The initial value when choosing the dimensions of the KShM links is the value of the full stroke of the slider, specified by the standard or for technical reasons for those types of machines for which the maximum stroke of the slider is not specified (scissors, etc.).

The following designations are introduced in the figure: dО, dА, dВ are the diameters of the fingers in the hinges; e is the value of the eccentricity; R is the radius of the crank; L is the length of the connecting rod; ω is the angular speed of rotation of the main shaft; α is the angle of short of the crank to the CNP; β is the angle of deviation of the connecting rod from the vertical axis; S - the value of the full stroke of the slider.

According to the given value of the slider stroke S (m), the radius of the crank is determined:

For an axial crank mechanism, the functions of slider displacement S, velocity V, and acceleration j from the angle of rotation of the crank shaft α are determined by the following expressions:

S = R, (m)

V = ω R , (m/s)

j \u003d ω 2 R, (m / s 2)

For a deaxial crank mechanism, the functions of slider displacement S, velocity V, and acceleration j from the angle of rotation of the crank shaft α, respectively:

S = R, (m)

V = ω R , (m/s)

j \u003d ω 2 R, (m / s 2)

where λ is the connecting rod coefficient, the value of which for universal presses is determined in the range of 0.08 ... 0.014;

ω is the angular speed of rotation of the crank, which is estimated based on the number of strokes of the slider per minute (s -1):

ω = (πn) / 30

The nominal force does not express the actual force developed by the drive, but represents the ultimate strength of the press parts that can be applied to the slider. The nominal force corresponds to a strictly defined angle of rotation of the crankshaft. For single-acting crank presses with one-way drive, the nominal force is taken to be the one corresponding to the angle of rotation α = 15 ... 20 o, counting from the bottom dead center.

Forces acting on the crankshaft journals. These forces include: the gas pressure force is balanced in the engine itself and is not transferred to its supports; the force of inertia is applied to the center of the reciprocating masses and is directed along the axis of the cylinder through the crankshaft bearings act on the engine housing, causing it to vibrate on the supports in the direction of the axis of the cylinder; the centrifugal force from the rotating masses is directed along the crank in its middle plane, acting through the crankshaft bearings on the engine housing ...

Share work on social networks

If this work does not suit you, there is a list of similar works at the bottom of the page. You can also use the search button

Lecture 12

DYNAMICS OF KShM

12.1. Gas pressure forces

12.2. Forces of inertia

12 .2.1. Bringing the masses of the parts of the KShM

12.3. Total forces acting in the KShM

12.3.1. Forces acting on the crankshaft journals

12.4. The order of operation of the engine cylinders, depending on the location of the cranks and the number of cylinders

When the engine is running, forces and moments act in the crankshaft, which not only affect the crankshaft parts and other components, but also cause the engine to run unevenly. These forces include:

- the gas pressure force is balanced in the engine itself and is not transmitted to its supports;

- the force of inertia is applied to the center of the reciprocating masses and is directed along the axis of the cylinder, through the bearings of the crankshaft they act on the engine housing, causing it to vibrate on the supports in the direction of the axis of the cylinder;

- the centrifugal force from the rotating masses is directed along the crank in its middle plane, acting through the crankshaft bearings on the engine housing, causing the engine to oscillate on the supports in the direction of the crank.

In addition, there are forces such as pressure on the piston from the crankcase, and gravity forces of the crankshaft, which are not taken into account due to their relatively small magnitude.

All forces acting in the engine interact with the resistance on the crankshaft, friction forces And accepted by the engine mounts.During each working cycle (720 ° for a four-stroke And 360° for two-stroke engines) the forces acting in the crankshaft continuously change in magnitude and direction and to establish the nature of the change in these forces from the angle of rotation of the crankshaft, they are determined every 1030 ° for certain positions of the crankshaft.

12.1. Gas pressure forces

Gas pressure forces act on the piston, walls and cylinder head. To simplify the dynamic calculation of the pressure force gases are replaced by one force directed along the axis of the cylinder and app female to the axis of the piston pin.

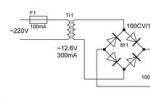

This force is determined for each moment of time (angle of rotationcrankshaft φ) according to the indicator diagram obtained on the basis of a thermal calculation or taken directly from the engine using a special installation. On fig. 12.1 shows expanded indicator diagrams of the forces acting in particular the change in the gas pressure force(R g ) on the angle of rotation of the crankshaft.

Rice. 12.1. Expanded indicator force diagrams,

operating in KShM

12.2. Forces of inertia

To determine the inertia forces acting in the crankshaft, it is necessary to know the masses of the moving parts. To simplify the calculation of the mass of moving parts, we will replace it with a system of conditional masses equivalent to real-life masses. This replacement is called mass reduction.

12.2.1. Bringing the masses of the parts of the KShM

According to the nature of the movement of the mass of parts, KShM can be divided into three groups:

- reciprocating parts (piston group and upper connecting rod head);

- parts that perform rotational motion (crankshaft and lower connecting rod head);

- parts that make a complex plane-parallel movement (rod rod).

The mass of the piston group(t p ) is considered to be concentrated on the axis of the piston pin at the point A (Fig. 12.2).

Rice. 12.2. Bringing the masses of the connecting rod

Mass of connecting rod groupreplaced by two masses: t w centered on the axis of the piston pin at the point A, t sk on the axis of the crank at point B. The values of these masses are found by the formulas:

where L w is the length of the connecting rod;

L sk distance from the center of the crank head to the center of gravity of the connecting rod.

For most existing engines t sh is in the range of 0.2 t w to 0.3 t w, and t wk from 0.7 t w to 0.8 t w. Value t w can be determined through the structural mass (Table 12.1), obtained on the basis of statistical data.

crank ground are replaced by two masses concentrated on the axis of the crank at the point V (t to ) and on the axis of the main neck at the point About (t about) (Fig. 12.3).

Rice. 12.3. Bringing the masses of the crank: a real; b equivalent

The mass of the main journal with part of the cheeks located symmetrically about the axis of rotation is balanced. The unbalanced masses of the crank are replaced by one reduced mass, subject to the condition that the centrifugal force of inertia of the actual mass is equal to the centrifugal force of the reduced mass. Equivalent mass lead to crank radius R and denote t to.

Mass of connecting rod journal t shsh with the adjacent parts of the cheeks, they are taken to be concentrated in the middle of the axis of the neck, and since its center of gravity is removed from the axis of the shaft by a distance equal to R , reduction of this mass is not required. Cheek mass t w with the center of gravity at a distance p from the axis of the crankshaft is replaced by the reduced mass located at a distance R from the axis of the crankshaft. The reduced mass of the entire crank is determined by the sum of the reduced masses of the connecting rod journal and cheeks:

When designing engines, the value t to can be obtained through the structural masses of the crank t" to (see table 12.1). For modern short-stroke engines, the value t w small compared to t shsh and it can be neglected.

Table 12.1. Values of constructive masses of KShM, kg/m 2

|

Element KShM |

Carburetor engines with D from 60 to 100 mm |

Diesels with D from 80 to 120 mm |

|

Piston group(t "n \u003d t w / F p) |

||

|

Aluminum alloy piston |

80-50 |

150-300 |

|

Cast iron piston |

150-250 |

250-400 |

|

Connecting rod (t "k = t w / F p) |

||

|

connecting rod |

100-200 |

250-400 |

|

Unbalanced parts of one knee of the crankshaft without counterweights(t "k = t k / F p ) |

||

|

Forged steel crankshaft with solid journals |

150-200 |

200-400 |

|

Cast iron hollow journal crankshaft |

100-200 |

150-300 |

Notes.

1. When using the table. 12.1 it should be borne in mind that large values T "suitable for engines with large cylinder bores.

2. Decreasing S/D reduces t"w and t"k.

3. V-shaped engines with two connecting rods on the neck correspond to large values t" to .

Thus, the system of concentrated masses, dynamically equivalent to the KShM, consists of the mass t A , concentrated at the point A and performing reciprocating motion:

and mass t V , concentrated at the point IN and having rotational motion:

V -shaped engines with dual crankshaft t V \u003d t k + 2t shk.

In the dynamic calculation of the motor, the values t p and t w determined from prototype data or calculated. The values t shh and t sh determined based on the dimensions of the crank and the density of the material of the crankshaft. For an approximate determination of the value t p , t w and t k constructive masses can be used:

Where .

12.2.2. Determination of the forces of inertia

The forces of inertia acting in the KShM, in accordance with the nature of the movement of the reduced masses, are divided intoinertial forces of translationally moving masses Pj and centrifugal forces of inertia of rotating masses R c .

Force of inertia from reciprocating massescan be determined by the formula

(12.1)

The minus sign indicates that the force of inertia is directed in the direction opposite to the acceleration. It can be considered as consisting of two forces (similar to acceleration).

First component

(12.2)

- inertia force of the first order.

Second component

(12.3)

- inertial force of the second order.

Thus,

Centrifugal force of inertia of rotating massesconstant in magnitude and directed away from the axis of the crankshaft. Its value is determined by the formula

(12.4)

A complete picture of the loads acting in the parts of the crankshaft can only be obtained as a result of the combination of the action of various forces that arise during engine operation.

12.3. Total forces acting in the KShM

Consider operation of a single cylinder engine. Forces acting in single-cylinder engine, shown in Fig. 12.4. In KShM gas pressure force R g , reciprocating inertia force effectively moving masses Pj and centrifugal force R c . Forces Р g and P j attached to the piston and act along its axis. Putting these two strength, we obtain the total force acting along the axis of the cylinder:

(12.5)

The displaced force P in the center of the piston pin is decomposed into two components:

(12. 6 )

- force directed along the axis of the connecting rod;

(12. 7 )

- force perpendicular to the wall of the cylinder.

Rice. 12.4. Forces acting in the crankshaft of a single-cylinder engine

Force P N is perceived by the side surface of the cylinder wall and causes wear of the piston and cylinder. It is considered positive if the moment it creates relative to the axis of the crankshaft is directed opposite to the direction of rotation of the engine shaft.

Strength R w is considered positive if it compresses the connecting rod, and negative if it stretches it.

Strength R w , attached to the crankpin ( R "sh ) is decomposed into two components:

(12.8)

- tangential force tangent to the crank radius circle;

(12.9)

- normal force (radial) directed along the radius of the crank.

Z-force is considered positive if it compresses the cheeks of the crank. Force T is considered positive if the direction of the moment it creates coincides with the direction of rotation of the crankshaft.

By the value of T determine the indicator torque of one cylinder:

(12.10)

Normal and tangential forces transferred to the center of the crankshaft ( Z" and T "), form a resultant force R"" w, which is parallel and equal in magnitude to the force R sh . Strength R"" w loads the main bearings of the crankshaft. In turn, strength R"" sh can be decomposed into two components: P"N, perpendicular to the axis of the cylinder, and the force P "acting along the axis of the cylinder. Forces P "N and P N form a pair of forces, the moment of which is called overturning. Its value is determined by the formula

(12.11)

This moment is equal to the indicator torque and is directed in the opposite direction:

Since then

(12.12)

The torque is transmitted through the transmission to the drive wheels, and the overturning moment is taken up by the engine mounts. Force R "is equal to the force R , and similarly to the latter, it can be represented as

Component P "g balanced by the force of gas pressure applied to the cylinder head, aP "j is a free unbalanced force transmitted to the engine mounts.

The centrifugal force of inertia is applied to the connecting rod journal of the crank and is directed away from the axis of the crankshaft. She's like strength P "j is unbalanced and is transmitted through the main bearings to the engine mounts.

12.3.1. Forces acting on the crankshaft journals

Radial force acting on the crankpin Z , tangential force T and centrifugal force R c from the rotating mass of the connecting rod. Forces Z and R c directed along one straight line, so their resultant

or

(12.13)

Here R c not defined as, but as , since we are talking about the centrifugal force of only the connecting rod, and not the entire crank.

The resultant of all forces acting on the connecting rod journal is calculated by the formula

(12.14)

The action of the force R w causes wear on the crankpin. The resultant force applied to the crankshaft journal is found graphically as the forces transmitted from two adjacent crankshafts.

12.3.2. Analytical and graphical representation of forces and moments

The analytical representation of the forces and moments acting in the KShM is represented by formulas (12.1) (12.14).

More clearly, the change in the forces acting in the crankshaft depending on the angle of rotation of the crankshaft can be represented as expanded diagrams that are used to calculate the strength of the crankshaft parts, assess the wear of the rubbing surfaces of the parts, analyze the uniformity of the stroke and determine the total torque of multi-cylinder engines, as well as construction of polar diagrams of loads on the shaft neck and its bearings.

Usually, when calculating, two expanded diagrams are built: one shows the dependencies, And (see Fig. 12.1), on the other dependencies and (Fig. 12.5).

Rice. 12.5. Expanded diagrams of tangential and real forces acting in the crankshaft

Expanded diagrams of the forces acting in the crankshaft make it possible to determine the torque of multi-cylinder engines in a relatively simple way.

From equation (12.10) it follows that the torque of a single-cylinder engine can be expressed as a function T=f (φ). The meaning of strength T depending on the change in the angle of rotation, it changes significantly, as can be seen in Fig. 12.5. Obviously, the torque will change similarly.

In multi-cylinder engines, the variable torques of the individual cylinders are summed along the length of the crankshaft, resulting in a total torque at the end of the shaft.The values of this moment can be determined graphically. For this, the projection of the curve T=f (φ) on the x-axis are divided into equal segments (the number of segments is equal to the number of cylinders). Each segment is divided into several equal parts (here, 8). For each obtained point, the abscissa determines the algebraic sum of the ordinates of the two curves (above the abscissa of the value with the “+” sign, below the abscissa of the value with the sign “-”). The obtained values are plotted respectively in coordinates x, y and the resulting points are connected by a curve (Fig. 12.6). This curve is the resultant torque curve for one engine cycle.

Rice. 12.6. Expanded Diagram of Resultant Torque

per engine cycle

To determine the average torque value, the area is calculated F, limited by the torque curve and the y-axis (above the axis the value is positive, below it is negative):

where L chart length along the abscissa; m M scale.

With a known scale of the tangential force m T find the scale of the torque m M = m T R , R crank radius.

Since the losses inside the engine were not taken into account when determining the torque, then, expressing the effective torque through the indicator, we get

where M to effective torque;η m mechanical efficiency of the engine.

12.4. Order operation of the engine cylinders depending on the location of the cranks and the number of cylinders

In a multi-cylinder engine, the location of the crankshaft cranks must, firstly, ensure the uniformity of the engine stroke, and, secondly, ensure the mutual balance of the inertia forces of the rotating masses and reciprocating masses.

To ensure the uniformity of the stroke, it is necessary to create conditions for alternating flashes in the cylinders at equal intervals of the angle of rotation of the crankshaft.Therefore, for a single-row engine, the angle φ corresponding to the angular interval between flashes in a four-stroke cycle is calculated by the formula φ = 720°/ i , where i the number of cylinders, and with a two-stroke according to the formula φ \u003d 360 ° / i .

The uniformity of alternation of flashes in the cylinders of a multi-row engine, in addition to the angle between the crankshaft cranks, is also affected by the angle γ between the rows of cylinders. For optimum running uniformity n -in-line engine, this angle must be in n times less than the angle between the crankshaft cranks, i.e.

Then the angular interval between flashes for a four-stroke engine

For two stroke

![]()

To satisfy the balance requirement, it is necessary that the number of cylinders in one row and, accordingly, the number of crankshaft cranks be even, and the cranks must be located symmetrically relative to the middle of the crankshaft.The arrangement of cranks, symmetrical relative to the middle of the crankshaft, is called "mirror".When choosing the shape of the crankshaft, in addition to the balance of the engine and the uniformity of its stroke, the order of operation of the cylinders is also taken into account.

The optimal order of operation of the cylinders, when the next stroke occurs in the cylinder furthest from the previous one, reduces the load on the main bearings of the crankshaft and improves engine cooling.

On fig. 12.7 shows the sequence of work of single-row cylinders ( a) and V-shaped (b ) four-stroke engines.

Rice. 12.7. The sequence of operation of the cylinders of four-stroke engines:

a single-row; b V-shaped

PAGE \* MERGEFORMAT 1

Other related works that may interest you.vshm> |

|||

| 10783. | Dynamics of the conflict | 16.23KB | |

| The dynamics of the conflict Question 1. General idea of the dynamics of the conflict pre-conflict situation Any conflict can be represented by three stages: 1 beginning 2 development 3 completion. Thus, the general scheme of the dynamics of the conflict consists of the following periods: 1 Pre-conflict situation - latent period; 2 Open conflict the conflict itself: the incident the beginning of the conflict escalation the development of the conflict the end of the conflict; 3 Post-conflict period. A pre-conflict situation is an opportunity for conflict... | |||

| 15485. | Asoslari dynamics | 157.05KB | |

| Moddiy nuqta dynamicsining birinchi asosii masalasini echish 5. Moddiy nuqta dinaming ikkinchi asosii masalasini echish 6. Moddiy nuqta dynamicsining birinchi asosii masalasini echish 6. Moddiy nuqta dynamicsining birinchi asosii masalasini echish va absolute zhismning harakati shu harakatni vuzhudga keltiruvchi kuchlar bilan birgalikda ўr ganilad. Dynamics dastlab moddy nuktaning harakati ўrganiladi. | |||

| 10816. | Population dynamics | 252.45KB | |

| Population dynamics is one of the most significant biological and ecological phenomena. Figuratively speaking, the life of a population is manifested in its dynamics. Models of population dynamics and growth. | |||

| 1946. | Mechanism dynamics | 374.46KB | |

| Tasks of dynamics: The direct task of dynamics is the force analysis of the mechanism according to the given law of motion, determine the forces acting on its links, as well as the reactions in the kinematic pairs of the mechanism. Various forces are applied to the mechanism of the machine unit during its movement. These are the driving forces of the resistance force, sometimes they are called the forces of useful resistance, gravity, friction, and many other forces. By their action, the applied forces inform the mechanism of one or another law of motion. | |||

| 4683. | DYNAMICS OF SCIENTIFIC KNOWLEDGE | 14.29KB | |

| The most important feature of scientific knowledge is its dynamics - the change and development of formal and content characteristics depending on the temporal and socio-cultural conditions for the production and reproduction of new scientific information. | |||

| 1677. | Leadership and group dynamics | 66.76KB | |

| The purpose of this work is to identify potential leaders in the student team as well as: Main topics in the study of leadership; Interaction between leader and group; Leader functions Theoretical approaches to leadership by various researchers. This work consists of two chapters: the first chapter the theoretical part is an overview of the main topics in the study of leadership, the relationship between the leader and the group, the leader's functions and theoretical approaches to leadership the second chapter the experimental study of one table of six diagrams and two ... | |||

| 6321. | DYNAMICS OF A MATERIAL POINT | 108.73KB | |

| The force acting on a particle in the system coincides with the force acting on a particle in the system. This follows from the fact that the force depends on the distances between a given particle and the particles acting on it, and possibly on the relative velocities of the particles, and these distances and velocities are assumed to be the same in Newtonian mechanics in all inertial frames of reference. Within the framework of classical mechanics, one deals with gravitational and electromagnetic forces, as well as with elastic and frictional forces. Gravity and... | |||

| 4744. | STRUCTURE AND DYNAMICS OF SOCIETY AS A SYSTEM | 22.85KB | |

| Society is a historically developing integral system of relations and interactions between people, their communities and organizations, which develops and changes in the process of their joint activities. | |||

| 21066. | DYNAMICS OF THE DEVELOPMENT OF ZOOPLANKTON IN NOVOROSSIYSKAYA BAY | 505.36KB | |

| Novorossiysk Bay is the largest bay in the North-Eastern part of the Black Sea. Together with the open water area adjacent to it, for many years it was one of the important fishing and spawning areas in the Russian sector of the Black Sea. Features of the geographical position, great depths and area, sufficient water exchange with the open sea, good food supply - all these factors contributed to the massive entry of various species of fish into the bay for breeding and feeding | |||

| 16846. | Modern financial and economic dynamics and political economy | 12.11KB | |

| The main contradiction of the modern financial and economic system is the contradiction between the production of real value and the movement of its monetary and financial forms. the transformation of the value embodied in various resources into a source of surplus value contained in the produced goods. The increase in capitalization creates an additional demand for money to service the increasing turnover of value, which leads to an increase in the monetization of the economy, which in turn creates additional opportunities for capitalization... | |||

3.1.1. Correction of the indicator chart

The indicator diagram should be rebuilt for other coordinates: along the abscissa axis - at the angle of rotation of the crankshaft φ and under the corresponding piston movement S . The indicator diagram is then used to graphically find the current value of the cycle pressure acting on the piston. To rebuild under the indicator diagram, a crank mechanism diagram is built (Fig. 3), where the straight line AC corresponds to the length of the connecting rod L in mm, straight line AO - crank radius R in mm. For various crank angles φ graphically determine the points on the axis of the cylinder ОО / , corresponding to the position of the piston at these angles φ . For the origin, i.e. φ=0 accept top dead center. From the points on the OO / axis, vertical straight lines (ordinates) should be drawn, the intersection of which with the polytropes of the indicator diagram gives points corresponding to the absolute values of gas pressure R c . When determining R c it is necessary to take into account the direction of the flow of processes according to the diagram and their correspondence to the angle φ pkv.

The modified indicator diagram should be placed in this section of the explanatory note. In addition, to simplify further calculations of the forces acting in the crankshaft, it is assumed that the pressure R c =0 at the inlet ( φ =0 0 -180 0) and release ( φ =570 0 -720 0).

Fig.3. Indicator chart, combined

with kinematics of the crank mechanism

3.1.2 Kinematic calculation of the crank mechanism

The calculation consists in determining the displacement, speed and acceleration of the piston for various angles of rotation of the crankshaft, at a constant speed. The initial data for the calculation are the radius of the crank R

=

S

/2

, connecting rod length L

and kinematic parameter

λ

=

R

/

L

- constant KShM. Attitude λ

=

R

/

L

depends on the type of engine, its speed, the design of the crankshaft and is within  =0.28 (1/4.5…1/3). When choosing, it is necessary to focus on a given engine prototype and take the nearest value according to table 8.

=0.28 (1/4.5…1/3). When choosing, it is necessary to focus on a given engine prototype and take the nearest value according to table 8.

crank angular velocity

The determination of kinematic parameters is carried out according to the formulas:

Piston movement

S

=

R

[(1- )

+

)

+

(1-

(1- )]

)]

piston speed

W

P

=

R  (

sin

(

sin  sin

2

sin

2 )

)

piston acceleration

j

P

=

R  (

( +

+

)

)

An analysis of the piston velocity and acceleration formulas shows that these parameters obey a periodic law, changing positive values to negative ones during the movement. Thus, the acceleration reaches its maximum positive values at pkv φ = 0, 360 0 and 720 0 , and the minimum negative at pkv φ = 180 0 and 540 0 .

The calculation is performed for the angles of rotation of the crankshaft φ

from 0º to 360º, every 30º the results are entered in table 7. In addition, the current angle of deviation of the connecting rod is found from the indicator diagram

for each current angle value φ

. Corner

for each current angle value φ

. Corner  it is considered with a sign (+) if the connecting rod deviates in the direction of rotation of the crank and with a sign (-) if in the opposite direction. Biggest connecting rod deflection ±

it is considered with a sign (+) if the connecting rod deviates in the direction of rotation of the crank and with a sign (-) if in the opposite direction. Biggest connecting rod deflection ±  ≤ 15º ... 17º will correspond to pkv.

≤ 15º ... 17º will correspond to pkv.  =90º and 270º.

=90º and 270º.

Table 7

Kinematic parameters of KShM

|

φ , hail |

moving, S m |

Speed, W P m/s |

Acceleration, j P m/s 2 |

Angle of deviation of the connecting rod, β hail |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

The task of kinematic calculation is to find displacements, velocities and accelerations depending on the angle of rotation of the crankshaft. Based on the kinematic calculation, a dynamic calculation and balancing of the engine are carried out.

Rice. 4.1. Scheme of the crank mechanism

When calculating the crank mechanism (Fig. 4.1), the ratio between the displacement of the piston S x and the angle of rotation of the crankshaft b is determined as follows:

The segment is equal to the length of the connecting rod, and the segment is equal to the radius of the crank R. With this in mind, as well as expressing the segments and through the product and R, respectively, by the cosines of the angles b and c, we learn:

From triangles and we find or, whence

We expand this expression into a series using Newton's binomial, and we obtain

For practical calculations, the necessary accuracy is fully provided by the first two terms of the series, i.e.

Taking into account the fact that

it can be written in the form

From this we obtain an approximate expression for determining the magnitude of the piston stroke:

Differentiating the resulting equation with respect to time, we obtain an equation for determining the piston speed:

In the kinematic analysis of the crank mechanism, it is believed that the speed of rotation of the crankshaft is constant. In this case

where u is the angular velocity of the crankshaft.

With this in mind, we get:

Differentiating it with respect to time, we obtain an expression for determining the piston acceleration:

S - piston stroke (404 mm);

S x - piston path;

Angle of rotation of the crankshaft;

The angle of deviation of the connecting rod axis from the axis of the cylinder;

R - crank radius

Connecting rod length = 980 mm;

l is the ratio of the radius of the crank to the length of the connecting rod;

u - angular speed of rotation of the crankshaft.

Dynamic calculation of KShM

The dynamic calculation of the crank mechanism is performed in order to determine the total forces and moments arising from the pressure of gases and from the forces of inertia. The results of dynamic analysis are used in the calculation of engine parts for strength and wear.

During each working cycle, the forces acting in the crank mechanism continuously change in magnitude and direction. Therefore, for the nature of the change in forces along the angle of rotation of the crankshaft, their values are determined for a number of different positions of the shaft every 15 degrees of PKV.

When constructing a force diagram, the initial is the specific total force acting on the finger - this is the algebraic sum of the gas pressure forces acting on the piston bottom and the specific inertia forces of the masses of parts moving reciprocating.

The values of gas pressure in the cylinder are determined from the indicator diagram, built on the basis of the results of thermal calculation.

Figure 5.1 - two-mass circuit of the crankshaft

Bringing the masses of the crank

To simplify the dynamic calculation, let's replace the real KShM with a dynamically equivalent system of concentrated masses and (Figure 5.1).

makes a reciprocating motion

where is the mass of the piston set, ;

Part of the mass of the connecting rod group, referred to the center of the upper head of the connecting rod and moving reciprocating with the piston,

makes a rotational movement

where - part of the mass of the connecting rod group, referred to the center of the lower (crank) head and moving rotationally along with the center of the connecting rod journal of the crankshaft

Unbalanced part of the crankshaft crank,

wherein:

where is the density of the material of the crankshaft,

crank pin diameter,

crank pin length,

The geometric dimensions of the cheek. To facilitate calculations, let's take the cheek as a parallelepiped with dimensions: cheek length, width, thickness

Forces and moments acting on the crank

Specific force inertia of KShM parts moving reciprocating are determined from the dependence:

We enter the obtained data with a step in table 5.1.

These forces act along the axis of the cylinder and, like the forces of gas pressure, are considered positive if directed towards the axis of the crankshaft, and negative if directed away from the crankshaft.

Figure 5.2. Scheme of forces and moments acting on the crankshaft

Gas pressure forces

The forces of gas pressure in the engine cylinder, depending on the piston stroke, are determined by the indicator diagram, built according to the thermal calculation data.

The force of gas pressure on the piston acts along the axis of the cylinder:

where is the gas pressure in the engine cylinder, determined for the corresponding position of the piston according to the indicator diagram obtained when performing a thermal calculation; to transfer the diagram from coordinates to coordinates, we use the Brix method.

To do this, we build an auxiliary semicircle. The point corresponds to its geometric center, the point is shifted by a value (Brix correction). Along the y-axis towards BDC. The segment corresponds to the difference in displacements that the piston makes during the first and second quarter of the crankshaft turn.

Having drawn From the points of intersection of the ordinate with the indicator diagram lines parallel to the abscissa axis to the intersection with the ordinates at the angle, we obtain a point of magnitude in coordinates (see diagram 5.1).

crankcase pressure;

Piston area.

The results are entered in table 5.1.

Total Strength:

The total force is the algebraic sum of the forces acting in the direction of the axis of the cylinder:

Force perpendicular to the axis of the cylinder.

This force creates lateral pressure on the cylinder wall.

The angle of inclination of the connecting rod relative to the axis of the cylinder,

Force acting along the axis of the connecting rod

Force acting along the crank:

Torque force:

Torque per cylinder:

We calculate the forces and moments acting in the crankshaft every 15 turns of the crank. The results of the calculations are entered in table 5.1

Construction of a polar diagram of forces acting on the crankpin

We build a coordinate system and with the center at point 0, in which the negative axis is directed upwards.

In the table of dynamic calculation results, each value b=0, 15°, 30°…720° corresponds to a point with coordinates. Let's put these points on the plane. Consistently connecting the points, we get a polar diagram. A vector connecting the center to any point on the diagram indicates the direction of the vector and its magnitude in the appropriate scale.

We build a new center spaced from along the axis by the value of the specific centrifugal force from the rotating mass of the lower part of the connecting rod. In this center, a connecting rod neck with a diameter is conditionally located.

The vector connecting the center with any point of the constructed diagram indicates the direction of the force on the surface of the crankpin and its magnitude in the appropriate scale.

To determine the average resulting per cycle, as well as its maximum and minimum values, the polar diagrams are rebuilt into a rectangular coordinate system as a function of the angle of rotation of the crankshaft. To do this, on the abscissa axis, for each position of the crankshaft, we plot the angles of rotation of the crank, and on the ordinate axis, the values taken from the polar diagram in the form of projections onto the vertical axis. When plotting a chart, all values are considered positive.

motor thermal strength index

When the engine is running in the crankshaft of each cylinder, the following forces act: gas pressure on the piston P, masses of the translationally moving parts of the crankshaftG , inertia of translationally moving partsP And and friction in crankshaft R T .

Friction forces are not amenable to precise calculation; they are considered included in the propeller drag and are not taken into account. Therefore, in the general case, the driving force acts on the pistonP d = P + G +P And .

Forces related to 1 m 2 piston area,

driving forceR d attached to the center of the piston pin (crosshead pin) and directed along the axis of the cylinder (Fig. 216). On the piston pinP d breaks down into components:

R n - normal pressure acting perpendicular to the axis of the cylinder and pressing the piston to the sleeve;

R sh - the force acting along the axis of the connecting rod and transmitted to the axis of the neck of the crank, where it, in turn, is decomposed into componentsR ? AndR R (Fig. 216).

An effortR ? acts perpendicular to the crank, causes its rotation and is called tangent. An effortR R acts along the crank and is called radial. From geometric relations we have:

Numerical value and sign of trigonometric quantities

for engines with different constant crankshafts? =R /L can be taken according to

size and signR d determined from the diagram of driving forces, representing a graphical representation of the law of change in driving force per revolution of the crankshaft for two-stroke engines and two revolutions for four-stroke engines, depending on the angle of rotation of the crankshaft. To get the value of the driving force, you must first build the following three diagrams.

1. Diagram of the change in pressure p in the cylinder depending on the angle of rotation of the crank?. According to the calculation of the engine working process, a theoretical indicator diagram is built, according to which the pressure in the cylinder p is determined depending on its volume V. In order to rebuild the indicator diagram from the coordinates pV to the coordinates p-? (pressure - shaft angle), lines c. m. t. and n. m. t. should be extended down and draw a straight line AB parallel to the axis V (Fig. 217). Segment AB is divided by a pointABOUT in half and from this point the radius AO describes a circle. From the center of the circle pointABOUT towards n. mt lay cutOO " = 1 / 2 R 2 / L Brix correction. Because

The value of the constant KShM? = R / L is accepted according to experimental data. To obtain the correction value OO", on the scale of the diagram, the value of the segment AO is substituted for R in the formula OO" = 1/2 ?R. From the point O ", which is called the Brix pole, a second circle is described with an arbitrary radius and divided into any number of equal parts (usually every 15 °). From the Brix poleABOUT "Rays are drawn through the division points. From the points of intersection of the rays with a circle of radius AO, straight lines parallel to the p axis are drawn upwards. Then, in the free space of the drawing, the coordinates of gas pressure are built using a gas pressure meterR - angle of rotation of the crank? °; taking the line of atmospheric pressure as the reference point, the values of the ordinates of the filling and expansion processes are taken from the p-V diagram for angles 0°, 15°, 30°, ..., 180° and 360°, 375°, 390°, ..., 540 °, transfer them to the coordinates for the same angles and connect the obtained points with a smooth curve. Similarly, the compression and exhaust sections are built, but in this case the Brix correctionOO "set aside on a segmentAB aside in. m. t. As a result of these constructions, a detailed indicator diagram is obtained (Fig. 218,A ), which can be used to determine the pressure of gasesR on the piston for any angle? crank rotation. The pressure scale of the expanded diagram will be the same as in the diagram in p-V coordinates. When constructing the diagram p = f(?), the forces that contribute to the movement of the piston are considered positive, and the forces that prevent this movement are negative.

2. Diagram of the mass forces of the reciprocating-moving parts of the crankshaft. In trunk internal combustion engines, the mass of translationally moving parts includes the mass of the piston and part of the mass of the connecting rod. The crossheads additionally include the masses of the rod and slider. The mass of the parts can be calculated if there are drawings with the dimensions of these parts. The part of the mass of the connecting rod that performs reciprocating motion,G 1 = G sh l 1 / l , WhereG sh - weight of connecting rod, kg; l - connecting rod length, m; l 1 - distance from the center of gravity of the connecting rod to the axis of the crank pin,m :

For preliminary calculations, the specific values of the mass of translationally moving parts can be taken: 1) for trunk-mounted high-speed four-stroke engines 300-800 kg/m 2 and low-speed 1000-3000 kg/m 2 ; 2) for trunk-mounted high-speed two-stroke engines 400-1000 kg/m 2 and low-speed 1000-2500 kg/m 2 ; 3) for crosshead high-speed four-stroke engines 3500-5000 kg/m 2 and low-speed 5000-8000 kg/m 2 ;

4) for crosshead high-speed two-stroke engines 2000-3000 kg/m 2 and low-speed 9000-10 000 kg/m 2 . Since the magnitude of the mass of the translationally moving parts of the crankshaft and their direction do not depend on the angle of rotation of the crank?, then the mass force diagram will have the form shown in Fig. 218,b . This diagram is built on the same scale as the previous one. In those parts of the diagram where the force of the mass contributes to the movement of the piston, it is considered positive, and where it interferes, it is negative.

3. Diagram of the forces of inertia of translationally moving parts. It is known that the force of inertia of a translationally moving bodyR And =Ga n (G - body mass, kg; a - acceleration, m / s 2 ). The mass of translationally moving parts of the KShM, referred to 1 m 2 piston area, m = G / F. The acceleration of this mass is determined byformula (172). Thus, the inertia force of the translationally moving parts of the KShM, referred to 1 m 2 piston area, can be determined for any angle of rotation of the crank by the formula

P calculation And for different? it is advisable to produce in tabular form. According to the table, a diagram of the inertial forces of the translationally moving parts is built on the same scale as the previous ones. The nature of the curveP And = f (?) is given in fig. 218,V . At the beginning of each piston stroke, inertia forces prevent its movement. Therefore, the forces R And have a negative sign. At the end of each stroke of the inertial force P And contribute to this movement and therefore acquire a positive sign.

The forces of inertia can also be determined graphically. To do this, take the segment AB, the length of which corresponds to the piston stroke on the scale of the abscissa axis (Fig. 219) of the expanded indicator diagram. From point A downward along the perpendicular, a segment AC is plotted on the scale of the ordinates of the indicator diagram, expressing the force of inertia of the translationally moving parts in c. m.t. (? = 0), equal toP i(w.m.t) = G / F R ? 2 (1 + ?). On the same scale, from point B, a segment of the VD is laid off - the force of inertia in n. m. t. (? \u003d 180 °), equal to P i(n.m.t) = - G / F R ? 2 (1 - ?). Points C and D are connected by a straight line. From the point of intersection of SD and AB, on the scale of ordinates, a segment EK equal to 3?G/A R? 2 . Point K is connected by straight lines to points C and D, and the resulting segments KS and KD are divided into the same number of equal parts, but not less than five. Dividing points are numbered in one direction and connected with the same name by straight lines.1-1 , 2-2 , 3-3 and so on through the points C andD and the points of intersection of the straight lines connecting the same numbers draw a smooth curve expressing the law of change in the forces of inertia during the downward movement of the piston. For the area corresponding to the movement of the piston to v. m.t., the inertia force curve will be a mirror image of the constructed one.

Driving force diagramP d = f (?) is constructed by algebraically summing the ordinates of the corresponding angles of the diagrams

When summing the ordinates of these three diagrams, the above rule of signs is preserved. According to the chartR d = f (?) It is possible to determine the driving force, referred to 1 m 2 piston area for any crank angle.

Force acting on 1 m 2 piston area, will be equal to the corresponding ordinate on the driving force diagram, multiplied by the ordinate scale. The total force driving the piston

where p d - driving force, referred to 1 m 2 piston area, n/m 2 ; D - diameter of the cylinder, m.

Using formulas (173), using the diagram of driving forces, one can determine the values of the normal pressure p n strengthR sh , tangential force P ? and radial forceP R at different positions of the crank. Graphical expression of the law of change of force P ? depending on the angle? crank rotation is called the shear force diagram. Calculation of valuesR ? for different? produced using a diagramP d = f : (?) and formula (173).

According to the calculation data, a diagram of tangential forces is built for one cylinder of a two-stroke (Fig. 220, a) and four-stroke engines (Fig. 220.6). Positive values are plotted up from the x-axis, negative values are plotted down. The tangential force is considered positive if it is directed in the direction of rotation of the crankshaft, and negative if it is directed against the rotation of the crankshaft. area chartR ? = f (?) Expresses on a certain scale the work of the tangential force in one cycle. Tangential forces for any angle? shaft rotation can be determined in the following simple way. Describe two circles - one with the radius of the crankR and the second auxiliary - with a radius? R (Fig. 221). Spend for a given angle? radius OA and extend it to the intersection with the auxiliary circle at point B. Build? From point A, the magnitude of the driving force P is plotted on the selected scale d for this?; then the segment ED, drawn perpendicular to the axis of the cylinder to the intersection with the straight lineAD , parallelSO , and will be the desired P ? for selected?.

Change in tangential force?R ? engine can be represented as a summary diagram of tangential forces?R ? = f (?). To build it, you need so many diagrams P ? = f (?), how many cylinders does the engine have, but shifted one relative to the other by an angle? vsp turning the crank between two subsequent flashes (Fig. 222,a-c ). By algebraically adding the ordinates of all diagrams at the corresponding angles, the total ordinates are obtained for various positions of the crank. Connecting their ends, get a diagram?P ? = f (?). The diagram of the total tangential forces for a two-cylinder two-stroke engine is shown in fig. 222, c. Similarly, a diagram is constructed for a multi-cylinder four-stroke engine.

Chart?R ? = f (?) can also be constructed analytically, having only one diagram of tangential forces for one cylinder. To do this, you need to split the diagramR ? = f (?) on plots every? vsp degrees. Each section is divided into the same number of equal segments and numbered, Fig. 223 (for four-strokez = 4). Curve ordinatesR ? = f (?) corresponding to the same point numbers are summed algebraically, as a result of which the ordinates of the total shear force curve are obtained.

To a chart?R ? = f (?) inflict the average value of the tangential force P ? cp . To determine the average ordinate P ? cp the total diagram of tangential forces on the scale of the drawing is the area between the curve and the abscissa axis in the length section? vsp divide by the length of this section of the diagram. If the curve of the total diagram of tangential forces intersects the abscissa axis, then to determine P ? Wed you need to divide the algebraic sum of the area between the curve and the x-axis by the length of the plot of the diagram. Plotting on the diagram the value of P ? Wed up from the x-axis, get a new axis. Sections between the curve and this axis, located above the line P ? , express positive work, and under the axis - negative. Between P ? Wed and the resistance force of the driven unit must be equal.

You can set dependency R ? Wed from the average indicator pressureR i : for two-stroke engine P ? cp =p i z/? and for a four-stroke engine P ? cp =p i z/2? (z is the number of cylinders). By P ? cp determine the average torque on the motor shaft

where D is the diameter of the cylinder, m; R - crank radius, m.