Design description

A diesel engine is a reciprocating piston engine with the same basic design and duty cycle as a gasoline engine. The main difference between a diesel engine and a gasoline engine is the fuel used and the way the fuel is ignited to burn it.

Job

Diesel engines use the heat of compression to ignite the air/fuel mixture in the combustion chamber. This ignition is performed using high compression pressure and diesel fuel injected into the combustion chamber at very high pressure. The combination of diesel fuel and high compression pressure provides self-ignition to start the combustion cycle.

Cylinder block

The cylinder blocks of diesel and gasoline engines are similar to each other, but there are some differences in their design. Most diesel engines use cylinder liners rather than cylinders built as part of the block. By using cylinder liners, repairs can be made to allow the engine to operate for a long time. On those diesel engines that do not use cylinder liners, the cylinder walls are thicker than those on a gasoline engine with the same displacement. To increase the bearing surface of the crankshaft, diesel engines have heavier and thicker main bridges.

Wet cylinder liners

Wet cylinder liners used in diesel engines are similar to those used in gasoline engines. The physical dimensions of the liners may vary to suit the operating conditions of the diesel engine.

Crankshaft

The crankshaft used in diesel engines has a similar design to the crankshaft on gasoline engines, but with two differences:

Diesel engine crankshafts are usually forged rather than cast. Forging makes the crankshaft more durable.

. Diesel engine crankshaft journals are usually larger than gasoline engine crankshaft journals.

The increase in necks allows the crankshaft to withstand heavy loads.

connecting rods

Connecting rods used in diesel engines are usually made from forged steel. Diesel engine connecting rods differ from gasoline engine connecting rods in that the caps are offset and have fine teeth on the connecting rod mating surface. Offset design with fine teeth helps keep the cap in place and reduces load on the connecting rod bolts.

Pistons and piston rings

The pistons used in light duty diesel engines look similar to the pistons used in gasoline engines. Diesel pistons are heavier than gasoline engine pistons because diesel pistons are usually made from forged steel rather than aluminum and the material is thicker internally.

The compression rings used in diesel engines are usually made of cast iron and are often plated with chromium and molybdenum to reduce friction.

cylinder head

Externally, the cylinder head of a diesel engine looks in many ways similar to the cylinder head of a gasoline engine. But there are many internal design differences that make diesel engines different, original.

On a diesel engine, the cylinder head itself must be much stronger and heavier to withstand the high heat and pressure loads. The design of the combustion chamber and air passages on diesel engines can be more complex than on a gasoline engine.

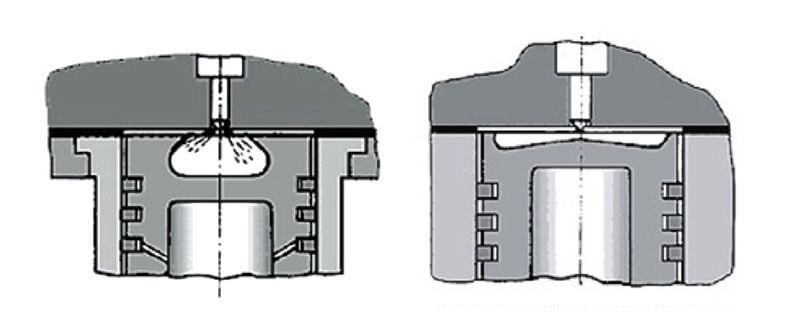

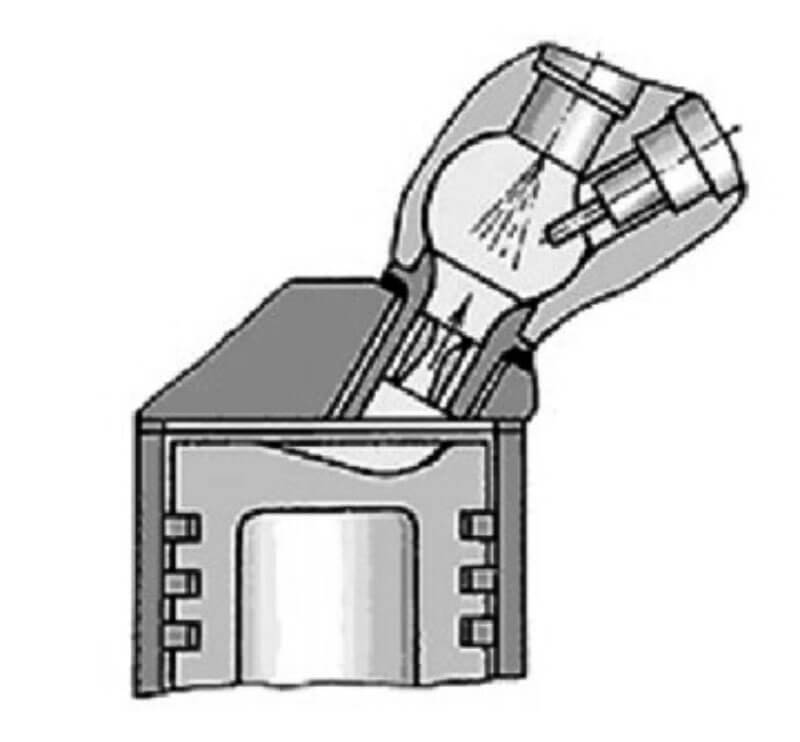

Several designs of combustion chambers are used in diesel engines, but two designs are most common: the undivided combustion chamber and the swirl chamber.

Undivided combustion chamber design

The most common type of combustion chamber for a diesel engine is the undivided chamber, also known as direct injection combustion chamber. In an undivided design, the provision of turbulence (swirl) of the intake air occurs due to the shape of the air intake channel. Fuel is injected directly into the combustion chamber.

Swirl chamber design

The swirl chamber design uses two combustion chambers for each cylinder. The main chamber is connected by a narrow channel to a smaller vortex chamber. The vortex chamber houses the fuel injector. The vortex chamber is intended to ensure the start of the combustion process. The intake air is introduced into the swirl chamber through a narrow channel. Fuel is then injected into the swirl chamber and the resulting mixture ignites. After that, the burning mixture enters the main combustion chamber, where it ends its combustion, forcing the piston to move down.

Valves and valve seats

Diesel engine valves are made from special alloys that are able to perform well under the high heat and pressure conditions of a diesel engine. Some valves are partially filled with sodium, which helps to remove heat. A large percentage of the heat is transferred from the valve head to the valve seat. To ensure adequate heat transfer, special attention must be paid to the width of the valve seat.

A wide valve seat has the advantage of being able to transfer more heat. However, a wide valve seat also has a greater potential for carbon deposits to accumulate, which can cause leakage in the valve. A narrow valve seat provides a better seal than a wide valve seat, but does not transfer the same amount of heat. In a diesel engine, a compromise must be made between wide and narrow valve seats.

Diesel engines often use valve seat inserts. The inserts have the advantage of being replaceable. Valve seat inserts are made from special metal alloys that withstand the heat and pressure of a diesel engine.

Fuel supply system

Conventional design

In a conventional diesel fuel supply system, fuel is drawn from the fuel tank, filtered, and fed to a high pressure pump. High pressure fuel is brought to the required pressure and fed to the fuel manifold, which feeds the fuel injectors. The injection control system activates the injectors at the appropriate times, which, during the compression stroke of the piston, inject fuel for its subsequent combustion.

Common rail design

Common rail diesel engines use independent fuel pressure generation and fuel injection systems. The high pressure fuel pump draws fuel from the tank and delivers it through the pressure regulator to the common fuel rail. The high pressure pump consists of a low pressure transfer pump and a high pressure chamber. Fuel injection is controlled by the powertrain control module (PCM) and the injector control module (IDM), which regulates the length of time the injectors are open based on engine operating conditions.

The common rail design significantly reduces exhaust emissions and minimizes operating noise. All this is a consequence of greater control of the combustion process. Fuel pressure adjustment and injector operation phases are controlled by UM and PCM. The design of the injector has also been changed, which now allows pre-injection (pre-injection) and post-injection (post-injection) fuel injection at various stages of the compression stroke and power stroke.

Improved fuel management results in cleaner, more consistent combustion and in-cylinder pressure. This has the effect of reducing exhaust toxicity and noise during operation.

Lubrication system

The lubrication system used in diesel engines is similar in principle to gasoline engine systems. Most diesel engines have some type of oil cooler to help remove heat from the oil. The oil flows under pressure through the channels of the engine and returns to the crankcase.

The lubricating oil used in diesel engines is different from the oil used in gasoline engines. The special oil is necessary because diesel engines tend to contaminate the oil more than gasoline engines. The high carbon content of diesel fuel causes the oil used in diesel engines to change color shortly after being used. Only engine oil that is specifically designed for diesel engines should be used.

Cooling system

The diesel engine cooling system usually has a larger capacity than the gasoline engine cooling system. The temperature inside a diesel engine must be carefully controlled because heat is used to ignite the fuel.

If the engine temperature is too low, the following problems occur:

Increased wear

. Poor fuel economy

. Accumulation of water and sludge in the engine crankcase

. Loss of power

If the engine temperature is too high, the following problems occur:

Increased wear

. badass

. Detonation

. Burning pistons and valves

. Lubrication problems

. Jamming of moving parts

. Loss of power

fuel injection system

The diesel engine works on the principle of self-ignition. The intake air and fuel are compressed so strongly in the combustion chamber that the molecules heat up and ignite without the aid of an external ignition spark. The compression ratio of a diesel engine is much higher than the compression ratio of a gasoline engine. The compression ratio in diesel engines with direct air intake is approximately 22:1. Turbodiesel engines have a compression ratio in the range of 16.5-18.5:1. Compression pressure is built up and the air temperature rises from approximately 500°C to 800°C (932°F to 1472°F).

Diesel engines can only be operated with a fuel injection system. Mixing occurs only in the phase of injection and combustion of the fuel.

At the end of the compression stroke, fuel is injected into the combustion chamber where it mixes with hot air and ignites. The quality of this combustion process depends on the quality of mixture formation. Because the fuel is injected so late it doesn't have much time to mix with the air. In a diesel engine, the air-fuel ratio is constantly maintained at a level greater than 17:1, thus ensuring that all fuel is burned. For more detailed information, refer to the publication "Operation of the engine and its systems".

date: 14.03.2018The principle of operation of a diesel engine is completely different than that of a gasoline-powered engine. This explains the principle of its nutrition. In a nutshell, the operation of a diesel engine is based on the ignition of the fuel mixture from strong compression, since high temperature causes it to ignite.

Repair of diesel engines is not so difficult if you know how it works and what the diesel engine is based on.

Diesel Engine System Operation Procedure

First, the cylinders of a diesel engine are filled with air. The pistons in them move upwards, creating a very high pressure, from compression the air will heat up to the point that the diesel fuel, being mixed with it, will ignite.

The temperature reaches its maximum value when the piston finishes its upward movement, then diesel fuel is injected through the nozzle, it does not deliver it in a stream, but sprays it. Further, due to the high degree of heating of the compressed air, the air-combustible mixture explodes. The pressure from the explosion reaches a critical point and forces the piston down. In the language of physics, work is being done.

The diesel engine system is designed in such a way that it supplies fuel to the engine, while simultaneously providing several other functions.

Parts of the diesel engine system, its mechanism of action

Diesel consists of:

- fuel tank,

- diesel fuel pump,

- filters,

- fuel pump, which delivers fuel at high pressure,

- glow plugs

- the main part of the engine, which is the nozzle.

The booster pump is responsible for taking diesel fuel from the tank and sending it to the fuel pump, and this pump itself for supplying fuel under pressure consists of several sections (there are as many of them as an internal combustion engine engine has cylinders - one section is responsible for servicing one cylinder).

The device of the pump for supplying fuel under the influence of pressure is as follows: inside it, along the bottom, there is a shaft with cams in its entire length, which rotates from the engine camshaft. The cams act on the pushers, causing the plunger (piston) to function. Rising, the plunger contributes to the pressure of the fuel in the cylinder. Thus, the fuel is pushed out by means of the injection pump into the main working part of the engine, which is the nozzle.

The diesel fuel entering the line needs pressure to move to the nozzle to spray through it. For this, a piston is needed - it captures the fuel at the bottom and advances it to the sectional top. Coming under pressure - fuel can already be qualitatively sprayed in the combustion chamber. In this pump, the pressure force reaches 2000 atmospheres.

One of the functions of the plunger is to control the amount of diesel fuel supplied to the nozzle with its moving part, which opens and closes the channels inside it, this part is connected to the pedal responsible for supplying gas in the car. How open the fuel supply channels and its volume is due to the angle at which the piston is rotated. Its rotation is carried out by a rail connected to the gas pedal.

At the top of the pump that supplies fuel under pressure is a valve, it is designed to open under pressure and slam shut if it is low. Thus, when the piston is down, the valve is in the slammed position, and fuel from the hose to which the nozzle is connected cannot enter the pump. The pressure generated in the section is sufficient to inject fuel into the cylinder, then the fuel is delivered through the hose to the nozzle, and it sprays it into the cylinder.

Nozzle - purpose and types

Very often, the repair of diesel engines is associated with the diagnosis of the operation of injectors and their repair or replacement.

They are of two types:

- mechanically controlled

- electromagnetic

In mechanically controlled ones, the hole that sprays the fuel opens depending on the pressure in the hose. Its hole is closed by a needle connected to a piston at the top of the nozzle. Until there is pressure, the needle does not allow fuel to exit through the atomizer. When the fuel enters under pressure, the plunger rises and pulls the needle. The nozzle holes open and fuel is sprayed into the cylinder.

It contains glow plugs that ignite fuel with air. They heat the air in a specialized compartment before it enters the cylinder. In fact, candles only make it easier to start the ICE engine, since the air is already at a sufficient temperature before it enters the cylinder. That is why, when it is warm outside, or if the engine has not yet cooled down after the ignition is turned off, it starts without the participation of candles, and when it is cold, this is impossible.

A diesel engine equipped with electromagnetic injectors is a more modern version. In this case, the pump supplying fuel does not have its own section for each cylinder, and the hose is one for all nozzles, and provides the necessary pressure and fuel injection immediately into all nozzles of the internal combustion engine cylinders.

With this ICE system, the injectors are affected by electrical impulses from the vehicle control unit: their valves, which open and close the fuel injection outlets, are electromagnetic. The engine control unit itself reads information from special sensors, and then gives a command to the electromagnetic control of the injectors.

Such a system for supplying fuel to a diesel engine is also much more economical.

Injectors began to be used in the production of engines as early as the thirties of the XX century, they were first installed on aircraft engines, then they began to be used in racing car engines. And they received mass application in the automotive industry only in the seventies and eighties of the last century. This was caused by the fuel crisis and awareness of the need to conserve nature: in order to make cars more powerful, the air-fuel mixture was specially enriched, but this led to an increase in fuel consumption and an excess of combustion products in the gas exhaust of cars. And in 1967, the problem was solved - then the electromagnetic nozzle was invented, in which the injection is carried out by an electronic command. Without a doubt, electronics is always better than mechanics, because it has a lot of obvious advantages over it.

Consider the history of creation, the principle of operation of a diesel engine, try to understand the reasons for its popularity, its design features, advantages, disadvantages and scope.

Rudolf Diesel assembled his brainchild in 1897. It was a smoothly running, extremely simple, easy-to-operate mechanism.

The technical documentation for the invention fit on 13 pages - Rudolf Diesel drew and described the engine on them, which was then named after him.

Thus began a story that has now resulted in millions of diesel-powered trucks, cars and ships.

Working principle of diesel engine

And yet, what is the principle of operation of a diesel engine? The principle of operation of a diesel engine is the compression ignition of fuel in the combustion chamber when mixed with a heated air mixture.

The mixture is supplied separately - first air is injected, then the piston compresses it and at top dead center fuel is injected through the nozzle

Air, in the process of compression, is heated to 800ºС, fuel is supplied with a pressure of up to 30 MPa, self-ignition occurs.

This process is accompanied by vibrations and noise. That is, a diesel engine is noisier than a gasoline engine.

The principle of operation of a diesel engine allows engines to be both two-stroke and four-stroke, but the majority of cars, nevertheless, are equipped with four-stroke engines.

In a two-stroke diesel engine, compared to a four-stroke one, due to a different principle of operation, the combination of two cycles, intake and exhaust (purge).

The two-stroke version is about one and a half times more powerful than the four-stroke version of the same size.

Diesel engine design

A diesel engine is almost the same as a gasoline engine - it only does not have an ignition system, and the principle of operation of a diesel engine is to ignite the fuel mixture not from a spark plug, but from air heated by high pressure.

True, high pressure (up to 30 atm.) in the combustion chamber implies increased requirements for details.

According to the design of the combustion chambers, diesel engines are divided into 3 types:

- Divided vortex combustion chamber;

- Undivided combustion chamber;

- Divided prechamber.

In such a device, the fuel mixture is supplied not to the main, but to an additional vortex chamber.

It is located in the cylinder head and is connected to the cylinder through a special channel. Ignition occurs in the vortex chamber and spreads to the main chamber.

Undivided combustion chamber

With this design, the chamber is located in the piston, and the fuel mixture enters the cavity above the piston.

This version of the chamber allows you to reduce fuel consumption, but increases the noise level during engine operation.

Divided prechamber

The diesel engine is equipped with a plug-in prechamber, it is connected to the cylinder by channels of small cross section.

The size and shape of the channels affect the speed of movement of gases during the combustion of fuel, while reducing noise and toxicity, increasing the resource.

Any diesel engine has a special fuel system. The high-pressure system delivers the right amount of fuel mixture to the cylinders. Let's look at its elements.

The main elements of the fuel system

- high pressure fuel pump ();

- fuel filter;

injection pump

Pump supplies fuel to the injectors in an amount that depends on the speed, the position of the regulator lever and the turbo boost pressure indicators.

In modern diesel engines, two systems of fuel pumps are used - in-line (plunger) or distribution. More about pumps.

Several other pumps are used in a modern injection system, they are called main.

In the Common Rail system, the injection pump pumps fuel into the rail, where pressure is maintained in all channels up to the injectors.

Special nozzles are electronically controlled and open at the right time to inject fuel into the combustion chamber. You can read about this system.

Fuel filter

The filter is set based on the engine model. Its function is to separate and remove water from diesel fuel and excess air from the system.

nozzles

To supply the fuel mixture to the combustion chambers, two types of nozzles are used - with multi-hole and font distributors.

The nozzle distributor determines the shape of the flame required for a more efficient ignition process.

Preheating

For a cold start of a diesel engine, preheating is used. It is provided by glow plugs installed in the combustion chamber.

When starting, the glow plugs heat up to 900ºС, heating the air mixture that enters the chamber.

The heating system makes it possible to safely start even at the lowest temperatures.

Turbocharging

Turbocharging in diesel engines increases power and efficiency.

With an increase in air supply, an increased pressure in the cylinders is provided, respectively, the combustion of the mixture improves, thereby increasing engine power.

To obtain optimal boost pressure in all operating modes, a turbocharger (turbine) is used.

Diesel advantages and disadvantages

Advantages

The main advantage of a diesel engine is its high-torque power.. It is able to develop high power at low revs, easily tolerates overloads, sudden braking and starts.

The second plus is economy.. A liter of diesel costs a little less than a liter of high-octane gasoline, although fuel sellers shamelessly equate it with the most expensive gasoline.

The efficiency of a diesel engine at medium speeds reaches 45 percent, and with a turbocharger it goes up to 50, for a gasoline engine such figures are not realistic at all. In addition, diesel consumes less fuel.

The third plus is environmental friendliness. The diesel engine has lower toxicity of exhaust gases.

The next advantage is durability and reliability., since diesel fuel is also a lubricant that protects engine components from wear.

Flaws

As for the shortcomings, one of the most significant is poor frost resistance. Summer fuel becomes thick at minus 5°C, winter fuel at minus 35°C.

Repair of a diesel and gasoline engine is approximately equivalent in cost if the high-pressure fuel pump does not fail. In this case, the owner gets into serious money. And it breaks down from low-quality domestic diesel fuel. In turn, good imported fuel is already a slightly different price.

Diesel engine is good at low and medium speeds. The desire to squeeze the maximum speed out of it brings rapid wear of components and parts.

And a car in a diesel version can cost a third more than a gasoline counterpart.

The turbodiesel has its drawbacks - the resource of the turbocharger is less than the resource of the engine itself. Usually it is no more than 150,000 kilometers. In addition, the turbine makes high demands on the quality of engine oil.

Well, at the expense of the smell of exhaust from a diesel engine. Perhaps for someone this is not critical, but the smell is there, and at the same time quite unpleasant.

Areas of use

Diesel engines currently use:

- on heavy trucks;

- on stationary power plants;

- on cars and trucks;

- on diesel locomotives and ships;

- on agricultural, special and construction equipment.

Well, you have learned what a diesel engine is, how many big pluses and small minuses it has.

Now, knowing how a diesel engine works, you will think about what next car to buy:.

Just visit the site!

Long gone are the days when the diesel engine was considered in many respects a compromise "smaller brother" of gasoline engines in the civil car industry.

Due to the characteristics of diesel fuel, this type has a number of obvious advantages.

The strengths are so obvious that even domestic designers puzzled over the introduction of this technology.

Now such engines have Gazelle Next, UAZ Patriot. Moreover, there were attempts to install a diesel engine on the Niva. Unfortunately, the release was limited to small export lots.

Positive factors have allowed the diesel engine to gain popularity in each of the automotive segments. We are talking about a four-stroke configuration, since a two-stroke diesel engine has not been widely used.

Design

The principle of operation of a diesel engine is to convert the reciprocating movements of the crank mechanism into mechanical work.

The way the fuel mixture is prepared and ignited is what distinguishes a diesel engine from a gasoline engine. In the combustion chambers of gasoline engines, a pre-prepared fuel-air mixture is ignited by a spark supplied by a spark plug.

A feature of a diesel engine is that the mixture formation occurs directly in the combustion chamber. The working cycle is carried out by injecting a dosed portion of fuel under enormous pressure. At the end of the compression stroke, the reaction of heated air with diesel fuel ignites the working mixture.

The two-stroke diesel engine has a narrower scope.

The use of single-cylinder and multi-cylinder diesel engines of this type has a number of design disadvantages:

- inefficient cylinder scavenging;

- increased oil consumption during active use;

- the occurrence of piston rings in high-temperature operation, and others.

A two-stroke diesel engine with an opposite piston arrangement has a high initial cost and is very difficult to maintain. The installation of such a unit is advisable only on marine vessels. In such conditions, due to its small size, low weight and greater power at identical speeds and displacement, a two-stroke diesel engine is more preferable.

The single-cylinder internal combustion unit is widely used in the household as an electric generator, engine for walk-behind tractors and self-propelled chassis.

This type of energy production imposes certain conditions on the design of a diesel engine. It does not need a gasoline pump, spark plugs, ignition coil, high-voltage wires and other components that are vital for the normal operation of a gasoline engine.

The following are involved in the injection and supply of diesel fuel: a high-pressure fuel pump and nozzles. To facilitate cold starts, modern engines use glow plugs that preheat the air in the combustion chamber. Many vehicles have an auxiliary pump installed in the tank. The task of the low pressure fuel pump is to pump fuel from the tank to the fuel equipment.

Development ways

Diesel engine innovation lies in the evolution of fuel equipment. The efforts of the designers are aimed at achieving the exact moment of injection and maximum atomization of the fuel.

Diesel engine innovation lies in the evolution of fuel equipment. The efforts of the designers are aimed at achieving the exact moment of injection and maximum atomization of the fuel.

The creation of a fuel "fog" and the division of the injection process into phases made it possible to achieve greater efficiency and increase power.

The most archaic examples had a mechanical injection pump and a separate fuel line to each nozzle. The device of the engine and TA of this type had great reliability and maintainability.

The further development path was to complicate the injection pump of a diesel engine. It appeared variable injection timing, a variety of sensors and electronic process control. In this case, all the same mechanical nozzles were used. In this type of design, the injected fuel pressure was between 100 and 200 kg/cm².

The next step was the introduction of the Common rail system. A fuel rail appeared in the diesel engine, where pressure up to 2 thousand kg / cm² can be maintained. High pressure fuel pumps of such motors have become much simpler.

The main design difficulty lies in the injectors. It is with their help that the moment, pressure and number of injection stages are regulated. The injectors of the accumulator type system are very demanding on the quality of the fuel. The airing of such a system leads to a rapid failure of its main elements. Common rail diesel engine is quiet, consumes less fuel and has more power. You have to pay for all this with a smaller resource and a higher repair cost.

Even more high-tech is the system using pump-injectors. In TA of this type, the nozzle combines the functions of pressurizing and spraying fuel. The parameters of a diesel engine with unit injectors are an order of magnitude higher than analog systems. However, as well as the cost of maintenance and requirements for fuel quality.

The Importance of Turbines

Most modern diesel engines are equipped with turbines.

Turbocharging is an effective way to increase the performance of a car.

Due to the increased pressure of the exhaust gases, the use of turbines paired with a diesel engine significantly increases throttle response and reduces fuel consumption.

The turbine is far from the most reliable unit of the car. More than 150 thousand km, they often do not go. This is perhaps its only drawback.

Thanks to the electronic engine control unit (ECU), chip tuning is available for the diesel engine.

Advantages and disadvantages

There are a number of factors that distinguish diesel engines favorably:

- economy. An efficiency of 40% (up to 50% with turbocharging) is simply an unattainable indicator for a gasoline counterpart;

- power. Almost all of the torque is available at the lowest rpm. A turbocharged diesel engine does not have a pronounced turbo lag. Such throttle response allows you to get real pleasure from driving;

- reliability. The run of the most reliable diesel engines reaches 700 thousand km. And all this without tangible negative consequences. Due to their reliability, diesel internal combustion engines are put on special equipment and trucks;

- environmental friendliness. In the fight for the preservation of the environment, the diesel engine is superior to gasoline engines. Less CO emissions and the use of exhaust gas recirculation (EGR) technology bring minimal harm.

Flaws:

- price. A complete set equipped with a diesel engine will cost 10% more than the same model with a gasoline unit;

- complexity and cost of maintenance. ICE units are made of more durable materials. The complexity of the engine and fuel equipment requires high-quality materials, the latest technologies and great professionalism in their manufacture;

- poor heat dissipation. A high percentage of efficiency means that less energy is lost when the fuel is burned. In other words, less heat is generated. In the winter season, the operation of a diesel engine for short distances will adversely affect its resource.

Considered pluses and minuses do not always balance each other. Therefore, the question of which of the engines is better will always be. If you are going to become the owner of such a car, consider all the features of his choice. It is your power plant requirements that will be the factor that will decide which is better: a gasoline or diesel engine.

Is it worth buying

New diesel cars are the type of purchase that will bring only joy. By refueling the car with high-quality fuel and doing maintenance according to regulatory requirements, you will 100% not regret your purchase.

New diesel cars are the type of purchase that will bring only joy. By refueling the car with high-quality fuel and doing maintenance according to regulatory requirements, you will 100% not regret your purchase.

But it is worth considering the fact that diesel cars are an order of magnitude more expensive than their gasoline counterparts. You will be able to compensate for this difference and subsequently save only when you overcome a large mileage. Overpay in order to drive up to 10 thousand km per year. is simply not appropriate.

The situation with used cars is slightly different. Despite the fact that diesel engines have a large margin of safety, over time, complex fuel equipment requires increased attention. The prices for spare parts for a diesel engine over 10 years old are really depressing.

The cost of a high-pressure fuel pump for a budget B-class car aged 15 years can shock some motorists. The choice of a car with a mileage of over 150 thousand must be taken very seriously. Before buying, it is better to make a comprehensive diagnosis in a specialized service. Since the low quality of domestic diesel fuel has a very detrimental effect on the resource of a diesel engine.

In this case, the reputation of the manufacturer will help to decide which engine is better to give preference to. For example, the Mercedes-Benz OM602 model is considered to be one of the most reliable diesel engines in the world. Buying a car with a similar power unit will be a profitable investment for many years. Many manufacturers have similar "successful" models of power plants.

Myths and misconceptions

Despite the prevalence of diesel vehicles, there are still prejudices and misunderstandings among the people. “It rumbles, it doesn’t heat in the winter, but you won’t start it in a big frost, it doesn’t go in the summer, and if something breaks, you still need to look for a master who will repair everything for space money,” - approximately such words can sometimes be heard from “experienced” motorists. These are all echoes of the past!

- Thanks to modern technology, only the rumble of idling makes it possible to distinguish diesel engines from gasoline ones. In motion, when road noise increases, the difference is not noticeable.

- To improve starting and warming up in the cold season, modern cars use various auxiliary systems. Due to the growing popularity, the number of services specialized in diesel engine maintenance is constantly increasing.

- There is an opinion that an internal combustion engine running on a diesel engine is difficult to force. This is true if we are talking about modifications of the cylinder-piston group. At the same time, chip tuning a diesel engine is a good way to increase its power characteristics without compromising resource life.

It is worth remembering that the principle of operation of a diesel engine is entirely aimed at achieving efficiency and reliability. You should not demand sky-high dynamic performance from such internal combustion engines.

Symptoms and causes of malfunctions

- Poor starting of a diesel engine when cold, and after a long period of inactivity - means poorly functioning glow plugs, air in the system, a check valve bleeds fuel pressure, poor compression, a discharged battery;

- increased noise, increased consumption and black smoke from the exhaust pipe - means clogging or wear of atomizers and nozzles, incorrect injection advance angles, dirty air purification filter;

- loss of diesel engine power - means lack of compression, failure of the turbine, clogging of the fuel and air filters, incorrect injection timing, dirty USR valve;

- gray or white smoke from the exhaust, increased oil consumption - means a cracked cylinder head or a broken cylinder head gasket (coolant leaves, and an emulsion appears in the oil), a turbocharger malfunction.

Proper operation

Improper operation can destroy even the most reliable motor.

Improper operation can destroy even the most reliable motor.

To extend the life of a diesel engine, and enjoy the pleasure of owning a car, following simple rules will help you:

- turbocharged diesel engines are very demanding on the quality of oil and fuel. Fill in only the oil that meets the requirements established for your internal combustion engine. Refuel only at trusted gas stations;

- carry out preheating maintenance in accordance with the standards declared by the manufacturer. In this case, you will not have problems starting a diesel engine in the cold season. Operation of the unit with a malfunctioning nozzle can subsequently lead to costly repairs to the internal combustion engine;

- after active trips, the turbine needs to be cooled. Do not turn off the engine immediately. Let it run for a while at idle;

- avoid push start. This way of reviving the engine can cause great harm to the crank mechanism of your internal combustion engine.

Both types of engines have not only pluses, but also minuses. The main goal of a car is to meet your requirements, no matter if it is equipped with a gasoline or diesel engine. Which is best for you depends on individual preferences.

Modern innovative technologies and progressive marketing allow people to choose from the cars they can afford. We have to compromise and sacrifice individual parameters less and less. This trend is especially noticeable in the evolution of diesel cars.

The same year it was successfully tested. Diesel actively engaged in the sale of licenses for the new engine. Despite the high efficiency and ease of operation compared to a steam engine, the practical use of such an engine was limited: it was inferior to the steam engines of that time in terms of size and weight.

The first Diesel engines ran on vegetable oils or light petroleum products. Interestingly, he initially proposed coal dust as an ideal fuel. Experiments also showed the impossibility of using coal dust as a fuel - primarily because of the high abrasive properties of both the dust itself and the ash resulting from combustion; there were also big problems with the supply of dust to the cylinders.

Principle of operation

Four stroke cycle

- 1st measure. Inlet. Corresponds to 0° - 180° crankshaft rotation. Through the open ~345-355° inlet valve, air enters the cylinder, at 190-210° the valve closes. At least up to 10-15 ° of rotation of the crankshaft, the exhaust valve is simultaneously open, the time of joint opening of the valves is called valve overlap .

- 2nd beat. Compression. Corresponds to 180° - 360° crankshaft rotation. The piston, moving to the TDC (top dead center), compresses the air 16 (in low-speed) -25 (in high-speed) times.

- 3rd beat. Working stroke, extension. Corresponds to 360° - 540° crankshaft rotation. When fuel is sprayed into hot air, fuel combustion is initiated, that is, its partial evaporation, the formation of free radicals in the surface layers of drops and in vapors, and finally, it flares up and burns out as it comes from the nozzle, combustion products, expanding, move the piston down. The injection and, accordingly, the ignition of the fuel occurs a little earlier than the moment the piston reaches the dead center due to some inertia of the combustion process. The difference from ignition timing in gasoline engines is that the delay is necessary only because of the presence of the initiation time, which in each particular diesel engine is a constant value and cannot be changed during operation. Combustion of fuel in a diesel engine thus occurs for a long time, as long as the supply of a portion of fuel from the nozzle lasts. As a result, the working process proceeds at a relatively constant gas pressure, due to which the engine develops a large torque. Two important conclusions follow from this.

- 1. The combustion process in a diesel engine lasts exactly as long as it takes to inject a given portion of fuel, but not longer than the working stroke.

- 2. The fuel/air ratio in the diesel cylinder can differ significantly from the stoichiometric one, and it is very important to provide an excess of air, since the flame of the torch occupies a small part of the volume of the combustion chamber and the atmosphere in the chamber must provide the required oxygen content to the last. If this does not happen, there is a massive release of unburned hydrocarbons with soot - "the diesel locomotive" gives "bear".).

- 4th beat. Release. Corresponds to 540° - 720° crankshaft rotation. The piston goes up, through the exhaust valve open at 520-530 °, the piston pushes the exhaust gases out of the cylinder.

Depending on the design of the combustion chamber, there are several types of diesel engines:

- Diesel with undivided chamber: the combustion chamber is made in the piston, and the fuel is injected into the space above the piston. The main advantage is the minimum fuel consumption. The disadvantage is increased noise ("hard work"), especially at idle. Currently, intensive work is underway to eliminate this shortcoming. For example, a Common Rail system uses (often multi-stage) pre-injection to reduce harshness.

- Split chamber diesel: fuel is supplied to the additional chamber. In most diesel engines, such a chamber (it is called a vortex or prechamber) is connected to the cylinder by a special channel so that when compressed, the air entering this chamber swirls intensively. This contributes to good mixing of the injected fuel with air and more complete combustion of the fuel. Such a scheme has long been considered optimal for light diesel engines and has been widely used in passenger cars. However, due to the worse efficiency, the last two decades have been actively replacing such diesel engines with single-chamber engines and Common Rail fuel supply systems.

push cycle

Purge of a two-stroke diesel engine: at the bottom - purge windows, the exhaust valve at the top is open

In addition to the four-stroke cycle described above, a two-stroke cycle can be used in a diesel engine.

During the working stroke, the piston goes down, opening the outlet windows in the cylinder wall, exhaust gases exit through them, the inlet windows open at the same time or somewhat later, the cylinder is blown with fresh air from the blower - carried out purge combining the intake and exhaust strokes. When the piston rises, all windows close. From the moment the inlet windows close, compression begins. Just before reaching TDC, fuel is sprayed from the nozzle and lights up. An expansion occurs - the piston goes down and opens all the windows again, etc.

Scavenging is an inherent weak link in the two-stroke cycle. The purge time, in comparison with other cycles, is small and it is impossible to increase it, otherwise the efficiency of the stroke will decrease due to its shortening. In a four-stroke cycle, half of the cycle is allotted for the same processes. It is also impossible to completely separate the exhaust and fresh air charge, so some of the air is lost, going straight into the exhaust pipe. If the change of cycles is provided by the same piston, there is a problem associated with the symmetry of opening and closing windows. For better gas exchange, it is more advantageous to have an advance opening and closing of the exhaust windows. Then the exhaust, starting earlier, will provide a decrease in the pressure of the residual gases in the cylinder by the beginning of the purge. With the exhaust windows closed earlier and the inlet windows still open, the cylinder is recharged with air, and if the blower provides excess pressure, it becomes possible to pressurize.

Windows can be used both for exhaust gases and for fresh air intake; such a purge is called slot or window. If the exhaust gases are vented through a valve in the cylinder head and the windows are only used to let in fresh air, the purge is called valve-slot. There are engines where in each cylinder there are two counter-moving pistons; each piston controls its windows - one inlet, the other outlet (Fairbanks-Morse - Junkers - Koreyvo system: diesel engines of this system of the D100 family were used on diesel locomotives TE3, TE10, tank engines 4TPD, 5TD (F) (T-64), 6TD (T -80UD), 6TD-2 (T-84), in aviation - on Junkers bombers (Jumo 204, Jumo 205).

In a two-stroke engine, the working strokes occur twice as often as in a four-stroke one, but due to the presence of a purge, a two-stroke diesel engine is more powerful than a four-stroke one of the same volume by a maximum of 1.6-1.7 times.

At present, low-speed two-stroke diesel engines are widely used on large marine vessels with a direct (gearless) propeller drive. Due to the doubling of the number of strokes at the same speed, the two-stroke cycle is beneficial when it is impossible to increase the speed, in addition, a two-stroke diesel engine is technically easier to reverse; such low-speed diesel engines have a power of up to 100,000 hp.

Due to the fact that it is difficult to organize a purge of the vortex chamber (or prechamber) in a two-stroke cycle, two-stroke diesel engines are built only with undivided combustion chambers.

Design options

For medium and heavy two-stroke diesel engines, the use of composite pistons is typical, which uses a steel head and an duralumin skirt. The main purpose of this complication of the design is to reduce the total mass of the piston while maintaining the maximum possible heat resistance of the bottom. Oil-cooled liquid-cooled designs are very often used.

Four-stroke engines containing crossheads in the design are allocated to a separate group. In crosshead engines, the connecting rod is connected to the crosshead - a slider connected to the piston by a rod (rolling pin). The crosshead works along its guide - the crosshead, without exposure to elevated temperatures, completely eliminating the effect of lateral forces on the piston. This design is typical for large long-stroke marine engines, often double-acting, the piston stroke in them can reach 3 meters; trunk pistons of such dimensions would be overweight, trunks with such a friction area would significantly reduce the mechanical efficiency of a diesel engine.

Reversible motors

The combustion of the fuel injected into the diesel cylinder occurs as it is injected. This is why a diesel produces high torque at low revs, which makes a diesel-powered vehicle more responsive in motion than the same gasoline-powered vehicle. For this reason, and due to the higher efficiency, most trucks are currently equipped with diesel engines.. For example, in Russia in 2007, almost all trucks and buses were equipped with diesel engines (the final transition of this vehicle segment from gasoline engines to diesel engines was planned to be completed by 2009) . This is also an advantage in marine engines, as high torque at low rpm makes it easier to use the engine's power efficiently, and higher theoretical efficiency (see Carnot cycle) gives higher fuel efficiency.

Compared to gasoline engines, diesel engine exhaust typically has less carbon monoxide (CO), but now, with the introduction of catalytic converters on gasoline engines, this benefit is less noticeable. The main toxic gases that are present in the exhaust in noticeable quantities are hydrocarbons (HC or CH), oxides (oxides) of nitrogen (NOx) and soot (or its derivatives) in the form of black smoke. The most polluting vehicles in Russia are truck and bus diesels, which are often old and unregulated.

Another important safety aspect is that diesel fuel is non-volatile (i.e. does not evaporate easily) and thus diesel engines are much less likely to catch fire, especially since they do not use an ignition system. Together with high fuel efficiency, this led to the widespread use of diesel engines in tanks, since the risk of a fire in the engine compartment due to fuel leaks was reduced in everyday non-combat operation. The lower fire hazard of a diesel engine in combat conditions is a myth, since when penetrating armor, a projectile or its fragments have a temperature that is much higher than the flash point of diesel fuel vapors and can also quite easily set fire to the leaked fuel. The detonation of a mixture of diesel fuel vapors with air in a pierced fuel tank is comparable in its consequences to an explosion of ammunition, in particular, in T-34 tanks, it led to rupture of welds and knocking out of the upper frontal part of the armored hull. On the other hand, a diesel engine in tank building is inferior to a carburetor in terms of specific power, and therefore in some cases (high power with a small engine compartment) it may be more advantageous to use a carburetor power unit (although this is typical for too light combat units).

Of course, there are also disadvantages, among which is the characteristic knock of a diesel engine during its operation. However, they are noticed mainly by owners of cars with diesel engines, and are almost invisible to an outsider.

The obvious disadvantages of diesel engines are the need to use a high-power starter, turbidity and solidification (waxing) of summer diesel fuel at low temperatures, the complexity and higher cost of repairing fuel equipment, since high-pressure pumps are precision devices. Also, diesel engines are extremely sensitive to fuel contamination with mechanical particles and water. Repair of diesel engines, as a rule, is much more expensive than the repair of gasoline engines of a similar class. The liter capacity of diesel engines is also usually inferior to that of gasoline engines, although diesel engines have more even and higher torque in their displacement. The environmental performance of diesel engines was significantly inferior to gasoline engines until recently. On classic diesel engines with mechanically controlled injection, it is only possible to install oxidative exhaust gas converters operating at exhaust gas temperatures above 300 ° C, which oxidize only CO and CH to carbon dioxide (CO 2) and water that are harmless to humans. Also, these converters used to fail due to poisoning with sulfur compounds (the amount of sulfur compounds in exhaust gases directly depends on the amount of sulfur in diesel fuel) and the deposition of soot particles on the catalyst surface. The situation began to change only in recent years in connection with the introduction of diesel engines of the so-called Common rail system. In this type of diesel engines, fuel injection is carried out by electronically controlled nozzles. The supply of a control electrical impulse is carried out by an electronic control unit that receives signals from a set of sensors. The sensors monitor various engine parameters that affect the duration and timing of the fuel pulse. So, in terms of complexity, a modern - and as environmentally friendly as a gasoline - diesel engine is in no way inferior to its gasoline counterpart, and in a number of parameters (complexity) it significantly surpasses it. So, for example, if the fuel pressure in the injectors of a conventional diesel engine with mechanical injection is from 100 to 400 bar (approximately equivalent to "atmospheres"), then in the latest Common-rail systems it is in the range from 1000 to 2500 bar, which entails presents a lot of problems. Also, the catalytic system of modern transport diesel engines is much more complicated than gasoline engines, since the catalyst must be able to work in conditions of an unstable exhaust gas composition, and in some cases the introduction of the so-called “particulate filter” (DPF - particulate filter) is required. A "particulate filter" is a conventional catalytic converter-like structure installed between a diesel exhaust manifold and a catalyst in the exhaust stream. A high temperature develops in the particulate filter, at which soot particles can be oxidized by residual oxygen contained in the exhaust gases. However, part of the soot is not always oxidized and remains in the "particulate filter", so the control unit program periodically switches the engine to the "particulate filter cleaning" mode by the so-called "post-injection", that is, injection of additional fuel into the cylinders at the end of the combustion phase in order to raise the temperature of the gases, and, accordingly, clean the filter by burning the accumulated soot. The de facto standard in the design of transport diesel engines has become the presence of a turbocharger, and in recent years - and " intercooler" - a device that cools the air after turbocharger compression - so that after cooling to get a large mass air (oxygen) in the combustion chamber at the same capacity of the collectors, and The supercharger made it possible to raise the specific power characteristics of mass diesel engines, as it allows more air to pass through the cylinders during the working cycle.

Basically, the design of a diesel engine is similar to that of a gasoline engine. However, similar parts of a diesel engine are heavier and more resistant to high compression pressures that occur in a diesel engine, in particular, the hone on the surface of the cylinder mirror is rougher, but the hardness of the cylinder block walls is higher. Piston heads, however, are specially designed for the combustion characteristics of diesel engines and are almost always designed for higher compression ratios. In addition, the piston heads in a diesel engine are located above (for an automobile diesel engine) the upper plane of the cylinder block. In some cases - in older diesel engines - the piston heads contain a combustion chamber ("direct injection").

Applications

Diesel engines are used to drive stationary power plants, on rail (diesel locomotives, diesel locomotives, diesel trains, railcars) and trackless (cars, buses, trucks) vehicles, self-propelled machines and mechanisms (tractors, asphalt rollers, scrapers, etc.). ), as well as in shipbuilding as main and auxiliary engines.

Myths about diesel engines

Turbocharged diesel engine

- Diesel engine is too slow.

Modern turbocharged diesel engines are much more efficient than their predecessors, and sometimes outperform their naturally aspirated (non-turbocharged) gasoline counterparts of the same displacement. This is evidenced by the Audi R10 diesel prototype, which won the 24-hour race at Le Mans, and the new BMW engines, which are not inferior in power to naturally aspirated (non-turbocharged) gasoline engines and at the same time have huge torque.

- The diesel engine is too loud.

Loud engine operation indicates improper operation and possible malfunctions. In fact, some older direct-injection diesels do work quite hard. With the advent of high-pressure common-rail fuel systems, diesel engines have been able to significantly reduce noise, primarily by dividing one injection pulse into several (typically from 2 to 5 pulses).

- The diesel engine is much more economical.

The main economy is due to the higher efficiency of the diesel engine. On average, a modern diesel consumes up to 30% less fuel. The service life of a diesel engine is longer than a gasoline engine and can reach 400-600 thousand kilometers. Spare parts for diesel engines are somewhat more expensive, the cost of repairs is also higher, especially for fuel equipment. For the above reasons, the cost of operating a diesel engine is somewhat less than that of a gasoline engine. Savings compared to gasoline engines increase in proportion to power, which determines the popularity of diesel engines in commercial vehicles and heavy vehicles.

- A diesel engine cannot be converted to use cheaper gas as fuel.

From the first moments of the construction of diesel engines, a huge number of them were built and are being built, designed to work on gas of different composition. There are basically two ways to convert diesel engines to gas. The first method is that a lean gas-air mixture is supplied to the cylinders, compressed and ignited by a small pilot jet of diesel fuel. An engine operating in this way is called a gas-diesel engine. The second way is to convert a diesel engine with a reduction in the compression ratio, install an ignition system and, in fact, build a gas engine instead of a diesel engine based on it.

record holders

Largest/Most Powerful Diesel Engine

Configuration - 14 cylinders in line

Working volume - 25 480 liters

Cylinder diameter - 960 mm

Piston stroke - 2500 mm

Average effective pressure - 1.96 MPa (19.2 kgf / cm²)

Power - 108,920 hp at 102 rpm. (recoil per liter 4.3 hp)

Torque - 7 571 221 Nm

Fuel consumption - 13,724 liters per hour

Dry weight - 2300 tons

Dimensions - length 27 meters, height 13 meters

The largest diesel engine for a truck

MTU 20V400 designed for installation on a BelAZ-7561 mining dump truck.

Power - 3807 hp at 1800 rpm. (Specific fuel consumption at rated power 198 g/kW*h)

Torque - 15728 Nm

The largest / most powerful serial diesel engine for a serial passenger car

Audi 6.0 V12 TDI since 2008 it has been installed on the Audi Q7.

Configuration - 12 cylinders V-shaped, camber angle 60 degrees.

Working volume - 5934 cm³

Cylinder diameter - 83 mm

Stroke - 91.4 mm

Compression ratio - 16

Power - 500 hp at 3750 rpm. (return per liter - 84.3 hp)

Torque - 1000 Nm in the range of 1750-3250 rpm.