There is an opinion that the selection of a three-way valve does not require preliminary calculations. This opinion is based on the assumption that the total flow through the branch pipe AB - does not depend on the stroke of the rod and is always constant. In fact, the flow through the common port AB fluctuates depending on the stroke of the stem, and the amplitude of the oscillation depends on the authority of the three-way valve in the regulated area and its flow characteristics.

Method for calculating a three-way valve

Three-way valve calculation perform in the following sequence:

- 1. Selection of the optimal flow characteristics.

- 2. Determination of the control capacity (valve authority).

- 3. Definition bandwidth and nominal diameter.

- 4. Selection of the control valve electric drive.

- 5. Check for noise and cavitation.

Flow characteristics selection

The dependence of the flow through the valve on the stroke of the stem is called the flow characteristic. The type of flow characteristic determines the shape of the plug and valve seat. Since the three-way valve has two gates and two seats, it also has two flow characteristics, the first is the characteristic along the straight stroke - (A-AB), and the second along the perpendicular - (B-AB).

Linear/linear. The total flow through the branch pipe AB is constant only when the valve authority is equal to 1, which is practically impossible to ensure. Operating a three-way valve with an authority of 0.1 will result in fluctuations in the total flow during stem movement, ranging from 100% to 180%. Therefore, valves with a linear/linear characteristic are used in systems that are insensitive to flow fluctuations, or in systems with a valve authority of at least 0.8.

logarithmic/logarithmic. The minimum fluctuations in the total flow through the branch pipe AB in three-way valves with a logarithmic / logarithmic flow characteristic are observed at a valve authority of 0.2. At the same time, a decrease in authority, relative to the specified value, increases, and an increase - reduces the total flow through the branch pipe AB. The fluctuation of the flow rate in the range of authorities from 0.1 to 1 is from +15% to -55%.

log/linear. Three-way valves with a logarithmic/linear flow characteristic are used if the circulation rings passing through the A-AB and B-AB connections require regulation according to different laws. Flow stabilization during the movement of the valve stem occurs at an authority equal to 0.4. The fluctuation of the total flow through the branch pipe AB in the range of authorities from 0.1 to 1 is from +50% to -30%. Control valves with a logarithmic / linear flow characteristic are widely used in control units for heating systems and heat exchangers.

Authority calculation

Authority of the three-way valve is equal to the ratio of pressure loss on the valve to the pressure loss on the valve and the regulated section. The authority value for three-way valves determines the range of fluctuation in the total flow through port AB.

A 10% deviation of the instantaneous flow rate through port AB during stroke is provided at the following authority values:

- A+ = (0.8-1.0) - for a linear/linear valve.

- A+ = (0.3-0.5) - for a valve with a logarithmic / linear characteristic.

- A+ = (0.1-0.2) - for a valve with a logarithmic / logarithmic characteristic.

Bandwidth calculation

The dependence of pressure loss on the valve from the flow through it is characterized by the Kvs capacity factor. The Kvs value is numerically equal to the flow in m³/h through a fully open valve, at which the pressure loss on it is 1 bar. As a rule, the Kvs value of a three-way valve is the same for the A-AB and B-AB strokes, but there are valves with different capacities for each of the strokes.

Knowing that when the flow rate changes by “n” times, the head loss on the valve changes by “n²” times, it is not difficult to determine the required Kvs of the control valve by substituting the calculated flow rate and head loss into the equation. From the nomenclature, a three-way valve is selected with the closest value of the throughput coefficient to the value obtained as a result of the calculation.

Selection of an electric drive

The electric actuator is matched to the previously selected three-way valve. Electric drives it is recommended to choose from the list of compatible devices indicated in the valve specifications, while paying attention to:

- The actuator and valve interfaces must be compatible.

- The stroke of the electric actuator must be at least the stroke of the valve stem.

- depending on inertia regulated system drives with different speeds should be used.

- The closing force of the actuator determines the maximum differential pressure across the valve at which the actuator can close it.

- One and the same electric actuator ensures the closing of a three-way valve working for mixing and flow separation, at different pressure drops.

- The supply voltage and control signal of the drive must match the supply voltage and control signal of the controller.

- Rotary three-way valves are used with rotary, and saddle valves with linear electric drives.

Calculation for the possibility of cavitation

Cavitation is the formation of steam bubbles in a water stream, which manifests itself when the pressure in it decreases below the saturation pressure of water vapor. The Bernoulli equation describes the effect of increasing the flow velocity and reducing the pressure in it, which occurs when the flow section narrows. The flow area between the shutter and the three-way valve seat is the very narrowing, the pressure in which can drop to saturation pressure, and the place where cavitation is most likely to occur. Vapor bubbles are unstable, they appear sharply and also collapse sharply, this leads to metal particles being eaten out of the valve shutter, which will inevitably cause it premature wear. In addition to wear, cavitation leads to increased noise during valve operation.

The main factors affecting the occurrence of cavitation:

- Water temperature - the higher it is, the greater the likelihood of cavitation.

- Water pressure - in front of the control valve, the higher it is, the less likely it is to cause cavitation.

- Permissible pressure losses - the higher they are, the higher the likelihood of cavitation. It should be noted here that in the valve position close to closing, the throttled pressure on the valve tends to the available pressure in the regulated area.

- The cavitation characteristic of a three-way valve is determined by the characteristics of the throttling element of the valve. The cavitation coefficient is different for various types control valves and should be specified in their technical characteristics, but since most manufacturers do not indicate this value, the calculation algorithm includes the range of the most probable cavitation coefficients.

As a result of the cavitation test, the following result can be produced:

- "No" - there will definitely be no cavitation.

- "Possible" - cavitation may occur on valves of some designs, it is recommended to change one of the above-described influence factors.

- "Yes" - cavitation will definitely be, change one of the factors influencing the occurrence of cavitation.

Noise calculation

High speed flow in the inlet of the three-way valve can cause high level noise. For most rooms where control valves are installed, the permissible noise level is 35-40 dB(A) which corresponds to a velocity in the valve inlet of about 3m/s. Therefore, when selecting a three-way valve, it is not recommended to exceed the specified speed.

Control valve capacity Kvs- the value of the Kvs coefficient is numerically equal to the water flow through the valve in m³ / h at a temperature of 20 ° C at which the pressure loss on it will be 1 bar. You can calculate the throughput of a control valve for specific system parameters in the Calculations section of the website.

control valve DN- nominal diameter of the hole in the connecting pipes. The DN value is used to unify the standard sizes of pipe fittings. The actual diameter of the hole may slightly differ from the nominal one up or down. An alternative designation for the nominal diameter DN, common in the post-Soviet countries, was the nominal diameter Du of the control valve. A number of conditional passages DN of pipeline fittings is regulated by GOST 28338-89 "Conditional passages (nominal sizes)".

PN control valve- nominal pressure - the highest overpressure of the working medium with a temperature of 20 ° C, at which long-term and safe operation is ensured. An alternative designation for the nominal pressure PN, common in the post-Soviet countries, was conditional pressure Ru valve. A number of nominal pressures PN pipeline fittings are regulated by GOST 26349-84 "Nominal (conditional) pressures".

Dynamic range control, is the ratio of the highest capacity of a fully open control valve (Kvs) to the smallest capacity (Kv) at which the declared flow characteristic is maintained. The dynamic range of control is also called the control ratio.

For example, a valve turndown ratio of 50:1 at Kvs 100 means that the valve can control a flow rate of 2m³/h while maintaining its characteristic flow characteristics.

Most control valves have turndown ratios of 30:1 and 50:1, but there are also very good control valves with a turndown ratio of 100:1.

Control valve authority- characterizes the control ability of the valve. Numerically, the value of authority is equal to the ratio of pressure losses in the fully open valve gate to pressure losses in the regulated section.

The lower the authority of the control valve, the more its flow characteristic deviates from the ideal and the less smooth the change in flow will be when the stem moves. So, for example, in a system controlled by a valve with a linear flow characteristic and low authority, closing the flow section by 50% can reduce the flow by only 10%, while with high authority, closing by 50% should reduce the flow through the valve by 40-50%.

Displays the dependence of the change in the relative flow through the valve on the change in the relative stroke of the control valve stem at a constant pressure drop across it.

Linear flow characteristic- the same increments in the relative stroke of the rod cause the same increments in the relative flow rate. Control valves with a linear flow characteristic are used in systems where there is a direct relationship between the controlled variable and the flow rate of the medium. Control valves with a linear flow characteristic are ideal for maintaining the temperature of the heating medium mixture in substations with dependent connection to the heating network.

Equal percentage flow characteristic(logarithmic) - the dependence of the relative increase in flow rate on the relative increase in the stroke of the rod is logarithmic. Control valves with a logarithmic flow characteristic are used in systems where the controlled variable is non-linearly dependent on the flow through the control valve. So, for example, control valves with an equal percentage flow characteristic are recommended for use in heating systems to control the heat transfer of heating devices, which depends non-linearly on the flow rate of the coolant. Control valves with a logarithmic flow characteristic perfectly control the heat dissipation of high-speed heat exchangers with low temperature drop. It is recommended to use valves with an equal percentage flow characteristic in systems where a linear flow characteristic is required, and it is not possible to maintain a high authority on the control valve. In this case, the reduced authority distorts the equal percentage characteristic of the valve, bringing it closer to linear. This feature is observed when the authorities of the control valves are not lower than 0.3.

Parabolic flow characteristic- the dependence of the relative increase in flow rate on the relative stroke of the rod obeys a quadratic law (passes along a parabola). Control valves with parabolic flow characteristics are used as a compromise between linear and equal percentage valves.

Specifics of the calculation of a two-way valve

Given:

environment - water, 115C,

∆paccess = 40 kPa (0.4 bar), ∆ppipe = 7 kPa (0.07 bar),

∆pheat exchange = 15 kPa (0.15 bar), nominal flow rate Qnom = 3.5 m3/h,

minimum flow Qmin = 0.4 m3/h

Calculation:

∆paccess = ∆pvalve + ∆ppipe + ∆pheat exchange =

∆pvalve = ∆paccess - ∆ppipe - ∆pheat exchange = 40-7-15 = 18 kPa (0.18 bar)

Safety allowance for working tolerance (provided that the flow rate Q was not overestimated):

Kvs = (1.1 to 1.3). Kv = (1.1 to 1.3) x 8.25 = 9.1 to 10.7 m3/h

From the serially produced series of Kv values, we choose the nearest Kvs value, i.e. Kvs = 10 m3/h. This value corresponds to the clear diameter DN 25. If we select a valve with a threaded connection PN 16 made of gray cast iron, we get the number (order number) of the type:

RV 111 R 2331 16/150-25/T

and corresponding drive.

Determination of the hydraulic loss of a selected and calculated control valve at full opening and a given flow rate.

The actual hydraulic loss of the control valve calculated in this way must be reflected in the hydraulic calculation of the network.

![]()

where a must be at least 0.3. The check established: the selection of the valve corresponds to the conditions.

Warning: The calculation of the authority of a two-way control valve is carried out in relation to the differential pressure across the valve in the closed state, i.e. available branch pressure ∆paccess at zero flow, and never relative to the pump pressure ∆ppump, due to the influence of pressure losses in the network pipeline up to the point of connection of the regulated branch. In this case, for convenience, we assume

Regulatory attitude control

Let's carry out the same calculation for the minimum flow rate Qmin = 0.4 m3/h. The minimum flow rate corresponds to pressure drops , , .

Required control ratio ![]()

must be less than the set control ratio of the valve r = 50. The calculation satisfies these conditions.

Typical circuit control loop layout using a two-way control valve.

Specifics of the calculation of a three-way mixing valve

Given:

environment - water, 90C,

static pressure at connection point 600 kPa (6 bar),

∆ppump2 = 35 kPa (0.35 bar), ∆ppipe = 10 kPa (0.1 bar),

∆pheat exchange = 20 kPa (0.2), nominal flow Qnom = 12 m3/h

Calculation:

Safety allowance for working tolerance (provided that the flow rate Q was not overestimated):

Kvs = (1.1-1.3)xKv = (1.1-1.3)x53.67 = 59.1 to 69.8 m3/h

From a serially produced series of Kv values, we choose the nearest Kvs value, i.e. Kvs = 63 m3/h. This value corresponds to the clear diameter DN65. If we choose flanged ductile iron valve, we get type no.

RV 113 M 6331-16/150-65

We then select the appropriate drive according to the requirements.

Determination of the actual hydraulic loss of the selected valve at full opening

Thus, the calculated actual hydraulic loss of control valves must be reflected in the hydraulic calculation of the network.

Warning: With three-way valves, the most important condition for error-free operation is the minimum differential pressure

on ports A and B. Three-way valves are able to cope with significant differential pressure between ports A and B, but at the cost of a deformation of the control characteristic, and thus a deterioration in the control capacity. Therefore, if there is even the slightest doubt about the pressure difference between the two connections (for example, if a three-way valve without a pressure compartment is directly connected to the primary network), we recommend using a two-way valve in connection with a hard circuit for good control.

Typical control line layout using a three-way mixing valve.

kv value.

The control valve creates an additional pressure loss in the network to limit the water flow within the required limits. The water flow depends on the differential pressure across the valve:

kv - valve flow rate, ρ - density (for water ρ = 1,000 kg / m 3 at a temperature of 4 ° C, and at 80 ° C ρ = 970 kg / m 3), q - liquid flow rate, m 3 / hour , ∆р – differential pressure, bar.

The maximum value of k v (k vs) is reached when the valve is fully open. This value corresponds to a water flow rate, expressed in m 3 /h, for a differential pressure of 1 bar. The control valve is selected so that the value of kvs provides the design flow for a given differential pressure available when the valve is operated under the given conditions.

It is not easy to determine the value of kvs required for a control valve, since the available differential pressure across the valve depends on many factors:

- Actual pump head.

- Pressure loss in pipes and fittings.

- Pressure loss at terminals.

The pressure loss, in turn, depends on the balancing accuracy.

When designing boiler plants, the theoretically correct values of pressure and flow losses are calculated for various elements of the system. However, in practice, it is rare for different elements to have precisely defined characteristics. During installation, as a rule, pumps, control valves and terminals are selected according to standard characteristics.

Control valves, for example, are produced with values of k vs increasing in geometric proportion, called the Reynard series:

k vs: 1.0 1.6 2.5 4.0 6.3 10 16......

Each value is approximately 60% larger than the previous one.

It is not typical for a control valve to provide exactly the calculated pressure loss for a given flow rate. If, for example, a control valve is to produce a pressure loss of 10 kPa at a given flow rate, then in practice it may be that a valve with a slightly higher kvs value will only create a pressure loss of 4 kPa, while a valve with a slightly lower kvs value will provide a pressure loss. at 26 kPa for the calculated flow rate.

|

∆p (bar), q (m 3 /h) |

∆p (kPa), q (l/s) |

∆p (mm BC), q (l/h) |

∆p (kPa), q (l/h) |

|

q = 10k v √∆p |

q = 100k v √∆p |

||

|

∆p = (36q/kv)2 |

∆p = (0.1q/kv)2 |

∆p = (0.01q/kv)2 |

|

|

kv = 36q/√∆p |

k v = 0.1 q/√∆p |

kv = 0.01q/√∆p |

Some formulas contain consumption, k v and ∆p (ρ = 1,000 kg/m3)

Also, pumps and terminals are often oversized for the same reason. This means that the control valves operate almost closed, and as a result, the regulation cannot be stable. It is also possible that periodically these valves open to the maximum, at start-up it is necessary, which leads to overspending in this system and insufficient flow in others. As a result, the question should be:

What if the control valve is oversized?

It is clear that, as a rule, it is impossible to accurately select the desired control valve.

Consider the case of a 2000 W air heater designed for a temperature drop of 20 K. The pressure loss is 6 kPa for a design flow rate of 2000x0.86/20=86 l/h. If the available differential pressure is 32 kPa and the pressure loss in the pipes and fittings is 4 kPa, a difference of 32 - 6 - 4 = 22 kPa should be across the control valve.

The required value of k vs will be 0.183.

If the minimum available kvs is 0.25, for example, the flow rate instead of the desired 86 l/h will be 104 l/h, an excess of 21%.

In variable flow systems, the differential pressure at the terminals is variable because the pressure loss in the pipes depends on the flow. Control valves are selected for design conditions. At low loads, the maximum potential flow in all installations is increased and there is no danger of excessively low flow in one individual terminal. If under design conditions it is required maximum load It is very important to avoid overspending.

A. Flow limitation by means of a balancing valve installed in series.

If, under design conditions, the flow at the open control valve is higher than the required value, a balancing valve can be installed in series to limit this flow. This will not change the actual control valve control factor, but will even improve its performance (see figure on page 51). The balancing valve is also a diagnostic tool and a shut-off valve.

B. Reduced maximum valve lift.

To compensate for oversized control valve, the degree of opening of the valve can be limited. This solution can be considered for valves with equal percentage characteristics, since it is possible to significantly reduce the value of k v , respectively, reducing the degree of maximum opening of the valve. If the valve opening degree is reduced by 20%, the maximum value of k v will be reduced by 50%.

In practice, balancing is carried out using balancing valves installed in series with the control valve fully open. Balancing valves are adjusted in each circuit so that at the calculated flow rate, the pressure loss is 3 kPa.

The degree of lift of the control valve is limited when obtained on the balancing valve 3 kPa. Since the plant is balanced and remains balanced, the required flow rate is actually obtained under design conditions.

C. Flow reduction with ∆p regulating valve in the group.

The differential pressure across the control valve can be stabilized as shown in the figure below.

The STAP differential pressure control valve is set to the desired flow rate for a fully open control valve. In this case, the control valve must be exactly sized and its control factor close to one.

A few rules of thumb

If two-way control valves are used in terminals, most of the control valves will be closed or nearly closed at low loads. Since the water flow is low, the pressure loss on pipes and fittings will be negligible. The entire pressure of the pump falls on the control valve, which must be able to resist it. This increase in differential pressure makes it difficult to control at low flow rates, since the actual control factor β" is significantly reduced.

Assume that the control valve is designed for a pressure loss of 4% of the pump head. If the system works with low flow, the differential pressure in this case is multiplied by 25. For the same valve opening, the flow is then multiplied by 5 (√25 = 5). The valve is forcibly operated in an almost closed position. This can lead to noise and fluctuations in the setpoint (under these new operating conditions, the valve is oversized by a factor of five).

That is why some authors recommend designing the system in such a way that the calculated pressure drop across the control valves is at least 25% of the pump head. In this case, at low loads, the excess flow on the control valves will not exceed a factor of 2.

It is always very difficult to find a control valve that can withstand such a high differential pressure without making noise. It is also difficult to find sufficiently small valves that meet the above criteria when using low power terminals. In addition, differential pressure variations in the system must be limited, for example by using secondary pumps.

Taking into account this additional concept, the calibration of a two-way control valve must satisfy the following conditions:

- When the system is operating under normal conditions, the flow rate at a fully open valve should be calculated. If the flow is higher than specified, the balancing valve in series should limit the flow. Then for a PI type controller, a control factor of 0.30 will be acceptable. If the control values are lower, the control valve should be replaced with a smaller valve.

- The pump head must be such that the pressure loss across the two-way control valves is at least 25% of the pump head.

For on-off controllers, the concept of control parameters is irrelevant, since the control valve is either open or closed. Therefore, its characteristics are not of great importance. In this case, the flow is slightly limited by the balancing valve installed in series.

), inside which there is a bellows container filled with a working fluid (gas, liquid, solid) with a high coefficient of volumetric expansion. When the temperature of the air surrounding the bellows changes, the working fluid expands or contracts, deforming the bellows, which, in turn, acts on the valve stem, opening or closing it ( rice. 1).

Rice. 1. Scheme of operation of a thermostatic valve

Basic hydraulic characteristic thermostatic valve is throughput kv. This is the flow rate of water that the valve is able to pass through with a pressure drop across it of 1 bar. Index " V» means that the coefficient is related to the hourly volume flow and is measured in m3/h. Knowing the capacity of the valve and the flow of water through it, it is possible to determine the pressure loss across the valve using the formula:

Δ P to = ( V / K v) 2 100 kPa.

Control valves, depending on the degree of opening, have different throughput. The capacity of a fully open valve is indicated by Kvs. The pressure loss on the thermostatic radiator valve in hydraulic calculations, as a rule, is determined not at full opening, but for a certain proportional band - X p.

X p is the zone of operation of the thermostatic valve in the range from the air temperature at full closing (point S on the control graph) to the user-defined temperature tolerance value. For example, if the ratio kv given at X p= S– 2, and the thermoelement is set in such a position that at an air temperature of 22 ˚С the valve will be completely closed, then this coefficient will correspond to the position of the valve at an ambient temperature of 20 ˚С.

From this we can conclude that the air temperature in the room will range from 20 to 22 ˚С. Index XP affect the temperature accuracy. At XP = (S- 1) the range of maintaining the temperature of the internal air will be within 1 ˚С. At XP = (S– 2) – range 2 ˚С. Zone X p = ( S– max) characterizes the operation of the valve without a temperature-sensitive element.

In accordance with GOST 30494-2011 “Residential and public buildings. Indoor microclimate parameters”, during the cold season in the living room, the optimum temperatures range from 20 to 22 ˚С, that is, the temperature maintenance range in the residential premises of buildings should be 2 ˚С. Thus, for the calculation of residential buildings, it is required to choose the values of throughput at XP = (S – 2).

Rice. 2. Thermostatic valve VT.031

On rice. 3 bench test results are shown ( rice. 2) with thermostatic element VT.5000 set to "3". Dot S on the graph, this is the theoretical closing point of the valve. This is the temperature at which the valve is so small consumption that it can be considered practically closed.

Rice. Fig. 3. Closing curve of valve VT.031 with thermocouple VT.5000 (pos. 3) at a pressure drop of 10 kPa

As you can see in the graph, the valve closes at 22°C. As the air temperature drops, the capacity of the valve increases. The graph shows the values of water flow through the valve at a temperature of 21 ( S– 1) and 22 ( S– 2) ˚С.

IN tab. 1 the passport values of the capacity of the thermostatic valve VT.031 are presented for various XP.

Table 1. Passport values of valve capacity VT.031

Valves are tested on a special stand, shown on rice. 4. Supported during testing constant differential pressure on the valve equal to 10 kPa. The air temperature is simulated by means of a thermostatic water bath into which the thermal head is immersed. The temperature of the water in the bath gradually increases, while the flow of water through the valve is recorded until it is completely closed.

Rice. 4. Bench tests of the valve VT.032 for throughput in accordance with GOST 30815-2002

In addition to the throughput values, thermostatic valves are characterized by such an indicator as the maximum pressure drop. This is such a pressure drop across the valve, at which it retains passport control characteristics, does not create noise, and also at which all valve elements will not be subject to premature wear.

Depending on the design, thermostatic valves have different maximum pressure drops. Most of the thermostatic radiator valves on the market have this characteristic of 20 kPa. At the same time, according to clause 5.2.4 of GOST 30815-2002, the temperature at which the valve closes at the maximum pressure drop should not differ from the closing temperature at a pressure drop of 10 kPa by more than 1 ˚С.

From the chart on rice. 5 it can be seen that valve VT.031 closes at 22 ˚С at pressure drop of 10 kPa and thermoelement setting “3”.

Rice. Fig. 5. Closing curves of the VT.031 valve with a VT.5000 thermoelement at a pressure drop of 10 kPa (blue line) and 100 kPa (red line)

At a pressure drop of 100 kPa, the valve closes at 22.8°C. The effect of differential pressure is 0.8 ˚C. Thus, in real operating conditions of such a valve at pressure drops from 0 to 100 kPa, when the thermoelement is set to the number "3", the valve closing temperature range will be from 22 to 23 ˚С.

If, in real operating conditions, the pressure drop across the valve increases more than the maximum, then the valve may create unacceptable noise, and its characteristics will also differ significantly from the passport ones.

What causes an increase in the pressure drop across a thermostatic valve during operation? The fact is that in modern two-pipe heating systems, the flow rate of the coolant in the system is constantly changing, depending on the current heat consumption. Some thermostats open, some close. A change in flow rates by sections leads to a change in the distribution of pressures.

For example, consider the simplest circuit (rice. 6) with two radiators. A thermostatic valve is installed in front of each radiator. There is a control valve on the common line.

Rice. 6. Calculation scheme with two radiators

Let us assume that the pressure loss on each thermostatic valve is 10 kPa, the pressure loss on the valve is 90 kPa, the total coolant flow is 0.2 m 3 /h and the coolant flow through each radiator is 0.1 m 3 /h. We neglect pressure losses in pipelines. The total pressure loss in this system is 100 kPa and is maintained at constant level. The hydraulics of such a system can be represented by the following system of equations:

Where V o - total consumption, m 3 / h, V p - flow through radiators, m 3 / h, kv c - valve capacity, m 3 / h, kv because - capacity of thermostatic valves, m 3 / h, Δ P c - pressure drop across the valve, Pa, Δ P because - pressure drop across the thermostatic valve, Pa.

Rice. 7. Calculation scheme with a disabled radiator

Suppose that in the room where the upper radiator is installed, the temperature has increased, and the thermostatic valve completely blocked the coolant flow through it ( rice. 7). In this case, the entire flow will go only through the lower radiator. The pressure drop in the system is expressed by the following formula:

where V about ′ is the total flow in the system after turning off one thermostatic valve, m 3 / h, V p ′ is the coolant flow through the radiator, in this case it will be equal to the total expense; m 3 / h.

If we take into account that the pressure difference is maintained constant (equal to 100 kPa), then it is possible to determine the flow rate that will be established in the system after one of the radiators is turned off.

The pressure loss across the valve will decrease as the total flow through the valve has decreased from 0.2 to 0.17 m 3 /h. The pressure loss on the thermostatic valve, on the contrary, will increase, because the flow through it has increased from 0.1 to 0.17 m 3 / h. The pressure loss on the valve and thermostatic valve will be:

From the above calculations, we can conclude that the pressure drop across the thermostatic valve of the lower radiator when opening and closing the thermostatic valve of the upper radiator will vary from 10 to 30.8 kPa.

But what happens if both valves block the movement of the coolant? In this case, the pressure loss at the valve will be zero, since there will be no movement of the coolant through it. Therefore, the pressure difference before the spool / after the spool in each radiator valve will be equal to the available pressure and will be 100 kPa.

If valves with an allowable differential pressure less than this value are used, the valve may open even though there is no real need to do so. Therefore, the pressure drop across the regulated section of the network must be lower than the maximum allowable pressure drop across each thermostat.

Let's assume that instead of two heatsinks, a certain set of heatsinks is installed in the system. If at some point all thermostats, except for one, close, then the pressure loss across the valve will tend to 0, and the pressure drop across the open thermostatic valve will tend to the available pressure, i.e., for our example, to 100 kPa.

In this case, the coolant flow through the open radiator will tend to the value:

That is, in the most unfavorable case (if only one of the many radiators remains open), the flow rate on the open radiator will increase by more than three times.

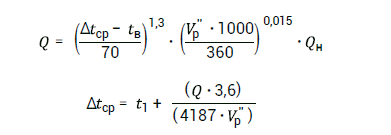

How much will the power of the heater change with such an increase in consumption? Heat dissipation Q sectional radiator is calculated by the formula:

Where Q n - rated power of the heater, W, Δ t cp - average temperature of the heater, ˚С, t c – internal air temperature, ˚С, V pr - coolant flow through the heater, n is the coefficient of dependence of heat transfer on the average temperature of the device, p is the coefficient of dependence of heat transfer on the coolant flow rate.

Assume that the heater has a nominal heat output Qн = 2900 W, design parameters of the coolant 90/70 ˚С. The coefficients for the radiator are accepted: n= 0.3, p = 0.015. During the billing period, at a flow rate of 0.1 m 3 / h, such a heater will have the following power:

To find out the power of the device at Vр''=0.316 m³⁄h, it is necessary to solve the system of equations:

Using the method of successive approximations, we obtain the solution of this system of equations:

From this we can conclude that in the heating system at the most adverse conditions, when all but one of the heating devices in the area are closed, the pressure drop across the thermostatic valve can rise to the available pressure. In the above example, with an available pressure of 100 kPa, the flow rate will increase three times, while the power of the device will increase by only 17%.

Increasing the power of the heater will lead to an increase in the air temperature in the heated room, which, in turn, will cause the thermostatic valve to close. Thus, the fluctuation of the differential pressure across the thermostatic valve during operation within the limits of the passport maximum value of the differential is acceptable, and will not lead to disruption of the system.

In accordance with GOST 30815-2002, the maximum pressure drop across the thermostatic valve is determined by the manufacturer in order to comply with the requirements for noiselessness and maintaining control characteristics. However, the manufacture of a valve with a wide range of allowable pressure drops is associated with certain design difficulties. Special requirements are also placed on the accuracy of manufacturing valve parts.

Most manufacturers produce valves with a maximum pressure drop of 20 kPa.

The exception is VALTEC VT.031 and VT.032 () valves with a maximum pressure drop of 100 kPa ( rice. 8) and Giacomini R401-403 series valves with a maximum differential pressure of 140 kPa ( rice. 9).

Rice. 8. Technical characteristics of radiator valves VT.031, VT.032

Rice. 9. Fragment technical description thermostatic valve Giacomin R403

Rice. 10. Fragment of the technical description of the thermostatic valve

When studying technical documentation, you must be careful, as some manufacturers have adopted the practice of bankers - to insert small text in the notes.

On rice. 10 a fragment from the technical description of one of the types of thermostatic valves is presented. The main column indicates the value of the maximum differential pressure of 0.6 bar (60 kPa). However, there is a note in the footnote that the valve's actual operating range is limited to only 0.2 bar (20 kPa).

Rice. 11. Thermostatic valve spool with axial fastening of the seal

The limitation is caused by noise generated in the valve at high pressure drops. As a rule, this applies to valves with an outdated spool design, in which sealing rubber simply fastened in the center with a rivet or bolt ( rice. eleven).

With large pressure drops, the seal of such a valve begins to vibrate due to incomplete fit to the spool plate, causing acoustic waves (noise).

The increased allowable pressure drop in the VALTEC and Giacomini valves is achieved due to a fundamentally different design of the spool assemblies. In particular, the VT.031 valves have a brass spool plunger “lined” with EPDM elastomer ( rice. 12).

Rice. 12. View of the valve spool assembly VT.031

Now the development of thermostatic valves with a wide range of operating pressure drops is one of the priorities of many companies.

- Based on the foregoing, the following recommendations can be made for the design of heating systems with thermostatic valves:

- It is recommended to determine the capacity coefficient of the thermostatic valve based on the allowable temperature range of the serviced premises. For example, for living rooms according to GOST 30494-2011, the optimal parameters of indoor air are in the range of 20–22 ˚С. The Kv value in this case is taken at Xp = S – 2.

In rooms of category 3a (premises with mass stay of people, in which people are mainly in a sitting position without street clothes), the optimal temperature range is 20–21 ˚С. For these premises, the Kv value is recommended to be taken at Xp = S - 1. - On the circulation rings of the heating system, devices (bypass valves or differential pressure regulators) must be installed that limit the maximum pressure drop so that the pressure drop across the valve does not exceed the limiting passport value.

Here are some examples of the selection and installation of devices to limit the pressure drop in the area with thermostatic valves.

Example 1 Estimated pressure losses in the apartment heating system ( rice. 13), including thermostatic valves, are 15 kPa. The maximum differential pressure across thermostatic valves is 20 kPa (0.2 bar). The pressure loss on the collector, including losses on heat meters, balancing valves and other fittings, we will take 8 kPa. As a result, the pressure drop to the collector is 23 kPa.

If you install a differential pressure regulator or bypass valve to the collector, then in case of overlapping of all thermostatic valves in this branch, the difference on them will be 23 kPa, which exceeds the passport value (20 kPa). Thus, in this system, a differential pressure regulator or bypass valve must be installed at each outlet after the manifold, and must be set to a differential of 15 kPa.

Rice. 13. Scheme for example 1

Example. 2. If we accept not a dead-end, but a radiant system of apartment heating ( rice. 14), then the pressure loss in it will be much lower. In the given example of a collector-beam system, the losses in each radiator loop are 4 kPa. The pressure loss on the apartment manifold is assumed to be 3 kPa, and the pressure loss on the storey manifold is 8 kPa.

In this case, the differential pressure regulator can be placed in front of the storey collector and adjusted to a differential of 15 kPa. Such a scheme allows to reduce the number of differential pressure regulators and significantly reduce the cost of the system.

Rice. 14. Scheme for example 2

Example 3 In this version, they are used with a maximum pressure drop of 100 kPa ( rice. 15). As in the first example, we assume that the pressure loss in the apartment heating system is 15 kPa. Pressure loss at the apartment input node (apartment station) 7 kPa. In front of the apartment station, the pressure drop will be 23 kPa. In a ten-story building, the total length of a pair of heating system risers can be taken to be about 80 m (the sum of the supply and return pipelines).

Rice. 15. Scheme for example

With average linear pressure losses along the riser of 300 Pa / m, total losses pressure in the risers will be 24 kPa. It follows that the pressure drop at the bottom of the risers will be 47 kPa, which is less than the maximum allowable pressure drop across the valve.

If you install a regulator on the differential pressure on the riser and set it to a pressure of 47 kPa, then even when all the radiator valves connected to this riser close, the pressure drop across them will be less than 100 kPa.

Thus, it is possible to significantly reduce the cost of the heating system by installing one regulator at the base of the risers instead of ten differential pressure regulators on each floor.