Many people know about such a device as a generator voltage regulator, but not everyone is able to say what principles underlie its operation and how diagnostics can be carried out. It is worth noting that this device is extremely important, because it is used to stabilize the voltage at the output of the generator. Imagine how the engine works in the process of movement. Its revolutions are constantly changing, and in a wide range, ranging from 700-900 rpm, and ending with five, seven or even ten thousand. As a result, the frequency of rotation of the generator rotor also varies over a wide range. And at any speed, a stable voltage must be maintained, which will be enough to charge the battery. If there are any defects, then a thorough check of the generator voltage regulator is required.

Mechanical voltage regulators

The history of the automotive industry goes back more than a hundred years, during which time many designs have been invented and implemented that improve the performance of all units. Among them is a relay-regulator, since a modern machine will not be able to work normally without it. Initially, mechanical devices were used, which were based on an electromagnetic relay. For example, the voltage regulator of the VAZ generator of the first models was just that.

He, as it turned out later, has no pluses, quite often there are shortcomings. Moreover, the main disadvantage is low reliability due to the presence of moving contacts. They are erased over time, as the device works constantly, without stopping. In addition, sometimes it is required to carry out adjustment work, which does not have a very good effect on the operation of the car. Modernity dictates the rule according to which the machine must be serviced in a timely manner in service centers. And the driver should not be able to carry out complex repairs, he only needs the ability to drive a car and change a wheel (this is the maximum).

Electronic relay-regulators

For the reasons indicated above, electronic type voltage regulators have become widespread. Progress does not stand still, so key transistors, triacs, thyristors have replaced electromagnetic relays. They have very high reliability, since there are no mechanical contacts, instead of which there is a semiconductor crystal. Of course, the production technology of such devices should be thought out. Otherwise, the semiconductor may fail. The voltage regulator of this type of generator is checked quite simply, you just need to take into account its features.

When compared with the previous, mechanical type of relay-regulators, one feature can be seen - electronic ones are produced in the same housing with brushes. This saves space, and most importantly, facilitates the replacement and diagnostics procedure. A special feature of electronic types is the accuracy of voltage regulation. The properties of a semiconductor do not change during operation. Therefore, the voltage at the output of the generator will always be the same. But it is worth talking about the method of regulation, about how the whole process takes place. And it is quite interesting, you will have to consider in general terms the design of the generator.

What elements does a car generator consist of

The base is the body, otherwise it is called the stator. It is the fixed part of any electrical machine. The stator has a winding. In automotive generators, it consists of three parts. The thing is that a three-phase alternating voltage is generated at the output, its value is about 30 volts. The reason for using this design is to reduce ripple, since the phases overlap each other, as a result, a direct current appears after the rectifier. Six semiconductor diodes are used for voltage conversion. They are unidirectional. If a breakdown occurs, then determining this with a tester is quite simple.

But there will be no voltage at the output of the stator winding, unless one condition is taken into account - a magnetic field is needed, and a moving one. It is not difficult to make it, it is enough to wind the winding on a metal anchor and apply power to it. But now the question of voltage stabilization arises. It makes no sense to do this at the output, since the elements will need to be very powerful, because the currents are large. But here one feature of electrical machines comes to the aid of designers - if a stabilized voltage is applied to the rotor winding, then the magnetic field will not change. Consequently, the voltage at the output of the generator also stabilizes. The VAZ 2107 generator works in the same way, the voltage regulator of which operates on the same principles as those of the "tens".

Voltage Regulator Components

Modern cars are equipped with fairly simple designs. They are non-separable, two elements are combined in one housing - the regulator itself and graphite brushes that transmit the supply voltage to the rotor winding of the generator. Moreover, electronic types of devices can be of two types. For example, the VAZ-2110 generator voltage regulator manufactured in the late 90s was made on a small circuit board. Modern devices are made using a single semiconductor crystal, in which all the elements are located. You can even say that this is a small chip.

Graphite brushes are connected to the terminals of the circuit board or semiconductor element. Voltage is supplied to them from the battery through a lamp, which is necessary for diagnosing the generator. Please note that you can not put LED elements in its place, since they have no internal resistance. Roughly speaking, the incandescent lamp also works as a fuse. If the thread burns out, then the voltage supply to the rotor winding stops, the generator stops working. If the lamp lights up, then there is a breakdown. Either the brushes are worn out, or the belt is broken, but sometimes it also happens that the semiconductor diodes in the rectifier fail. In this case, it is necessary to replace the generator voltage regulator with a new one.

How to remove the regulator

If the fault is only in the voltage regulator, then there is little work to replace it. You will also need a special tool - one screwdriver is enough. It is not necessary to completely disassemble the generator, since the brushes with the voltage regulator are located on its back cover.

You don't even need to loosen the belt. It is necessary to remove the generator voltage regulator 2110 in two cases:

- The brushes are completely worn out.

- A breakdown has occurred in the semiconductor.

Options for checking the device will be presented below. First, disconnect the battery. The fact is that a power wire goes from it to the generator, there is no protection on it, because it is used to charge the battery. And the current consumption of this circuit is very high. There is one connector on the regulator housing, disconnect the wire from it. Now you can unscrew the two mounting bolts. After that, the generator voltage regulator can be easily removed from the rear cover. It's time to check it out.

Voltage Regulator Diagnostics

First of all, pay attention to the condition of the brushes - if their length is less than 0.5 cm, then it is necessary to change the assembly assembly. Don't invent the wheel. It makes no sense to solder new brushes, since reliability will only suffer from this. Since there are several ways to check the generator voltage regulator, it’s worth starting with the most difficult thing - removing the device. For diagnostics, you will need a power supply, at the output of which the voltage can be changed within 10-18 Volts.

You also need an incandescent lamp. Its electrical parameters are as follows: supply voltage - 12 volts, power - 2-3 watts. Serve as follows:

- Positive output to the connector in the regulator housing (it is the only one on new samples).

- Minus the common plate.

The incandescent lamp is switched on between two brushes. The procedure is as follows:

- When a voltage of 12-12.5 volts is applied, the incandescent lamp should be on.

- At voltages above 15 volts, it should go out.

If it lights up at any supply voltage, or does not light up in any of these cases, then there is a breakdown of the regulator and it needs to be replaced.

How to make a diagnosis without removal?

It is not recommended to carry out such a check, since it is not possible to assess the condition of the brush assembly. But cases are different, so even such a diagnosis can bear fruit. To work, you will need a multimeter or, if there is none, an incandescent lamp. The main thing for you is to measure the voltage in the vehicle's on-board network, to determine if there are any surges. But they can be seen while driving. For example, flashing light when the engine speed changes.

But measurements taken using a multimeter or a voltmeter with an extended scale will be more accurate. Start the engine and turn on the low beam. Connect a multimeter to the battery terminals. The voltage should not exceed 14.8 volts. But it is also impossible for it to fall below 12. If it is not in the allowed range, then there is a breakdown of the voltage regulator. It is possible that the contacts at the connection points of the device with the generator are broken, or the wire contacts are oxidized.

Modernization of the regulator circuit

How complete the battery will be charged depends on the voltage regulator. Unfortunately, the simple constructions described above have a wide range of parameters. Therefore, buying three copies of the same devices in the same store, you will get a different output voltage. And this is a fact, no one will argue. If the battery does not have enough charge, then it will lose its capacity in a short time. And it won't start the engine. You will need to restore it only with a stationary charger.

But you can install a three-level generator voltage regulator, which allows you to change the characteristics by simply switching the toggle switch. In his circuit there are two semiconductors, in which the characteristics are slightly different. This makes it possible to adjust the output voltage. When one semiconductor is turned on, 14.5 volts appears at the output, and if another is put into the circuit, it will be slightly higher. The use of such a device is relevant in the winter, when the battery capacity decreases and additional charging is required.

How to install a three-level regulator?

For this procedure, you will need a small set of tools. You need a screwdriver, heat shrink insulation, self-tapping screws, it is possible that you will need a drill with a 2-4 mm drill. So, everything is in order. First of all, you need to unscrew the two bolts that secure the brush assembly and the regulator. In its place, you need to put a new one that comes with the kit. Its difference from a simple one is that there are only brushes there, semiconductors are located in a separate block. You need to place the second node near the generator, on the car body.

To do this, make small holes for fastening. It is worth noting that the block with semiconductors needs additional cooling. Therefore, it will be necessary to install it on an aluminum radiator, only after that to make fasteners to the body elements. If sufficient cooling is not provided, then the device may fail, as well as a violation of its operation - the regulation will not occur correctly. After finishing the fastening work, connect the two nodes with wires, conduct insulation. It is advisable to fasten the connecting wires with the help of clamps-screeds to the existing bundles.

Is it possible to make a three-level regulator yourself?

If you are familiar with radio engineering, you can find a cathode and an anode on a diode, then it will not be difficult for you to make such a device yourself. The question is, does it make sense. You will need two Schottky diodes to make. If you have them, then the price of the structure will be scanty. But if you have to buy them (and it is not known at what price), then you can compare the costs with the cost of a finished three-level regulator. The three-level type generator voltage regulator circuit is simple, anyone who knows how to handle a soldering iron can repeat it.

To implement your idea, you will also need a plastic case. You can also use aluminum, it will even be better, since cooling will be more efficient. It is only desirable to cover all surfaces with a layer of insulation so that the contacts do not close to the case when driving. You will also need to install a switch that will switch semiconductor elements. The work on installing the device on a car is similar to that described in the previous paragraph. It is also worth noting that you still need to purchase a brush assembly.

conclusions

Do not neglect such a device as the voltage regulator of a car generator. The battery life depends on its quality and condition. And if there are any defects in the device, then it must be replaced. Monitor the condition of this element, if necessary, clean the contacts so that failures do not appear. The generator is located in the lower part of the engine compartment, and if there is no mudguard, then a lot of water and dirt gets on it in bad weather. And this leads to the appearance of defects, not only in the voltage regulator, but even in the stator and rotor windings. Therefore, car care is necessary for the normal functioning of all systems. And before checking the generator voltage regulator, conduct a thorough inspection and clean all structural elements from contamination.

In order to stabilize the voltage in the vehicle's on-board network, a special device, a regulator, is used. Its performance has a significant impact not only on the individual characteristics of the car, but also on the durability of electronic and mechanical components.

Electronic relay regulators

How a relay regulator works

The generator creates a voltage that increases with increasing rotor speed. Its level also depends on the amount of current that passes through the connected load and on the parameters of the magnetic field formed by the excitation winding.

To ensure automatic tuning, it is necessary to measure the voltage at the output of the generator. To do this, it is converted into a measuring signal, which will be compared with a reference parameter. When changes are detected, the comparing unit must form a control signal that changes the current strength in the excitation winding in a certain way, which ultimately will make it possible to exert the necessary influence on the output voltage level.

The general principles are clear. But their implementation was different, depending on the level of technological development. The very first circuits used different solutions, up to the mechanical forces that actuated the spring assemblies in the relay. Of course, such designs were notable for their low reliability. Protective coatings were damaged in places where contacts were interrupted under the action of electrical discharges. Over time, moving parts fell into disrepair.

More advanced schemes corresponding to the current level of development will be considered below. But to understand the processes, it is quite enough to consider the simplest option, with a relay in the protection and control circuits. Similar devices are still used in trucks:

Electronic relay regulators

This simple circuit uses a single transistor. Here it acts as a key. If the generator rotates slowly, the output voltage is relatively low. Under these conditions, the control relay contacts (P n) are open, and the transistor is in the open state. When the voltage rises above a certain level, the relay closes the circuit. The semiconductor junction in the transistor closes. Further, the current does not pass along the collector-emitter path, but through the resistors (R d) and (R y). The excitation winding creates a magnetic field with less energy, which reduces the speed of rotation of the rotor. The output voltage drops.

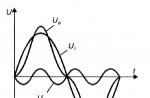

On fig. the changes in the electrical parameters in the winding are shown below. Below are the explanations:

Voltage regulator created using a combined circuit

- The values (n1) and (n2) are different rotor speeds at which the corresponding measurements were made (the frequency n2 is greater than n1).

- It can be seen that t on (the turn-on time of the winding) is greater on the upper graph, and less on the lower graph. Thus, with an increase in the speed of rotation, the winding creates a magnetic field for less time.

- The parameter t off (the time during which the switch-off occurs) explains the meaning of the second stage of the process. With acceleration of rotation and increase in voltage in the winding, the current decreases. This process provides the desired result, reducing the output voltage.

Features of regulators of different types

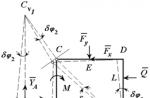

The diagram of a standard vibration type product is shown in the following figure:

Changing electrical parameters

This list shows the main parts of the design:

- 1 - spring;

- 2 - anchor;

- 3 - yoke;

- 4 - core;

- 5, 6, 9, 10, 15 - windings of the relay, current limiter and regulator;

- 7, 12, 17 - movable group of contacts;

- 8, 11, 16 - fixed group of contacts;

- 14 - shunt;

- 13, 18 and 19 - resistors.

It is clear that numerous mechanical contacts and moving parts reduce reliability. Such a relay voltage regulator of the generator has a large weight and impressive dimensions.

Below is a schematic diagram of one of the BOSCH regulators, which uses only electronic element base:

Schematic diagram of the BOSCH voltage regulator

This solution significantly improves reliability. It does not require a lot of space to accommodate a compact product. This device, subject to production technologies, is highly resistant to vibrations and temperature extremes.

In some versions, the board is filled with a compound, which further increases the protective properties and extends the service life in the most severe conditions.

Below are the features of individual elements:

- On the right side of the figure (part 2) is a diagram of an oscillator with rectifier diodes. At the top is a light that indicates the device is turned on.

- On the left side (part 1) is the electrical circuit of the regulator.

- (VT2) and (VT3) are the designation of transistors connected according to the classical scheme to increase the gain.

As a rule, such devices use an electronic element created in a single package and even on a single silicon chip.

- The zener diode is marked with symbols (VD1). This device does not pass current to a level that determines the stabilization voltage. As soon as the threshold value is broken, the current begins to flow through the corresponding circuit.

This circuit diagram performs its functions as follows:

- With the help of resistors (R1) and (R2), the voltage from the generator output is divided in the required proportion and fed to the zener diode.

- While the rotor speed is low, its level is insufficient to break through the semiconductor junction of the zener diode. In such a situation, no current can flow through the corresponding circuit. It does not arrive at the base (VT1). Therefore, the transistor is closed.

- The current passes to the base (VT2) along a different path, through (R6). This dual transistor is open. In this state, the winding is connected to the power circuit and creates a magnetic field.

- As the speed increases, or with a certain change in resistance in the load, the voltage at the generator output increases. If a certain threshold is exceeded, the semiconductor junction of the zener diode will be broken.

- After that, the current will go to the base (VT1) and open it. The path of current through the collector-emitter path to the ground point will be open. The semiconductor junction of the composite transistor will close, which will break the power supply circuit of the winding.

- When the excitation current level decreases, the rotor speed slows down, the voltage level drops, and the zener diode junction closes.

Health check

The consistent development of technology opens up new opportunities for improving the consumer parameters of electronics while reducing weight and size. In modern cars, even the last scheme, from the options discussed above, will look like an anachronism.

Modern regulators are more complex devices. They are distinguished by increased accuracy of control and stabilization of the generator voltage. They are created in sealed cases, filled with compound mixtures, which, after solidification, create reliable protection against moisture penetration and other external influences. These structures are non-separable, therefore, in the event of a breakdown, they are completely replaced.

It can be stated that in practice there is no repair not only in specialized workshops. Private craftsmen and amateurs to do everything themselves have to go to a specialized store to purchase the necessary assembly assembly. Thus, it is not the ability to solder individual elements and understand their performance, but general diagnostics that is of primary importance. To carry it out, you will need a tester and probes, a 12 V light bulb and a set of connecting wires, a charger.

Regulator mounted on the generator housing

Below is an algorithm of actions that will help to localize the malfunction. These recommendations are general. Therefore, it is necessary to take into account the special recommendations of the manufacturer for the correct dismantling of the voltage regulator and other components:

- With the engine turned off, the voltage at the battery terminals is measured (the norm is in the range from 11.9 to 12.7 V).

- After starting the power unit, a new voltage level is fixed, which should increase from the initial level by 0.9-1.1 V.

- Gradually increase engine speed. For convenience, this procedure is best performed with a partner. At medium - the voltage rises to 13.8-14.1 V. At the highest - up to 14.4-14.5 V.

If the acceleration of the rotation of the generator rotor does not affect the voltage level, then the regulator may break.

For a more accurate diagnosis, you will need to dismantle it and connect it according to the following scheme:

Regulator test circuit

When you turn on the charger and gradually increase the level to 14.4-14.5 V, the lamp will light up. As soon as this threshold is exceeded, it will turn off. When the voltage drops, the lamp will light up again. A malfunction is indicated not only by the absence of the described reactions, but also by the operation of the device at a higher voltage level. Under such conditions, the battery will be overcharged, which will reduce its life. After the diagnosis is completed, you can decide to replace the damaged regulator.

Video. Checking the voltage regulator.

In order to use the above technology in a timely manner, it is necessary to pay attention to deviations from the norm of the battery charge. Before dismantling the regulator, you should make sure that there are no oxide contaminations in the places of electrical contacts. In some situations, simply clearing the connections will resolve the issue. To prevent the occurrence of such problems in the future, it is recommended to use special means to protect contacts.

Rice. 1. Ways to control the excitation current: G - generator with parallel excitation; W in - excitation winding; R d - additional resistance; R - ballast resistance; K - current switch (regulating body) in the excitation circuit; a, b, c, d, e are indicated in the text.

A modern automobile internal combustion engine (ICE) operates in a wide range of speed changes (900: .. 6500 rpm). Accordingly, the rotor speed of the automobile generator changes, and hence its output voltage.

The dependence of the generator output voltage on the internal combustion engine speed is unacceptable, since the voltage in the vehicle's on-board network must be constant, and not only when the engine speed changes, but also when the load current changes. The function of automatic voltage regulation in the automobile generator is performed by a special device - automotive alternator voltage regulator. This material is devoted to the consideration of voltage regulators of modern automotive alternators.

Voltage regulation in generators with electromagnetic excitation

Ways of regulation. If the main magnetic field of the generator is induced by electromagnetic excitation, then the electromotive force E g of the generator can be a function of two variables: the frequency n of rotation of the rotor and the current I in in the excitation winding - E g \u003d f (n, I c).

It is this type of excitation that takes place in all modern automotive alternators that operate with a parallel excitation winding.

When the generator is running without load, its voltage U g is equal to its electromotive force EMF E g:

U g \u003d E g \u003d SF n (1).

Voltage U g of the generator under current I n load is less than the EMF E g by the amount of voltage drop across the internal resistance r g of the generator, i.e. can be written that

E g \u003d U g + I n r g \u003d U g (1 + β) (2).

The value β \u003d I n r g / U g is called the load factor.

From a comparison of formulas 1 and 2, it follows that the generator voltage

U g = nSF/(1 + β), (3)

where C is a constant design factor.

Equation (3) shows that both at different frequencies (n) of rotation of the generator rotor (n \u003d Var), and with a changing load (β \u003d Var), the stability of the voltage U g of the generator can only be obtained by a corresponding change in the magnetic flux Ф.

The magnetic flux Ф in a generator with electromagnetic excitation is formed by the magnetomotive force F in \u003d W I in the windings W in the excitation (W is the number of turns of the winding W in) and can be easily controlled using the current I in the excitation winding, i.e. F \u003d f (I c). Then U g \u003d f 1 which allows you to keep the voltage U g of the generator within the specified control limits for any changes in its speed and load by the appropriate choice of the control function f (I c).

The automatic function f (I c) of regulation in voltage regulators is reduced to a decrease in the maximum value of current I c in the excitation winding, which occurs at I c = U g / R w (R w is the active resistance of the excitation winding) and can be reduced in several ways ( Fig. 1): connecting to the winding W in parallel (a) or in series (b) additional resistance R d: shorting the excitation winding (c); rupture of the excitation current circuit (d). The current through the excitation winding can also be increased by shorting the series additional resistance (b).

All these methods change the excitation current stepwise, i.e. intermittent (discrete) current regulation takes place. In principle, analog regulation is also possible, in which the value of the series additional resistance in the excitation circuit changes smoothly (e).

But in all cases, the voltage U g of the generator is kept within the specified control limits by the appropriate automatic adjustment of the excitation current.

Discrete - pulse regulation

In modern automotive generators, the magnetomotive force F in the excitation windings, and hence the magnetic flux Ф, is changed by periodic interruption or an abrupt decrease in the current I in excitations with a controlled interruption frequency, i.e. apply discrete-pulse regulation of the operating voltage U g of the generator (previously, analog regulation was used, for example, in coal-fired voltage regulators).

The essence of discrete-pulse regulation will become clear from the consideration of the principle of operation of the generator set, consisting of the simplest contact-vibration voltage regulator, and an alternating current generator (ACG).

Rice. 2. Functional (a) and electrical (b) circuits of a generator set with a vibration voltage regulator.

A functional diagram of a generator set operating in conjunction with an onboard battery (ACB) is shown in fig. 2a, and the electrical circuit - in fig. 26.

The generator includes: phase windings W f on the stator ST, rotating rotor R, power rectifier VP on semiconductor diodes VD, excitation winding W in (with active resistance R w). The mechanical energy of rotation A m \u003d f (n) the generator rotor receives from the internal combustion engine. The vibration voltage regulator RN is made on an electromagnetic relay and includes a switching element CE and a measuring element IE.

The switching element of the KE is a vibrating electrical contact K, closing or opening the additional resistance R d, which is connected in series with the excitation winding W in the generator. When the switching element is triggered (contact K opens), a signal τR d is formed at its output (Fig. 2a).

The measuring element (ME, in Fig. 2a) is that part of the electromagnetic relay that implements three functions:

- the comparison function (CS) of the mechanical elastic force F n of the return spring P with the magnetomotive force F s = W s I s of the relay winding S (W s is the number of turns of the winding S, I s is the current in the relay winding), while the result of the comparison is the generated in the gap with period T (T = t p + t h) armature oscillations N;

- the function of the sensitive element (SE) in the feedback circuit (DSP) of the voltage regulator, the sensitive element in the vibration regulators is the winding S of the electromagnetic relay, connected directly to the voltage U g of the generator and to the battery (to the latter through the ignition key VZ);

- the function of the master device (ZU), which is implemented using a return spring P with an elastic force F p and a reference force F o.

The operation of a voltage regulator with an electromagnetic relay can be clearly explained using the speed characteristics of the generator (Fig. 3 and 4).

Rice. 3. Change U g, I c, R b in time t: a - dependence of the current value of the generator output voltage on time t - U g \u003d f (t); b - dependence of the current value in the excitation winding on time - I c \u003d f (t); c - dependence of the arithmetic mean value of the resistance in the excitation circuit on time t - R b \u003d f (t); I - time corresponding to the frequency (n) of rotation of the generator rotor.

While the voltage U g of the generator is lower than the voltage U b of the battery (U g

With an increase in the speed of the internal combustion engine, the generator voltage increases and when a certain value is reached U max) > U b) the magnetomotive force F s of the relay winding becomes greater than the force F p of the return spring P, i. F s \u003d I s W s > F p. The electromagnetic relay is activated and contact K opens, while additional resistance is included in the excitation winding circuit.

Even before contact K opens, the current I in in the field winding reaches its maximum value I in max \u003d U g R w > I wb, from which, immediately after contact K opens, it begins to fall, tending to its minimum value I in min \u003d U g /(Rw + Rd). Following the drop in the excitation current, the generator voltage begins to decrease accordingly (U g \u003d f (I c), which leads to a drop in current I s \u003d U g / R s in the relay winding S and contact K is again opened by the force of the return spring P (F p > F s) By the time the contact K opens, the generator voltage U g becomes equal to its minimum value U min, but remains slightly higher than the battery voltage (U gmin > U b).

Starting from the moment contact K opens (n = n min, Fig. 3), even with a constant frequency n of rotation of the generator rotor, the armature N of the electromagnetic relay enters the mechanical self-oscillation mode and contact K, vibrating, starts periodically, with a certain switching frequency f to \u003d I / T \u003d I / (t p + t h) then close, then open the additional resistance R d in the generator excitation circuit (green line in the section n \u003d n cf \u003d const, Fig. 3). In this case, the resistance R in in the excitation current circuit changes abruptly from the value of R w to the value of R w + R d.

Since during the operation of the voltage regulator contact K vibrates with a sufficiently high frequency f to switching, then R in \u003d R w + τ p where the value τ p is the relative time of the open state of contact K, which is determined by the formula τ p \u003d t p / ( t c + t p), I / (t c + t p) \u003d f to - switching frequency. Now, the average value of the excitation current, which has been established for a given frequency f to switching, can be found from the expression:

I cf \u003d U g cf / R c \u003d U g cf / (R w + τ p R d) \u003d U g cf / (R w + R d t p / f k),

where R in is the arithmetic mean (effective) value of the pulsating resistance in the excitation circuit, which also increases with an increase in the relative time τ p of the open state of the contact K (green line in Fig. 4).

Rice. 4. Speed characteristics of the generator.

Switching processes with excitation current

Let us consider in more detail what happens when switching with the excitation current. When contact K is closed for a long time, the maximum excitation current I in \u003d U g / R w flows through the winding W in the excitation.

However, the excitation winding W in the generator is an electrically conductive coil with a large inductance and a massive ferromagnetic core. As a consequence, the current through the excitation winding after the contact K is closed increases with deceleration. This is because the rate of current rise is hindered by hysteresis in the core and counteracting the rising current - the self-induction EMF of the coil.

When contact K is opened, the excitation current tends to a minimum value, the value of which, with a permanently open contact, is determined as I in \u003d U g / (R w + R d). Now the EMF of self-induction coincides in direction with the decreasing current and somewhat prolongs the process of its decrease.

It follows from the foregoing that the current in the excitation winding cannot change instantly (stepwise, as an additional resistance R d) either when closing or when opening the excitation circuit. Moreover, at a high vibration frequency of contact K, the excitation current may not reach its maximum or minimum value, approaching its average value (Fig. 4), since the value t p = τ p / f k increases with increasing frequency f to switching, and the absolute time t C of the closed state of contact K decreases.

From joint consideration of the diagrams shown in fig. 3 and fig. 4, it follows that the average value of the excitation current (red line b in Fig. 3 and Fig. 4) decreases with increasing speed n, since this increases the arithmetic mean value (green line in Fig. 3 and Fig. 4) of the total, pulsating in time, resistance R in the excitation circuit (Ohm's law). In this case, the average value of the generator voltage (U cf in Fig. 3 and Fig. 4) remains unchanged, and the output voltage U g of the generator pulsates in the range from U max to U min.

If the generator load increases, then the regulated voltage U g initially drops, while the voltage regulator increases the current in the field winding so that the generator voltage rises back to its original value.

Thus, when the generator load current changes (β = V ar), the regulation processes in the voltage regulator proceed in the same way as when the rotor speed changes.

Regulated voltage ripple. At a constant frequency n of rotation of the generator rotor and at a constant load, the operating excitation current ripples (ΔI in in Fig. 46) induce the corresponding (in time) ripples of the regulated generator voltage.

The amplitude of the ripples ΔU g - 0.5 (U max - U min) * voltage regulator U g does not depend on the amplitude of tone ripples ΔI in in the excitation winding, since it is determined by the regulation interval specified using the measuring element of the regulator. Therefore, voltage ripples U g at all frequencies of rotation of the generator rotor are almost the same. However, the rate of rise and fall of voltage U g in the control interval is determined by the rate of rise and fall of the excitation current and, ultimately, the speed (n) of the generator rotor.

* It should be noted that ripples 2ΔU g are an inevitable and harmful side effect of the operation of the voltage regulator. In modern generators, they are closed to ground by a shunt capacitor Csh, which is installed between the positive terminal of the generator and the case (usually Csh \u003d 2.2 μF)

When the load of the generator and the frequency of rotation of its rotor do not change, the vibration frequency of the contact K is also unchanged (f k \u003d I / (t c + t p) \u003d const). In this case, the voltage U g of the generator pulsates with an amplitude ΔU p \u003d 0.5 (U max - U min) about its average value U cf.

When the rotor speed changes, for example, upwards or when the generator load decreases, the time t c of the closed state becomes less than the time t p of the open state (t c

With a decrease in the frequency of the generator rotor (n↓), or with an increase in load (β), the average value of the excitation current and its ripple will increase. But the generator voltage will continue to fluctuate with an amplitude ΔU g around a constant value U g cf.

The constancy of the average voltage value U g of the generator is explained by the fact that it is determined not by the operating mode of the generator, but by the design parameters of the electromagnetic relay: the number of turns W s of the relay winding S, its resistance R s , the value of the air gap σ between the armature N and the yoke M, as well as force F p of the return spring P, i.e. the value U cf is a function of four variables: U cf = f(W s , R s , σ, F p).

By bending the support of the return spring P, the electromagnetic relay is adjusted to the value U cf so that at the lower rotor speed (n = n min - Fig. 3 and Fig. 4) contact K would begin to open, and the excitation current would have time to reach its maximum value I in \u003d U g / R w. Then the pulsations ΔI in and the time t z, the closed state are maximum. This sets the lower limit of the operating range of the controller (n = n min). At medium rotor speeds, the time t c is approximately equal to the time t p, and the excitation current ripples become almost two times smaller. At a rotational speed n close to the maximum (n = n max - Fig. 3 and Fig. 4), the average value of the current I in and its ripple ΔI in are minimal. At n max, the self-oscillations of the regulator are disrupted and the voltage U g of the generator begins to increase in proportion to the rotor speed. The upper limit of the operating range of the regulator is set by the value of the additional resistance (at a certain resistance value R w).

conclusions. The foregoing about discrete-pulse control can be summarized as follows: after starting the internal combustion engine (ICE), with an increase in its speed, there comes a moment when the generator voltage reaches the upper control limit (U g = U max). At this moment (n = n min), the switching element of the CE opens in the voltage regulator and the resistance in the excitation circuit increases abruptly. This leads to a decrease in the excitation current and, as a result, to a corresponding voltage drop U g of the generator. The voltage drop U g below the minimum control limit (U g = U min) leads to a reverse circuit of the switching element of the KE and the excitation current begins to increase again. Further, from this moment, the voltage regulator enters the self-oscillation mode and the process of switching the current in the excitation winding of the generator is periodically repeated, even at a constant frequency of rotation of the generator rotor (n = const).

With a further increase in the frequency of rotation n, proportionally to it, the time t c of the closed state of the switching element of the CE begins to decrease, which leads to a smooth decrease (in accordance with the increase in frequency n) of the average value of the excitation current (red line in Fig. 3 and Fig. 4) and amplitude ΔI in its pulsation. Due to this, the voltage U g of the generator also begins to pulsate, but with a constant amplitude ΔU g near its average value (U g = U cf) with a sufficiently high oscillation frequency.

The same processes of current switching I in and voltage ripple U g will also take place when the generator load current changes (see formula 3).

In both cases, the average voltage U g of the generator remains unchanged over the entire range of operation of the voltage regulator in frequency n (U g cf = const, from n min to n max) and when the generator load current changes from I g = 0 to I g = max .

In the foregoing is the basic principle of regulating the voltage of the generator using an intermittent change in the current in its excitation winding.

Electronic voltage regulators for automotive alternators

The vibration voltage regulator (VRN) considered above with an electromagnetic relay (EM relay) has a number of significant disadvantages:

- as a mechanical vibrator VRN is unreliable;

- contact K in the EM relay burns out, which makes the regulator short-lived;

- VRN parameters depend on temperature (the average value U cf of the operating voltage U g of the generator floats);

- VRN cannot operate in the mode of complete de-energization of the field winding, which makes it insensitive to changes in the output voltage of the generator (high voltage ripple U g) and limits the upper limit of the voltage regulator;

- electromechanical contact K of the electromagnetic relay limits the value of the maximum excitation current to 2 ... 3 A, which does not allow the use of vibration controllers on modern high-power alternators.

With the advent of semiconductor devices, it became possible to replace the contact K of the EM relay with the emitter-collector junction of a powerful transistor with its base control by the same contact K of the EM relay.

This is how the first contact-transistor voltage regulators appeared. In the future, the functions of an electromagnetic relay (SU, CE, UE) were fully implemented using low-level (low-current) electronic circuits on semiconductor devices. This made it possible to manufacture purely electronic (semiconductor) voltage regulators.

A feature of the operation of the electronic regulator (ERN) is that it does not have an additional resistor R d, i.e. in the excitation circuit, almost complete shutdown of the current in the excitation winding of the generator is realized, since the switching element (transistor) in the closed (open) state has a sufficiently large resistance. This makes it possible to control a larger excitation current and at a higher switching speed. With such a discrete-pulse control, the excitation current has a pulsed character, which makes it possible to control both the frequency of current pulses and their duration. However, the main function of the ERN (maintaining a constant voltage U g at n = Var and at β = Var) remains the same as in the VRN.

With the development of microelectronic technology, voltage regulators first began to be produced in a hybrid version, in which packageless semiconductor devices and attached miniature radio elements were included in the electronic circuit of the regulator along with thick-film microelectronic resistive elements. This made it possible to significantly reduce the weight and dimensions of the voltage regulator.

An example of such an electronic voltage regulator is the Ya-112A hybrid-integrated regulator, which is installed on modern domestic generators.

Regulator Ya-112A(see the diagram in Fig. 5) is a typical representative of the circuit solution for the problem of discrete-pulse regulation of the voltage U g of the generator by current I in excitation. But in the design and technological performance, currently produced electronic voltage regulators have significant differences.

Rice. 5. Schematic diagram of the Ya-112A voltage regulator: R1 ... R6 - thick-film resistors: C1, C2 - hinged miniature capacitors; V1...V6 - unpackaged semiconductor diodes and transistors.

As for the design of the Ya-112A regulator, all of its semiconductor diodes and triodes are unpackaged and mounted using a hybrid technology on a common ceramic substrate together with passive thick-film elements. The entire regulator block is hermetically sealed.

The Ya-112A regulator, like the vibration voltage regulator described above, operates in an intermittent (key) mode, when the control of the excitation current is not analog, but discrete-pulse.

The principle of operation of the voltage regulator Ya-112A of automobile generators

As long as the voltage U g of the generator does not exceed a predetermined value, the output stage V4-V5 is in a constantly open state and the current I in the field windings directly depends on the voltage U g of the generator (section 0-n in Fig. 3 and Fig. 4). As the generator speed increases or its load decreases, U g becomes higher than the response threshold of the sensitive input circuit (V1, R1-R2), the zener diode breaks through and the output stage V4-V5 closes through the amplifying transistor V2. In this case, the current I in in the excitation coil is turned off until U g again becomes less than the specified value U min. Thus, during the operation of the regulator, the excitation current flows intermittently through the excitation winding, changing from I in \u003d 0 to I in \u003d I max. When the excitation current is cut off, the generator voltage does not immediately drop, since the inertia of the demagnetization of the rotor takes place. It may even slightly increase with an instantaneous decrease in the load current of the generator. The inertia of the magnetic processes in the rotor and the self-induction EMF in the excitation winding exclude an abrupt change in the generator voltage both when the excitation current is turned on and when it is turned off. Thus, the sawtooth voltage ripple U g of the generator remains with electronic regulation.

The logic of constructing a circuit diagram of an electronic regulator is as follows. V1 - a zener diode with a divider R1, R2 form the input current cut-off circuit I in at U g\u003e 14.5 V; transistor V2 controls the output stage; V3 - blocking diode at the input of the output stage; V4, V5 - powerful transistors of the output stage (composite transistor) connected in series with the excitation winding (switching element of the CE for current I c); V6 shunt diode to limit the self-induction EMF of the field winding; R4, C1, R3 is a feedback circuit that accelerates the process of cutting off the current I in excitation.

An even more advanced voltage regulator is an integrated electronic regulator. This is a design in which all its components, except for a powerful output stage (usually a composite transistor), are implemented using thin-film microelectronic technology. These regulators are so miniature that they practically do not take up any space and can be installed directly on the generator housing in a brush holder.

An even more advanced voltage regulator is an integrated electronic regulator. This is a design in which all its components, except for a powerful output stage (usually a composite transistor), are implemented using thin-film microelectronic technology. These regulators are so miniature that they practically do not take up any space and can be installed directly on the generator housing in a brush holder.

An example of IRN design is the BOSCH-EL14V4C regulator, which is installed on alternators with a power of up to 1 kW (Fig. 6).

Depending on the device and the principle of operation, the relay-voltage regulators of the generator in the car are divided into several types: built-in, external, three-level and others. Theoretically, such a device can be made independently, the easiest and cheapest option in terms of implementation is to use a shunt device.

[ Hide ]

Purpose of the relay-regulator

The generator voltage regulator is designed to stabilize the current in the installation. When the engine is running, the voltage in the electrical system of the car must be at the same level. But since the crankshaft rotates at different speeds and the engine speed is not the same, the generator unit produces different voltages. Without adjusting this parameter, malfunctions in the operation of the electrical equipment and appliances of the machine may occur.

The relationship of auto current sources

Every car uses two power sources:

- Battery - required to start the power unit and primary excitation of the generator set. The battery consumes and stores energy when recharging.

- Generator. Designed for power and needed in order to generate energy regardless of the speed. The device allows you to recharge the battery when working at high speeds.

In any electrical network, both nodes must be working. If the DC generator fails, the battery will last no more than two hours. Without a battery, the power unit will not start, which drives the rotor of the generator set.

The LR West channel spoke about the malfunctions of the electrical networks in Land Rover vehicles, as well as the relationship between the battery and generators.

Voltage regulator tasks

Tasks performed by an electronic adjustable device:

- change in the value of the current in the excitation winding;

- the ability to withstand the range from 13.5 to 14.5 volts in the mains, as well as at the battery terminals;

- power off the excitation winding when the power unit is off;

- battery charging function.

"People's Auto Channel" spoke in detail about the purpose, as well as about the tasks that the voltage regulator in the car performs.

Varieties of relay-regulators

There are several types of automotive relay-regulators:

- external - this type of relay allows you to increase the maintainability of the generator unit;

- built-in - installed in the rectifier plate or brush assembly;

- changing by minus - equipped with an additional cable;

- plus-adjustable - characterized by a more economical connection scheme;

- for installation in alternating current units - the voltage cannot be regulated when applied to the excitation winding, since it is installed in the generator;

- for DC devices - relay-regulators have the function of cutting off the battery when the engine is not running;

- two-level relays - today they are practically not used, in them the adjustment is carried out by springs and a lever;

- three-level - equipped with a comparing module circuit, as well as a matching signaling device;

- multilevel - equipped with 3-5 additional resistor elements, as well as a control system;

- transistor samples - are not used on modern vehicles;

- relay devices - are characterized by more improved feedback;

- relay-transistor - have a universal circuit;

- microprocessor relays - characterized by small size, as well as the ability to smoothly change the lower or upper threshold;

- integral - are installed in the brush holders, therefore, when they are worn, they change.

Relay-regulators DC

In such units, the connection diagram looks more complicated. If the machine is stationary and the engine is not running, the generator set must be disconnected from the battery.

When performing a relay test, you must ensure that three options are available:

- battery cut-off when the vehicle is parked;

- limiting the maximum current parameter at the output of the unit;

- the ability to change the voltage parameter for the winding.

Relay-regulators of alternating current

Such devices are characterized by a more simplified test scheme. The car owner needs to diagnose the magnitude of the voltage on the excitation winding, as well as at the output of the unit.

If an alternator is installed in the car, then it will not work to start the engine “from the pusher”, unlike a direct current unit.

Built-in and external relay-regulators

The procedure for changing the voltage value is performed by the device at a specific installation location. Accordingly, the built-in regulators act on the generator unit. And the external type of relay is not connected to it and can be connected to the ignition coil, then its work will only be aimed at changing the voltage in this area. Therefore, before performing diagnostics, the car owner must make sure that the part is connected correctly.

The Sovering TVi channel spoke in detail about the purpose, as well as the principle of operation of this type of device.

Two-level

The principle of operation of such devices is as follows:

- Current passes through the relay.

- As a result of the formation of a magnetic field, the lever is attracted.

- A spring with a specific force is used as a comparing element.

- When the voltage increases, the contact elements open.

- Less current is applied to the excitation winding.

In VAZ cars, mechanical two-level devices were previously used for regulation. The main drawback was the rapid wear of structural components. Therefore, instead of mechanical, electronic regulators were installed on these models of machines.

These details were based on:

- voltage dividers, which were assembled from resistor elements;

- a zener diode was used as a driving part.

Due to the complex wiring diagram and inefficient voltage level control, this type of device has become less common.

Three-level

This type of regulators, as well as multilevel ones, are more advanced:

- The voltage is supplied from the generator device to a special circuit and passes through a divider.

- The received data is processed, the actual voltage level is compared with the minimum and maximum values.

- The mismatch pulse changes the current parameter that is supplied to the excitation winding.

Three-level devices with frequency modulation do not have resistances, but the frequency of operation of the electronic key in them is higher. For control, special logic circuits are used.

plus and minus control

Schemes for negative and positive contacts differ only in connection:

- when installed in a positive gap, one brush is connected to ground, and the second goes to the relay terminal;

- if the relay is installed in the minus gap, then one brush element must be connected to the plus, and the second - directly to the relay.

But in the second case, another cable will appear. This is due to the fact that these relay modules belong to the class of devices of the active type. For its operation, a separate power supply is required, so the plus is connected individually.

Photo gallery "Types of generator voltage relay-regulator"

This section contains photos of some types of devices.

Remote type devices  Built-in regulator

Built-in regulator  Transistor-relay type

Transistor-relay type  Integral device

Integral device  DC generator device

DC generator device  AC regulator

AC regulator  Two-tier device type

Two-tier device type  Three-level control device

Three-level control device

The principle of operation of the relay-regulator

The presence of a built-in resistor device, as well as special circuits, makes it possible for the regulator to compare the voltage parameter that the generator produces. If the value is too high, the controller is disabled. This allows you to prevent overcharging of the battery and failure of electrical equipment that is powered by the mains. Malfunctions of the device will lead to battery failure.

switch winter and summer

The generating device works stably regardless of the ambient temperature and season. When its pulley is set in motion, current is generated. But in the cold season, the internal structural elements of the battery can freeze. Therefore, the battery charge is restored worse than in the heat.

The switch for changing the season of operation is located on the relay housing. Some models are equipped with special connectors, you need to find them and connect the wires in accordance with the diagram and the symbols printed on them. The switch itself is a device by which the voltage level at the battery terminals can be increased to 15 volts.

How to remove the relay-regulator?

Removing the relay is allowed only after disconnecting the terminals from the battery.

To dismantle the device with your own hands, you will need a screwdriver with a Phillips or flat tip. It all depends on the bolt that secures the regulator. The generator unit, as well as the drive belt, do not need to be dismantled. The cable is disconnected from the regulator and the bolt that secures it is unscrewed.

User Viktor Nikolayevich spoke in detail about the dismantling of the regulatory mechanism and its subsequent replacement with a car.

Symptoms

“Symptoms” that will require the regulator to be checked or repaired:

- when the ignition is activated, a light indicator of a discharged battery appears on the control panel;

- the icon on the dashboard does not disappear after starting the engine;

- the brightness of the glow of the optics may be too low and increase with increasing crankshaft speed and pressing the gas pedal;

- the power unit of the machine is difficult to start the first time;

- The car battery is often discharged;

- with an increase in the number of revolutions of the internal combustion engine more than two thousand per minute, the bulbs on the control panel turn off automatically;

- the dynamic properties of the vehicle are reduced, which is especially evident at increased crankshaft speeds;

- the battery may be leaking.

Possible causes of malfunctions and consequences

The need to repair the generator voltage regulator relay will arise with such problems:

- interturn circuit of the winding device;

- short circuit in the electrical circuit;

- breakdown of the rectifier element as a result of breakdown of diodes;

- errors made when connecting the generating set to the battery terminals, reversal;

- the ingress of water or other liquid into the body of the regulatory device, for example, in high humidity on the street or when washing a car;

- mechanical malfunctions of the device;

- natural wear of structural elements, in particular, brushes;

- poor quality of the device used.

As a result of a malfunction, the consequences can be serious:

- High voltage in the car's electrical network will damage the electrical equipment. The microprocessor control unit of the machine may fail. Therefore, it is not allowed to disconnect the battery terminal clamps when the power unit is running.

- Overheating of the winding device as a result of an internal short circuit. Repairs will be costly.

- Breakage of the brush mechanism will lead to a malfunction of the generator set. The knot may jam, the drive strap may break.

User Snickerson spoke about the diagnostics of the regulatory mechanism, as well as the reasons for its failure in cars.

Diagnostics of the relay-regulator

It is necessary to check the operation of the regulatory device using a tester - a multimeter. It must first be set to voltmeter mode.

Embedded

This mechanism is usually built into the brush assembly of the generator set, so level diagnostics of the device will be required.

The check is done like this:

- The protective cover is being dismantled. Using a screwdriver or wrench, the brush assembly is loosened, it must be brought out.

- The wear of the brush elements is checked. If their length is less than 5 mm, then replacement is mandatory.

- Checking the generator device using a multimeter is performed together with the battery.

- The negative cable from the current source closes to the corresponding plate of the regulatory device.

- The positive contact from the charging equipment or battery is connected to the same output on the relay connector.

- Then the multimeter is set to the operating range from 0 to 20 volts. The probes of the device are connected to the brushes.

In the operating range from 12.8 to 14.5 volts, there should be voltage between the brush elements. If the parameter increases by more than 14.5 V, then the tester needle should fall to zero.

When diagnosing the built-in relay-voltage regulator of the generator, it is allowed to use a control light. The light source should turn on at a certain voltage interval and go out if this parameter increases more than the required value.

The cable that controls the tachometer must be ringed with a tester. On diesel vehicles, this conductor is designated W. The resistance level of the wire should be approximately 10 ohms. If this parameter falls, this indicates that the conductor is broken and needs to be replaced.

remote

The diagnostic method for this type of device is carried out in a similar way. The only difference is that the regulator relay does not need to be removed and removed from the generator set housing. You can diagnose the device with the power unit running, changing the crankshaft speed from low to medium to high. With an increase in their number, it is necessary to activate the optics, in particular, distant lighting, as well as the radio, stove and other consumers.

The channel "AvtotechLife" talked about self-diagnosis of the regulatory device, as well as about the features of this task.

Independent connection of the relay-regulator to the on-board network of the generator (step by step instructions)

When installing a new regulator device, the following points must be taken into account:

- Before performing the task, it is imperative to diagnose the integrity, as well as the reliability of the contacts. This is a cable that runs from the vehicle body to the generator set housing.

- Then the terminal clamp B of the regulator element is connected to the positive contact of the generating set.

- It is not recommended to use twisted wires when making a connection. They heat up and become unusable after a year of operation. Soldering should be used.

- It is recommended to replace the regular conductor with a wire with a cross section of at least 6 mm2. Especially if a new generator is installed instead of the factory one, which is designed to operate at currents above 60 A.

- The presence of an ammeter in the generator-battery circuit allows you to determine the power of power sources at a specific time.

Remote controller connection diagram

Wiring diagram for remote type devices

This device is installed after the wire is determined, into the gap of which it will connect:

- In older versions of Gazelles and RAF, mechanisms 13.3702 are used. They are made in a metal or polymer case and are equipped with two contact elements and brushes. They are recommended to be connected to a negative circuit break, the outputs are usually marked. The positive contact is taken from the ignition coil. And the output Ш of the relay is connected to a free contact on the brushes.

- In VAZ cars, devices 121.3702 are used in a black or white case, there are also double modifications. In the latter, if one of the parts breaks down, the second regulator will remain operational, but you need to switch to it. The device is installed in a break in the positive circuit with terminal 15 to the contact of the B-VK coil. The conductor number 67 is connected to the brushes.

In newer versions of the VAZ, the relays are installed in the brush mechanism and connected to the ignition switch. If the car owner replaces the standard unit with an AC unit, then the connection must be made taking into account the nuances.

More about them:

- The need to fix the unit to the body of the vehicle is determined by the car owner independently.

- Instead of a positive output, contact B or B+ is used here. It must be connected to the car's electrical network through an ammeter.

- The remote type of devices in such cars is usually not used, and the built-in regulators are already integrated into the brush mechanism. From it comes one cable, designated as D or D +. It must be connected to the ignition switch.

In vehicles with diesel engines, the generator unit can be equipped with a W output - it is connected to the tachometer. This contact can be ignored if the unit is placed on a gasoline modification of the car.

User Nikolai Purtov spoke in detail about installing and connecting remote devices to a car.

Connectivity Check

The motor must be running. And the voltage level in the car's electrical network will be controlled depending on the number of revolutions.

Perhaps, after installing and connecting a new generator device, the car owner will encounter difficulties:

- when the power unit is activated, the generator unit starts up, the voltage value is measured at any speed;

- and after turning off the ignition, the vehicle engine runs and does not turn off.

The problem can be solved by disconnecting the excitation cable, only after that the engine will stop.

Engine stalling can occur when the clutch is released while pressing the brake pedal. The cause of the malfunction is the residual magnetization, as well as the constant self-excitation of the winding of the unit.

In order not to encounter such a problem in the future, you can add a light source to the break in the exciting cable:

- the light will be on when the generator is off;

- when the unit is started, the indicator goes out;

- the amount of current that passes through the light source will not be sufficient to excite the winding.

The Altevaa TV channel talked about checking the connection of the regulatory device after connecting it to the 6-volt network of the motorcycle.

Tips for increasing the life of the relay-regulator

In order to prevent a quick failure of the regulatory device, it is necessary to adhere to several rules:

- The generator set must not be heavily contaminated. From time to time, you should perform a visual diagnosis of the condition of the device. In case of serious contamination, the unit is removed and cleaned.

- The tension of the drive belt should be checked periodically. If necessary, it is stretched.

- It is recommended to monitor the condition of the generator set windings. They must not be allowed to darken.

- It is necessary to check the quality of the contact on the control cable of the regulatory mechanism. Oxidation is not allowed. When they appear, the conductor is cleaned.

- Periodically, you should diagnose the voltage level in the electrical network of a car with the engine running and turned off.

How much does a regulator cost?

The cost of the device depends on the manufacturer and type of regulator.

Is it possible to make a regulator with your own hands?

An example is considered on the regulatory mechanism for a scooter. The main nuance is that for correct operation, it will be necessary to disassemble the generating unit. With a separate conductor, it is necessary to bring out the mass cable. The assembly of the device is carried out according to the scheme of a single-phase generator.

Action algorithm:

- The generator unit is disassembled, the stator element is removed from the scooter motor.

- On the left around the windings there is a mass, it must be soldered.

- Instead, a separate cable is soldered for winding. Then this contact is brought out. This conductor will be one end of the winding.

- The generator unit is being reassembled. These manipulations are carried out so that two cables come out of the unit. They will be used.

- Then, a shunt device is connected to the received contacts. At the final stage, a yellow cable from the old relay is connected to the positive terminal of the battery.

Video "Visual guide to assembling a homemade regulator"

User Andrey Chernov clearly showed how to independently make a relay for the generator set of a VAZ 2104 car.

Depending on the device and the principle of operation, the relay-voltage regulators of the generator in the car are divided into several types: built-in, external, three-level and others. Theoretically, such a device can be made independently, the easiest and cheapest option in terms of implementation is to use a shunt device.

[ To uncover]

Purpose of the relay-regulator

The generator voltage regulator is designed to stabilize the current in the installation. When the engine is running, the voltage in the electrical system of the car must be at the same level. But since the crankshaft rotates at different speeds and the engine speed is not the same, the generator unit produces different voltages. Without adjusting this parameter, malfunctions in the operation of the electrical equipment and appliances of the machine may occur.

The relationship of auto current sources

Every car uses two power sources:

- Battery - required to start the power unit and primary excitation of the generator set. The battery consumes and stores energy when recharging.

- Generator. Designed for power and needed in order to generate energy regardless of the speed. The device allows you to recharge the battery when working at high speeds.

In any electrical network, both nodes must be working. If the DC generator fails, the battery will last no more than two hours. Without a battery, the power unit will not start, which drives the rotor of the generator set.

The LR West channel spoke about the malfunctions of the electrical networks in Land Rover vehicles, as well as the relationship between the battery and generators.

Voltage regulator tasks

Tasks performed by an electronic adjustable device:

- change in the value of the current in the excitation winding;

- the ability to withstand the range from 13.5 to 14.5 volts in the mains, as well as at the battery terminals;

- power off the excitation winding when the power unit is off;

- battery charging function.

"People's Auto Channel" spoke in detail about the purpose, as well as about the tasks that the voltage regulator in the car performs.

Varieties of relay-regulators

There are several types of automotive relay-regulators:

- external - this type of relay allows you to increase the maintainability of the generator unit;

- built-in - installed in the rectifier plate or brush assembly;

- changing by minus - equipped with an additional cable;

- plus-adjustable - characterized by a more economical connection scheme;

- for installation in alternating current units - the voltage cannot be regulated when applied to the excitation winding, since it is installed in the generator;

- for DC devices - relay-regulators have the function of cutting off the battery when the engine is not running;

- two-level relays - today they are practically not used, in them the adjustment is carried out by springs and a lever;

- three-level - equipped with a comparing module circuit, as well as a matching signaling device;

- multilevel - equipped with 3-5 additional resistor elements, as well as a control system;

- transistor samples - are not used on modern vehicles;

- relay devices - are characterized by more improved feedback;

- relay-transistor - have a universal circuit;

- microprocessor relays - characterized by small dimensions, as well as the possibility of smoothly changing the lower or upper threshold;

- integral - are installed in the brush holders, therefore, when they are worn, they change.

Relay-regulators DC

In such units, the connection diagram looks more complicated. If the machine is stationary and the engine is not running, the generator set must be disconnected from the battery.

When performing a relay test, you must ensure that three options are available:

- battery cut-off when the vehicle is parked;

- limiting the maximum current parameter at the output of the unit;

- the ability to change the voltage parameter for the winding.

Relay-regulators of alternating current

Such devices are characterized by a more simplified test scheme. The car owner needs to diagnose the magnitude of the voltage on the excitation winding, as well as at the output of the unit.

If an alternator is installed in the car, then it will not work to start the engine “from the pusher”, unlike a direct current unit.

Built-in and external relay-regulators

The procedure for changing the voltage value is performed by the device at a specific installation location. Accordingly, the built-in regulators act on the generator unit. And the external type of relay is not connected to it and can be connected to the ignition coil, then its work will only be aimed at changing the voltage in this area. Therefore, before performing diagnostics, the car owner must make sure that the part is connected correctly.

The Sovering TVi channel spoke in detail about the purpose, as well as the principle of operation of this type of device.

Two-level

The principle of operation of such devices is as follows:

- Current passes through the relay.

- As a result of the formation of a magnetic field, the lever is attracted.

- A spring with a specific force is used as a comparing element.

- When the voltage increases, the contact elements open.

- Less current is applied to the excitation winding.

In VAZ cars, mechanical two-level devices were previously used for regulation. The main drawback was the rapid wear of structural components. Therefore, instead of mechanical, electronic regulators were installed on these models of machines.

These details were based on:

- voltage dividers, which were assembled from resistor elements;

- a zener diode was used as a driving part.

Due to the complex wiring diagram and inefficient voltage level control, this type of device has become less common.

Three-level

This type of regulators, as well as multilevel ones, are more advanced:

- The voltage is supplied from the generator device to a special circuit and passes through a divider.

- The received data is processed, the actual voltage level is compared with the minimum and maximum values.

- The mismatch pulse changes the current parameter that is supplied to the excitation winding.

Three-level devices with frequency modulation do not have resistances, but the frequency of operation of the electronic key in them is higher. For control, special logic circuits are used.

plus and minus control

Schemes for negative and positive contacts differ only in connection:

- when installed in a positive gap, one brush is connected to ground, and the second goes to the relay terminal;

- if the relay is installed in the minus gap, then one brush element must be connected to the plus, and the second - directly to the relay.

But in the second case, another cable will appear. This is due to the fact that these relay modules belong to the class of devices of the active type. For its operation, a separate power supply is required, so the plus is connected individually.

Photo gallery "Types of generator voltage relay-regulator"

This section contains photos of some types of devices.

The presence of a built-in resistor device, as well as special circuits, makes it possible for the regulator to compare the voltage parameter that the generator produces. If the value is too high, the controller is disabled. This allows you to prevent overcharging of the battery and failure of electrical equipment that is powered by the mains. Malfunctions of the device will lead to battery failure.

switch winter and summer

The generating device works stably regardless of the ambient temperature and season. When its pulley is set in motion, current is generated. But in the cold season, the internal structural elements of the battery can freeze. Therefore, the battery charge is restored worse than in the heat.

The switch for changing the season of operation is located on the relay housing. Some models are equipped with special connectors, you need to find them and connect the wires in accordance with the diagram and the symbols printed on them. The switch itself is a device by which the voltage level at the battery terminals can be increased to 15 volts.

How to remove the relay-regulator?

Removing the relay is allowed only after disconnecting the terminals from the battery.

To dismantle the device with your own hands, you will need a screwdriver with a Phillips or flat tip. It all depends on the bolt that secures the regulator. The generator unit, as well as the drive belt, do not need to be dismantled. The cable is disconnected from the regulator and the bolt that secures it is unscrewed.

User Viktor Nikolayevich spoke in detail about the dismantling of the regulatory mechanism and its subsequent replacement with a car.

Symptoms

“Symptoms” that will require the regulator to be checked or repaired:

- when the ignition is activated, a light indicator of a discharged battery appears on the control panel;

- the icon on the dashboard does not disappear after starting the engine;

- the brightness of the glow of the optics may be too low and increase with increasing crankshaft speed and pressing the gas pedal;

- the power unit of the machine is difficult to start the first time;

- The car battery is often discharged;

- with an increase in the number of revolutions of the internal combustion engine more than two thousand per minute, the bulbs on the control panel turn off automatically;

- the dynamic properties of the vehicle are reduced, which is especially evident at increased crankshaft speeds;

- the battery may be leaking.

Possible causes of malfunctions and consequences

The need to repair the generator voltage regulator relay will arise with such problems: