A fuel injector is an element of the injection system of a modern car. It is this element that is responsible for executing the command to supply fuel to the cylinder. The brain gives out a signal in microseconds, for this time a signal of a given duration arrives at the injector, the injector opens and fuel is injected under the pressure of the fuel system (fuel pump). More details below, nozzle cleaning is also here, at the very bottom.

How the nozzle works

Fuel injector Honda Civic, nothing more than a tap. Yes, this is a tap to which a voltage of 9-15 volts is applied, an electromagnet coil attracts a needle and fuel, like a torch, comes out of it. The injector is also a solenoid.

Parameters, properties, values

The fuel system of most vegetable Honda Civic consists of a fuel tank (45l), a fuel pump, connection lines, a fuel filter, a fuel rail, the injectors themselves, and a “return” system with a valve. Fuel from the gas tank is supplied to the fuel pumps through the fuel wire to the fuel rail (through the filter). A pressure regulator NR-1 (Fuel Pressure Regulator - FPR) is installed on the fuel rail, in most cases it is enough, it was installed on most engines, but with a different mounting system. In general, fuel enters the fuel rail at a pressure of about 3 bar (3 atmospheres, 3000 mbar), if the pressure is higher, the FPR NR-1 valve throws the excess into the return line, from the return line the fuel enters the gas tank.

The value of the nozzles like 190, 240 (180, 235) and so on. shown in cubic centimeters. The full designation looks like this 240 [email protected]

, that is, the nozzle in 1 minute at a pressure of 3 bar (this is the normal pressure of most pumps) throws out 240 cubes of liquid.

If you used to have nozzles 190, and you want to install 240 just by replacing them, then you need to ask yourself a question. For what? 190 nozzles do not work at 100% even at full engine load, that is, there is a margin of 15%. Yes, I agree that if you increased the volume or you installed an air blower (turbine), then you need to replace the nozzles. And so you get an extra expense. The computer program says that, for example, at 450 mbar (45 kPa), nozzle 190 should work for only 100 ms, replacing it with 240 you will not change the opening time in the fuel map get an overly rich mixture. This is the same as if you were asked to open a large and small tap with water at the same time, for the same time, where do you think the flow will be more? Consider changing injectors carefully. If you don't have a dyno and/or a tuning daemon like Moates or Hondata I I wouldn't recommend changing injectors..

An important parameter of the injectors is the resistance, it is necessary that the resistance of the new and old injectors be the same. To do this, according to the "fashionable" ResistorBox is bought ($ 30-100). And according to normal, powerful ceramic resistances ($ 0.5-5). If you do not balance the resistance with the brain, then there is a possibility that the brain outputs to the injectors will burn out. Low-resistance atomizers 2.5-3 ohms, High-resistance 12 ohms. The danger is precisely in low-resistance ones, of course they are high-performance, but additional control is needed. At 50% load of 2.5 Ohm (low-resistance) injector at 7 minutes, when the engine is running at 6000 rpm, the brain starts to burn, the temperature of the keys (transistors) is 170-200 degrees Celsius, in the normal state it is 60 degrees. Usually transistors like STA413A, STA464C are used up to a maximum of 150 degrees, then either the parameters go away or the case breaks.

Nozzle cleaning, performance check

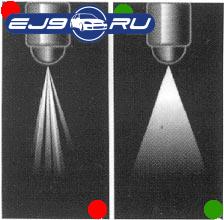

To clean the injectors, they must first be removed. You can of course do it in the engine, but it is not advisable to pollute the engine with chemicals. Your task is to create pressure with chemistry for cleaning, and open / close the nozzles periodically. The easiest way is to take the audio terminals to them, connect the Krona-9v battery, or the same 12v car battery and click through the button or open the circuit. Through a connecting tube (homemade), a pressurized Carbcleener-type cylinder and a nozzle are connected. You need to fasten very strongly otherwise the nozzle will fly out. Press the canister, pressurize, press the button, repeat until there is a normal spray pattern.

A more intelligent and lazy way is to connect the injector either to a signal generator (not the car's generator!) or to replace a computer speaker (active, not passive, from the mains) on which the signal program will run. Download the signal generator program. Adjust the frequency within 1-200Hz.

Ultrasound is the harshest method, and it is a great way to clean and crush dirt into small particles. Ideally, at this moment, the opening and closing signals would also be given to the nozzle. The disadvantage of this method is that it is possible, along with dirt, to increase internal cracks, or to destroy the nozzle from the inside.

To check the performance of the injector, it is enough to apply voltage to the injector from the Kron battery, you should hear a click. A more correct way would be to check for “continuity” with a multimeter.

Injector volume of some engines

Partially complete table from Accel. Another moment, except for resistance, the nozzle has a volume, as I said above. Only the manufacturer, KEIHIN, will tell you for sure. In general, there are only 2 volumes 180 (190) and 235 (240). As a percentage, this is a 5 and 2 percent difference, respectively. The difference between 240 and 190 is 25 percent.

- D14A2 - 190cc

- D14A3\D14A4 - 190 cc

- D14A5 - 190cc

- D14A7 - 190cc

- D14A8 - 190cc

- D14Z1 - 190cc

- D14Z2 - 190cc

- D14Z3\D14Z4 - 190 cc

- D15A3 - 180cc

- D15B6 - 180/235cc

- D16B2 - 190cc

- D15B7 - 235cc

- D15Z6 - 190cc

- D15Z8 - 190cc

- D16A6 - 235cc

- D16B2 - 190cc

- D16W4 - 190cc

- D16Y5 - 190cc

- D16Y7 - 180cc

- D16Y8 - 240 cc

- D16Z6 - 235 cc

- H22A1 - 235cc

- H23A1 - 235cc

- B20A5 - 235cc

- B18C1 - 235cc

- B16A3 - 235cc

Resistance of some Honda injectors

- Honda Civic (92-00 EX/Si) 240cc (23lb) 12Ohm

- Honda All (86-91) 240cc (23lb) 3Ohm

- Honda Civic (01-Up EX) 240cc (23lb) 11Ohm

- Honda Civic (03-Up Si) 290cc (28lb) 12Ohm

- Honda Civic (06-Up Si) 330cc (31lb) 10Ohm

- Honda Prelude (92-96 VTEC) 330cc (31lb) 2Ohm

- Honda Prelude (97-02) 290cc (28lb) 12Ohm

- Honda S2000 360cc (24lb) 12Ohm

This article is relevant for 1992-2000 Honda vehicles such as Civic EJ9, Civic EK3, CIVIC EK2, CIVIC EK4 (partially). The information will be relevant for owners of Honda Integra in DB6, DC1 bodies, with ZC, D15B, D16A engines.

Helpful Hints: Warm up your car longer in winter. Wait until the rpm drops to at least 1000 RPM. Full list of tips

For most questions, the community can help you.