Let's talk today about hydraulic lifters, what underlies them, about the purpose and principle of operation, as well as how to determine that hydraulic lifters do not work.

A bit of history.

The first patents for hydraulic expansion joints were registered in the US as early as 1920. And the serial production of American passenger cars with hydraulic lifters began in 1960. Since then, this technology has spread around the world.

Now back to our topic.

During the operation of an internal combustion engine, its parts heat up and increase. This can lead to problems such as breakdown, accelerated wear of parts, deterioration in the performance of power units. And in order to exclude this, at the design stage, thermal gaps are created between some parts. Such gaps are absorbed by the expansion of the parts when the motor is heated. But over time, as a result of wear, the heating of the parts is no longer enough to absorb the gaps. Thus, engine performance begins to deteriorate.

The thermal gap has a direct effect on the performance of the power unit. Due to the fact that the wear of parts leads to a constant change in clearances, at the beginning of the twentieth century it was decided to introduce a mechanism for regulating them in the engine using ordinary wrenches. But such a procedure had to be done regularly, therefore, the complexity of maintenance increased, and therefore its cost rose. These problems are solved with the help of hydraulic compensators.

Contamination can occur if the wrong oil is used, if the timing of its replacement is not observed, if the oil filter is faulty, which passes dirty oil through the bypass valve.

When the engine lubrication system is faulty, the filling of the hydraulic compensator with oil is slowed down, and gaps in the gas distribution mechanism are not absorbed.

For the correct operation of the hydraulic compensator, its internal volume must be completely filled with oil. If this does not happen, then we can talk about the failure of the main function of this device, namely, the elimination of gaps in the details. Therefore, shock loads appear, making themselves felt with a characteristic knock. Thus, the parts begin to wear out faster, and the operation of the motor deteriorates.

The breakage of the hydraulic compensator can also be caused by the ingress of small particles from worn parts with oil, as a result, the assembly may jam. To prevent this, it is necessary to constantly monitor and maintain the internal cleanliness of the engine.

If, when removing the timing cover, you find that the surface of the engine is dirty, then you should not use fast-acting flushing agents. In this case, the hydraulic compensator may fail due to exfoliated pieces of dirt that can enter its internal cavities with the oil flow.

With small gaps between the moving elements of the hydraulic compensator in the engine, high-quality low-viscosity oils are used - synthetic or semi-synthetic. These include oils SAE 0W40,5W40,10W30, etc.

Mineral oils are not recommended as they are highly viscous and tend to form gum deposits.

As for diagnosis and replacement.

If the hydraulic compensator fails, then a knock appears. To determine such a malfunction, a phonendoscope is used, since sound propagates well in metal. If you have any doubts about your compensator, then you should dismantle it and check it.

It is removed with a magnet. And if the hydraulic compensator is stuck or stuck, then you have to remove it with a puller, but first you need to weld a rod with a hook to it.

There are also types of hydraulic lifters that provide for disassembly. This allows you to determine the degree of wear of internal parts. The hydraulic compensator should be disassembled with particular care so that the surfaces of the mating elements are not damaged.

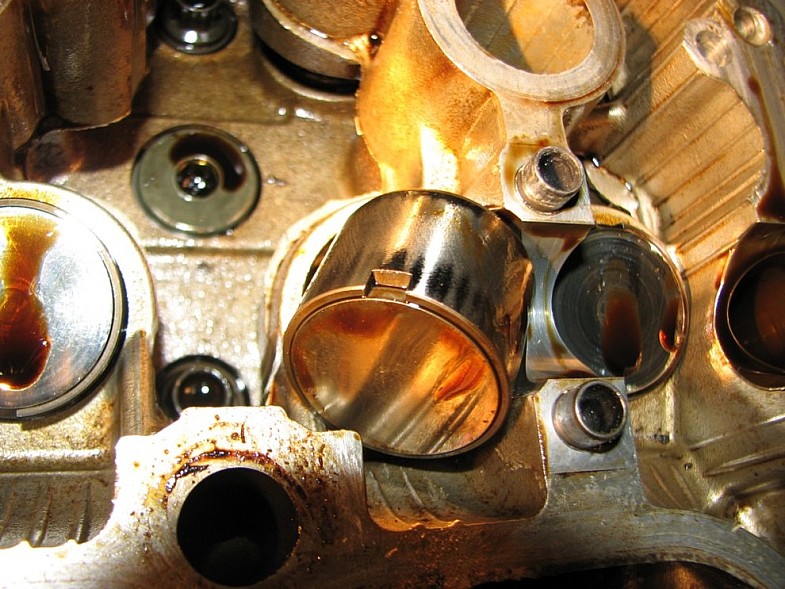

During visual inspection, external damage (potholes, scratches or scuffs) of the end surface of the hydraulic compensator, which are subjected to loads, can be detected. During operation, a depression may also form.

There is another effective and simple way to monitor the condition of the dismantled hydraulic compensator.

After filling it with oil, check that it does not shrink when hand pressure is applied. If the result did not meet your expectations, then the hydraulic lifter is faulty and needs to be replaced.

And if the hydraulic compensator is in normal working condition, this can be determined as follows. When compressed in a clamp, it will provide significant resistance, and reduce the length after 20-30 seconds, and very slightly.