The Xingtai 180 mini-tractor appeared on the CIS market to meet the demand for compact agricultural machinery. Among other manufacturers of this kind of equipment, the Chinese company Xingtai has earned a good reputation. Their mini-tractors are characterized by an affordable price, compact size and great functionality.

The first Xingtai models appeared on the domestic market 23 years ago, since that time the company's products have changed a lot. Now one of the most popular models is the Xingtai 180.

The purpose of the Xingtai 180 tractor

The Chinese mini-tractor is actively used in construction, agriculture and for municipal purposes. In addition to its compact size and wide functionality, the new Xingtai also has a modern design.

In the agricultural sector, equipment can perform harrowing, hilling, plowing the soil, sowing vegetables and grain products, hay making and is used for transporting products. Small dimensions will allow you to work without problems even inside the greenhouse.

For utilities, such a mini-tractor is also a real find. It is accepted for cleaning asphalt in places where large equipment cannot drive in, for mowing the lawn, for watering plants and for washing a certain area. Not bad copes with the work of Xingtai and in the winter, here he will help remove the snow with the help of attachments.

When transporting goods, this small tractor is capable of transporting up to two tons. Various attachments and trailers are used for transportation. The low price, efficiency and compact size make more and more farmers opt for the Xingtai 180 mini tractor.

Specifications

Equipment dimensions:

The thrust gain in xt-180 is 3.7 kH. The speed of the mini-tractor is in the range from 2.7 to 23 kilometers per hour. The smallest turning radius is 3900 mm.

Fuel consumption

This model of agricultural machinery is characterized by quite economical fuel consumption. Only 2-3 liters are required for a mini-tractor for an hour of work, depending on the intensity and complexity of the tasks performed. The tank can be filled with 17 liters of fuel.

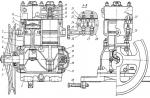

Engine

The most commonly used modification of the Xingtai 180 tractor with a 4-stroke engine for 2 cylinders - TY 290. This unit is equipped with fuel injection and a cooling system, with which you can perform tasks for a long time without interruption, the equipment will not overheat.

The motor is started using an electric starter, it is safe and practical. The tractor also has a plunger pump.

Engine Specifications:

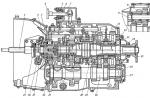

Device

The Xingtai 180 tractor comes with a gearbox (six front and two rear) with a single-plate clutch. The rear wheels act as the driving wheels.

Mounted devices work with the help of hydraulics, which is aimed only at lifting. The hitch is equipped with a standard 3-point hitch for tractors.

To attach equipment to a Xingtai tractor, you need to use a special power take-off shaft that rotates 540 times per minute. The Xingtai 180 minitractor is equipped with a drum brake system for the rear wheels. The hinged mechanism is controlled by means of levers and the BOM mechanism.

Advantages and disadvantages

Advantages of using this mini-tractor:

- wide functionality;

- high and low beam headlights allow you to work not only during the day, but also in the dark;

- due to its compact size, Xingtai performs well even in greenhouses;

- a wide range of attachments;

- economical fuel consumption.

Among the offered mini tractors, there are many Chinese-made machines. And many do not know whether to buy them or not, since there is very little information on this topic. Since this tractor is more attractive in price, buyers are not afraid of some flaws in various models, and for those who can improve the tractor, this is not a problem at all.

Most importantly, Chinese mini tractors have a good foundation, consisting of an engine, gearbox, transmission and wheels. Therefore, everything else can be finalized in the process or simply replaced. Of course, for potato growers, the track, in Chinese tractors, is also the wrong size. Therefore, you have to modify the tractor for yourself.

In addition, the process of acquiring a cheap mini tractor not in a store is not known to everyone. That is why we offer a buyer's report on how he acquired it and remade it for himself. Wrote this story Valery from the city of Orel:

Alexander, the owner of a store in Serpukhov, at first also offered an advance payment, but believing me (special thanks to him for this), he delivered the tractor to the store. Having hired a low-floor van of the Volkswagen LT model, I drove from Orel to Serpukhov and took the tractor. Together with the tractor, I purchased a drive cutter with a width of 120. On the websites of sellers of mini tractors, as a rule, such parameters of Xingtai mini tractors as length and width almost always do not correspond to reality. So I, believing the price lists that the width of the Xingtai 180 tractor does not exceed 120 cm, like the Xingtai 160, fell for it.

I will dwell separately on the track of the tractor, since I have previously read a lot on various forums that people do not know what and how it is made, whether it can be changed, and whether it is worth buying such a tractor. When I saw the tractor with my own eyes and measured it with a tape measure, I realized that its minimum width along the outer edges of the rear wheels was 142 cm. to the left due to disks.

If the axle shafts of the rear wheels are machined, then the width of the tractor can be reduced from a minimum of 130 cm along the outer edges of the rear wheels to 115 cm. At the same time, the width of the tractor along the protruding axle shafts will remain 142 cm. In my configuration, the 180 was also equipped with a front sliding beam and weights rear wheels 50 kg. every. I am writing this information for those who would like to use Xingtai for the cultivation and processing of potatoes. But it is necessary to discuss with the seller in advance about the complete set of the tractor with a front sliding beam. If it is not possible to come and look at the tractor yourself, ask the seller to measure the width with a tape measure. Believe me, many of the sellers do not know the real width of the tractor and were not interested, they did not delve into the nuances of operating the tractor, and this is very important, since it really differs from the passport data published on most sites.

My salesperson was visibly surprised by the actual width of the tractor. I would also like to note that the Xingtai 180 I bought had rear wheels measuring 9.5 by 24 inches, front wheels 5 by 16 inches, instead of 20 and 14 as it is written in passports and price lists. In addition, a licensed engine model TI 295 was installed on it. Such an engine is installed on Xingtai 220. Obviously, the difference in them is only in terms of cubic volume and, accordingly, power. The price of a tractor in this configuration was 153 thousand rubles.

Having driven the tractor into the garage, he began to hunt for its detailed study, inspection, elimination of shortcomings, and, oddly enough, alteration for himself. To begin with, I note that all tractors are assembled dry or with a minimum amount of lubrication in the bearings. I was convinced of this by squirting almost the entire 800-gram jar of grease into all the grease fittings.

The front axle bearings were completely dry. The same thing happened in the steering tips, stub axles of the front suspension, front beam axle, power take-off shaft bearing. I recommend everyone to replace the Chinese grease fittings with Russian ones, since theirs are complete *****, they cannot withstand the syringe, they break, bend, fail. The tractor maintenance passport says that grease should be added to the steering wheel gearbox - grease (strange), but I didn’t find a grease gun anywhere, so I drilled a hole in the upper plug of the gearbox, cut the thread and installed an angular grease gun. Do not be too lazy to spray the tractor first, and then do it regularly, this can significantly extend the life of many mechanisms. Convinced from experience.

My next alteration affected the exhaust system. The existing exhaust pipe protruded so high beyond the dimensions of the tractor that there was no question of any work on it in the garden, since it was really possible to be injured by a branch caught on the pipe, and not every garage can be entered with such a pipe.

From water pipes, corners, sheet metal, I welded a knee adapter and lowered the exhaust pipe along the engine hood at a level between the generator and the starter, after shortening the protruding end of the exhaust pipe by 25 cm. I spied this technique on Japanese tractors, and the former wound I have a homemade tractor, I had such a device that has proven itself well.

Not without alteration of the electrical equipment of the tractor. The Chinese mass off button did not work initially, I had to replace it with a domestic one. The turn on toggle switch broke after several turns - it was replaced with a domestic one, at the same time a turn repeater on the dashboard was added to the circuit with a file, boring out the existing hole for a control light with a peephole from domestic agricultural machinery. In addition, I installed a horn button and a signal that was not included in the package. In general, Chinese light switches are also very flimsy and their turn to be replaced is just around the corner. Although I liked the fuse box for its simplicity and the ability to use thin wire as a fuse. In the field, this is much better than looking for a replacement fuse with a tricky shape.

The frame for fastening the battery was replaced with a plate of the appropriate length, 4 mm thick and 40 mm wide, since there was a real threat of a short circuit of the battery due to its irregular shape. The PTO engagement lever has been reworked. The native one was short and replaced with a self-made one, longer and bent to the side so as not to lean when it is turned on. The same was done with the decompressor lever. It is enlarged to the top and a ball is installed at the end. Similar work was done with the lever for manually setting the fuel supply and engine speed. From the lower position, I turned it upside down with a handle, and on the reverse side I welded a lever with a hole for traction.

The next alteration is the attachment point for the rear linkage spacer rods. The factory pipe and the loops welded to it incorrectly along the edges were made of thin metal, did not inspire confidence, did not work correctly. Everything was replaced with a thick-walled pipe and a metal plate welded to it of the appropriate thickness with holes closer to the center, which made it possible to fully use the expansion rods.

Since the drive cutter purchased for the tractor had a tillage width of 120 cm, in order for the tractor not to protrude beyond its dimensions and trample the edge of the soil with the processed cutter, it was necessary to narrow the track of the rear wheels of the tractor to 105 cm, width up to 128 cm.) for this purpose, it was necessary to remove the rear wheels and the hubs of their mounting from the axle shafts and remove the tubular rings that limit the shift of the hubs along the axle shaft. The hubs had to be removed with special effort and complexity. This is due to the fact that despite the existing collapsible parts, they fit very tightly to the axle shafts.

As it turned out later, during their assembly, the workers drove the key into the keyway with a hammer. To remove the hubs without damage, I had to make a special puller. But after all the parts were ground in, lubricated, the scuffs were eliminated, and in the future it will be much easier to do. In general, as I wrote above, if necessary, the rear wheel track can still be narrowed by turning the axle shafts to fit the diameter of the hubs to the brake drums, this is an additional 6-7 cm on each side.

In order to install the rear wheel guards with a narrowed track of the tractor, I had to cut the footboards by 6 cm on each side with a grinder, re-drill the mounting holes of the rear wheel wings by 5 cm to the side. Narrowing the tractor track to the minimum dimensions is also necessary for the correct attachment and operation of the tractor with a plow. Adjusting the track of the front wheels did not cause much trouble, because everything is done there easily and simply. At the end, it is only necessary to adjust the toe angle of the front wheels.

The tractor seat was reworked for itself. It was lowered 3 cm lower, the back was tilted a little more back, because it was almost vertical and overcooked. So that the lower back does not rest against the lower tube of the seat, the tube was cut out by a grinder and removed. The factory back and seat covers are made of leatherette of extremely poor quality, so the covers were re-sewn. The gear lever also had to be removed and greased into it, since it was assembled dry. In addition, in the auto parts store I picked up corrugated rubber from OKI for it and installed it as an anther and protection from dirt and rain.

During the installation of the cutter and the connection of the cardan shaft to the PTO of the tractor, it was found that when it is raised hydraulically to the transport (uppermost state) position, the cardan shaft has a slightly longer length, which prevents it from being raised. I had to remove the cardan and cut its splined part (a piece of rectangular pipe) by 6 - 7 cm. But this is mine, maybe someone will not have to do this due to the different design of the cutter or other reasons.

In addition, during the installation and running-in of the cutter, I encountered the fact that the passport does not indicate anywhere how much and what kind of oil to fill in the gearbox. Filled with an ordinary budget motor. I found an oil leak through a microcrack or marriage when casting the top cover of the side bearing. The oil had to be drained, the cover removed, the crack drilled and riveted with an aluminum rivet. In addition, on the side hubs of the working shaft of the cutter, I found the absence of grease fittings, although there were holes and threads. I also had to screw them in and squirt them.

The fasteners for fastening the tractor hood were also modified and adjusted in place so that the hood is correctly fixed without distortions to its other part integrated with the instrument panel. In general, what the Chinese have done with fixing the tank for diesel fuel, the instrument panel that is attached to the tank, does not lend itself to common sense, since it is not practical, not reliable and needs to be redone. From engine vibration, spot welding can fall off at the most inopportune moment. Therefore, before the start of the season, I think it is still possible to make my own changes there.

Now, after a month and a half from the date of purchase of the tractor, I began to realize how well I did after all, that I bought a tractor in the winter. I still have time to correct the shortcomings. There are no complaints about the mechanical part of the tractor yet. Assembled soundly, powerfully, reliably. The engine starts and runs well. At the same time, it seemed that the air cleaner was too noisy at the time of air intake. It seems to me that this is due to its insufficient bandwidth. Its noise level is almost equal to that of the exhaust, and is clearly audible at all stages of engine operation.

The unification of the air cleaner for all types of engines with significantly different cubic volumes, from the single-cylinder Xingtai 120 to the two-cylinder 220, did not play the best role here. In the future, I will try to experiment with air cleaners from domestic cars. There is enough space under the hood to hide it there without compromising accessibility to other components and assemblies.

Material taken: http://www.mastercity.ru/showthread.php?t=47101&page=6

In Russia, the demand for small agricultural machinery has really increased. Among the whole variety of equipment for farmers and just private households, such a Chinese brand as Xingtai has proven itself well. This product has been known in Russia since the distant 1992, when the first mini tractors only appeared on its fields.

Much has changed since then, and now, judging by the numerous reviews on the forums, the most popular tractor from the products of this brand is the cheap and functional model XT 180. All less powerful models, from XT 120 to XT 160, are somewhat weaker and not for any mounted equipment is recommended. XT 180 is easy to operate, has high maintainability - it always has a complete set, it is able to operate at temperatures from -30 to +40 °C. In addition, it has a huge number of standard attachments manufactured around the world.

The minitractor is a truly versatile machine. In agriculture, it is used for plowing the land, harrowing, hilling, sowing vegetables and grain crops, planting and harvesting potatoes and onions, for harvesting hay up to its storage in windrows after the baler. Due to its very small size, it can also be used in greenhouses. In housing and communal services, it is used for cleaning streets, including in inaccessible places, for mowing lawns, for washing and watering streets. In winter - for snow removal with an auger snow blower, a blade, or a brush. And, of course, mini tractors can be perfectly used as a light vehicle capable of carrying loads up to 2 tons.

Brief technical characteristics of the Xingtai XT-180 tractor

The XT 180 is a full-fledged tractor that has everything you need for autonomous work with attachments and transporting loads on trailers. It uses a very reliable diesel low-speed 2-cylinder TY 290 engine as a power unit. Its power at 2200 crankshaft revolutions per minute is 18 liters. With. (13.26 kW). The average fuel consumption is highly dependent on the operating mode and is 259 g/kWh. During operation, this is really about 2 liters per hour, so the fuel tank with its volume of 17 liters is enough for quite a long time. The engine is liquid-cooled, the engine is started using an electric starter.

The transmission consists of a single-plate clutch, an 8-speed gearbox - of which, taking into account overdrive and downshift, 6 speeds forward and 2 back, and a conventional bevel differential with two satellites, similar to a car. The rear drive wheels are 9.5x24”, the front ones are 5x16”. The wheelbase is 144 cm. The ground clearance is 30 cm, which is quite enough for a mini tractor. The track width for both wheels is adjustable - for the front wheels it can be set from 96 to 140 cm, for the rear wheels - from 99 to 140 cm. - 9.37 km / h.

To ensure work with attachments, there is a single-acting hydraulics - only on the rise. The towing device is made according to the classic three-point tractor scheme. The central link has a pin hole -20 mm, and 2 lift linkage levers 22 mm each. In addition, there is a power take-off shaft - PTO with a rotation speed of 540 rpm at rated engine speed, specially for connecting active attachments.

According to the traction data, the XT-180 belongs to the class 0.4 - its traction force on the trailer is 3.7 kN (362 kgf). Such a traction force is provided by the weight of the tractor itself, together with weighting agents, equal to approximately 940 kg. With this weight and dimensions of 2530x1200x1750 mm, it has a turning radius of 3.9 m. Drum-type brakes are made only on the rear wheels. The tractor is controlled using the steering wheel, brake pedals, clutch pedals, gas pedals, high/low gear selector lever and gearshift lever. To control attachments, there is a hydraulic control lever, as well as a PTO control lever. In addition, the XT 180 is equipped with dipped and main beam headlights, an audible signal, and a complete set of lighting equipment in accordance with the requirements for cars of this class.

Attachment

Of the main attachments, it should immediately be noted a single-axle dump trailer with a hydraulic drive and sides that lean back on all sides, with a carrying capacity of up to 2 tons.

Of the attachments that are aggregated with the XT 180 minitractor, the following equipment driven by the PTO is most in demand in agriculture:

- active rotator for direct cultivation of the land with a working width of 1 m, a working depth of 14-25 cm and an hourly productivity of up to 50-70 acres;

- vibrating potato digger with a working width of 40 cm and a depth of up to 25 cm, for harvesting potatoes and other root crops, productivity per hour up to 15 acres;

– conveyor potato digger, with a working width of 65 cm and a depth of up to 25 cm, is designed to collect potatoes and lay them in a swath, with a capacity of up to 40 acres per hour;

- a potato planter with a fertilizer function, planting depth adjustment from 6 to 15 cm, row spacing - from 40 to 75 cm, hilling and an hourly productivity of about 14 acres;

– segmented hay mowers for harvesting hay with a grip of 1.6, 1.8 and 2.1 m and an hourly capacity of 1.5, 1.7 and 2 hectares, respectively;

– 9-row seeder with adjustable seeding depth and fertilizer application;

- a baler for harvesting hay, which is used to capture mowed rolls of hay or straw, folding them into rolls with a diameter of 70-80 cm, 50 cm long and wrapping them with twine.

In addition to active equipment, the simplest trailed equipment is also in demand, such as:

– double-furrow reversible plow with furrow width up to 40 cm, adjustable plowing depth up to 20 cm and productivity per hour up to 20 acres;

- a disc harrow with a width of 1.1 and 1.3 m, capable of processing up to 1.3 and up to 1.6 hectares per hour, respectively;

– a rake with a working width of 210 cm for raking hay with an hourly capacity of up to 1.8 ha;

- a three-blade hiller with a grip of up to 3 m and a hilling depth of 8-15 cm, for hilling, weeding, saving moisture and loosening the soil, as well as for cutting furrows before planting various crops, per hour productivity up to 45 acres.

Attached equipment for public utilities is also produced, for example:

- ripper-leveler, installed at the rear and used when cleaning areas for chipping ice and packed snow, and also used to level the surface of the soil, like a grader;

- a brush for sweeping territories, used, as a rule, in public utilities;

– blade with a front mounted width of 150 cm, with its own hydraulic cylinder, for removing snow, debris and other work related to the movement of bulk cargo across the territory;

- rear-mounted shovel of a bulldozer with a width of 1.5 and 1.3 m;

– rear-mounted lifting body with a capacity of 0.5 and 0.3 m for loading and transporting a small amount of goods.

For road and construction work on a farm yard, installing poles, planting trees and other similar work, drills are also produced in the following sizes (diameter, depth): 228x914, 355x762, 457x762, 508x500, 508x762.

About clones

And a little about the clones of this tractor. The real Xingtai is made in China at the Tundeselmash plant in Xingtai. It is their tractors that have the lowest prices. At the same time, such brands as Uralets XT-180, SWATT Xingtai XT-180, Caliber MT-180 appeared in Russia. Naturally, the prices are higher for everyone. Least of all, they are overestimated at the SWATT company near Moscow, but there, apart from a different color, no “improvements” were noticed.

The most pleasant improvement for Uralets. They announce the possibility of blocking the gearbox. The rest of the "improvements" are insignificant, but as a result, the cost has increased compared to the official dealer price.

So, what benefits does the owner of the Xingtai XT-180 mini-tractor have?

1. Relatively low price - from 140 thousand rubles.

2. High functionality due to a large number of various attachments.

2. High maintainability, which is ensured by the wide distribution of this equipment and various spare parts for this brand of mini-tractors.

Mini tractors have always had a number of advantages over heavy equipment. Techniques of this type do not need much space, can work in tight spaces, and save fuel. And the type of work of the minitractor is no less than that of the "big brother".

Minitractor Uralets -180 is one of the most popular models of minitractors of domestic production. A lot of people talk about him, write and shoot videos. The history of the 180 model began in 1991, when the first such model was imported from China. But even now these mini tractors help people in the fields, gardens and roads. You can buy this model in any remote corner of Russia. What features does this model have and how to buy it in this article.

General description of the model, application and purpose

Designers improve the Uralets 180 every year and modern models are completely different from their grandfathers. At the Urals 180, at the present stage of development, the design received separate braking of the rear wheels and a more advanced hydraulic output. Attachments Uralets 180 is diverse and grows every year. The XT is an economical and manoeuvrable model that can work in greenhouses, narrow streets and small areas. The design of the case has changed and has become more optician, the material used for its manufacture is high-strength plastic. This makes the model easy and less expensive.

Designers improve the Uralets 180 every year and modern models are completely different from their grandfathers. At the Urals 180, at the present stage of development, the design received separate braking of the rear wheels and a more advanced hydraulic output. Attachments Uralets 180 is diverse and grows every year. The XT is an economical and manoeuvrable model that can work in greenhouses, narrow streets and small areas. The design of the case has changed and has become more optician, the material used for its manufacture is high-strength plastic. This makes the model easy and less expensive.

Spare parts for this mini tractor can be found in any agricultural equipment store in the country. It is fully adapted to the climatic zone of Russia and is used at different times of the year.

He easily copes with any kind of work put before this type of equipment. In agriculture, they are used for plowing, harrowing, loosening the soil, planting and harvesting root crops (potatoes, onions, beets, etc.), spraying and spudding crops, mowing and harvesting hay.

Utilities also like to use the Uralets 180 model. With it, you can take care of lawns and clean streets at any time of the year. This technique copes well with the loading and unloading of heavy or bulk cargo. And many more specialized types of work can be performed by this versatile craftsman. The only condition for such a wide application is the purchase of attachments and trailers.

Separately, I would like to say about the Urals XT 180. This model is also produced by Tractor LLC Chelyabinsk Tractor Plant, but their engine manufacturers are different. XT has a Chinese-made Xingtai engine. And so in general it is one and the same model. HT can be seen in the proposed video:

It is the base model and differs only in name. But in fact it is all one technique.

Technical characteristics of the minitractor 180

The technical characteristics of the Uralets xt180 are not inferior to many models of powerful tractors. The only thing they are different about is their compactness, the Uralets is 253x120x175 cm in size. The hook has a traction capacity of 3.7 kN. The turn of the XT minitractor is 3.9 0. But with all its minimalism, it develops a speed of up to 27 km / h. This mini tractor weighs only 940 kg, but the weight can vary by 50-100 kg, depending on the configuration of attachments.

The technical characteristics of the Uralets xt180 are not inferior to many models of powerful tractors. The only thing they are different about is their compactness, the Uralets is 253x120x175 cm in size. The hook has a traction capacity of 3.7 kN. The turn of the XT minitractor is 3.9 0. But with all its minimalism, it develops a speed of up to 27 km / h. This mini tractor weighs only 940 kg, but the weight can vary by 50-100 kg, depending on the configuration of attachments.

Engine type - diesel two-cylinder four-stroke engine. Some models come with a gasoline engine, they are excellent in noise level and fuel consumption. Gearbox (3+1)+2. The front wheel track of the XT reaches 120-134 cm, rear 100-120 cm. The number of wheels: 2x4. The manufacturer, when finalized, can increase it to 140 cm.

With all this, the machine is very economical, the consumption does not reach 246.2 g/kW/h. This is one of the reasons for such popularity among farmers.

In addition, the XT minitractor has a beautiful design and a dual braking system with improved hydraulics. But every year the minitractor is improved. The model is easy to maintain, and the number of spare parts makes its work uninterrupted. It is believed that this is the fastest payback model on the Russian market of mini tractors. For greater convenience, manufacturers and sellers offer to test this technique. On the territory of Russia there are 165 service centers of this model.

Of course, like any model of tractors, the Urals has its negative sides. But to the credit of the manufacturers, this model has few of them. The main ones are:

- This model cannot work with heavy equipment, they are even unacceptable to install. For example, excavator, KUHN, etc.

- This technique is not suitable for all farmers, if you have large land, then it is better to use more powerful models.

Features of the Uralets XT180 model:

- The rubber of the front wheels is "industrial" domestic.

- Domestic battery with the latest current pre-start system.

- The wiring has been improved and strengthened.

- Diesel engines have a cold start system.

- There is a sound signal, which is not available on most mini tractors of other models.

- The gears in the gearbox are reinforced.

- The rear hitch has reinforced levers.

- The muffler is made of welded pipe.

- The seat for the convenience of the driver is horizontally adjustable.

- All lubricants and fluids used in the domestic production model.

- All instructions and catalogs in Russian.

- The manufacturer guarantees this model for 1 year from the date of purchase.

How Uralets works can be seen in the proposed video:

Owner reviews about Uralets

Nothing can characterize technology more accurately than users. Reviews about this machine can be found on numerous forums. For the convenience of readers, we have combined the most frequent of them in a table in the form of opposites to each other.

| Positive reviews | Negative Feedback |

| The tractor can be borrowed. This is especially useful for rural residents who have 5 hectares each, who use the plowing service for a fee. It is more profitable to purchase your own mini tractor and it will pay off in a year. And if you plow the land for neighbors for money, then you will still remain in profit. When calculating for a year of work, it paid off both the loan and interest, and even the gasoline spent on work | The high cost of replacing an oily engine in this model. But if you take into account the total costs and profits, then a quick payback. |

| The price and quality of the XT model is adequate, especially when compared with JM or SF. The XT 180 model is one of the most powerful in its line. Works without buildup with any mounted and trailed equipment. The fuel consumption is very low compared to the JM type model. In winter, it showed itself at 100%, easily rakes ice, sleet and even a stale embankment. Starts up quickly in cold winters. | It takes time to master, it is difficult to immediately get used to the elements of the control system. Spending on training is about the same as driving a passenger car. |

| Easily steerable and manoeuvrable model, especially useful when working in small and tight areas. Indispensable in the greenhouse industry. Power 18 hp suitable for all agricultural work. Beautiful and modern design. | The body is made of plastic, which makes the model more vulnerable to mechanical damage. |

| Does not damage lawns when working on them and has a wide range of attachments. | Attachments are unreasonably expensive, the price of some models reaches 100 thousand rubles. |

Judging by customer reviews, this technique has more pluses than minuses. And the cons either pay off during work, or require a small amount of personal time.

The price of a minitractor xt 180

In Russia, the cost of the Uralets minitractor is from 140,000 rubles. Much depends on the manufacturer and the basic configuration. Most companies offer to buy this equipment on credit, which makes it affordable for small businesses. And of course, the ambitions of the manufacturer are not unimportant in the matter of pricing. The average cost of Uralets 180 from various manufacturers is presented in the form of a table:

To the price from the manufacturer, each dealer makes his own markup. But you can buy this car from the manufacturer. Moreover, not everyone knows that the main manufacturer Traktor LLC has delivery throughout Russia. The only thing is that you won’t be able to buy such equipment on credit from the manufacturer

The Chinese brand Xingtai has been known to Russian farmers for two decades; the products are in demand in the CIS.

The work that Tractor Xingtai 180 performs will be listed in this article. The list consists of nine items. Not bad for 18 hp. combined with dimensions. For owners of small plots, this is a good combination, and it is appreciated.

Areas of use

The Xingtai 180 minitractor is used in agricultural, construction and municipal areas.

Works performed:

- plowing the land;

- harrowing and hilling of the soil;

- sowing vegetables and cereals;

- harvesting;

- hay making;

- cargo transportation;

- hay harvesting and much more.

Due to the small dimensions of the device, it is possible to carry out work in greenhouses.

This machine is appreciated by utility workers, as it is convenient to drive into hard-to-reach places for asphalt cleaning, where the driver of a full-size vehicle will not be able to maneuver. In addition, grass cutting, lawn watering and sidewalk cleaning can be carried out quickly using quick-release attachments. The machine has an all-weather purpose, thanks to a wide arsenal of special devices, including for clearing snow from roads and pedestrian roads. An auger-type snow blower, a brush or a blade do an excellent job with snow drifts.

The traction force of 3.7 kN Xingtai 180 is more than enough to transport building materials or, for example, crops with a total weight of up to 2000 kg. High maneuverability, low price and economical fuel consumption will help to make a choice in favor of this model.

Vehicle parameters

Good off-road patency of this vehicle is achieved thanks to a ground clearance of 300 mm, with a wheelbase width of 144 cm. The dimensions of the car are comparable to a small car: 242 cm in length and 130 cm in width. The speed mode of movement varies in the range from 0.75 m/s to 6.4 m/s, thus covering the entire range of tasks facing the vehicle.

The features of the model include the following indicators:

- wheel formula 2 by 4;

- 8-speed gearbox;

- the machine is supplied with a motor with one or two cylinders, to choose from;

- two-satellite closed differential;

- independent PTO;

- sliding mechanism of the bridge.

The weight of the car in 940 kg and the absence of a cab made it much easier for the Xingtai 180 driver to maneuver and control the equipment. In some modifications of the vehicle, a cab is still provided, which increases operator comfort during all-weather use of the machine. This structural element can be supplied as a base part or installed as an option.

Compared to previous mini tractor models, this model is additionally equipped with:

- two pairs of hydraulic outlets (with 2-channel distribution);

- receiver and compressor;

- three-point reinforced attachment for attachments;

- pneumatic system with trailer brake control function.

The installation of these nodes increased the cost of the minitractor, but at the same time its efficiency and versatility increased, which in turn saves the owner from unnecessary costs.

With an average mode of operation of the machine, a 17-liter fuel tank is enough for an eight-hour work shift, since diesel fuel consumption is in the range of 2-3 liters per hour.

Modification Xingtai 180, equipped with a four-stroke two-cylinder diesel engine TY 290 with a direct injection system and water cooling, is in the greatest demand among consumers. The water "jacket" of cooling allows the machine to work for a long time, preventing excessive heating. The motor is started in a safe mode for the operator using an electric starter.

Parameters of internal combustion engine TY 290:

- the volume of the cylinders is 1270 ml;

- unit power 18 hp;

- cylinders with a diameter of 9 cm.

Construction Xingtai 180

The minitractor has a single-plate clutch transmission, a simple bevel-type differential and a gearbox with two speeds reverse and six forward gears. The drive is made with traction on the rear axle.

Servicing of additional equipment is provided by a hydraulic system that works only on the rise. Torque is transmitted to the active attachments using a power take-off shaft with a rotation speed of 540 rpm.

The minitractor has a drum-type brake system installed only on the rear axle.

Machine controls:

- control pedals (clutch mechanism, gas drive, brake system);

- steering wheel, gearshift levers.

The PTO control and hydraulic shift levers control the attachments.

The Xingtai 180 lighting system has short-range and long-range lights, lighting equipment and a sound notification mechanism are also installed.

Attachment

A wide range of removable elements, which are designed to be installed on the trailer hitch of the machine, ensures the multitasking of vehicles.

Most popular types:

- vibrating potato harvester;

- active soil cutter;

- potato seeder with the possibility of fertilizing and changing the depth of planting seed;

- nine-row seeder (with settings for the depth of seeding into the soil and the option of fertilizing the soil);

- conveyor-type potato digger used when harvesting potatoes and then moving them into a swath;

- segment mower for cleaning grass;

- disc type harrow;

- plow;

- rake with different grip;

- device for collecting and folding hay.

With such an arsenal of attachments, the minitractor can be loaded at 100%, which allows you to recoup the funds invested in it within 12 months.

Pros and cons of Xingtai 180

The unit has a number of advantages.

These include:

- wide scope of use;

- long-range and short-range lighting devices that provide the ability to perform tasks around the clock;

- ease of use in confined spaces, greenhouses;

- a large arsenal of devices integrated for use as removable nodes;

- low fuel consumption.

Along with the positive qualities of this transport, there are also disadvantages.

Cons of a mini tractor:

- when cultivating the land, the lack of differential lock sometimes affects, the wheels can slip when working on heavy soils;

- some trailers are quite expensive;

- poor wear resistance of the body, vulnerable to damage;

- it takes some time to get used to the controls, it is difficult to operate transport without preparation.

Questions arising during the operation of equipment and answers to them

Often the owners of a mini tractor have a question about the filling volume of the hydraulic system of transport. The suspension system uses 15W40 engine oil in the summer, and in the winter, 10W40 is poured in an amount of 5 liters.

Regarding the dismantling of the Xingtai 180 checkpoint. Owners of a mini tractor need to know that there are adjustment parameters for the central gear, the values of which should be followed. More information about this can be found in the instructions for the machine.

How to change the track of a car - this question often arises with the owner of a vehicle when cultivating and harvesting potatoes. For these purposes, an adjustable front beam is provided, and the rear wheel track can be changed by rearranging the disks with the reverse side.