Hai! How to make a motorcycle is what interests the most fanatical motorcyclists and bikers. Why? The point is not the high cost of new factory motorcycles or even the fashion for homemade vehicles. Such a desire is caused rather by the desire to express oneself, as well as to find a bike that is as customized as possible.

The vse-o-moto.com team will help you with this. Below you will find a list of tips for assembling a two-wheeler with your own hands.

Most riders prefer riding bikes with an upright stance. Therefore, we recommend developing a classic type iron horse or a chopper. It is also advisable to take into account that it is better to move the footrests forward for the purpose of comfortable eating.

Creating a first-class bike from the Urals, Izh, Minsk. Voskhod and other serial iron horses, do not forget about the aesthetics of a huge steering wheel extended over a long distance. The most attractive type of fuel tank will be the “droplet”. An extended type of front fork will also add maximum beauty to your motorcycle with your own hands.

Before making a motorcycle, it won’t hurt to study video lessons either. You need to understand what parts of the future bike you can make yourself (primarily the frame, instrument panels, cases, plastic fairings, wheel spokes, saddle, etc.), and what you can hardly even design in drawings (engine , wheel rims and electronic components).

How to make a homemade motorcycle?

First you need to decide on the frame, but we will talk about this below. Now let's move on to engine selection. There are many engine options. Internal combustion engines are created by factories in two types: four-stroke and two-stroke. As an alternative, you can install an electric motor. In the latter case, you need to provide a lot of space for batteries in the frame of the two-wheeler. Of the internal combustion engines, 4-stroke engines are more valued in practice and are also used.

You don't have to buy a new engine. By visiting transport dumps/flea markets and searching a little on the Internet on bulletin boards, you can pick up quite good options for engines and spare parts for them. It's best to polish and tune everything you find.

These days it’s not difficult to find ready-made drawings and diagrams of unique motorcycles made with your own hands from paper, from a lighter, from Lego, from the Urals, etc. Experienced customizers from TV screens will also tell you how to make a moto. To this day, the “Western” media have produced many interesting television programs on this subject. You can also order custom assembly in a professional workshop by experienced mechanics who work in almost any city in our great homeland.

Where to start assembling a motorcycle with your own hands?

Having ready-made motorcycle project diagrams at hand, as well as materials for their practical implementation, you can safely move on to the direct processing of pipes and metal sheets in the process of creating a frame. Each part of the chassis can be chromed or painted to give it a more aesthetic appearance. This is also done to prevent corrosion of the chassis.

You can also create wheel rims with your own hands. Still, why “reinvent the wheel” if many compatriots know from practice how to make a motorcycle from the Urals or Dnieper MT. using the frame, engine and electronics of the latter. By adding other unique nodes to them, you will clearly get an iron horse that is unlike any other.

Having installed an extended fork (preferably adapted for a front disc brake), homemade traverses (created using a steel sheet with a thickness of several tens of millimeters), the bike’s handlebars are mounted using brackets. The brackets are also used to mount the rear shock absorbers. They are considered a secure base for holding the seat back. Here you can fix various panniers and the trunk of the bike.

How to assemble a complete homemade motorcycle

It is better to choose/create a two-level saddle for a two-wheeled custom. Before creating it, you need to find a thick sheet of steel (about 2 mm). The latter will bend along the contour from the future tank to the rear panel. To make the edges of the saddle more rigid, you need to bead its sides 1 cm down. The soft part of the seat can be made of ordinary thick foam rubber. Leather is best suited for all this as upholstery. When installing the seat, it is necessary to install rubber gaskets on the frame directly under it.

Also make sure that in the future your homemade bike can be placed on a leg as easily as possible when parked. For these purposes, it is better to choose a side knife, which is mounted on the left side member of the frame and has the ability to easily recline in the presence of a spring.

The steering wheel should be attached not only to rear-view mirrors, levers, cables, but also to various electrical appliances, which can be purchased together with the body in many places. The devices that look most beautiful are those placed in chrome-plated boxes/cylinders.

You need to know how to make a motorcycle with your own hands as correctly as possible even before installing the throttle handle on the steering wheel. The latter is made with small turned rubber rings.

Don’t forget about installing turn indicators on your homemade bike. Their absence on a motorcycle can lead to various dangers on the road. You can supplement the classic set of lighting devices (headlight, brake, turn signals) by installing small flashlights near the front headlight. Additional safety will be provided by installing safety arches on a homemade iron horse.

Important to remember: When making a motorcycle with your own hands, make sure that in the future you will be able to register it with the road control authorities. Any major changes in the design of the bike must be registered with the traffic police/traffic police.

How are engines for BMW motorcycles assembled?

Description:

The factory assembly process of the legendary boxer engine for BMW motorcycles.

How it works (Motorcycles).

Every boy dreams of building his own motorcycle and riding it like a breeze when he grows up.

Czech writer Martin Sodomka shares the passion of little researchers for mechanisms. Especially for them, he wrote an amazing book, “How to Build a Motorcycle.”

And today we will talk about it.

A new technical fairy tale

The book “How to Build a Motorcycle” is the third in a series of technical tales. The first two - “How to assemble a car” and “How to assemble an airplane” - have already managed to win the hearts of children and parents.

In the new story, the main characters - Arnie the mouse, Bill the sparrow and Christian the frog - have a new idea. This time they decided to assemble a motorcycle.

The story in the book is simple and fascinating. As always, together with the heroes, the child will follow the entire process of assembling a motorcycle, find out what it has in common with a car, and also understand such complex mechanisms as shock absorbers, brakes, clutch, gearbox and carburetor.

And, by the way, the book is a real serious reference book. But it is presented so captivatingly that it is perceived as a fairy tale.

Down to the screw

We are sure that if you see the book - until you scroll through to the end - you will not stop. There are bright, beautiful, lively illustrations on every page. And all images of details are signed. To make it easy to understand what we are talking about.

And on almost every page there are detailed diagrams that tell and show how the engine works, how the wheel, steering wheel and suspension work. Look how everything is described in detail - right down to the screw:

Just something complicated

Martin Sodomka is an engineer and designer by training, so he definitely knows a lot about mechanisms. In addition, he assembles retro cars himself: from the first to the last screw. And at the same time he is very well versed in children's literature and owns his own publishing house.

He brilliantly managed to combine his technical knowledge and artistic talent and write truly meaningfully and simply about complex things.

The texts in the book are excellent. Both interesting and understandable:

“Look: these are shock absorbers,” Karl showed. - Just like in a car, they smooth out vibrations due to unevenness in the road, so that the motorcycle does not gallop along it like a mountain goat over the hills. The shock absorbers are attached to brackets on the frame at the top, and to the pendulum at the bottom.

Laws of physics

The book is really very informative. Look, this is what just one illustration looks like. Looking at it and reading the text, the child learns:

- What is ignition and how does it work?

- What is a battery and a capacitor?

- How are the headlights arranged?

- What does the brake light control and much more.

But that is not all.

The book not only explains the operation of different parts of a motorcycle, but also reveals the operation of the laws of physics. This knowledge will definitely be useful at school.

The book “How to Assemble a Motorcycle” is a truly joyful gift for little technology lovers, as well as their dads. Even adults will be delighted by Martin Sodomka's technical tales. And they will help children develop erudition and spend many interesting evenings. Isn’t it great to already understand the structure of a motorcycle and the laws of physics at the age of 5-7? Knowledge that will be useful for life.

What can I say - a book for “real men” from the age of 6. And if a dad has a motorcycle and his son sleeps and sees how to tame it, then it’s a godsend. It is about three fearless friends - Arnie the mouse, Bill the sparrow and Christian the frog, who have just returned from warm countries on a plane that they themselves built. This time they decided to build a real motorcycle and race it. The titles of the sections of the book sound quite adult: “Drum brake with mechanical drive”, “Engine”, “Gearbox”, “Wiring diagram”, etc. Each of them clearly describes the stages of assembling a motorcycle and provides diagrams of the structure of its parts, down to the smallest details. Mothers leafing through the book will probably get lost in a sea of unfamiliar words (at least those like me, who are used to riding my husband’s motorcycle only as a passenger). But among the younger generation with a technical spirit, all these ball bearings, bushings and crank mechanisms evoke reverent interest and a desire to look at pictures, even instead of cartoons.

The unusual design of the book deserves special attention. It looks like it's been lying around in a garage for a couple of months, it's worn out in some places, taped up in some places, and covered in fuel oil stains in others. But, despite the visual dilapidation, the book is made very well, with thick matte pages, a hard cover and beautiful illustrations made by the author of the book, Martin Sodomka, with colored pencils. Holding such a publication in your hands is a real pleasure, regardless of your type of thinking, technical or humanitarian :)

Overall, a solid five. Laskava Roksolana, www.labirint.ru/reviews/goods/513343/

I bought this book on the recommendation of a friend. Somehow it’s easier for me with girls, but as a boy I’m always tormented about which book to buy. This book, as they say, is it! An auto mechanic friend of mine looked at this book and said that all the information in the book is reliable, and the book contains a lot of detailed and useful information about the structure of a motorcycle. As for the age audience of this book, the book turned out to be interesting both for a small child of 6 years old and for an adult child of 30 years old))) Alisa Sazonova, www.labirint.ru/reviews/goods/513343/

Buy on OZON.ru for 489

How to assemble a motorcycle?

A motorcycle is a means of transportation that may already be more relevant than a car. By riding a motorcycle you can avoid numerous and protracted traffic jams. But it’s worth considering that maintaining a motorcycle is not that cheap. Repairing an “iron horse” may cost you more than repairing a car.

Stage one: developing an idea for a future motorcycle

You, of course, understand that there are a great many types of motorcycles. First of all, determine the class of your future motorcycle. This is what will serve as the basis for choosing style and design.

It is possible that you are full of fresh and creative ideas that you are ready to bring to life right now. But the fact is that only professionals can handle this. And if you have never assembled a motorcycle before, you should choose something simpler that will be easy to implement and then transform and improve. It is for this purpose that you choose what you will start from when assembling your “horse”.

At this stage, it is necessary to fully understand the idea of the future motorcycle. Draw up a so-called action plan. You need to think about the design, the shape of the motorcycle, the set of parts you will need for assembly, the engine components (its power), and so on.

Stage two: draw a diagram

At this stage you need to draw a diagram of the future motorcycle. You don't have to be an outstanding artist to be able to draw a motorcycle diagram. Let this all be very conditional, the main thing is that you transfer your idea to paper. In general, all ideas should be sketched and written down on paper, because perhaps in the process you will improve your own ideas, and in order not to forget anything, record and sketch everything.

Using the finished diagram, you can draw up a scale drawing on which to calculate the dimensions of parts for a motorcycle (for example, a frame). For this we need:

- a simple pencil;

- eraser;

- large ruler;

- paper (it is better to use scale paper for drawing);

- meter (or tape measure) for taking measurements of motorcycle parts;

- calculator for making calculations.

It will be useful to make not only a general drawing of the motorcycle, but also all the parts separately. Having a visual diagram in front of you will make it easier for you to navigate while assembling the motorcycle, which will reduce the risk of errors. So, later, using the finished drawing, you can check whether all the parts are installed correctly, and whether you inadvertently forgot something.

You can also draw a finished motorcycle and color it.

Stage three: set of elements

At this stage it is necessary to purchase or possibly find all spare parts, such as:

- engine;

- wheels;

- frame;

- metal pipes;

- suspension;

- fuel tank;

- muffler.

In addition to the basic elements, you will need additional parts and tools for  possible improvements, for example:

possible improvements, for example:

- hammer, sledgehammer;

- welding (and, accordingly, electrodes);

- spanners;

- Screwdriver Set;

- various pliers (pliers, pliers);

- bolts, and washers and nuts for them;

- grinder for sawing off parts;

- putty set;

- good paint (it’s better to take it in a can so that there are no smudges later) and acetone;

- kerosene for cleaning parts from rust;

- small wiring;

- stickers for decorating the "iron horse".

In general, you need to purchase everything that you wrote down on your list at the first stage, and, perhaps, added in the process of creating the image of the motorcycle.

Stage four: manual assembly

If you don't have a lot of experience, you may not be able to collect everything the first time,  as it should be. The main thing is not to despair. You can always ask for advice from specialists, those people who deal with assembling a motorcycle or simply know its structure. There are also many resources on the Internet to help you understand the structure of a motorcycle.

as it should be. The main thing is not to despair. You can always ask for advice from specialists, those people who deal with assembling a motorcycle or simply know its structure. There are also many resources on the Internet to help you understand the structure of a motorcycle.

A hand-built motorcycle is called “custom”, which means “custom”. This term describes the motorcycle's prefabricated appearance, which suggests that all the parts were handpicked and the design is also a unique idea - yours or someone else's.

Motorcycle assembly procedure

Now that everything has been checked, you can take your motorcycle out onto the street and try to ride a certain distance. Don't try to get the most out of your bike right away. Start testing little by little. If you notice any unusual noises, the vehicle may have been assembled incorrectly and requires additional careful inspection. Don’t let things take their course, because it’s for your own safety.

After successful tests, you can get down to business with the design: paint your motorcycle as you please, install additional units and gadgets. Now your vehicle is on the move, surprise people with new ideas and be proud of the result.

Now you know how to assemble a motorcycle. If you follow the suggested instructions, there should be no problems with assembly. Be attentive to details, because they are no less important than the main assembly of the motorcycle.

Detailed assembly is described in the article.

Designing motorcycles is no less exciting than creating any other vehicles. In addition, a motorcycle, which is essentially a naked concept of a self-propelled mechanism, requires greater design sophistication, inventive talent and the instincts of a good mechanic. I present to the readers my ideas for designing homemade motorcycles. I can say that I have some experience in this kind of work: at the “Motosam-90” show-competition, my home-made motorcycle, the eighth in a row, was presented, a photo of which the magazine’s readers could see in the report from the show in No. 2 for 1991 . The photographs presented on these pages show three more motorcycles of my design. I want to tell readers about one of them - the last and most successful.

Over the course of thirteen years, I designed and built twelve two-wheeled vehicles. They were all significantly different from each other. Moreover, two motorcycles were designed using a partial monocoque design, and three were completely frameless, with a monocoque monocoque body. It is precisely this design solution that I prefer today: it seems to me the most reliable and advantageous in terms of strength, weight and ergonomics.

I hope that my design experience can be useful for those who are planning to make a motorcycle.

So what is a regular frame motorcycle? To simplify the answer, we can say that this is a frame, a fuel tank, tool boxes, an air filter housing with an intake noise muffler, an exhaust muffler, a rear fender with a tail light bracket and numbers, a saddle base, a trunk, as well as a kilogram of all kinds of bolts, nuts, bushings , pins, washers and rubber bands, with the help of which all of the above are connected into a single structure.

If you sum up the masses of these components and assemblies, you get a very impressive value. In addition, when all this is put together, it forms a far from aesthetically pleasing “skeleton”, which has many secret places where absolutely irremovable dirt will inevitably accumulate - you can only get rid of it by completely disassembling the motorcycle.

A year or two passes - and the tool boxes begin to rattle, cracks creep along the rear fender, the number plate along with the bracket falls off... And if the motorcyclist, God forbid, gets into at least a minor accident or even simply falls? In these cases, the frame bends and dents appear on the tank and tool boxes. Huge lower mufflers cause even more trouble, clinging even to smooth asphalt when cornering and significantly reducing passability on bad roads.

The two-wheeled vehicle, designed according to the “monocoque” design scheme, is free of all these shortcomings. Such a motorcycle is a monoblock welded box-shaped structure that performs the functions of all the parts and assemblies listed above. Interestingly, the spatial box structure is significantly more rigid and durable than the classic frame structure (including duplex frames). The use of a monocoque design in a motorcycle design not only reduces the weight of a two-wheeled vehicle, but also brings the center of gravity of the motorcycle closer to the ground. This happens due to the fact that in this design the tool box and battery compartment are located in the lower part of the body, and a lightweight air filter with an intake noise muffler is located in the upper part, where the fuel tank cap is located on classic motorcycles. The air intake is made above the steering column - in this area the cleanest, dust-free air is. An exhaust noise muffler may also be located inside the monocoque, but reliable thermal insulation from the fuel and seat cushion must be ensured.

1 - rearview mirror, 2 - secret fuel tank plug, 3 - shock absorber compensation chamber, 4 - shock absorber with a stroke of 120 mm, 5 - swing lever, 6 - push lever, 7 - brake rod, 8 - rear part of the body with exhaust muffler (left) and oil tank (right), 9 - rear turn signal, 10 - parking light and brake light (dual), 11 - exhaust pipe (left), 12 - brake disc with a diameter of 300 mm, 13 - chain catcher, 14 - rear wheel sprocket (z=37), 15 - rear wheel suspension pendulum, 16 - drive sprocket (z=15), 17 - foot brake pedal, 18 - drive box lever gears, 19 - winch drum, 20 - muffler - resonator, 21 - winch cable guide bracket, 22 - front brake disc with a diameter of 300 mm.

Rice. 2. Monocoque body layout. The cell size of the scale grid is 100×100 mm.

Pictures 1 and 2 show my enduro motorcycle and its monocoque body with rear suspension and engine protective frame. The weight of the monocoque is only 23 kilograms, and the useful volume of such a body is about 56 liters, of which 41 liters are for fuel tanks (more than that of the Zhiguli!), and the remaining volume of the body is fully used. At the same time, the motorcycle does not look bulky. On the contrary, it has relatively small dimensions - in particular, the base of the machine is only 1350 mm (smaller than that of any Izhevsk motorcycle).

It must be said that making a monocoque body is no more difficult than welding a good frame and equipping it with all the attached parts. You just need to strictly adhere to the pre-developed technology so that all the parts fit together well and are convenient to weld.

When drawing the design of the body, take care to ensure a comfortable position for the driver - this is especially important for enduro-type motorcycles - as well as the safety of the motorcyclist’s movements, ease of movement in a sitting position, in a rack and in the drawbar.

After choosing the optimal, in the designer’s opinion, layout solution, you should draw the entire motorcycle in full size - depict a side view, top view, front and rear, and also draw the most characteristic sections. The more detailed the drawing documentation, the easier further work on the manufacture of a two-wheeled vehicle will be.

It is most rational to place the engine directly on the axis of the pendulum. In this case, the reaction from the tension of the drive chain is connected directly to the pendulum. And it is far from small - sometimes it reaches the breaking strength of the chain, that is, almost two tons! It is necessary to mount the powerful and not very well balanced Izh-Planet engine (as well as all cross-country motors) using silent blocks or rubber cushions. You just need to take into account that the chain not only pulls the engine back, but also turns it in a horizontal plane due to the asymmetrical arrangement of the chain.

When creating a monocoque body, it is very convenient to use the volumetric prototyping method. In this case, the body layout is assembled from cardboard blanks, which are connected using strips of paper and glue. In the process of making a model, as a rule, changes occur in the design of the body, since not everything can be provided for in flat drawing projections. Simultaneously with prototyping the body, it is advisable to work out a technological map of its assembly - this will ensure the convenience of welding work. It is necessary to take into account the possible warping of metal workpieces when welding the body with uneven heating. Keep in mind that the parts that hold the swingarm and steering column are welded last. If necessary, they should be adjusted to the body so that on the finished motorcycle the planes of the wheels coincide with the plane of symmetry of the monocoque body.

The finished volumetric model is cut at the gluing points, and the cardboard patterns of the monocoque elements are numbered: it is from these patterns that blanks will be cut from a steel sheet of the appropriate thickness - from 1.2 to 1.5 mm. The easiest way to do this is with a chisel on a massive anvil.

Welding should be carried out in strict accordance with the technological map. To make the seams look neat and strong, the edges of the parts being welded should be slightly bent, as shown in Figure 3.

To ensure sufficient strength of the monocoque body, it is advisable to introduce additional reinforcements, flanges, and stiffeners into its design. For example, the steering column on my motorcycle and the transverse stiffening beam, to which the bracket for the only shock absorber of the rear suspension is welded, are additionally connected by a rectangular steel pipe of 25x40 mm. In addition, it is convenient to place electrical wiring and motorcycle control cables inside this pipe.

The design of the intake silencer significantly affects the engine power and its torque characteristics. The larger its volume, the easier the engine “breathes,” and the less air pulsation in the filter, which means less noise. Experts recommend setting the muffler volume to at least 20 engine displacements. The path from the air filter to the carburetor must be smooth, eliminating turbulence in the air flow, which significantly reduces engine power.

After welding, the monocoque body is checked for leaks - first with water and then with clean gasoline. If there are no leaks, the welding seams are coated from the inside with liquid epoxy glue - it will fill small pores, bind pieces of slag and drops of metal - this is especially important for the intake noise muffler.

The rear suspension is pendulum type, with cantilever wheel mounting. Wheel travel is about 260 mm. The pendulum hinge is on ball bearings and sealed with oil seals. Chain tension is done using an eccentric. The disc brake is mechanically driven.

The front suspension is based on the fork from the CZ-516 cross-country motorcycle. The wheel is for 21-inch tires, the disc brake pad drive is hydraulic.

The soft saddle pad is glued directly to the monocoque body, and the faux leather cover is attached to it with flush screws.

I would like to warn readers who do not have sufficient experience in designing motor vehicles that creating homemade two-wheeled vehicles is a very difficult matter. In this material I tried to talk about my work and those ideas that I consider promising for amateur motorcycle building. However, I would categorically not advise novice motorcycle builders to start creating a powerful machine based on this material. It might be better to start with simpler motorcycles. After all, I was moving towards a monocoque, having created more than a dozen intermediate structures...

Alexey GARAGASHIAN, St. Petersburg

Noticed a mistake? Select it and click Ctrl+Enter to let us know.

Fantasy made of plastic and metal... or how to make a motorcycle with your own hands? In Moscow, bikers presented their cars. Every detail counts when the footrest is made to look like a skeleton and the frame resembles a bass guitar.

Smiles on the faces of stern men in leather jackets and bandanas appear only when it comes to motorcycles. All models are made by hand, inside and out. Presenting their work, the bikers get excited like kids at a kindergarten party.

Omar Volpyansky: “It turned out to be light and weightless. If you sit down on the motorcycle and look from the side, you cannot see the saddle under the driver. It seems like he’s just hanging in the air.”

“The devil knows what!” this is the first reaction of visitors when they glance at the next model. This is no longer a motorcycle and not yet a car Fantasy of Alexander Ermikhin made of plastic and metal. It took almost a year to create it. There is nothing on the instrument panel except the speedometer.

Alexander Ermikhin: “It’s enough for him to just know how fast he’s going. In general, nothing else is interesting here, because everything here is done so correctly and competently that there is no need to show either oil pressure or temperature.”

Modern Vintik and Shpuntikov, who lovingly polish their motorcycles to a shine, are called customizers.

Alexander Keller: “Customizers are people who make fun of motorcycles, giving them an unusual form and content.”

Over ten years in Russia, customizing has turned from a garage hobby into an industry. But it should not be confused with tuning. Tuning is an improvement of the finished product, while customizers build from scratch, and every little detail is important here.

If the body of the motorcycle is decorated with skulls, then the footrest is in the form of a skeleton. But it also comes in the form of a chicken leg. It seems that the Discovery Channel star, American customizing legend Eddie Trot, liked this model.

Eddie Trot, chairman of the jury: “A couple of years ago I thought that Russian customizers were a little behind the rest of the world. Now I see that this is not so.”

It’s almost useless to torture castamizers, how they manage to come up with all this on a whim, from dreams, “they sat down and drew it.” One of the options sounded like this: “We once listened to the song “You shouldn’t bend to a changing world.”

Just as poets dedicate their poems to someone, so customizers address their works to specific people. So, one model, for example, is dedicated to the musicians from the group “Time Machine”. The bass guitar, the supporting part of the frame, is real: it plays if you connect it. But only musicians have the right to sit behind the wheel of this handsome man.

Kastmizers do not hide their motives - this is the desire to stand out. And, of course, no representative of the fair sex can resist a man on such a motorcycle.

Designing motorcycles is no less exciting than creating any other vehicles. In addition, a motorcycle, which is essentially a naked concept of a self-propelled mechanism, requires greater design sophistication, inventive talent and the instincts of a good mechanic. I present to the readers my ideas for designing homemade motorcycles. I can say that I have some experience in this kind of work: at the “Motosam-90” show-competition, my home-made motorcycle, the eighth in a row, was presented, a photo of which the magazine’s readers could see in the report from the show in No. 2 for 1991 . The photographs presented on these pages show three more motorcycles of my design. I want to tell readers about one of them - the last and most successful.

Over the course of thirteen years, I designed and built twelve two-wheeled vehicles. They were all significantly different from each other. Moreover, two motorcycles were designed using a partial monocoque design, and three were completely frameless, with a monocoque monocoque body. It is precisely this design solution that I prefer today: it seems to me the most reliable and advantageous in terms of strength, weight and ergonomics.

I hope that my design experience can be useful for those who are planning to make a motorcycle.

So what is a regular frame motorcycle? To simplify the answer, we can say that this is a frame, a fuel tank, tool boxes, an air filter housing with an intake noise muffler, an exhaust muffler, a rear fender with a tail light bracket and numbers, a saddle base, a trunk, as well as a kilogram of all kinds of bolts, nuts, bushings , pins, washers and rubber bands, with the help of which all of the above are connected into a single structure.

If you sum up the masses of these components and assemblies, you get a very impressive value. In addition, when all this is put together, it forms a far from aesthetically pleasing “skeleton”, which has many secret places where absolutely irremovable dirt will inevitably accumulate - you can only get rid of it by completely disassembling the motorcycle.

A year or two passes - and the tool boxes begin to rattle, cracks creep along the rear fender, the number plate along with the bracket falls off... And if the motorcyclist, God forbid, gets into at least a minor accident or even simply falls? In these cases, the frame bends and dents appear on the tank and tool boxes. Huge lower mufflers cause even more trouble, clinging even to smooth asphalt when cornering and significantly reducing passability on bad roads.

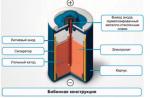

The two-wheeled vehicle, designed according to the “monocoque” design scheme, is free of all these shortcomings. Such a motorcycle is a monoblock welded box-shaped structure that performs the functions of all the parts and assemblies listed above. Interestingly, the spatial box structure is significantly more rigid and durable than the classic frame structure (including duplex frames). The use of a monocoque design in a motorcycle design not only reduces the weight of a two-wheeled vehicle, but also brings the center of gravity of the motorcycle closer to the ground. This happens due to the fact that in this design the tool box and battery compartment are located in the lower part of the body, and a lightweight air filter with an intake noise muffler is located in the upper part, where the fuel tank cap is located on classic motorcycles. The air intake is made above the steering column - in this area the cleanest, dust-free air is. An exhaust noise muffler may also be located inside the monocoque, but reliable thermal insulation from the fuel and seat cushion must be ensured.

1 - rearview mirror, 2 - secret fuel tank plug, 3 - shock absorber compensation chamber, 4 - shock absorber with a stroke of 120 mm, 5 - swing lever, 6 - push lever, 7 - brake rod, 8 - rear part of the body with exhaust muffler (left) and oil tank (right), 9 - rear turn signal, 10 - parking light and brake light (dual), 11 - exhaust pipe (left), 12 - brake disc with a diameter of 300 mm, 13 - chain catcher, 14 - rear wheel sprocket (z=37), 15 - rear wheel suspension pendulum, 16 - drive sprocket (z=15), 17 - foot brake pedal, 18 - drive box lever gears, 19 - winch drum, 20 - muffler - resonator, 21 - winch cable guide bracket, 22 - front brake disc with a diameter of 300 mm.

Rice. 2. Monocoque body layout. The cell size of the scale grid is 100×100 mm.

Pictures 1 and 2 show my enduro motorcycle and its monocoque body with rear suspension and engine protective frame. The weight of the monocoque is only 23 kilograms, and the useful volume of such a body is about 56 liters, of which 41 liters are for fuel tanks (more than that of the Zhiguli!), and the remaining volume of the body is fully used. At the same time, the motorcycle does not look bulky. On the contrary, it has relatively small dimensions - in particular, the base of the machine is only 1350 mm (smaller than that of any Izhevsk motorcycle).

It must be said that making a monocoque body is no more difficult than welding a good frame and equipping it with all the attached parts. You just need to strictly adhere to the pre-developed technology so that all the parts fit together well and are convenient to weld.

When drawing the design of the body, take care to ensure a comfortable position for the driver - this is especially important for enduro-type motorcycles - as well as the safety of the motorcyclist’s movements, ease of movement in a sitting position, in a rack and in the drawbar.

After choosing the optimal, in the designer’s opinion, layout solution, you should draw the entire motorcycle in full size - depict a side view, top view, front and rear, and also draw the most characteristic sections. The more detailed the drawing documentation, the easier further work on the manufacture of a two-wheeled vehicle will be.

It is most rational to place the engine directly on the axis of the pendulum. In this case, the reaction from the tension of the drive chain is connected directly to the pendulum. And it is far from small - sometimes it reaches the breaking strength of the chain, that is, almost two tons! It is necessary to mount the powerful and not very well balanced Izh-Planet engine (as well as all cross-country motors) using silent blocks or rubber cushions. You just need to take into account that the chain not only pulls the engine back, but also turns it in a horizontal plane due to the asymmetrical arrangement of the chain.

When creating a monocoque body, it is very convenient to use the volumetric prototyping method. In this case, the body layout is assembled from cardboard blanks, which are connected using strips of paper and glue. In the process of making a model, as a rule, changes occur in the design of the body, since not everything can be provided for in flat drawing projections. Simultaneously with prototyping the body, it is advisable to work out a technological map of its assembly - this will ensure the convenience of welding work. It is necessary to take into account the possible warping of metal workpieces when welding the body with uneven heating. Keep in mind that the parts that hold the swingarm and steering column are welded last. If necessary, they should be adjusted to the body so that on the finished motorcycle the planes of the wheels coincide with the plane of symmetry of the monocoque body.

The finished volumetric model is cut at the gluing points, and the cardboard patterns of the monocoque elements are numbered: it is from these patterns that blanks will be cut from a steel sheet of the appropriate thickness - from 1.2 to 1.5 mm. The easiest way to do this is with a chisel on a massive anvil.

Welding should be carried out in strict accordance with the technological map. To make the seams look neat and strong, the edges of the parts being welded should be slightly bent, as shown in Figure 3.

To ensure sufficient strength of the monocoque body, it is advisable to introduce additional reinforcements, flanges, and stiffeners into its design. For example, the steering column on my motorcycle and the transverse stiffening beam, to which the bracket for the only shock absorber of the rear suspension is welded, are additionally connected by a rectangular steel pipe of 25x40 mm. In addition, it is convenient to place electrical wiring and motorcycle control cables inside this pipe.

The design of the intake silencer significantly affects the engine power and its torque characteristics. The larger its volume, the easier the engine “breathes,” and the less air pulsation in the filter, which means less noise. Experts recommend setting the muffler volume to at least 20 engine displacements. The path from the air filter to the carburetor must be smooth, eliminating turbulence in the air flow, which significantly reduces engine power.

After welding, the monocoque body is checked for leaks - first with water and then with clean gasoline. If there are no leaks, the welding seams are coated from the inside with liquid epoxy glue - it will fill small pores, bind pieces of slag and drops of metal - this is especially important for the intake noise muffler.

The rear suspension is pendulum type, with cantilever wheel mounting. Wheel travel is about 260 mm. The pendulum hinge is on ball bearings and sealed with oil seals. Chain tension is done using an eccentric. The disc brake is mechanically driven.

The front suspension is based on the fork from the CZ-516 cross-country motorcycle. The wheel is for 21-inch tires, the disc brake pad drive is hydraulic.

The soft saddle pad is glued directly to the monocoque body, and the faux leather cover is attached to it with flush screws.

I would like to warn readers who do not have sufficient experience in designing motor vehicles that creating homemade two-wheeled vehicles is a very difficult matter. In this material I tried to talk about my work and those ideas that I consider promising for amateur motorcycle building. However, I would categorically not advise novice motorcycle builders to start creating a powerful machine based on this material. It might be better to start with simpler motorcycles. After all, I was moving towards a monocoque, having created more than a dozen intermediate structures...

Alexey GARAGASHIAN, St. Petersburg

Building a homemade motorcycle with your own hands: photo and description of the work done.

In general, the start of work on the motorcycle was November 2014 in Krasnodar. it all started with a proposal to bring a Ural motorcycle from the village and slightly modernize it for ourselves.

The rear swingarm was bored out to accommodate the Audi Q7 wheel by 20 inches. The question arose of connecting the wheel to the gearbox: chain, cardan, adapter? Everything is wrong - the wheel is too wide. As a result, the drive from Oka's car was taken. We made flanges for joining the box, drive and wheel. With minimal gaps, of course, but everything worked out. We made a hub to connect the axle and the wheel.

A successful test proved the functionality of the design. This process took at least 4 months.

Initially they wanted to make the front fork like on a chopper - recumbent, having digested the glass. There was a test ride for the first time, which showed that the fork shock absorbers were not working. The feathers made for the extended fork were also bent. To solve the problem, we reduced the angle of attack of the fork by turning out a new steering tube.

The rear fender was made from 2 mm steel; the front fender was later abandoned altogether - it spoiled the appearance. The saddle was also forged from 2 mm steel, upholstered and covered with leather. They made footrests, moved the gear shift and brake to them, and placed running lights there.

Rear brake - hydraulics: clutch master and slave cylinder from VAZ 2107. Front brake: double-disc hydraulic brake from Yamaha R1 4-piston. To install them, the hub had to be re-made. But the new hub no longer fit into the original fork, so it had to be expanded by making new yokes.

The tank and steering wheel remain unchanged. Indicator lamps are built into the traverses. They initially planned to make the headlight unique, so they didn’t redo anything, but took the high beam from a VAZ 2107 and made a housing for it. The engine was switched to 1 carburetor from the Oka, and an intake manifold was made.

Protective shields were made under the seat, where all the wiring was placed. The rear stops and turn signals are made of super bright LEDs. The motorcycle is painted in Rhapsody color. In total, taking into account improvements and alterations, the motorcycle took 2.5 years. The motorcycle is named “Monster”.

It is a dream of many, because it gives a person unprecedented freedom of movement. Unlike most sportbikes and city models, such a motorcycle is capable of moving quite quickly even outside good roads, without threatening its owner with falling and injury. At the same time, a cross bike is much easier to control than an enduro bike and other heavy types of equipment, also adapted for off-road riding. However, many simply cannot afford a high-quality motorcycle, because cheap models of real sports SUVs with two wheels are practically not found on the Russian market. Therefore, you should learn how to make a motocross motorcycle with your own hands - this will help you save a lot of money and adapt the resulting equipment to your needs.

Selection and preparation

As a basis for a cross-country motorcycle, you can choose a used small-class bike - it is best to choose models with an engine capacity in the range of 125-350 cubic centimeters. The best option would be a road-going Japanese car aged 12-15 years with a well-preserved engine and an intact frame. In addition, you can even choose a Soviet motorcycle - for example, “Voskhod” or “Minsk”. It won't catch the stars from the sky at sporting events, but it will allow you to get a lot of fun from off-road adventures.

The motorcycle will have to be disassembled - you must remove all the components from it, leaving only the frame. It is better to go through the motor, transmission and drive components, diagnosing possible faults and eliminating them before starting assembly. The frame and tank of the future motocross motorcycle should be cleaned of paint, then covered with putty and a new coating applied according to your wishes. After such preparation, you can begin selecting components and gradual assembly.

Parts selection

First of all, you need to pay attention to the future motocross motorcycle, since they will bear the main load. It is better to immediately abandon the use of alloy wheels, since they will not be able to properly absorb strong impacts, which will lead to their rapid deformation. The best option is to buy ready-made wheels based on spokes. A budget-friendly way to get wheels for a motocross motorcycle is to buy rims and install spokes of the required length yourself. There is no need to think long about the size of the wheels and reinvent the motorcycle, since the sport has adopted the standard - 120/70-17 in the front and 160/60-17 in the rear.

If you want to make a cross bike from Minsk, you will have to tinker with converting the rear suspension to a monoshock absorber. It is much easier to disassemble and select a fork of the appropriate size from a 125 cc Japanese motorcycle. All that remains is to choose the shock absorber itself - in this case, it is better to select the desired model based on the weight of the vehicle itself and its rider, and then make adjustments after assembly. Remember that the rear wheel travel of a motocross motorcycle should be 200-280 mm - based on this value, rear suspension components are selected.

Next, you should take care of the front suspension, which is subject to the highest demands. Unfortunately, in this case it will not be possible to make do with economical compromise options, so it is better to buy a fork from a motocross motorcycle assembled. You don’t have to look at the performance of the shock absorbers and the presence of high-quality oil in them - some can be changed during operation. For a motocross motorcycle, the ability to fine-tune the front suspension is very important, so you should pay attention to the integrity of the adjustment mechanisms. The fork travel should be approximately similar to that of the rear monoshock.

For safety reasons, you should also take care of installing other brake mechanisms that will effectively slow down the motocross motorcycle if necessary. The best option is to purchase a special sports kit consisting of other discs, calipers, hoses and fasteners. However, buying one can be quite expensive, so you can also buy used brakes from a larger motorcycle, which will provide fast deceleration without any problems. If your future motocross bike has drum brakes, you will either have to completely redo the wheels, or accept the mediocre performance of them, improving the deceleration slightly by fine-tuning the pads.

The last thing you need to take care of is the frame. Once you have purchased all of the above components to build your motocross bike, you will see that the standard mounting points need some work. Try to make maximum use of standard places for fixing certain parts, if possible without resorting to welding. However, you may need to completely reshape some parts of the motocross motorcycle frame, for which it is best to use high-strength steel pipes and a fairly powerful welding machine.

Tuning

Once you're done with the must-have part, you can also upgrade the motocross bike to suit your needs. First of all, this concerns the installation of modern carburetors with high performance - they will inevitably increase fuel consumption, but will allow for stable engine operation at high speeds. You can achieve good results by adjusting the standard carburetors of the resulting motocross motorcycle. However, if you encounter problems such as loud pops or black exhaust, it is better to return to standard settings or even contact a specialist. If you are going to make a dirt bike from Voskhod, you will also need to replace the standard paper filter with a foam filter, increasing its throughput without sacrificing performance.

Most experts advise taking care of high-quality tail when creating a motocross motorcycle. In this case, it is designed not only to improve the appearance of your bike, but also to protect its components from impacts on the off-road. Therefore, it is better to purchase a special tuning kit made of high-strength plastic. In addition, to save money, the necessary tail parts can be found at disassembly.

What are the results?

The resulting homemade motocross motorcycle will not be able to compete with factory models, no matter how much you might want it to. However, there is a way to make it truly perfect - for this you need to select components that perfectly match each other, as well as fine-tune them, which can take months or even years. Additionally, a motocross bike with custom components will require more frequent maintenance—you'd be surprised how many problems can arise when riding a homemade machine. Therefore, it is worth considering the option of saving for inexpensive foreign production. Moreover, purchasing high-quality components separately will also cost a considerable amount.