For this, it is allowed to use only a torque wrench - it allows you to accurately control the moment of tension itself. Before working with the previously mentioned tool, its holder must be set to - 0 (zero). This will define the starting position as the reference point.

Starting to tighten the bolts, you need to monitor the indicators from the very beginning. If they did not change, then, most likely, the fasteners succumbed to stretching, which is generally in line with the norm. There are no problems to be feared here. However, with a sharp increase in torque, it will be necessary to stabilize the extension of the holder.

Tightening pattern

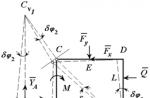

First of all, it is important to remember that you need to pre-tighten the bolts in this order:

First of all, it is important to remember that you need to pre-tighten the bolts in this order:

- the first two are installed from above and below into the central holes;

- third and fourth from the bottom, respectively, to the right and left of the middle;

- the fifth and sixth above are also on both sides of the central one;

- the seventh and eighth go to the leftmost holes;

- ninth and tenth to the right.

- the first stage - twisting is carried out up to an indicator of 2 kgf * m;

- on the second lap, tightening is carried out according to the above algorithm, with the only difference being that the force is brought up to 8 kgf * m;

- in the third pass, all the bolts turn clearly 90 degrees;

- the fourth stage is fully consistent with the previous one, and is the final one.

Afterword

Before reassembling the assembly, it is imperative to check the condition of all the bolts. At the slightest discrepancy, it will be necessary to replace it. It is important to understand that otherwise a good result will not be achievable.

Also, do not put off replacing the gasket, because subsequently such a minor problem will turn into the need to repair the entire power plant. In severe cases, the entire engine needs to be replaced. We also invite you to watch the video tutorial:

Tighten bolt? What's the problem: a wrench and ... go ahead, tighten yourself to the stop.

So a person who has little idea of \u200b\u200bthe importance of the correct tightening order of the cylinder head bolts will think. And what kind of engine malfunctions can lead to a violation of the procedure and technology for tightening the cylinder head bolts. In fact, this is a very sensitive question, so let's figure it out.

Why does a motorist need to know the procedure for tightening the cylinder head?

Naturally, if you have a lot of banknotes and even shake out the ashtray in the cabin, you are going to a car service, then there is no need. But for those motorists who want and can repair a car in general, and in particular, this information will not be superfluous.

It is important! Before we share with you the features of the cylinder head tightening order, you should pay attention to the fact that each engine model has its own bolt tightening parameters.

In no case, especially when working with the cylinder head of modern cars, should you rely on your knowledge and experience gained during the repair of the cylinder head on other engines. The procedure for tightening and tightening the cylinder head bolts is carried out in strict accordance with the manufacturer's requirements for this engine. You can easily find these parameters in the manual for the repair and maintenance of the engine.

Knowing the order of tightening and tightening the cylinder head will not be needed so often. In the event that it is necessary to replace the cylinder head gasket or when repairing the engine.

What are the common features of cylinder head tightening technology

Let's start with the fact that, according to the old memory of operating domestic car models, many motorists are worried about the need for preventive broaching of cylinder head bolts. Especially after an engine overhaul or cylinder head repair.

Broach of the cylinder head in modern engines is not required. This is due to the fact that for fastening the head to apply

self-tightening bolts or so-called "spring bolts".

Their characteristic is such that after the first tightening they no longer need to be drawn during the period of operation. Moreover, broaching the cylinder head in this case can only damage the quality of the bolts.

If earlier, cylinder head broaching was one of the mandatory maintenance items for a car, today this item can only be applied to obsolete models of Moskvich, GAZ and VAZ engines.

Rules for tightening the cylinder head

With different parameters and characteristics, the general rules for tightening bolts are in principle applicable to all types of engines.

- Mandatory use of the manufacturer's parameters for: the order (scheme) of tightening the cylinder head bolts and the tightening torque.

- When tightening the cylinder head, use only a serviceable and tested torque wrench, and not a simple wrench. In this case, the eye and the hope for muscle memory are not helpers.

- A mandatory requirement is the ideal condition of the cylinder head mounting bolts: in no case should you use old bolts, do not install cut bolts, check the condition and cleanliness of the thread before tightening. The repeated use of "spring" bolts will no longer provide the necessary tightening force, which will eventually lead to oil leakage from under the cylinder head gasket.

- It is strictly forbidden to tighten or tighten the cylinder head with TTY type bolts (this type of bolt is used mainly on aluminum cylinder heads). TTY bolts are not tightened to the torque, but to the set degree. This information should be in the manufacturer's instructions.

- When buying a cylinder head gasket, it should have the manufacturer's specification, which indicates what torque is applicable to this particular type of gasket. This must be taken into account so that the figures for the engine tightening torque and the gasket tightening torque do not diverge dramatically.

- If the hole for the cylinder head bolt is “blind”, then pouring oil into it before tightening the head, try not to overfill. Otherwise, the bolt will not reach the end. If the hole is through and goes into the cooling system, then before screwing in the bolt, lubricate the thread with plastic sealant.

If you still decide to tighten (broaching) the cylinder head bolts, then take into account that it is done: for an engine with a cast-iron cylinder head - to “hot”, i.e. at least 80 0 engine temperature, for an engine with an aluminum cylinder head to "cold".

The value of all fastening elements in the engine is very high. This is an axiom. The tightening of the cylinder head bolts is no exception.

Features of tightening cylinder head bolts

Cause? And she is simple. Just think about what loads all the fasteners experience: constant vibration, crazy temperature changes. As a result of the research, a figure of 5000 kg was obtained. and higher. This is approximately the same tensile load at full throttle for each engine bolt.

One of the main conditions that guarantee the correct action at or at is compliance with the manufacturer's requirements. Different engine models have different cylinder head tightening torques. The tightening order of the cylinder head may also differ. There are recommendations in the manuals for each model, and they must be followed.

Having its own characteristics, in relation to different models, tightening the cylinder head bolts also has nuances that apply to the cylinder head bolt tightening procedure in general, and are the same for everyone.

And it is advisable for you to know them, since no one guarantees that the service will do it competently and as for yourself.

The tightening torque of the cylinder head is affected by:

- Lubrication of the threads of the holes and the bolts themselves. It is recommended to lubricate with non-viscous types of engine oil.

- The condition of the thread, both the hole and the bolt itself. Deformation and clogging of the thread before tightening are contraindicated, this can lead to a decrease in the compression force of the gasket with all the consequences ...

- New bolt or already used. A new bolt has a higher resistance and torque readings may be distorted. It is desirable that when using new bolts, the tightening of the cylinder head bolts is carried out after 2-3 cycles of tightening and unscrewing the bolts. It is recommended to tighten the bolts to 50% of the final tightening torque and loosen.

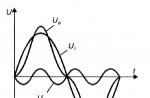

When tightening the bolts, special attention should be paid to the accuracy of the tool, namely the torque wrench. Dial indicator wrenches are both convenient and accurate. But, they react sharply to drops and bumps, like any precision instrument.

- Refer to the manufacturer's instructions for the exact torque and sequence for tightening the cylinder head.

- Bolts must be in perfect condition. Do not save, and in no case cut the thread. After all, you are doing it for yourself.

- Bolt threads and holes must be clean. Wire brush in your hands.

- In the case of a "blind" hole for the bolts, try not to pour oil into them, otherwise the bolt will not fully fit into place. And it would be useful to lubricate the threads with plastic sealant if the hole goes into the engine cooling system.

- TTY type bolts (usually used in engines with aluminum cylinder heads) are strictly forbidden to be re-tightened, as they may break. Their repeated use will also not be able to provide the necessary compression of the gasket, which means a leak.

- When installing a gasket, be sure to refer to the gasket manufacturer's specification for tightening torque. If you have a past experience with changing gaskets, then forget about it. Each engine has its own specifics.

- Returning to the TTY type bolts, you need to emphasize that for them there is a clear degree, and not the tightening torque of the cylinder head bolts. That is, you will need a tool with an angle indicator.

- Tightening or, if necessary, is carried out for engines: with cast-iron cylinder heads when hot, and with aluminum cylinder heads when cooled to room temperature.

Good luck with your DIY cylinder head tightening.

Expert opinion

Ruslan Konstantinov

Automotive expert. Graduated from IzhGTU named after M.T. Kalashnikov with a degree in Operation of Transport and Technological Machines and Complexes. Over 10 years of professional car repair experience.

When tightening the cylinder head bolts, many, due to inexperience and ignorance, can make a lot of mistakes that can cause serious repair work in the future. Often, improper tightening leads to damage and deformation of both the cylinder head and the block. The most common mistakes are oil getting into the bolt wells, working with the wrong size or worn sockets for a torque wrench or tightening without it at all, overtightening the bolts, my violation of the tightening order, and using the wrong size bolts (long or vice versa short).

Often, the wells where the bolts are screwed become rusty or clogged with dirt; it is not always possible to clean them. It is strictly forbidden to pour oil into them, exactly, as well as to tighten the bolts into dirty holes, otherwise it is impossible to achieve the desired effort. Oil can only be applied to the threads directly on the bolts. Often there were cases when, when these tips were ignored, the well collapsed, and this threatened to replace the cylinder block, since it is not always possible to repair it.

It is impossible to tighten without a torque wrench, under no circumstances, tightening the bolts “by eye” is almost always done in excess of the allowable force, this leads to breakage of the bolts and repair of the cylinder block. It is also recommended to always use new bolts, even if your old ones look perfect, the fact is that they tend to stretch after being tightened.

The durability of the cylinder head is determined by many factors - from proper use and timely maintenance to tightening the bolts of the device in compliance with a certain pattern. Therefore, it is important to know what moment the VAZ 2109 is and the sequence of the task.

[ Hide ]

When is it necessary to puff?

On most injection and carburetor vehicles with 8 and 16 valve engines, it is not necessary to tighten the cylinder head bolts during the operation of the car. But in the case of the domestic "Nine", it is necessary to correctly stretch the cylinder head and tighten the screws at least when carrying out maintenance of the machine. If it is found that moisture has begun to collect in the car at the point of contact of the block itself with the cylinders, then it will be necessary to tighten the bolts. Since the appearance of moisture in this place indicates a possible leakage of motor fluid.

Reasons why you might need a braces:

- The device has been damaged due to motor overheating. The operation of the motor in conditions of excessive temperature is fraught with serious malfunctions. It will require repair of the cylinder head of the power unit, its grinding and subsequent installation with a puff.

- Cylinder head gasket damaged or leaking. If this problem is not solved in a timely manner, engine fluid will enter the cooling system. A damaged gasket must be replaced. After changing the part, the head bolts must be tightened correctly.

- The engine has been running for a certain amount of time.

How is the tightening torque of the VAZ 2109 bolts adjusted?

If it is necessary to tighten the cylinder head of the Nine engine, it is important to observe not only the strength and degree of tightening of the bolts, but also other conditions. Below we will consider how to properly stretch the cylinder head on the VAZ 2109.

What will be needed?

The procedure for pulling fasteners after removal and repair, as well as when installing the cylinder head, is carried out exclusively with a torque wrench.

A dynamometer is a tool designed to tighten the cylinder head screws of various engines.

In addition to the key, you will also need a caliper or a regular ruler.

User Marat Ibatullin made a video in which he clearly showed how the task of tightening the screws is performed.

Scheme of work

The order of tightening the bolts on cars with an injector or carburetor engine is determined by the manufacturer and indicated in the service book for the car. According to the scheme, the pulling procedure begins with the central two cylinder head bolts.

Tighten the cylinder head bolts as follows:

- First, you need to turn the screws with a force in newtons of 2.0 kg / cm.

- Then the bolts are tightened in compliance with the torque of 7.5-8.5 kg / cm.

- After that, all screws must be tightened by 90 degrees.

- At the end, one more turn of each bolt is made by 90 degrees.

How to tighten the screws of the head of the VAZ 2109 block with your own hands:

- The holder of the torque wrench is placed in the zero position. This indicates that the tool data corresponds to the moment of the initial position.

- Evaluate the indicators on the key before starting the tightening procedure.

- The tool holder can now be rotated. Follow the readings as you complete the task.

- If it happens that during tightening the torque does not change, then the head mount may be stretched. This is quite normal, as it should be. First, the screws are tightened with a wrench to 2 kg/cm. Observe the sequence of tension indicated in the diagram.

- At the next stage, the tightening is performed again in the same sequence. Only now the bolts must be tightened up to about 8 kg/cm.

- At the end of the procedure, the screws must be tightened once by 90 degrees in a circle, and then again by 90 degrees.

The RUS13 channel in its video showed how the cylinder head is installed on the VAZ 2109 engine and the bolts are tightened.

Tightening rules

What nuances should be considered when carrying out this procedure:

- Observe the appropriate tightening torque for the VAZ 2109 cylinder head.

- The use of wrenches and other tools is not allowed, since the degree of tension can only be determined using a dynamometer.

- To tension, only work screws are allowed. The bolts must meet the requirements of the power unit installed on the machine.

- Before performing the task, make sure that the holders are in good condition.

- If the cylinder head has been changed or repaired, then the old tension bolts cannot be used, new ones must be purchased. On sixteen-valve power units, it is allowed to reuse screws to fix the block head, but only if the length of the parts is no more than 9.5 cm. It is necessary to measure the length of the screw only with a washer. If the bolts are larger than 9.5 cm, they must be replaced.

- If the vehicle is equipped with an aluminum head, then the cylinder head is fixed on TTU-type screws. They are not subject to tightening, since they are screwed into the thread with a certain degree.

- When buying a cylinder head gasket, you need to pay attention to the manufacturer's specifications. Often they prescribe a certain tightening factor required for specific gaskets. Please note that the indicated moment of force should not be much different from the one that is applied in the process of doing the work.

- In power units equipped with aluminum cylinder heads, the tightening procedure is carried out on a cold engine. As for cast-iron engines, in such internal combustion engines it is necessary to perform a tightening on a hot one.