discs and pads

There are situations when the brake discs heat up after replacing the pads. You can feel this by the characteristic burnt smell that occurs after sudden braking, especially at high speed. Here are some rules to help you avoid this situation:

- From disks required remove all preservative grease. Even if it is not immediately visible, it is advisable to degrease the surface, otherwise, lapping will take a long time.

- A place on the hub for a new disk is required cleaned with a metal brush. The procedure will help get rid of debris and not warp the plane relative to the wheel axis.

- On the caliper fingers and cavities for them remove all old grease. The new lubricant should only be special, and not ordinary grease. Otherwise, the structure may be jammed at the wrong moment.

- It is required after assembly on the side raised by the jack to scroll the wheel by hand. One must rotate without problems. A slight rustling on the pads is allowed. If a couple of turns were made and the wheel jammed, then the assembly went wrong.

Eliminate deformation with a groove

Possible causes of clamping may be:

- the caliper piston and the inner pad were not aligned (the pad has a recess that must be aligned with the same piston element, otherwise misalignment will appear);

- a problem with installing fingers or an incorrectly selected lubricant for them;

- the landing zone for the friction pads must be cleaned of debris with a brush, and high-temperature grease is also applied to this place to prevent the pads from sticking.

Conclusion

Most of the causes of disk overheating can be fixed on your own. Most often this is due to performance and driving style. Accordingly, it is necessary to regularly monitor the condition of the pads and discs: grind the surface in time, change the pads before the grinding begins from erasing the fasteners on the disc, and also install high-quality components.