- an engine model developed and assembled by Avtodiesel OJSC (Yaroslavl Motor Plant). YaMZ 7511.10 from the family of eight-cylinder V-shaped four-stroke diesel engines is designed for use on the MZKT-065272 chassis, on the MZKT-74181 truck tractors.

YaMZ 7511.10 is a further development and modernization of eight-cylinder V-engines of the YaMZ plant. In fact, YaMZ 7511.10 is a forced version of the YaMZ-238DE2 engine, in which power is significantly increased. Distinctive features of the YaMZ - 7511.10 model range are a built-in liquid-oil heat exchanger, a new sleeve-piston group with an improved oil cooling system, a high-performance water pump and an improved high-pressure fuel pump. This diesel engine model is designed to use a charge air unit mounted on the frame of the product. In addition to excellent specific characteristics and a good power range, this series of engines is reliable in operation, durable, has excellent maintainability and can be operated in extreme environmental conditions at temperatures from -50 to +50°C.

The engines of the Yaroslavl Motor Plant are an acceptable price, high reliability and quality assurance.

YaMZ 7511.10 engine- four-stroke, 8-cylinder, has a V-shaped arrangement of cylinders, a working volume of 14.866 cm 3, liquid cooling, direct fuel injection, mechanical speed control, turbocharged, complies with Euro-2 environmental standards for the emission of harmful substances. YaMZ 7511.10 diesel engines can be equipped with YaMZ-184 clutch and YaMZ-239 gearboxes, the resource before engine overhaul is 10,000 hours.

Main technical characteristics of YaMZ-7511.10 and its modifications

Modification of the YaMZ-7511.10-01 engine equipped with TKR-9, ZHMT, fan clutch, individual cylinder block and head, high-performance water pump, 12/14 high-pressure fuel pump and its drive, torsional vibration damper, front support, generator 6582.3701-03 (2 kW), fan impeller with a diameter of 660 mm, flywheel for diaphragm clutch with additional marks and flywheel mount, clutch m YaMZ-184, gearbox YaMZ-239. The engine model is operated on the MZKT-65272 chassis.

Modification of the YaMZ-7511.10-06 engine assembled on the basis of YaMZ-7511.10-01 and is equipped with a YaMZ-184-10 clutch with a set of clutch release clutch parts. This engine modification is used on MZTK-8021, -80211 chassis, on MZTK-74181 truck tractors and MAZ-533608, -630308, -631708, -543208, -544008, -642208, -640308, -641708, -630308, as well as supplied as spare parts.

Modification of the YaMZ-7511.10-10 engine designed on the basis of YaMZ-7511.10-06, equipped with a PTO clutch (184.420004), used on the KO-816-1 snowplow.

Modification of the YaMZ-7511.10-11 engine assembled on the basis of YaMZ-7511.10-02, equipped with a flywheel housing with a spacer ring, a flywheel with a bearing, an oil level indicator, a YaMZ-184 clutch, a YaMZ-239 gearbox. This modification is used on wheeled chassis BAZ-690990, -6909902.

Modification YaMZ-7511.10-12 has a YaMZ-7511.10-02 engine as a base, equipped with an oil sump without a shell, an oil level indicator, a right exhaust manifold, a fuel drain pipe from the injectors with a fitting at an angle of 45 ° to the longitudinal axis of the engine, a fan clutch (238ND), a YaMZ-184 clutch, a YaMZ-2391-01 gearbox. The engine does not have a turbocharger mounting stud and is used on the chassis and dump trucks 8 × 4 Ural-6563.

Modification YaMZ-7511.10-16 as a base it has a YaMZ-7511.10-02 engine, it is equipped with an oil sump without a shell, an oil level indicator, it is not equipped with a gearbox and clutch. The modification is used on the KrAZ-7140N1S6 chassis and the KrAZ-6140TE truck tractor.

ADJUSTMENT YAMZ ENGINES-7511.10, NMЗ-7512.10, IMZ-7513.10, YaMZ-7601.10

BELTS TENSION ADJUSTMENT

The drive of the water pump, compressor and generator is carried out by V-belts, on the reliable operation of which the normal operation of these units depends. Therefore, in the daily care of engines, protect the belts from oil and fuel, control their tension and adjust it. Especially carefully check the tension of the belts during the first 50 hours of engine operation, since at this time they are most stretched. The tension of the belts must always be normal, since both excessive and insufficient tension leads to premature failure. In addition, excessive tension on the water pump drive belt can cause damage to the pump bearings.

A normally tensioned water pump belt, when pressed on the middle of a long branch with a force of 40 N (4 kgf), bends by 10 ... 15 mm (Fig. 44), and the compressor belt bends by 4 ... 8 mm on a short branch (Fig. 45). Check the tension of the generator drive belts by pressing with a force of 40 N (4 kgf) on the middle of the branch of each belt (Fig. 46), while the generator drive belts must bend by 10 ... 15 mm. If the belts bend more or less than specified, adjust their tension.

Adjust the tension of the water pump belt (Fig. 44) with a tensioner, for which:

loosen the bolts of the tensioner bracket lever;

using a Ø12 mm knob inserted into the hole in the tensioner bracket lever, tension the belt;

without loosening the tension force, tighten the bolts of the tensioner bracket lever;

check belt tension.

Rice. 44. Checking the tension of the water pump belt

Rice. 45. Checking the tension of the compressor belt

Rice. 46. Checking the alternator belt tension

Adjust the tension of the compressor belt with a tensioner. Before adjusting, loosen the lock nut one turn, the tensioner pulley axle nut half a turn, and the tensioner bolt nut two turns.

Rotate the tensioner bolt to adjust the belt tension. After adjustment, tighten the axle nut and locknut to 120…150 N m (12…15 kgf m) and the tensioner bolt nut

on the head of the right row of cylinders, the rocker arms of the exhaust valves to the end of the axle, the intake valves - to the thrust washer;

on the head of the left row of cylinders rocker arms of the exhaust valves to the thrust washer, inlet valves

- to the end of the axle.

The exhaust valves of the right bank of cylinders are located closer to the fan, the left row of cylinders - to the flywheel.

Adjustment sequence:

Rice. 48. Cranking the crankshaft

Rice. 49. Valve clearance adjustment

To adjust the gaps, unscrew the nut of the adjusting screw, insert the probe into the gap and, turning the screw with a screwdriver (Fig. 49), set the gap to 0.25 ... 0.30 mm. While holding the screw with a screwdriver, tighten the nut and check the clearance. With properly adjusted

gap, a probe 0.25 mm thick should enter with light pressure, 0.30 mm thick - with force.

To adjust the valve clearances of the remaining cylinders, turn the crankshaft in the same direction until the intake valve of the regulated cylinder is completely closed and an additional 1/3 turn. Adjust gaps as indicated above (see item 6).

After adjusting the clearances, start the engine and listen to its operation. Knocks in the valve mechanism should not be. If there is a characteristic knock of the valves, stop the engine and repeat the gap adjustment.

Install and secure the cylinder head covers, check the condition of the gaskets. Oil should not leak at the place where the covers fit.

CHECKING AND ADJUSTING FUEL INJECTION ADVANCE ANGLE YAMZ ENGINES-7511.10, NMЗ-7512.10, IMZ-7513.10, YaMZ-7601.10

To adjust the fuel injection advance angle, two hatches are provided on the flywheel housing (see Fig. 50), and the angle values \u200b\u200bare marked on the flywheel in two places. For the lower pointer 3, these values are made on the flywheel in numerical terms, and for the side pointer 4, in letter terms, while the letter "A" corresponds to a numerical value of 20 °; the letter "B" -15 °; the letter "B" -10 °; the letter "G" -5 °.

Rotate the engine crankshaft clockwise (when viewed from the fan side) until the marks on the crankshaft pulley and the distribution gear cover or on the flywheel with the pointer, corresponding to the fuel injection advance setting angle - 6º ... 7º, are aligned. In this case, the valves in the 1st cylinder must be closed.

Rice. 50. Alignment of the marks on the flywheel with the indicators of the flywheel housing:

1 – flywheel housing; 2-flywheel; 3, 4 - pointers of the flywheel housing; 5–top hatch plug; A - direction of rotation of the crankshaft

You can rotate the crankshaft with a key for the crankshaft pulley bolt or with a crowbar for the holes in the flywheel (Fig. 48) with the flywheel housing manhole cover removed.

At the moment of combining the labels, the label must be aligned

"A" at the end of the coupling (Fig. 50, 51) with the risk "B" on the index. If the marks do not line up, you need to make adjustments.

The procedure for adjusting the injection advance angle (Fig. 51):

without knocking down the combined position of the marks, tighten the bolt of the terminal connection to a torque of 16 ... 18 kgf m. In this case, the deviation of the plate package from the position in one plane should be within ±1 mm. The measurement should be made near the places where the plates are fastened. In the event of the appearance of corrugations on the plates 4, they are eliminated by alternately loosening and subsequent tightening with a torque of 11 ... 12.5 kgf m of four bolts 5 fastening the plates to the coupling half flange and to the damper coupling;

..

torque of 10 ... 20 N m (1 ... 2 kgf m), with a larger tightening torque, the adjustment will be violated due to the movement of the pulley axis.

Adjust the alternator drive belt tension by moving the alternator relative to the axis of its attachment. Before adjusting, loosen the generator fastening bolts, the generator bracket fastening nuts and the generator fastening bolt to the bracket. After adjustment, securely fasten the generator. With increased exhaust and a break in at least one of the alternator drive belts, replace both belts with a set to ensure a uniform load on them.

CYLINDER HEAD TIGHTENING YAMZ ENGINES-7511.10, NMЗ-7512.10, IMZ-7513.10, YaMZ-7601.10

Rice. 47. The procedure for tightening the cylinder head nuts:

a) - a common head for four cylinders; b) - a common head for three cylinders; c) - an individual cylinder head.

Check the tightening torque of the cylinder head nuts with a torque wrench in a cold state of the engine and, if necessary, tighten them up to a torque of 235 ... 255 N. m (24…26 kgf . m).

Tighten the nuts in the sequence shown in fig. 47 in ascending order of numbers.

ATTENTION ! IT IS STRICTLY FORBIDDEN TO TIGHTEN THE NUTS TO A TORQUE GREATER THAN SPECIFIED, AS THIS WILL RESULT IN BROKEN STUDS AND BROKEN THE CYLINDER HEADS, AND THIS WILL NOT RESTORE THE TIGHTNESS OF THE CONNECTION.

ATTENTION ! WHEN INSTALLING THE CYLINDER HEAD TO THE ENGINE OR LOOKING SIGNIFICANTLY, TIGHTEN THE NUTS IN AT LEAST THREE TIMES (SEE SECTION "REPAIR")

After tightening the cylinder head nuts, adjust the thermal clearances in the valve mechanism and install the cylinder head covers.

ADJUSTING CLEARANCES IN THE VALVE MECHANISM YAMZ ENGINES-7511.10, NMЗ-7512.10, IMZ-7513.10, YaMZ-7601.10

Thermal gaps in the valve mechanism are designed to ensure a hermetic fit of the valve on the seat when the parts of the valve drive expand during engine operation. The value of the thermal gap at the intake and exhaust valves is set the same and is adjustable within 0.25 ... 0.30 mm. When re-checking the gaps after scrolling the crankshaft of the adjusted engine, it is possible to change them to the limits of 0.20 ... 0.35 mm due to an error in the shape and location of the surfaces of the parts of the gas distribution mechanism, which is acceptable.

If the thermal gaps are too large, the valve lift decreases, as a result of which filling and cleaning of the cylinders deteriorate, shock loads increase and wear of the gas distribution mechanism parts increases. At very small gaps, as a result of thermal expansion of the parts of the gas distribution mechanism,

tight fit of valves to the seats, gas-dynamic processes in the engine cylinders are disturbed, the power and technical and economic indicators of the engine are deteriorating. In addition, reducing the clearance in the exhaust valve drive can lead to overheating of the valves and their burnout.

Adjust thermal gaps on a cold engine or not earlier than 1 hour after it has stopped.

When adjusting the thermal clearances and re-checking them, it is recommended to press the rocker arms of the valves:

loosen bolt 2 of the terminal connection: flange 3 - drive coupling half 1;

by turning the damper coupling, align the indicated marks;

Rice. 51. High pressure fuel pump drive coupling:

1-leading coupling half; 2–bolt terminal connection; 3 – coupling half flange; 4–drive plates; 5–bolts of fastening of plates of a drive; 6 washers; 7–damper clutch; 8 - pointer; 9 – high pressure fuel pump; A-mark on the damper coupling; B-mark on the pointer

The YaMZ 7511 engine is the next generation of the legendary YaMZ 238 engine, which was produced by the Yaroslavl Motor Plant for MAZ vehicles. The main difference is the presence of a turbocharger and an increase in the environmental standard to Euro-2.

Specifications

The devices of the YaMZ 7511 motor are somewhat different from their predecessors. The designers improved a number of components and assemblies, which made it possible not only to increase the power of the internal combustion engine, but also the service life. So, constructive changes have suffered:

- Installed liquid-oil heat exchanger.

- A high capacity water pump has been installed.

- Improved sleeve-piston group with oil cooling system.

- Upgrading high pressure fuel pumps.

Now consider the main technical characteristics that the YaMZ 7511 engine has:

| Name | Characteristic |

| Type | Diesel, turbocharged diesel |

| Volume | 14.86 liters (14,860 cc) |

| Configuration, parameter | V-shaped |

| Number of cylinders | 8 |

| Number of valves | 16 |

| Economy | Euro 2 |

| Cylinder diameter | 130 mm |

| Compression ratio | 16,5 |

| Cooling | Liquid |

| valve mechanism | OHV |

| Block and head material | Cast iron |

| Resource | 800,000 - 1,000,000 km |

| Fuel | Diesel fuel |

| The order of operation of the cylinders | 1-5-4-2-6-3-7-8 |

| Applicability | Onboard vehicles, chassis MAZ-533608-020, MAZ-533608-021, MAZ-533608-043, MAZ-630308-020, MAZ-630308-021, MAZ-630308-040, MAZ-631708-010, MAZ-631708-020, MAZ-6 31708-030, MAZ-631708-041, MAZ-631708-061; Drive tractors MAZ-543208-0204, MAZ-544008-030-020, MAZ-544008-030-021, MAZ-642208-020, MAZ-642208-022, MAZ-640308-020-020-010, MAZ-640308-020-020; timber trucks, short log trucks MAZ-641708-220, MAZ-630308-226 |

Service

Servicing the YaMZ 7511 engine is quite simple, since there are no special differences from servicing the older brother of the 238th. Each scheduled service should be carried out at intervals of 20,000-25,000 km. If you follow the instructions for maintenance and repair, then you must perform the following series of operations:

- Change of oil.

- Valve mechanism adjustment.

- Replacement of filters. So, depending on the modification of the engine, there may or may not be the following filter elements: a fine and coarse oil filter, a filter element for coarse and fine fuel purification, an air filter, an exhaust eco-filter.

- Nozzle cleaning.

- High pressure fuel pump adjustments.

- Other operations aimed at maintaining the power unit.

Repair manual

Engine malfunctions from time to time know about themselves. Often, this is due to the wear of the main components and assemblies or improper operation. Also, the maintenance of the motor can be considered a very important factor.

- Injection pump malfunctions associated with poor fuel quality in the CIS.

- Cooling system. This failure occurs due to mechanical wear of the components.

- The wiring diagram is not perfect.

- Wear of the piston group.

- valve mechanism.

- Starter and generator.

The most common question that motorists ask on the Internet is the tightening torque of the cylinder head. For tightening the cylinder head mountings, there is a diagram that must be followed.

They must be tightened with the force provided by the manufacturer, which is - the nuts of the studs for fastening the cylinder head 240–260 (24–26) N m (kgf m).

If the cylinder head mounts are too tight, then engine malfunctions are possible, including breakdown and extrusion of the gasket.

Conclusion

The YaMZ 7511 engine is a high-class and powerful modern engine, which during its service life has proved that it is worthy of attention. High technical characteristics, power, as well as ease of maintenance and repair, made the YaMZ engine popular and beloved, both in Russia and beyond.

YaMZ 7511 engine

Characteristics of YaMZ-7511

| Production | "Autodiesel" Yaroslavl Motor Plant |

| Engine brand | 7511 |

| Release years | 1996-present |

| Block material | cast iron |

| engine's type | diesel |

| Configuration | V-shaped |

| Number of cylinders | 8 |

| Valves per cylinder | 2 |

| Piston stroke, mm | 140 |

| Cylinder diameter, mm | 130 |

| Compression ratio | 16.5 |

| Engine volume, cc | 14866 |

| Engine power, hp / rpm | 360/1900 375/1500 400/1900 420/1900 |

| Torque, Nm/rpm | 1570/1100-1300 -/- 1715/1100-1300 1765/1100-1300 |

| Environmental regulations | Euro 2 |

| Turbocharger | TKR-100 |

| Engine weight, kg | 1250 (YaMZ-7511) |

| Fuel consumption, l/100 km (for MAZ-6422) | 27 |

| Oil consumption, % of fuel consumption, up to | 0.2 |

| Engine oil: -in summer -in winter (less than +5° С) |

M-10 M-8 |

| How much oil is in the engine, l | 32 |

| Oil change is carried out, hours | 1000 |

| Dimensions, mm: - length - width - height |

1388 1045 1100 |

| Engine resource, km - according to the plant - on practice |

800 000 - |

| The engine was installed | MAZ-5336, 5432, , , 6303 MAZ-6317, , 6417, 6422, 6425 Ural-6563 KrAZ-6140, 7140, 7634 DET-320 KO-816 MZKT-65272, 74181, 8021 RSM 1401 Torum-740 |

Reliability, problems and repair of YaMZ-7511

In 1996, an updated version of the 238th family was released, which was named YaMZ-7511. Consider the differences between 238 and 7511. The YaMZ-238DE2 cylinder block with a V8 configuration (camber angle 90º) and oil nozzles was chosen as the basis for creating a new diesel engine. Inside it is a 238DK crankshaft with a main journal diameter of 110 mm, and a connecting rod journal diameter of 88 mm - the same crankshaft as on 238DE2. Connecting rods, pistons, piston rings are the same as on 238DE2, with a piston pin of 52 mm, and the height of the pistons is 85 mm. The flywheel also remained unchanged.

Here is an oil pump with a capacity of 165 l / h (was 140 l / h).

For 7511, cast-iron 8-valve heads from YaMZ-238DE2 were used. The camshaft is still in the block, and its characteristics are the same as those of 238DE2 (phase 233/272).

Valve adjustment at YaMZ-7511 is required after 1000 hours of operation. Valve clearances are the same - 0.25-0.30 mm for intake and exhaust.

The 7511 diesel engine has direct fuel injection with a mechanical injection pump 175 and nozzles 267-01. Nozzle pressure - 270 kgf / cm 2.

The oil pressure on a warm engine is in the range of 4-7 kgf / cm 2.

This is a turbo engine and the TKR-100 turbine is used here, the boost pressure has been increased from 1.08 bar to 1.23 bar.

Here, a fine fuel filter from its predecessor is used.

In fact, the 7511 engine differs from the 238 DE2 only in a pump and increased boost pressure, which made it possible to bring the power up to 400 hp.

Based on this engine, a 6-cylinder YaMZ-7601 was produced.

This family is currently in production, but environmental standards are being tightened all the time, and today diesel 7511 is being replaced with a cleaner YaMZ-658.

Differences of YaMZ 7511 engines

1. YaMZ-7511 - 400 hp version Here is the injection pump 175-01 (on models from YaMZ-7511.10 to YaMZ-7511.10-20) and 175-40 (on models from YaMZ-7511.10-34 to YaMZ-7511.10-43).

This engine was used on MAZ-5336, 5432, 5440, 6303, 6317, 6403, 6417, 6422, 6425; Ural-6563, KrAZ-6140, 7140, DET-320, KO-816, MZKT-65272, 74181, 8021, RSM 1401 and Torum-740 combines.

2. YaMZ-7512 - analogue for 360 hp and with injection pump 175-11. There is an engine on MoAZ-7505, 4048 and on the Polesie combine.

3. YaMZ-7513 - 420 hp motor with pump 175-50. Was put on MZKT-6527, 6922 and 7418.

4. YaMZ-7514 - an analogue of 7511 for 375 hp with another generator and with injection pump 175-70. Designed for diesel generators AD-200.

Problems and reliability of YaMZ-7511

This engine is no different from the YaMZ-238 Euro 2 and their problems are the same: 7511 also heats up, troit, speed fluctuates, etc. all problems are described using the example of the 238th, but in general this is a very reliable unit.

________________________________________________________________

Diesel engines for trucks and tractors. Spare parts, adjustments and repairs.

_______________________________________________________________

Diesel engine YaMZ-7511

The YaMZ-7511 diesel engine manufactured by the Yaroslavl Motor Plant is designed for heavy-duty MAZ vehicles and special equipment and has good fuel-economic, efficient and operational characteristics. The environmental standard of the motor complies with EURO-2.

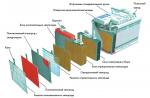

The appearance of the YaMZ-7511.10 diesel engine with individual cylinder heads and a lamellar liquid-oil cooler (LMO) is shown in Figure 1.

Figure 1 - YaMZ-7511 power unit with individual cylinder heads

Technical characteristics of the YaMZ-7511 diesel engine

Engine type - Four-stroke with compression ignition and turbocharging

Number of cylinders - 8

The arrangement of the cylinders is V-shaped, the camber angle is 90 degrees

Cylinder firing order - 1-5-4-2-6-3-7-8

Direction of rotation of the crankshaft - Right

Cylinder diameter, mm - 130

Piston stroke, mm - 140

Working volume, l - 14.86

Compression ratio - 16.5

Rated power, kW (hp) - 294 (400)

The frequency of rotation of the crankshaft at rated power, min-1 - 1900

Maximum torque, Nm (kgsm) - 1715 (175)

Rotational speed at maximum torque, min-1 - 1100-1300

Idling speed, min-1:

Maximum - 2150

- minimum - 600±50

Specific fuel consumption by speed characteristic, g/kWh (g/l.s.h):

Minimum - 194 (143)

- at rated power - 215 (158)

Specific oil consumption for waste in % of fuel consumption, not more than - 0.2

Mixing method - Direct injection

Combustion chamber - Undivided type in the piston

Camshaft - Common for both rows of cylinders, gear driven

Valve timing:

Intake valves - opening, deg. to TDC - 21.5 / closing, deg. after NMT - 31.5

- exhaust valves - opening, deg. to TDC - 63 / closing, deg. after BMT - 29.5

Number of valves per cylinder - One intake and one exhaust

Thermal valve clearances on a cold engine, mm - 0.25-0.30

YaMZ-7511 diesel lubrication system

Type - Mixed, with oil cooling in a liquid-oil heat exchanger (LMT): bearings of the crankshaft, camshaft, rocker axles, high-pressure fuel pump, turbocharger are lubricated under pressure; other rubbing surfaces are lubricated by spraying.

Oil pump - Gear type, single section

Oil pressure in a warm engine in the block line kPa (kgf/cm2):

At rated speed - 400-700 (4-7)

- at minimum speed, not less than - 100 (1)

Oil filters - Two: a full-flow fine oil filter (PFTOM) with a replaceable filter element and a centrifugal oil cleaner (CM)

Oil cooling system - With a liquid-oil heat exchanger (LMO), which is installed on the engine, plate or tubular type

Piston oil cooling system - Nozzles for jet oil cooling of pistons with holes with a diameter of 2.5 mm are located on pipes on the right and left sides of the engine with oil withdrawal through a throttle bushing with a diameter of 6 mm in the area of the engine lubrication system between the ZHMT and PFTOM.

Oil pressure at the start of opening the valves of the lubrication system, kPa (kgf/cm2):

Oil pump pressure reducing valve - 700-800 (7.0-8.0)

- differential valve - 490-520 (4.9-5.2)

- oil filter bypass valve - 200-250 (2.0-2.5)

- signaling device for opening the bypass valve of the oil filter - 180-230 (1.8-2.3)

- bypass valve ZhMT 274±25 (2.8±0.25) (only for lamellar type ZhMT)

Fuel system of YaMZ-7511.10 engine

Type - Divided type

High pressure fuel pump with a regulator and a fuel priming pump - Eight-section, plunger, spool-type plungers.

High pressure fuel pump model - 175.1111005-40

The order of operation of the fuel pump sections is 1-3-6-2-4-5-7-8

Speed regulator - Centrifugal, all-mode

Fuel priming pump - Piston with manual fuel pump

Nozzles - Closed type, with multi-hole atomizers: on engines with common heads - 267.1112010-02 or 204.1112010-50.01 / on engines with individual heads - 51.1112010-01

Adjusting fuel injection advance angle (It is set according to the marks on the flywheel and the injection pump housing):

On engines with common heads - (6 + 1) degrees

- on engines with individual heads - (8 + 1) degrees

Fuel filters:

Coarse cleaning - Settling filter

- fine cleaning - With a replaceable filter element. On the cover is a bypass valve-jet. Valve-jet opening pressure 20-40 (0.2-0.4) kPa (kgf/cm2)

Supercharging system - Gas turbine single turbocharger with radial centripetal turbine and centrifugal compressor

Turbocharger - Model 122 (YaMZ)

Boost pressure (excessive) at nominal operation, kPa (kgf / cm2) - 125 (1.25)

Cooling system of the YaMZ-7511 diesel engine

Type - Liquid, closed type, with forced circulation of the coolant.

The cooling system is equipped with a thermostatic device to automatically maintain the thermal regime of the engine.

Water pump - Centrifugal type, belt driven. Fan - Six-bladed, with gear drive and friction clutch for turning on the fan.

Liquid-oil heat exchanger - Plate or tubular type. Equipped with a faucet or plug for draining the coolant.

Thermostats - Solid filled. Opening start temperature 80 C.

electrical equipment

Type - Single-wire circuit. Rated voltage 24 V. Generator - Alternating current, with a two-strand belt drive, with a rated voltage of 28 V.

The generator model is determined by the configuration. Starter - Electric starter mod. 25.3708-21 or 4581 (Slovakia), nominal voltage 24 V.

To facilitate starting a cold engine, an electric torch device is provided.

additional characteristics

Clutch - YaMZ-184

Gearbox - YaMZ-239

Refueling capacities, l:

Engine lubrication system - 32

- cooling system (without radiator volume and expansion tank) - 22

Mass of an unfilled power unit with individual cylinder heads, kg:

Without clutch and gearbox - 1250

- with clutch - 1295

- with clutch and gearbox - 1685

Weight of an unfilled power unit with common cylinder heads:

Without clutch and gearbox - 1215

- with clutch - 1260

- with clutch and gearbox - 1635