Different cars, depending on the type of engine, may have two or more valves per cylinder. Some of them serve to inlet the fuel-air mixture, others release exhaust gases. The first valves are simply called intake, and the second - exhaust. And they are actuated and regulated by the so-called valve (or gas distribution) mechanism. There is a lot of controversy about how to adjust the valves in the most profitable and simple way.

Importance of adjusting engine valve clearances

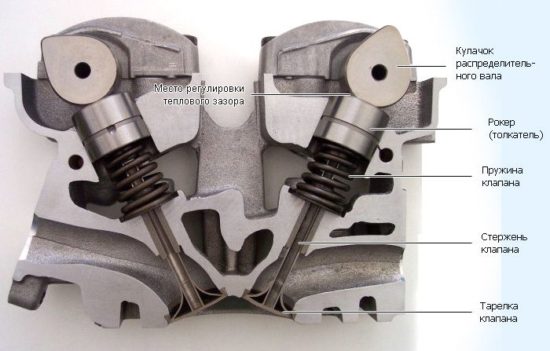

After starting, the engine and all its parts begin to heat up, and therefore expand. At the same time, one should not forget about the natural wear and tear of rubbing and contacting parts. This necessitates strictly defined clearances between some components. And the thermal clearances of the valves (between the camshaft cam and the valve stem) are among the most important.

If the gap is too small, the engine will not be able to fully realize its potential, which will not be slow to affect the dynamic and speed characteristics of the car. Along the way, overheating of the exhaust valves and melting of their edges will occur.

If the gap is more than expected, then the characteristic “clatter” of the engine will be a wake-up call for the car owner, which can sometimes go away with the car warming up. With increased clearance, the camshaft cam starts to "knock" on the valve stem rocker instead of pushing through it.

Sectional view of a valve train using the example of a twin camshaft engine

The need to adjust the valves is ripe if the following signs are visible:

- in the area of \u200b\u200bthe cylinder head cover there is an extraneous, slightly ringing sound;

- the gas distribution mechanism was repaired;

- the last adjustment of the thermal clearances of the valves was carried out more than 20 thousand km ago;

- engine output has dropped noticeably;

- as a consequence, high fuel consumption is possible.

In most modern motors, hydraulic compensators are used to adjust thermal gaps. It is convenient and does not require third-party intervention, although there is an opinion that the wear of components still occurs a little faster. The engines of many cars, in particular on the VAZ classic, require manual adjustment of thermal gaps. Someone considers this business simple, someone, on the contrary, is responsible and serious work. It all depends on experience, options for techniques, skill and patience. Work is recommended to be carried out after approximately 20 thousand kilometers since the last adjustment.

There is also not much difference whether you have to deal with a gasoline or diesel engine. There are no significant and fundamental differences in the process of adjusting the valves.

Even better is to combine valve clearance adjustment with an engine oil change. And in that exact order. This will allow dirt, dust and sand that can get into the engine during adjustment to leave then along with the old oil and oil filter.

Preparation

Before starting work, it is better to thoroughly wash the car body and clean the engine compartment of dust and dirt so that nothing extra gets into the engine after removing the cylinder head cover. Then it is very desirable to install the car on the most even surface, tighten the parking brake and place stops under the wheels. It will be useful to have good and uniform lighting. If the latter is not enough, get additional light sources.

It is not at all necessary to buy such stops, it is quite possible to make them yourself

Next, you need to wait until the engine cools down to the recommended temperature (usually 15-25 ° C) so that the measurements are as accurate as possible. Sometimes experienced craftsmen take up the “hot” adjustment, taking into account certain corrections for the increased temperature of the motor. But engines are different, with their own nuances and amendments, so it's better to wait. Free time can be used to replace filters, check optics, etc.

The valve clearances can also be adjusted with the cylinder head removed. Here, to whom which scheme of work is more convenient, this method cannot be considered wrong. It should only be remembered that when installing the cylinder head on the machine and broaching, clearance shifts are possible either in plus or minus from the required indicators. Therefore, it is better to play it safe and double-check.

List of tools for work

- Set of wrenches.

- A couple of screwdrivers.

- Measuring probe.

- Set of adjusting washers.

- Micrometer.

- Tweezers.

- Special device for adjusting valves.

A set of tools for adjusting valves on VAZ cars

Valve clearance adjustment using a feeler gauge

- First you need to unhook all the tubes from the valve cover, the cables leading to the damper actuators, and dismantle the air filter housing. To make the crankshaft scroll easier, the candles can also be unscrewed.

- Unscrew the two nuts and remove the cover, after which oil residues are removed from the top of the cylinder head.

- Remove the front timing belt cover.

- The piston of the cylinder from which the clearance adjustment will begin is set to the top dead center of compression. All valves in this position will be closed. In the process, for the most accurate result, you can focus on the marks applied by the manufacturer.

- Next, the crankshaft should be rotated clockwise along the sprocket. For optimal valve adjustment, it is required that the marks on the crankshaft and bearing housing coincide. For more convenience, you can apply your own labels. Then in the future the position of each cylinder can be determined by the teeth of the sprocket.

- On the screw used to set the gap, the lock nut is pressed. The gap is set in such a way that the flat feeler gauge is the bolt turning limit. Then the locknut is tightened. Along the way, it is necessary to monitor the tightening force of the locknut, otherwise the obtained parameters can be knocked down.

- Having finished with the tightening, it is necessary to check the set gap again with a probe. The latter should pass with a slight effort. If the result differs from the desired - carry out the adjustment again.

- Repeat the process for all subsequent valves.

Above was a method for adjusting valves using a feeler gauge. On many modern cars, special shims are used for this procedure. The whole scope of work is perfectly demonstrated in the video below.

An example of valve adjustment on a VAZ 2108–2115

How to adjust a 6-cylinder in-line engine: video

How to adjust with a rail and indicator

A special rail paired with an indicator can also be used to adjust the thermal clearance of the valves. This set helps to achieve greater accuracy than using a feeler gauge or washers.

Video about the sequence of work

If there is HBO (gas)

If the car is equipped with gas-balloon equipment, valve adjustment acquires its own characteristic features. The intake valve clearances can be set according to the instructions, as for gasoline. But graduation needs special attention. This is due to the characteristics of the fuel-air mixture on gas, the combustion temperature of which is higher and the combustion time is lower. In the presence of HBO, it is better to adjust the exhaust valves at intervals twice as often, and set the gaps themselves to the maximum allowable according to the instructions. Some masters advise to bet 10-20% more than recommended.

Using the above methods, it is possible to accurately adjust the thermal clearances of the valves, simultaneously optimizing the gas distribution phases and improving the overall operation of the entire gas distribution mechanism. This will increase the service life of engine components and its motor resource.