Method of calculation and indicators of the cost of mileage and downtime of vehicles

^ 5.4.6.1 General. The cost of mileage (idle) of motor vehicles is determined by direct account in the context of variable and fixed cost groups.

The amount of direct costs is determined per 1 km of a car run as the sum of expenses for the following items: fuel, lubricants and other operating materials, tires, maintenance and repair of rolling stock.

The value of fixed costs is determined per 1 hour of operation of the car as the sum of expenses for items: depreciation (as a percentage of the cost per year), driver wages and overhead costs.

5.4.6.2 Calculation of the cost of 1 auth. - km of run

The cost of 1 car - km of car run is calculated according to the following formula:

Where:  - fuel costs, rub.;

- fuel costs, rub.;

- expenses for lubricants, rub.;

- expenses for lubricants, rub.;

- the cost of restoring tire wear, rub.;

- the cost of restoring tire wear, rub.;

- depreciation deductions, rub.;

- depreciation deductions, rub.;

- the cost of repair and maintenance of the car, rub.;

- the cost of repair and maintenance of the car, rub.;

- salary of the driver, rub.;

- salary of the driver, rub.;

- the amount of overhead costs, % of direct costs;

- the amount of overhead costs, % of direct costs;

T is the average annual time of using the car, h;

- regional correction factor to the cost of mileage of the car.

- regional correction factor to the cost of mileage of the car.

Fuel cost calculation

Fuel costs are determined by the following formula:

, (20)

, (20)

Where:  - cost of 1 liter of fuel, rub.;

- cost of 1 liter of fuel, rub.;

- standard fuel consumption, l/km or m³/km:

- standard fuel consumption, l/km or m³/km:

for cars and buses

, (21)

, (21)

Where:  - basic rate of fuel consumption per mileage or downtime of a car (according to NIIA), l/100km or m³/100km;

- basic rate of fuel consumption per mileage or downtime of a car (according to NIIA), l/100km or m³/100km;

- correction factor taking into account the surcharge to fuel consumption in winter:

- correction factor taking into account the surcharge to fuel consumption in winter:

, (22)

, (22)

Where:  - the number of winter months in a year;

- the number of winter months in a year;

- the size of the established allowance (according to NIIAT), %.

- the size of the established allowance (according to NIIAT), %.

for flatbed trucks, dump trucks and vans

where: - basic rate of fuel consumption per mileage or idle time of the car, l/100km or m³/100km;

- fuel consumption rate for transport work, l/100km or m³/100km;

- fuel consumption rate for transport work, l/100km or m³/100km;

G is the carrying capacity of the vehicle, t;

- load capacity utilization factor;

- load capacity utilization factor;

- vehicle mileage utilization factor (with load).

- vehicle mileage utilization factor (with load).

Lubricant Cost Calculation

The cost of lubricants is determined by the following formula:

Where:  - normative fuel consumption per mileage or idle time of the car, l/km or m³/km;

- normative fuel consumption per mileage or idle time of the car, l/km or m³/km;

- consumption rate of engine oil per 100 liters of total fuel consumption, l;

- consumption rate of engine oil per 100 liters of total fuel consumption, l;

- cost of 1 liter of motor oil, rub.;

- cost of 1 liter of motor oil, rub.;

- transmission oil consumption rate per 100 liters of total fuel consumption, l;

- transmission oil consumption rate per 100 liters of total fuel consumption, l;

- cost of 1 liter of gear oil, rub.;

- cost of 1 liter of gear oil, rub.;

- consumption rate of special oil per 100 liters of total fuel consumption, l;

- consumption rate of special oil per 100 liters of total fuel consumption, l;

- cost of 1 liter of special oil, rub.;

- cost of 1 liter of special oil, rub.;

- consumption rate of greases per 100 liters of total fuel consumption, kg;

- consumption rate of greases per 100 liters of total fuel consumption, kg;

- cost of 1 kg of greases, rub.

- cost of 1 kg of greases, rub.

^

Calculating the cost of restoring tire wear

Where:  - the norm for the restoration of wear and repair of tires per 1000 km of run, shares of units;

- the norm for the restoration of wear and repair of tires per 1000 km of run, shares of units;

- cost of 1 set of tire, inner tube, rim tape, rub.;

- cost of 1 set of tire, inner tube, rim tape, rub.;

K - the number of running tires on the car, pcs.

^

Calculation of depreciation charges

Where:  - the rate of depreciation for the complete restoration of the car,%;

- the rate of depreciation for the complete restoration of the car,%;

- the cost of a car (tractor), thousand rubles;

- the cost of a car (tractor), thousand rubles;

- depreciation rate for the full restoration of the trailer,%;

- depreciation rate for the full restoration of the trailer,%;

Car maintenance cost calculation

Where:  And

And  - the cost rate for maintenance of the car and trailer, respectively, set for 1000 km of run,%;

- the cost rate for maintenance of the car and trailer, respectively, set for 1000 km of run,%;

p - coefficient to the cost rate, taking into account road conditions: for roads of category I - 0.84; for roads of category II - 0.92; for roads of category III - 1.0; for roads of category IV - 1.17; for roads of category V - 1.25;

The cost of a car (tractor), thousand rubles;

Trailer cost, thousand rubles

Driver payroll

, (28)

, (28)

Where:  - hourly tariff rate of the driver (according to the "Industry Tariff Agreement for Road Transport for 2002-2004"), rub.;

- hourly tariff rate of the driver (according to the "Industry Tariff Agreement for Road Transport for 2002-2004"), rub.;

- coefficient to the tariff rate of the driver.

- coefficient to the tariff rate of the driver.

Calculation of the cost of 1 auto-hour of car operation

^ Calculation of the cost of 1 vehicle-hour of vehicle downtime

(30)

The formation of a regulatory framework for calculating the specific indicators of losses from an increase in the cost of transporting goods and passengers in 2010 prices was carried out by recalculating the basic indicators of the main types of variable and fixed costs for transportation by car brands, developed at the Department of Economics of the Road Economy of MADI (STU) for pricing conditions in 2002

The calculated values of indicators of variable and fixed costs for brands of cars, buses and trucks are given in Appendix A.

Methodology for calculating operational socio-economic losses of users

5.5.1 Calculation of user costs for lane closure repairs

During the road repair work, additional operational socio-economic losses of road users occur, associated with the restriction of the traffic flow and the occurrence of congestion due to this.

The determination of operational socio-economic losses during the periods of repair of pavement structures is carried out according to the formulas of Section 5.4.6 with some adjustment:

For the duration of each repair period (which, if the repair work is not multiple of one year, is entered for an incomplete year in days);

On the conditions for organizing traffic during repair work, which are characterized by two parameters: the size of the narrowing of the carriageway of the structure (if it does not completely close) and the length of the repair work zone.

The initial data for calculating these types of losses are:

with partial blocking of traffic on the road

The length of each zone of repair work, km;

Average traffic flow speed in the repair area, km/h;

The average downtime of cars in the case of their alternate passing along one lane;

with a complete closure of traffic on the road

The length of the detour of the repaired area;

The speed of the traffic flow on the detour;

Duration of repair work, days

To perform calculations, it is necessary to have certain data on the characteristics of the organization of road work in order to perform an analysis and obtain an estimate of the costs of users. The initial data required for this:

Planned year of work.

The duration of the work (number of days).

Specific hours of each day of work.

The length of the repair work zone, km.

Throughput during work (vehicles per hour along the lane).

Speed limit in the work area, km/h.

Number of open lanes during maintenance work.

Annual average daily traffic in the year of construction (total for both directions).

The composition of the traffic flow.

The number of trucks without trailers in the traffic flow.

Trucks with trailers and tractors with semi-trailers as part of the traffic flow.

Annual growth rate of traffic intensity.

Speed limit under normal operating conditions (km/h).

The number of lanes in normal traffic.

Average hourly intensity of the traffic flow (bus/hour) along the lane.

Maximum throughput in congestion (capacity of each lane in congestion).

Maximum traffic intensity (bus/day).

Maximum queue length (km).

Rural or urban hourly transport distribution.

The cost of time for passenger cars by car brands (rubles/hour).

Cost of time for single trucks without trailers by car brands (rubles/hour).

Cost of time for trucks with trailers and semi-trailers by car brands (rubles/hour).

The time of movement of the traffic flow when the lane is blocked (  , hour):

, hour):  , hour, (31)

, hour, (31)

Where:  - traffic flow movement time in the work area, hour:

- traffic flow movement time in the work area, hour:

, rub (39)

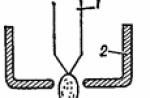

Figure 1. Scheme of the flow of cars: a - with free movement; b - when the lane is blocked

Let's take the five most popular cars in their classes - each in the most sought-after configuration - and estimate the operating costs for the first three years, after which the factory warranty usually ends and the car changes hands. Since many (not taxi drivers and not “snowdrops”) annually roll 20–25 thousand km, we took the total mileage for three years to be 70 thousand.

The expenditure index speaks most precisely about the amount of spending. It shows how much each kilometer traveled or one day of owning a car costs. If you include car washes, paid parking, unscheduled repairs, fines for traffic violations, etc., the indices will noticeably change, but such expenses entirely depend on the mode of operation and lifestyle of the owner, so we did not take them into account.

Entertaining arithmetic: the more expensive the car, the more money it will pull out during operationWhat do our calculations say? The conclusion is not new, although not everyone comes to it on their own. The more expensive the car, the more money it will pull out in operation - because maintenance, consumables, insurance are more expensive, and a powerful car with an automatic transmission has higher fuel consumption. Moreover, an expensive car depreciates faster with age - not in percentage terms, but in absolute terms: you will sell it for much less than you bought it new.

Of course, it is impossible to approach the purchase of a car purely rationally. We are driven not only by cold calculation, emotions cannot be avoided. But such an index clearly shows how expensive a car is more burdensome for the family budget. Will you pull?

2.3 The calculation of the item "Costs per 1 km of run" is made according to the formula

where - the cost of fuel, cash units. / km;

Costs for lubricants and cleaning materials, cash units / km;

The cost of those maintenance and current repairs, cash units /km;

Depreciation costs, cash units /km;

Tire repair and retreading costs, monetary unit / km;

Costs for drivers' salaries, cash units / km;

Overhead costs, cash units / km.

2.4. Calculation of the item "Fuel costs" is made according to the formula:

![]() ,

,

where is the wholesale price of fuel;

Fuel consumption rate, l / 100 km;

Coefficient that takes into account increased fuel consumption in winter.

2.5 The calculation of the item "Costs for lubricants and cleaning materials" is made according to the formula:

where , - consumption rates of engine, transmission oils and plastic lubricants per 100 km of run.

Wholesale prices, respectively, for the oils used, monetary units.

2.6 Calculation of the item "Costs for maintenance and operational repairs" is made according to the formula:

Where ![]() - cost according to the cost norms for TO-1, TO-2, SW, cash units;

- cost according to the cost norms for TO-1, TO-2, SW, cash units;

The average cost of current repairs per 1000 kilometers;

![]() - standard mileage of the car to TO-1, TO-2, EO, km;

- standard mileage of the car to TO-1, TO-2, EO, km;

![]() ,

,

where is a coefficient that takes into account the reduction in maintenance costs for a new car.

2.7 Calculation of the item "Depreciation costs" is made according to the formula:

![]() ,

,

where - wholesale price, cash units;

Annual car mileage, km;

The annual depreciation rate for the complete restoration of the car,%,

Annual rate of depreciation for overhaul of a car, %.

2.8 The calculation of the item "Costs for the restoration and repair of tires" is made according to the formula:

![]() ,

,

where is the wholesale (retail) price for one tire, cash units;

Number of running tires, pcs.;

Tire depreciation mileage, i.e. tire mileage, km;

Tire repair cost factor.

2.9 Calculation of the item "Costs for the salary of drivers" is made according to the formula:

![]() ,

,

where is the tariff earnings of the driver, cash units;

Coefficient taking into account additional payments and bonuses;

12 is the number of months in a year.

2.10. The calculation of the item "Overhead costs" is made according to the formula:

![]() ,

,

where - the standard of annual overhead costs for one car, monetary units.

![]()

![]()

II. Drawing up an estimate of operating costs per 1 km of run

Table 51 - OPERATING COST ESTIMATES

| № | Expenditures | Amount, rubles | Result rise in price Saving |

|

| Base | New | |||

| 1 | 2 | 3 | 4 | 5 |

| 1 | Fuel costs | 0,0754 | 0,0742 | -0,0012 |

| 2 | Lubrication cost | 0,00605 | 0,00608 | 0,00003 |

| 3 | Maintenance cost | 1,035 | 1 | -0,035 |

| 4 | Depreciation cost | 0,0256 | 0,3023 | 0,2767 |

| 5 | Tire repair costs | 0,0075 | 0,0082 | 0,0007 |

| 6 | Payroll costs | 0,0425 | 0,0386 | -0,0039 |

| 7 | Overhead cost | 0,026 | 0,0236 | -0,0024 |

| 8 | Total: | 1,21805 | 1,45298 | 0,23493 |

III. Costs per unit of transport work (cost of 1 t-km) are determined by the formula:

![]() ;

;

IV. Annual operating costs are calculated by the volume of transport work performed by the new car for the base and new car:

![]() ,

,

where , - operating costs per year, respectively, for the basic and new equipment.

PART 3. Calculation of indicators of economic efficiency of new technology.

I. Determining conditionally annual savings (rising in price) is carried out in three areas:

3.1 in the field of production:

![]() ,

,

where is the annual program for the production of new equipment.

3.2. in the field of operation:

![]() ,

,

3.3. in general for the national economy:

![]() ,

,

II. The determination of the annual economic effect on the national economy is carried out according to one of the following formulas:

3.4. If new technology reduces costs, both in production and in the field of operation, the economic effect is calculated by the formula:

3.5 If a new technique gives an economic effect only in the field of operation, and is more expensive in production, then the economic effect is calculated by the formula:

3.6. If the new technique is of higher quality (with a higher price), the economic effect is calculated by the formula.

How to correctly calculate the cost of transportation, and what is the cost of transportation? This question arises before the majority of logisticians. This is necessary to properly control the price-to-cost ratio. In addition, similar calculations may be required to provide the customer to justify the requested price. The service for transporting goods must be paid by the customer of transport services.

What should be included in the shipping cost?

Shipping costs are based on many factors. Their size can be influenced by the features of the product, its weight and dimensions, the number of seats, the category of complexity, the type of packaging. The density of the cargo can be different: products can be ordinary, liquid, bulk or food products. Having received information from the consignor about the transported goods, the carrier takes into account the peculiarities of its transportation and, based on this, calculates the cost of delivery of the products.

Calculation of the price of cargo transportation

Most often, the cost of transportation is directly proportional to the mass, volume or number of places occupied by the cargo. The logistician must single out for himself the most defining of the listed points. The calculation of the rate should be based on a certain condition: the mass of one cubic meter should not exceed a specific number of kilograms. With a consolidated tariff, the estimated weight of the cargo is taken as the basis. For example, the mass of one cubic meter is 0.5 tons, and one linear meter is 1.5 tons. 2 calculated weights are calculated: according to "drivers" and cubic meters. Then they are compared with the real weight. Of the three results obtained, you need to choose the largest. As a result, you need to look at the tariff scheme and find out the cost of a particular delivery.

Calculation of the transportation tariff, price per kilometer

What rule do transport companies follow when calculating their rates? Traditionally, the calculation takes place for each kilometer. The list of basic expenses includes the purchase of fuel, materials and equipment. This also includes infrastructure costs, payment of tax and other contributions. The result is the cost of one kilometer of track, plus taxes and improvement costs. In the event that the carrier operates only on a specific route and knows its own monthly and mileage costs, it is much easier for it to calculate the fare. Approximately 25% is allocated for the development of the transport sector. As a result, prices per kilometer are obtained. Although, the carrier must understand that in reality the profit is rarely higher than 5-10%.

Calculation of the price of cargo transportation, rate for a full circle

When further calculating the cost of delivery, the tariff per kilometer must be multiplied by twice the number of kilometers to the final destination. As a result, you get a bet for a full “circle”. With one-sided loading, the number of kilometers should not be doubled, but single. The number of trips per month is based on mileage per day. The resulting number is the cost of the round trip. It must be remembered that the cost will be noticeably lower if loading is combined with unloading in one day.

Freight cost calculation often used by transport companies

There is another option for calculating the price of cargo transportation, which is based on the budget of a transport company. With it, all expenses of the organization are distributed in equal parts among different customers.

Do not forget that prices can be affected not only by internal reasons and calculations. For example, each region has its own tariff. In the central cities of Russia they are higher than the average by 20-30%. In this case, the increase in the cost of transportation is explained by the large number of proposals for the transportation of products.

Truck driver fell asleep at the wheel

We summarize all costs for trucks in table 8. We take the costs from previous calculations. Other direct costs are planned in the amount of 10% of the sum of all direct costs.

P.6=(p.1+2+3+4+5)*10/100

Overhead costs are the costs associated with the salaries of the fleet management staff.

Overhead costs are planned in the amount of 20% of the total cost, including other direct costs minus the cost of fuel and lubricants.

P.7=(P.1+3+4+5+6)*20/100

Table 8- Cost of 1 t-km.

Next, we add up all the costs, we find "Total costs". Costs per 1 t-km are determined by dividing each cost element separately by the planned traffic volume (Qt-km). The lower it is, the more efficiently the fleet of trucks is used. Compare the planned cost with the actual cost and give proposals for its reduction. Make calculations with conclusions.

Individual calculation task for practical lesson No. 3

Task. The motor transport enterprise has 2 brands of cars

Depreciation rate 0.37% per 1000 km.

Mileage utilization rate 0.53.

Load capacity utilization factor 0.86.

The price of 1 liter is taken from PZ No. 3

Of all the drivers 8 people. have I class.

2 people - II class.

Premiums accept 100%.

Tire replacement costs per year for all vehicles are:

For KamAZ vehicles - 588,000 rubles.

According to ZILs - 378,000 rubles.

Determine the cost of 1 t-km at the enterprise.

Arrange the calculations in the form of tables.

Solution:

Table 1- Planning the volume of cargo transportation

Average load capacity of machines q=

Volume of transport work Q n - rv =

Table 2- Driver's salary

We determine the payroll: (by analogy with the calculation in PZ No. 3)

Table 3- Calculation of depreciation charges

Table 4- Determining the need for fuel and lubricants

| Car brands | Total mileage | Fuel consumption rate per 100 km (l) | Total fuel (gr2*gr3 / 100) (l) | Engine oil | Specialist. oils | Transmis. oils | Greases | ||||

| norm (l) | required (l) | norm (l) | required (l) | norm (l) | required (l) | norm (kg) | required (kg) | ||||

| KAMAZ-5320d | |||||||||||

| ZIL-4502 | |||||||||||

| TOTAL | X | X | ? | X | ? | X | ? | X | ? |

Table 5- Determining the cost of fuel and lubricants

Table 6- Determining the cost of TR

Table 7- Cost of 1 t-km.

Practice #4

Payroll for drivers and maintenance workers

Task 1.

Transportation distance (l) – 80 km, incl. 55 km on 1 group of roads

25 km on the 3rd group of roads

Vehicle load capacity (q) KAMAZ - 5320 - 8 tons.

on the 3rd group of roads - 28 km / h

for the 3rd group of roads (β) - 0.45

The norm of time for loading, unloading (t PR) - 15 minutes per 1 ton of cargo

Preparatory and final time (t PZ) - 23 min = 0.38 hours

The driver's hourly rate (CH) KamAZ - 5320 - 53.40 rubles.

Determine the driver's salary for 1 flight.

Solution:

- Number of t-km for 1 flight:

q * l (1 road groups) =

q * l (3 groups of roads) =

- Travel time of 1 flight:

t = Nt-km * Qt-km + tpr

a) Norm of time per 1 t-km:

Nt-km = , min/t-km

b) Travel time of 1 flight:

t = Nt-km 1gr * (number of t-km 1gr) + Nt-km 3gr * (number of t-km 3gr) + tpr*q, hour

c) Driver's total work time:

t = t + t , hour

- Driver's salary for 1 flight:

St \u003d t * Sch / 60, rub / t

Zp main \u003d St-km 1g * (number of t-km 1g) + St-km 3g * (number of t-km 3g) + St * q, rub

c) Supplement for classiness:

Dkl \u003d (t * sch) * 0.25, rub.

d) Premium - 20%:

Pr \u003d (Zp main + Dcl) * 0.2, rub.

e) Total salary:

Zp from the beginning =

Individual calculation task for practical lesson No. 4

Task 2.

Transportation distance (l) – 50 km

Vehicle load capacity (q) KAMAZ - 5320 - 16 tons.

Estimated travel speed (Vt) on the 1st group of roads - 49 km / h

Mileage coefficient for the 1st group of roads (β) - 0.5

Load capacity utilization factor (γ) - 1

The norm of time for loading, unloading (t) - 10 minutes per 1 ton of cargo

Preparatory and final time (t) - 23 min \u003d 0.38 hours

- Driver's salary for 1 flight:

a) Piece rate for 1 t-km:

St-km \u003d Nt-km * Sch / 60, rub / t-km

Price for 1 ton of loading, unloading:

St \u003d t pr * Sch / 60, rub / t

b) Driver's salary for 1 flight - basic:

Zp main \u003d St-km * (number of t-km) + St * q, rub

c) Supplement for classiness:

Dkl \u003d (t SM * SCH) * 0.25, rub.

d) Premium - 20%:

Pr \u003d (Zp main + Dcl) * 0.2, rub.

e) Total salary:

Ztot \u003d Zp main + Dkl + Pr, rub.

f) Salary including vacation pay and UST:

Zp from the beginning \u003d Ztot * 1.083 * 1.356, rub

Zp from the beginning =

Practice #5