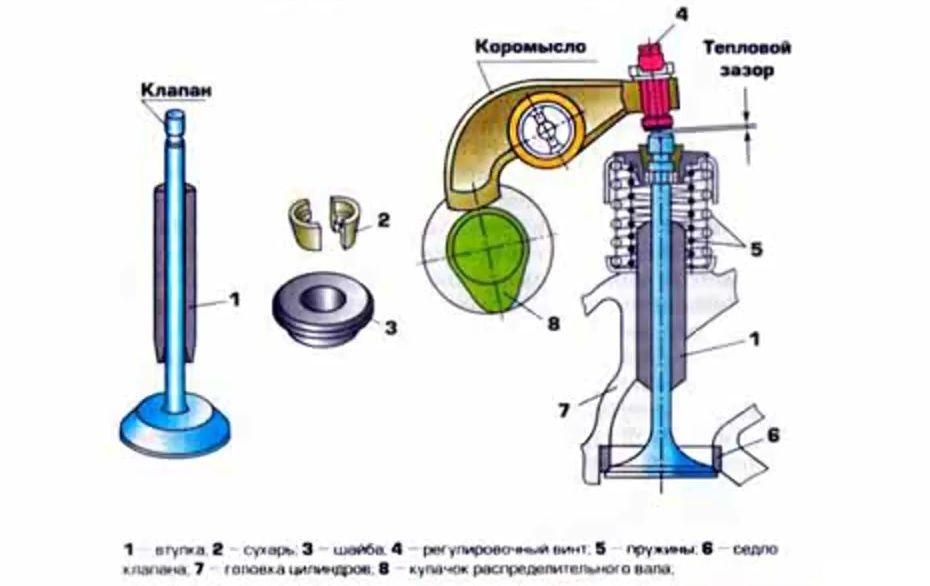

The operation of any internal combustion engine depends on the precise operation of the gas distribution mechanism (timing), the parts of which are the camshaft (camshaft), actuator and valves. After reading the article, you will learn why the thermal gap is important, how it is measured and adjusted, and what happens if it is set incorrectly.

During engine operation, all timing parts heat up and increase in size. As a result, the distance between the valve lifter and the camshaft changes. When the engine is warmed up to operating temperature, the pusher is close to the camshaft and valve. This ensures the most efficient operation of the engine. If the end face of a fully closed valve is higher than the pusher, a gap appears between the valve disc and the valve seat, which. If the end of a fully closed valve is located below the tappet, then during the corresponding valve timing it will open a little less than necessary. As a result, the power of the motor will drop, because the less the valve is open, the more difficult it is for air to enter through it or for exhaust gases to exit.

Valve clearance adjustment

On production cars, three methods are used to adjust the thermal gap:

- With screw;

- With the help of the selection of washers;

- With the help of hydraulic lifters.

The screw-adjustable valve actuator was popular in the early to mid-twentieth century. This drive had only one indisputable advantage - ease of adjustment. Its main drawback is the need to adjust the thermal gap every 10 thousand kilometers. Adjustment of the thermal gap using washers was used on high-speed motors from the 80s of the twentieth century until the first decade of the twenty-first century. To adjust the thermal gap, a set of washers of various thicknesses is required.

Re-adjustment of the thermal gap is carried out after 20-50 thousand kilometers. With the advent of hydraulic compensators, it became possible to adjust the valves with an interval of 100-300 thousand kilometers.

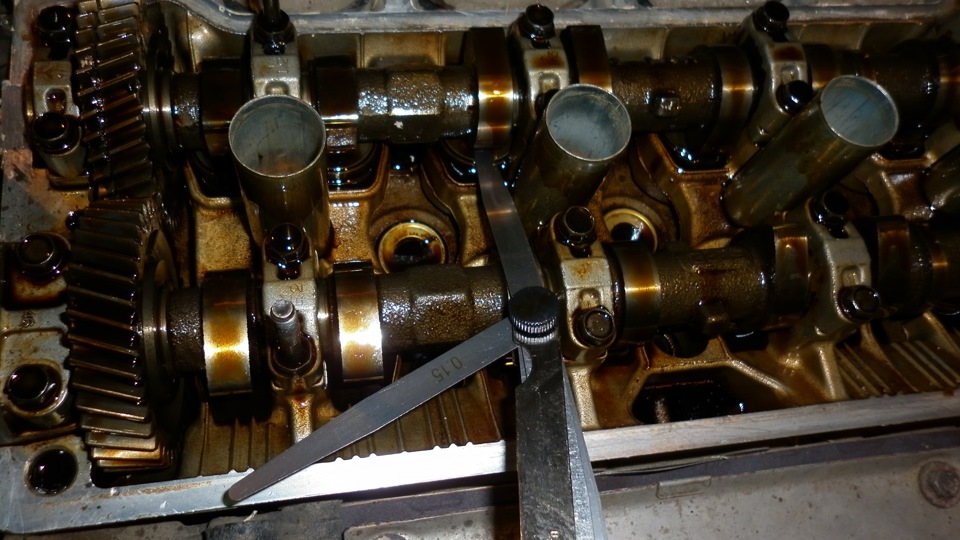

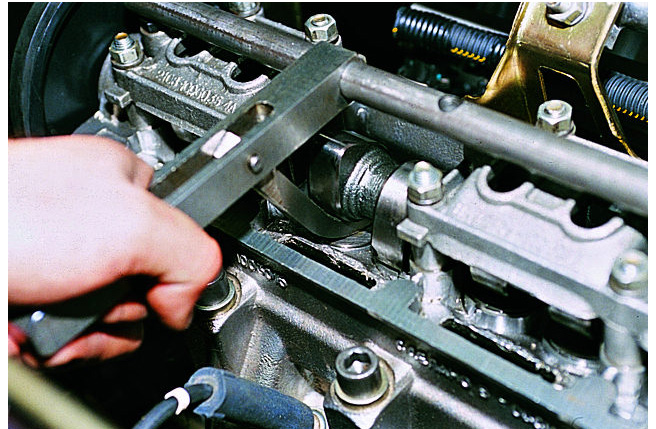

How and how to measure the thermal clearance of valves

The value of the thermal gap is checked on a cold engine. For this operation, you will need a feeler gauge and additional tools that depend on the type of valve lifter:

For screw adjustment:

- ring wrench corresponding to the pusher nut;

- open-end wrench corresponding to the adjusting bolt;

- hammer.

To adjust with washers:

- a set of washers;

- micrometer;

- puller;

- special tool for changing washers;

- tweezers.

To adjust with a hydraulic compensator:

- calipers.

To measure the clearance on a screw-adjusted tappet, turn it so that the camshaft cam of the selected valve points away from the tappet. With a hammer, lightly hit the pusher above the valve, then swing it left and right several times with your fingers. Using a feeler gauge, measure the gap between the pusher and the valve and compare it with the value specified in the vehicle's operating instructions (manual). If the gap is different from the recommended, then, holding the adjusting bolt, unscrew the lock nuts. Then, using the bolt, set the correct clearance and, holding the bolt with a wrench, tighten the lock nuts. Then check the gap again.

To measure the thermal gap on an engine with shim adjustment, the crankshaft is rotated so that the camshaft cam of the selected valve is pointing up. Then, using a feeler gauge, measure the gap and compare with that specified in the manual. If the gap is different, then with the help of a puller, the pusher (steel cylinder) is sunk and the washer is removed with tweezers. The thickness is written on the washers in millimeters with an accuracy of one hundredth. If the inscription is erased, it is necessary to measure the thickness of the washer in the middle with a micrometer. You cannot use a caliper for this operation because it will show the thickness at the edges. After that, it is necessary to select a washer of a suitable size, install it in place and check the gap again.

The adjustment of the thermal gap of the hydraulic compensators is carried out during the repair or check of the engine. To do this, remove the pusher guide or camshaft, then pull out the hydraulic lifters and use a caliper to measure the height of the valve stem. If its height corresponds to the tolerance of the hydraulic compensator, which is written on it, then adjustment is not required. If it does not match, then the compensator is changed to a suitable one. After that, the pusher guide or camshaft is installed in place.

Symptoms of a change in the thermal gap

If a serviceable engine began to emit a soft tapping, the frequency of which changes with engine speed and does not disappear after warming up, a slight increase in the thermal gap is possible. If, in addition to knocking, a serviceable engine began to lose power, throttle response or economy, a strong increase in the thermal gap is possible. If a serviceable engine begins to lose power, throttle response and economy, but there is no valve knock, and candles, fuel filter, ignition timing, and tire pressure are normal, a reduction in thermal clearance (clamped valves) is possible.

Why is it dangerous to change the thermal gap of the engine

If the valve is clamped, then the hot gases generated during the combustion of the fuel heat not only the lower, but also the upper part of the plate, then the temperature of the valve increases, which can lead to its burnout. This is especially dangerous if the motor is running under heavy load or incorrectly.

Valve burnout will lead to a sharp drop in engine power, an increase in fuel consumption and engine overheating. If the valves start knocking, then there is no threat to the motor. The problem is that at an early stage, turning the crankshaft bearing manifests itself with a similar knock, so it is easy to confuse them.