A bypass turbojet engine (TEF) is an “improved” turbojet engine, the design of which makes it possible to reduce fuel consumption, which is the main disadvantage of a turbofan engine, due to improved compressor operation and, accordingly, an increase in the volume of air masses passing through a turbofan engine.

For the first time, the design and principle of operation of the turbofan engine was developed by the aircraft designer A.M. The cradle back in 1939, but then they did not pay much attention to its development. Only in the 50s, when turbojet engines began to be massively used in aviation, and their "gluttony" became a real problem, his work was noticed and appreciated. Since then, the turbofan engine has been constantly improved and successfully used in all areas of aviation.

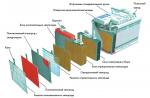

In fact, a bypass turbojet engine is the same turbojet engine, the body of which “envelops” another, external, body. The gap between these bodies forms the second circuit, while the first one is the internal cavity of the turbojet engine. Of course, the weight and dimensions increase at the same time, but the positive result from the use of such a design justifies all the difficulties and additional costs.

Device

The first circuit contains high and low pressure compressors, a combustion chamber, high and low pressure turbines and a nozzle. The second circuit consists of a guide vane and a nozzle. This design is basic, but some deviations are possible, for example, the flows of the inner and outer circuits can mix and exit through a common nozzle, or the engine can be equipped with an afterburner.

Now briefly about each constituent element of the turbofan engine. A high pressure compressor (HPC) is a shaft on which movable and fixed blades are fixed, forming a stage. Movable blades during rotation capture the air flow, compress it and direct it into the housing. The air enters the fixed blades, slows down and is additionally compressed, which increases its pressure and gives it an axial motion vector. There are several such stages in the compressor, and the compression ratio of the engine directly depends on their number. The same design is for the low pressure compressor (LPC), which is located in front of the HPC. The difference between them is only in size: LPC blades have a larger diameter, covering the cross section of both the primary and secondary circuits, and a smaller number of steps (from 1 to 5).

In the combustion chamber, compressed and heated air is mixed with fuel, which is injected by injectors, and the resulting fuel charge ignites and burns, forming gases with a large amount of energy. The combustion chamber can be one, annular, or made of several pipes.

The turbine in its design resembles an axial compressor: the same fixed and movable blades on the shaft, only their sequence is changed. First, the expanded gases fall on the fixed blades, which equalize their movement, and then on the movable ones, which rotate the turbine shaft. There are two turbines in the turbofan engine: one drives the high-pressure compressor, and the second drives the low-pressure compressor. They work independently and are not mechanically connected to each other. The LPC drive shaft is usually located inside the HPC drive shaft.

A nozzle is a converging pipe through which exhaust gases exit in the form of a jet stream. Usually, each circuit has its own nozzle, but it also happens that the jet streams at the outlet enter a common mixing chamber.

The outer, or second, circuit is a hollow annular structure with a guide vane through which air passes, pre-compressed by a low-pressure compressor, bypassing the combustion chamber and turbines. This air flow, falling on the fixed blades of the guide vane, is leveled and moves to the nozzle, creating additional thrust due to compression of the LPC alone without burning fuel.

The afterburner is a pipe placed between the low pressure turbine and the nozzle. Inside it has swirlers and fuel injectors with igniters. The afterburner makes it possible to create additional thrust by burning fuel not in the combustion chamber, but at the turbine outlet. Exhaust gases after passing LPT and HPT have a high temperature and pressure, as well as a significant amount of unburned oxygen coming from the secondary circuit. Through the nozzles installed in the chamber, fuel is supplied, which mixes with gases and ignites. As a result, the output thrust sometimes doubles, however, the fuel consumption also increases. Turbofan engines equipped with an afterburner are easily recognizable by the flame that escapes from their nozzle during flight or upon launch.

cross section of the afterburner, swirlers are visible in the figure.

The most important parameter of a turbofan engine is the bypass ratio (k) - the ratio of the amount of air that has passed through the second circuit to the amount of air that has passed through the first. The higher this figure, the more economical the engine will be. Depending on the degree of bypass, the main types of bypass turbojet engines can be distinguished. If its value is<2, это обычный ТРДД, если же к>2, then such engines are called turbofan engines (TVRD). There are also turboprop-fan engines, in which the value reaches 50 or even more.

Depending on the type of exhaust gas discharge, turbofan engines are distinguished without mixing flows and with it. In the first case, each circuit has its own nozzle, in the second, the gases at the outlet enter the common mixing chamber and only then go outside, forming a jet thrust. Mixed-flow engines, which are installed on supersonic aircraft, can be equipped with an afterburner, which allows you to increase thrust even at supersonic speeds, when secondary thrust plays little role.

Principle of operation

The principle of operation of the TVRD is as follows. The air flow is captured by the fan and, partially compressed, is directed in two directions: to the first circuit to the compressor and to the second circuit to the fixed blades. In this case, the fan does not play the role of a screw that creates thrust, but a low-pressure compressor that increases the amount of air passing through the engine. In the primary circuit, the flow is compressed and heated as it passes through the high pressure compressor and enters the combustion chamber. Here it mixes with the injected fuel and ignites, resulting in the formation of gases with a large supply of energy. The flow of expanding hot gases is directed to the high-pressure turbine and rotates its blades. This turbine rotates the high-pressure compressor, which is mounted with it on the same shaft. Next, the gases rotate the low-pressure turbine, which drives the fan, after which they enter the nozzle and break out, creating jet thrust.

At the same time, in the second circuit, the air flow captured and compressed by the fan hits the fixed blades, which straighten the direction of its movement so that it moves in the axial direction. In this case, the air is additionally compressed in the second circuit and goes outside, creating additional traction. Also, the thrust is affected by the combustion of oxygen in the secondary air in the afterburner.

Application

The scope of application of bypass turbojet engines is very wide. They were able to cover almost the entire aviation, displacing the turbojet and theater engines. The main disadvantage of jet engines - their inefficiency - was partially overcome, so that now most civilian and almost all military aircraft are equipped with turbofan engines. For military aviation, where compactness, power and lightness of engines are important, turbofan engines with a low bypass ratio (to<1) и форсажными камерами. На пассажирских и грузовых самолетах устанавливаются ТРДД со степенью двухконтурности к>2, which saves a lot of fuel at subsonic speeds and reduces the cost of flights.

Low bypass bypass turbojet engines in military aircraft.

SU-35 with 2 AL-41F1S engines installed on it

Advantages and disadvantages

Bypass turbojet engines have a huge advantage over turbojet engines in the form of a significant reduction in fuel consumption without loss of power. But at the same time, their design is more complex, and the weight is much greater. It is clear that the greater the bypass ratio, the more economical the motor, but this value can be increased in only one way - by increasing the diameter of the second circuit, which will make it possible to pass more air through it. This is the main disadvantage of the turbofan. It is enough to look at some turbojet engines installed on large civil aircraft to understand how they make the overall structure heavier. The diameter of their second circuit can reach several meters, and in order to save materials and reduce their weight, it is shorter than the first circuit. Another disadvantage of large structures is the high drag during flight, which to some extent reduces the flight speed. The use of turbofan engines in order to save fuel is justified at subsonic speeds, when the sound barrier is overcome, the secondary jet thrust becomes ineffective.

Various designs and the use of additional structural elements in each individual case makes it possible to obtain the desired version of the turbofan engine. If economy is important, turbofan engines with a large diameter and a high bypass ratio are installed. If you need a compact and powerful engine, conventional turbofan engines with or without an afterburner are used. The main thing here is to find a compromise and understand what priorities a particular model should have. Military fighters and bombers cannot be equipped with engines with a three-meter diameter, and they don’t need it, because in their case the priority is not so much economy as speed and maneuverability. Here, turbofan engines with afterburners (TRDDF) are also more often used to increase traction at supersonic speeds or during launch. And for civil aviation, where the aircraft themselves are large, large and heavy engines with a high bypass ratio are quite acceptable.

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru/

1. Design description

turbine engine strength power

1.1 AL-31F

AL-31F is a dual-circuit twin-shaft turbojet engine with mixing flows of the internal and external circuits behind the turbine, an afterburner common for both circuits and an adjustable supersonic all-mode jet nozzle. Low-pressure axial 3-stage compressor with adjustable inlet guide vane (VNA), high-pressure axial 7-stage compressor with adjustable VNA and guide vanes of the first two stages. Turbines of high and low pressure - axial single-stage; blades of turbines and nozzle devices are cooled. The main combustion chamber is annular. Titanium alloys (up to 35% of the mass) and heat-resistant steels are widely used in the engine design.

1.2 Turbine

General characteristics

The engine turbine is axial, jet, two-stage, two-shaft. The first stage is a high pressure turbine. The second stage is low pressure. All turbine blades and disks are cooled.

The main parameters (H=0, M=0, "Maximum" mode) and materials of the turbine parts are given in Tables 1.1 and 1.2.

Table 1.1

|

Parameter |

|||

|

The degree of reduction of the total gas pressure |

|||

|

Turbine efficiency in terms of stagnant flow parameters |

|||

|

Circumferential speed at the periphery of the blades, m/s |

|||

|

Rotor speed, rpm |

|||

|

Sleeve ratio |

|||

|

Gas temperature at the turbine inlet |

|||

|

Gas consumption, kg/s |

|||

|

Load parameter, m/s |

Table 1.2

High pressure turbine design

The high-pressure turbine is designed to drive the high-pressure compressor, as well as propulsion and aircraft units mounted on the gearboxes. The turbine structurally consists of a rotor and a stator.

High pressure turbine rotor

The turbine rotor consists of rotor blades, disk and trunnion.

The working blade is cast, hollow with a semi-loop flow of cooling air.

In the inner cavity, in order to organize the flow of cooling air, ribs, partitions and turbulators are provided.

In subsequent series, the blade with a half-loop cooling scheme is replaced by a blade with a cyclone-vortex cooling scheme.

A channel is made in the inner cavity along the leading edge, in which, as in a cyclone, an air flow with a swirl is formed. The swirling of air occurs due to its tangential supply to the channel through the openings of the baffle.

From the channel, air is ejected through the holes (perforation) of the blade wall onto the back of the blade. This air creates a protective film on the surface.

In the central part of the blade on the inner surfaces there are channels, the axes of which intersect. A turbulent air flow is formed in the channels. Air jet turbulence and an increase in the contact area provide an increase in heat transfer efficiency.

Turbulators (bridges) of various shapes are made in the region of the trailing edge. These turbulators intensify heat transfer and increase blade strength.

The profile part of the blade is separated from the lock by a shelf and an elongated leg. The shelves of the blades, docking, form a conical shell that protects the locking part of the blade from overheating.

An elongated leg, ensuring the distance of the high-temperature gas flow from the lock and disk, leads to a decrease in the amount of heat transferred from the profile part to the lock and disk. In addition, the elongated stem, having a relatively low bending stiffness, reduces the level of vibration stresses in the profile part of the blade.

A three-prong herringbone lock ensures the transfer of radial loads from the blades to the disc.

The tooth, made in the left part of the lock, fixes the blade from moving it along the flow, and the groove, together with the fixation elements, ensures that the blade is kept from moving against the flow.

On the peripheral part of the blade, in order to facilitate running-in when touching the stator and, consequently, to prevent the destruction of the blade, a sample was made on its end

To reduce the level of vibration stresses in the working blades, dampers with a box-shaped design are placed between them under the shelves. When the rotor rotates under the action of centrifugal forces, the dampers are pressed against the inner surfaces of the shelves of the vibrating blades. Due to friction at the points of contact of two adjacent flanges on one damper, the energy of blade vibrations will be dissipated, which ensures a decrease in the level of vibration stresses in the blades.

The turbine disc is stamped, followed by machining. In the peripheral part of the disc there are grooves of the “Herringbone” type for fastening 90 rotor blades, grooves for accommodating plate locks for axial fixation of the blades and inclined holes for supplying air that cools the rotor blades.

The air is taken from the receiver formed by two flanges, the left side surface of the disk and the swirler. Balancing weights are placed under the lower shoulder. On the right plane of the disk web there is a shoulder of the labyrinth seal and a shoulder used when dismantling the disk. Cylindrical holes are made on the stepped part of the disk for fitting bolts connecting the shaft, disk and turbine rotor pin.

Axial fixation of the working blade is carried out by a tooth with a lamellar lock. A lamellar lock (one for two blades) is inserted into the grooves of the blades in three places of the disk, where cutouts are made, and accelerates around the entire circumference of the blade crown. Lamellar locks, installed at the location of the cutouts in the disk, have a special shape. These locks are mounted in a deformed state, and after straightening they enter the grooves of the blades. When straightening the lamellar lock, the blades are supported from opposite ends.

The rotor is balanced by weights fixed in the groove of the disk shoulder and fixed in the lock. The tail of the lock is bent on a balancing weight. The place of the bend is controlled for the absence of cracks by inspection through a magnifying glass. The rotor can be balanced by moving the blades, trimming the ends of the weights is allowed. Residual imbalance is not more than 25 gcm.

The disk with the trunnion and the HPC shaft is connected by fitting bolts. The heads of the bolts are fixed against rotation by plates bent on the cuts of the heads. The bolts are kept from longitudinal movement by the protruding parts of the heads included in the annular groove of the shaft.

The trunnion provides support for the rotor on a roller bearing (inter-rotor bearing).

The trunnion flange is centered and connected to the turbine disk. On the outer cylindrical grooves of the trunnion, the sleeve of the labyrinth seals is placed. Axial and circumferential fixation of labyrinths is carried out by radial pins. To prevent the pins from falling out under the influence of centrifugal forces, after they are pressed in, the holes in the bushings are flared.

On the outer part of the pin shank, below the labyrinths, there is a contact seal fixed with a castellated nut. The nut is locked with a plate lock.

Inside the trunnion in cylindrical belts, the bushings of the contact and labyrinth seals are centered. The bushings are held by a castellated nut screwed into the trunnion threads. The nut is locked by bending the antennae of the crown into the end slots of the trunnion.

In the right part of the internal cavity of the trunnion, the outer ring of the roller bearing is located, which is held by a castellated nut screwed into the trunnion thread, which is locked in the same way.

The contact seal is a pair of steel bushings and graphite rings. Flat springs are placed between graphite rings for guaranteed contact of pairs. Between the steel bushings, a spacer bushing is placed to prevent pinching of the mechanical contact seal.

High pressure turbine stator

The high-pressure turbine stator consists of an outer ring, nozzle vane blocks, an inner ring, a swirling device, and a seal with HPT inserts.

The outer ring is a cylindrical shell with a flange. The ring is located between the combustion chamber housing and the LPT housing.

A groove is made in the middle part of the outer ring, along which the dividing wall of the heat exchanger is centered.

In the left part of the outer ring, the upper ring is attached to the screws, which is the support of the flame tube of the combustion chamber and provides the supply of cooling air to blow the outer shelves of the blades of the nozzle apparatus.

A seal is installed on the right side of the outer ring. The seal consists of an annular spacer with screens, 36 HPT sector inserts and sectors for attaching HPT inserts to the spacer.

Annular threading is made on the inner diameter of the HPT inserts to reduce the surface area when the HPT rotor blades touch to prevent overheating of the peripheral part of the rotor blades.

The seal is attached to the outer ring with drilled pins. Through these drillings, cooling air is supplied to the HPT inserts.

Through the holes in the inserts, the cooling air is ejected into the radial gap between the inserts and the rotor blades.

Plates are installed between the inserts to reduce the flow of hot gas.

When assembling the seal, the HPT inserts are attached to the spacer in sectors using pins. This fastening allows the HPT inserts to move relative to each other and spacers when heated during operation.

The blades of the nozzle apparatus are combined into 14 three-bladed blocks. The blade blocks are cast, with deflectors plugged in and soldered in two places with a soldered bottom cover with a trunnion. The cast construction of blocks, having high rigidity, ensures the stability of the angles of installation of the blades, the reduction of air leakage and, consequently, the increase in the efficiency of the turbine, in addition, such a design is more technologically advanced.

The internal cavity of the scapula is divided into two compartments by a partition. In each compartment there are deflectors with holes that provide a jet flow of cooling air onto the inner walls of the blade. The leading edges of the blades are perforated.

In the upper shelf of the block, there are 6 threaded holes, into which the screws for fastening the blocks of nozzle devices to the outer ring are screwed.

The lower shelf of each block of blades has a trunnion, along which the inner ring is centered through the bushing.

The profile of the pen with adjacent surfaces of the shelves is aluminosilicated. Coating thickness 0.02-0.08 mm.

To reduce the flow of gas between the blocks, their joints are sealed with plates inserted into the slots of the ends of the blocks. The grooves in the ends of the blocks are made by electroerosive method.

The inner ring is made in the form of a shell with bushings and flanges, to which a conical diaphragm is welded.

On the left flange of the inner ring, a ring is attached with screws, on which the flame tube rests and through which air is supplied, blowing the inner shelves of the blades of the nozzle apparatus.

In the right flange, the swirling apparatus is fixed with screws, which is a welded shell structure. The swirling device is designed to supply and cool the air going to the rotor blades due to acceleration and swirling in the direction of turbine rotation. To increase the rigidity of the inner shell, three reinforcing profiles are welded to it.

The acceleration and swirl of the cooling air take place in the converging part of the swirl apparatus.

Air acceleration provides a decrease in the temperature of the air used to cool the rotor blades.

The swirl of the air ensures the alignment of the circumferential component of the air velocity and the circumferential speed of the disc.

Low pressure turbine design

The low-pressure turbine (LPT) is designed to drive the low-pressure compressor (LPC). Structurally, it consists of a LPT rotor, LPT stator and LPT support.

Low pressure turbine rotor

The low-pressure turbine rotor consists of a LPT disk with working blades fixed on the disk, a pressure disk, a trunnion and a shaft.

The working blade is cast, cooled with a radial flow of cooling air.

In the inner cavity there are 11 rows of 5 pieces each of cylindrical pins - turbulators connecting the back and trough of the blade.

The peripheral shroud reduces the radial clearance, which leads to an increase in the efficiency of the turbine.

Due to the friction of the contact surfaces of the shroud shelves of adjacent rotor blades, the level of vibration stresses decreases.

The profile part of the blade is separated from the locking part by a shelf that forms the boundary of the gas flow and protects the disk from overheating.

The blade has a herringbone-type lock.

The casting of the blade is carried out according to investment models with surface modification with cobalt aluminate, which improves the structure of the material by grinding grains due to the formation of crystallization centers on the surface of the blade.

In order to increase heat resistance, the outer surfaces of the feather, shroud and lock shelves are subjected to slip aluminosicillation with a coating thickness of 0.02-0.04.

For axial fixation of the blades from moving against the flow, a tooth is made on it, abutting against the disk rim.

For axial fixation of the blade from moving along the flow, a groove is made in the locking part of the blade in the region of the flange, into which a split ring with a lock is inserted, which is kept from axial movement by the disc shoulder. During installation, the ring, due to the presence of a cutout, is crimped and inserted into the grooves of the blades, and the shoulder of the disk enters the groove of the ring.

The fastening of the split ring in working condition is made by a lock with clamps that are bent onto the lock and pass through the holes in the lock and the slots in the shoulder of the disk.

Turbine disk - stamped, with subsequent machining. In the peripheral zone for placing the blades there are grooves of the "Herringbone" type and inclined holes for supplying cooling air.

Annular flanges are made on the disc web, on which labyrinth covers and a pressure labyrinth disc are placed. The fixation of these parts is carried out with pins. To prevent the pins from falling out, the holes are flared.

A pressure disk having blades is needed to compress the air supplied to cool the turbine blades. To balance the rotor, balancing weights are fixed on the pressure disk with lamellar clamps.

Annular collars are also made on the disc hub. Labyrinth covers are installed on the left shoulder, a trunnion is installed on the right shoulder.

The trunnion is designed to support the low-pressure rotor on a roller bearing and transmit torque from the disk to the shaft.

To connect the disk to the trunnion, a forked flange is made on it in the peripheral part, along which centering is carried out. In addition, the centering and transfer of loads go through radial pins, which are kept from falling out by the labyrinth.

A labyrinth seal ring is also fixed on the LPT trunnion.

On the peripheral cylindrical part of the trunnion, a mechanical contact seal is placed on the right, and a sleeve of a radial-face contact seal is placed on the left. The bushing is centered along the cylindrical part of the trunnion and is fixed in the axial direction by the bending of the comb.

In the left part of the trunnion on the cylindrical surface there are bushings for supplying oil to the bearing, the inner ring of the bearing and sealing parts. The package of these parts is tightened with a castellated nut, locked with a lamellar lock. Splines are made on the inner surface of the trunnion to ensure the transmission of torque from the trunnion to the shaft. In the body of the trunnion there are holes for supplying oil to the bearings.

In the right part of the trunnion, on the outer groove, the inner ring of the roller bearing of the turbine support is fixed with a nut. The castellated nut is locked with a plate lock.

The low pressure turbine shaft consists of 3 parts connected to each other by radial pins. The right part of the shaft with its splines enters the reciprocal splines of the trunnion, receiving torque from it.

Axial forces from the pin to the shaft are transmitted by a nut screwed onto the threaded shaft shank. The nut is secured against loosening by a splined bushing. The end splines of the bushing fit into the end slots of the shaft, and the splines on the cylindrical part of the bushing fit into the longitudinal splines of the nut. In the axial direction, the splined bushing is fixed by adjusting and split rings.

On the outer surface of the right side of the shaft, a labyrinth is fixed with radial pins. On the inner surface of the shaft, a splined bushing of the drive of the oil pumping pump from the turbine support is fixed with radial pins.

On the left side of the shaft, splines are made that transmit torque to the spring and then to the low-pressure compressor rotor. On the inner surface of the left side of the shaft, a thread is cut into which a nut is screwed, locked with an axial pin. A bolt is screwed into the nut, which tightens the low-pressure compressor rotor and the low-pressure turbine rotor.

On the outer surface of the left side of the shaft there is a radial-face contact seal, a spacer bushing and a bevel gear roller bearing. All these parts are tightened with a castellated nut.

The composite design of the shaft allows to increase its rigidity due to the increased diameter of the middle part, as well as to reduce weight - the middle part of the shaft is made of titanium alloy.

Low pressure turbine stator

The stator consists of an outer housing, blocks of nozzle blades, and an inner housing.

The outer housing is a welded structure consisting of a conical shell and flanges, along which the housing is joined to the high-pressure turbine housing and the support housing. Outside, a screen is welded to the body, forming a channel for supplying cooling air. Inside there are flanges along which the nozzle apparatus is centered.

In the area of the right flange there is a bead on which LPT inserts with honeycombs are installed and fixed with radial pins.

The blades of the nozzle apparatus in order to increase the rigidity in eleven three-blade blocks.

Each blade is cast, hollow, cooled with internal deflectors. Feather, outer and inner shelves form the flow part. The outer shelves of the blades have flanges, with which they are centered along the grooves of the outer casing.

Axial fixation of blocks of nozzle blades is carried out by a split ring. The peripheral fixation of the blades is carried out by the protrusions of the body, which are included in the slots made in the outer shelves.

The outer surface of the shelves and the profile part of the blades is aluminosicillated in order to increase the heat resistance. The thickness of the protective layer is 0.02-0.08 mm.

To reduce the flow of gas between the blocks of blades, sealing plates are installed in the slots.

The inner shelves of the blades end with spherical pins, along which the inner casing is centered, representing a welded structure.

Grooves are made in the ribs of the inner body, which enter the scallops of the inner shelves of the nozzle blades with a radial clearance. This radial clearance provides freedom for the thermal expansion of the blades.

Turbine support ND

The turbine support consists of a support housing and bearing housing.

The support body is a welded structure consisting of shells connected by posts. Racks and shells are protected from the gas flow by riveted screens. On the flanges of the inner shell of the support, conical diaphragms are fixed, supporting the bearing housing. On these flanges, a labyrinth seal bushing is fixed on the left, and a screen protecting the support from the gas flow is fixed on the right.

On the flanges of the bearing housing, a contact seal bushing is fixed on the left. On the right, the oil cavity cover and the heat shield are fixed with screws.

A roller bearing is placed in the inner bore of the housing. Between the housing and the outer ring of the bearing there are an elastic ring and bushings. Radial holes are made in the ring, through which oil is pumped during vibrations of the rotors, to which energy is dissipated.

Axial fixation of the rings is carried out by a cover, attracted to the bearing support by screws. In the cavity under the heat shield there is an oil extraction pump and oil nozzles with pipelines. The bearing housing has holes that supply oil to the damper and nozzles.

Turbine cooling

Turbine cooling system - air, open, regulated by discrete changes in air flow through the air-to-air heat exchanger.

The leading edges of the blades of the nozzle apparatus of the high-pressure turbine have convective-film cooling with secondary air. The shelves of this nozzle apparatus are cooled by secondary air.

The rear strips of the SA blades, the disk and rotor blades of the LPT, the turbine housings, the SA blades of the fan turbine and its disk on the left side are cooled by air passing through the air-to-air heat exchanger (VHT).

The secondary air enters the heat exchanger through the holes in the combustion chamber housing, where it is cooled by - 150-220 K and goes through the valve apparatus to cool the turbine parts.

The air of the secondary circuit through the support legs and holes is supplied to the pressure disk, which, by increasing the pressure, ensures its supply to the working blades of the LPT.

The turbine housing is cooled from the outside by the secondary air, and from the inside by the air from the IWT.

Turbine cooling is carried out in all engine operating modes. The turbine cooling circuit is shown in Figure 1.1.

Power flows in the turbine

Inertial forces from rotor blades through locks of the "Herringbone" type are transferred to the disk and load it. The unbalanced inertial forces of the bladed discs are transmitted through the fit bolts on the HPT rotor and through the centering collars and radial pins on the HPT rotor to the shaft and pins supported by bearings. Radial loads are transferred from the bearings to the stator parts.

The axial components of the gas forces arising on the working blades of the HPT are transferred to the disk due to the friction forces on the contact surfaces in the lock and the “tooth” of the blade against the disk. On the disc, these forces are summed up with the axial forces arising from the pressure drop across it and are transferred to the shaft through tight bolts. Fitted bolts from this force work in tension. The axial force of the turbine rotor is added to the axial force.

Outer contour

The outer circuit is designed to bypass a part of the air flow compressed in the LPC behind the LPC.

Structurally, the outer contour consists of two (front and rear) profiled cases, which are the outer shell of the product and are also used for fastening communications and units. The shells of the outer case are made of titanium alloy. The case is included in the power circuit of the product, perceives the torque of the rotors and partly the weight of the internal circuit, as well as the overload forces during the evolution of the object.

The front casing of the outer circuit has a horizontal connector to provide access to HPC, CS and turbine.

The profiling of the flow path of the outer contour is ensured by the installation in the front casing of the outer contour of the inner screen, connected with it by radial stringers, which are also stiffening ribs of the front casing.

The rear casing of the outer contour is a cylindrical shell bounded by the front and rear flanges. On the rear housing from the outside there are stiffening stringers. Flanges are located on the housings of the outer housing:

· To take air from the internal circuit of the product after 4 and 7 stages of HPC, as well as from the channel of the external circuit for the needs of the facility;

· For igniters KS;

· For HPC blades inspection windows, CS inspection windows and turbine inspection windows;

· For communications of a supply and removal of oil to a support of the turbine, venting of an air and oil cavity of a back support;

· Air bleed into jet nozzle (RS) pneumatic cylinders;

· For fixing the feedback lever of the control system ON HPC;

· For communications for supplying fuel to the CS, as well as for communications for bleeding air after HPC into the fuel system of the product.

Bosses for fastening are also designed on the body of the outer contour:

· Fuel distributor; fuel-oil heat exchangers of the oil tank;

· Fuel filter;

· KND automation reducer;

· Drain tank;

· Ignition unit, communications of systems of start of FC;

· Frames with attachment points for the nozzle and afterburner regulator (RSF).

In the flow part of the outer circuit, two-hinged communication elements of the product system are installed, which compensate for thermal expansion in the axial direction of the bodies of the outer and inner circuits during the operation of the product. The expansion of the housings in the radial direction is compensated by the mixing of two-hinged elements, structurally made according to the "piston-cylinder" scheme.

2. Calculation of the strength of the turbine impeller disk

2.1 Calculation scheme and initial data

A graphical representation of the HPT impeller disk and the calculation model of the disk are shown in Fig. 2.1. The geometric dimensions are presented in Table 2.1. A detailed calculation is presented in Appendix 1.

Table 2.1

|

Section i |

||||

n - the number of revolutions of the disk in the design mode is 12430 rpm. The disc is made of EP742-ID material. The temperature along the radius of the disk is not constant. - blade (contour) load, simulating the action of the centrifugal forces of the blades and their interlocks (blade roots and disk protrusions) on the disk in the design mode.

Characteristics of the disc material (density, modulus of elasticity, Poisson's ratio, coefficient of linear expansion, long-term strength). When entering the characteristics of materials, it is recommended to use ready-made data from the archive of materials included in the program.

The contour load is calculated according to the formula:

The sum of the centrifugal forces of the feathers of the blades,

The sum of the centrifugal forces of the interlocks (blade roots and disk protrusions),

The area of the peripheral cylindrical surface of the disk through which centrifugal forces are transmitted to the disk and:

Forces calculated by the formulas

z- number of blades,

The area of the root section of the blade feather,

Stress in the root section of the blade feather, created by centrifugal forces. The calculation of this voltage was made in Section 2.

The mass of the ring formed by the locking connections of the blades with the disk,

The radius of inertia of the locking ring,

u - angular speed of rotation of the disk in the design mode, calculated through revolutions as follows: ,

The mass of the ring and the radius are calculated by the formulas:

The area of the peripheral cylindrical surface of the disk is calculated by formula 4.2.

Substituting the initial data into the formula for the above parameters, we get:

Calculation of the disc strength is made by the program DI.EXE, available in the computer class 203 of the department.

It should be borne in mind that the geometric dimensions of the disk (radii and thicknesses) are entered into the DI.EXE program in centimeters, and the contour load - in (translation).

2.2 Calculation results

The calculation results are presented in Table 2.2.

Table 2.2

The first columns of Table 2.2 present the initial data on the disk geometry and temperature distribution along the disk radius. Columns 5-9 present the calculation results: radial stresses (rad.) and circumferential stresses (circum.), reserves for equivalent stress (e.g. equiv.) and breaking revolutions (cyl. sec.), as well as disk elongation under the action of centrifugal forces and thermal expansions at different radii.

The smallest margin of safety in terms of equivalent stress was obtained at the base of the disk. Permissible value . The strength condition is met.

The smallest margin of safety for breaking revolutions was also obtained at the base of the disk. Allowed value . The strength condition is met.

Rice. 2.2 Stress distribution (radius and ambient) along the disk radius

Rice. 2.3 Distribution of margin of safety (equivalent voltage margins) along the disc radius

Rice. 2.4 Distribution of safety margin over breaking revolutions

Rice. 2.5 Distribution of temperature, stress (rad. and ambient) along the radius of the disk

Literature

1. Khronin D.V., Vyunov S.A. etc. "Design and design of aircraft gas turbine engines". - M, Mechanical Engineering, 1989.

2. "Gas turbine engines", A.A. Inozemtsev, V.L. Sandratsky, OJSC Aviadvigatel, Perm, 2006

3. Lebedev S.G. Course project on the discipline "Theory and calculation of aircraft blade machines", - M, MAI, 2009.

4. Perel L.Ya., Filatov A.A. Rolling bearings. Directory. - M, Mechanical Engineering, 1992.

5. Program DISK-MAI, developed at the department 203 MAI, 1993.

6. Inozemtsev A.A., Nikhhamkin M.A., Sandratsky V.L. “Gas turbine engines. Dynamics and strength of aircraft engines and power plants. - M, Mechanical engineering, 2007.

7. GOST 2.105 - 95.

Hosted on Allbest.ru

...Similar Documents

Thermogasdynamic calculation of the engine, selection and justification of parameters. Coordination of compressor and turbine parameters. Gas-dynamic calculation of the turbine and profiling of the turbine blades of the first stage of the turbine on a computer. Calculation of the turbine blade lock for strength.

thesis, added 03/12/2012

Thermogasdynamic calculation of the engine. Coordination of compressor and turbine operation. Gas-dynamic calculation of an axial turbine on a computer. Profiling of high-pressure turbine blades. Description of the engine design, calculation for the strength of the turbine disc.

thesis, added 01/22/2012

Thermogas-dynamic calculation of the engine, profiling of the blades of the impellers of the first stage of the turbine. Gas-dynamic calculation of the turbofan turbine and development of its design. Development of a bevel gear processing plan. Engine efficiency analysis.

thesis, added 01/22/2012

Design of the flow path of an aircraft gas turbine engine. Calculation of the strength of the working blade, turbine disk, attachment point and combustion chamber. Technological process of flange manufacturing, description and calculation of processing modes for operations.

thesis, added 01/22/2012

Description of the design of the engine. Thermogasdynamic calculation of a turbojet bypass engine. Calculation of the strength and stability of the compressor disc, combustion chamber housings and the blade lock of the first stage of the high-pressure compressor.

term paper, added 03/08/2011

Calculation for long-term static strength of the elements of the R-95Sh aircraft turbojet engine. Calculation of the working blade and disk of the first stage of a low-pressure compressor for strength. Justification of the design on the basis of a patent study.

term paper, added 08/07/2013

Design of the working process of gas turbine engines and features of gas-dynamic calculation of units: compressor and turbine. Elements of thermogasdynamic calculation of a two-shaft thermojet engine. High and low pressure compressors.

test, added 12/24/2010

Calculation of the strength of the elements of the first stage of the high-pressure compressor of a turbojet bypass engine with mixing flows for a combat fighter. Calculation of machining allowances for external, internal and end surfaces of rotation.

thesis, added 06/07/2012

Coordination of compressor and turbine parameters and its gas-dynamic calculation on a computer. Profiling of the impeller blade and calculating its strength. Scheme of the process, carrying out turning, milling and drilling operations, analysis of engine efficiency.

thesis, added 03/08/2011

Determination of the work of expansion (the available heat drop in the turbine). Calculation of the process in the nozzle apparatus, relative velocity at the entrance to the radar. Shank strength calculation, tooth bending. Description of the GTE drive turbine, selection of parts material.

In 2006, the management of the Perm Engine Building Complex and OAO Territorial Generating Company No. 9 (Perm Branch) signed an agreement for the manufacture and supply of a GTES-16PA gas turbine power plant based on a GTE-16PA with a PS-90EU-16A engine.

We asked Daniil SULIMOV, Deputy General Designer-Chief Designer of Aviadvigatel JSC, to tell us about the main differences between the new engine and the existing PS-90AGP-2.

The main difference between the GTE-16PA plant and the existing GTU-16PER is the use of a power turbine with a rotation speed of 3000 rpm (instead of 5300 rpm). Reducing the rotational speed makes it possible to abandon the expensive gearbox and increase the reliability of the gas turbine plant as a whole.

Specifications of GTU-16PER and GTE-16PA engines (under ISO conditions)

Optimization of the main parameters of the power turbine

The basic parameters of a free turbine (ST): diameter, flow path, number of stages, aerodynamic efficiency are optimized to minimize direct operating costs.

Operating costs include the cost of purchasing ST and costs for a certain (acceptable for the customer as a payback period) period of operation. The choice of a payback period that is quite visible for the customer (no more than 3 years) made it possible to implement an economically sound design.

The choice of the optimal variant of a free turbine for a specific application as part of the GTE-16PA was made in the engine system as a whole based on a comparison of direct operating costs for each variant.

Using one-dimensional modeling of the ST, the achievable level of aerodynamic efficiency of the ST was determined by the average diameter for a discretely given number of stages. The optimal flow part for this variant was chosen. The number of blades, taking into account their significant impact on the cost, was chosen from the condition of ensuring the Zweifel aerodynamic load factor equal to one.

Based on the selected flow path, the weight of the SP and the production cost were estimated. The turbine options in the engine system were then compared in terms of direct operating costs.

When choosing the number of stages for ST, the change in efficiency, acquisition and operation costs (fuel cost) are taken into account.

The cost of acquisition increases evenly with the growth of the cost price with an increase in the number of stages. In a similar way, the realized efficiency also grows - as a result of a decrease in the aerodynamic load on the stage. Operating costs (fuel component) fall with increasing efficiency. However, the total costs have a clear minimum at four stages in the power turbine.

The calculations took into account both the experience of our own developments and the experience of other companies (implemented in specific designs), which made it possible to ensure the objectivity of the estimates.

In the final design, by increasing the load per stage and reducing the efficiency of the ST from the maximum achievable value by about 1%, it was possible to reduce the total costs of the customer by almost 20%. This was achieved by reducing the cost and price of the turbine by 26% relative to the variant with maximum efficiency.

Aerodynamic design ST

The high aerodynamic efficiency of the new ST at a sufficiently high load was achieved by using the experience of JSC Aviadvigatel in the development of low-pressure turbines and power turbines, as well as the use of multi-stage spatial aerodynamic models using the Euler equations (excluding viscosity) and Navier-Stokes (taking into account viscosity).

Comparison of the parameters of power turbines GTE-16PA and HPP Rolls-Royce

Comparison of the parameters of the ST GTE-16PA and the most modern Rolls-Royce TRD family TRD (Smith diagram) shows that in terms of the angle of rotation of the flow in the blades (approximately 1050), the new ST is at the level of Rolls-Royce turbines. The absence of a strict weight limit inherent in aircraft structures made it possible to somewhat reduce the load factor dH/U2 by increasing the diameter and circumferential speed. The value of the output speed (typical of ground structures) made it possible to reduce the relative axial speed. In general, the potential of the designed ST to realize efficiency is at the level characteristic of the stages of the Trent family.

The peculiarity of the aerodynamics of the designed ST is also to ensure the optimal value of the turbine efficiency at partial power modes, which are typical for operation in the base mode.

While maintaining the rotational speed, a change (decrease) in the load on the ST leads to an increase in the angles of attack (deviation of the direction of the gas flow at the inlet to the blades from the calculated value) at the inlet to the blade rims. Negative angles of attack appear, the most significant in the last stages of the turbine.

The design of ST blade rows with high resistance to changes in angles of attack is ensured by special profiling of the rows with additional verification of the stability of aerodynamic losses (according to 2D/3D Navier-Stokes aerodynamic models) at high inlet flow angles.

The analytical characteristics of the new ST showed as a result a significant resistance to negative angles of attack, as well as the possibility of using the ST to drive generators that produce current at a frequency of 60 Hz (with a rotation speed of 3600 rpm), that is, the possibility of increasing the rotational speed by 20% without noticeable loss of efficiency. However, in this case, loss of efficiency is practically inevitable at low power modes (leading to an additional increase in negative angles of attack).

ST design features

To reduce the material consumption and weight of the ST, proven aviation approaches to turbine design were used. As a result, the mass of the rotor, despite the increase in the diameter and number of stages, turned out to be equal to the mass of the rotor of the GTU-16PER power turbine. This ensured a significant unification of the transmissions, the oil system, the pressurization system of the supports and the cooling system of the ST were also unified.

The amount and quality of air used to pressurize transmission bearings has been increased, including its cleaning and cooling. The quality of lubrication of transmission bearings has also been improved by using filter elements with a filtration fineness of up to 6 microns.

In order to increase the operational attractiveness of the new GTE, a specially developed control system has been introduced, which allows the customer to use turbo-expander (air and gas) and hydraulic launch types.

The weight and size characteristics of the engine make it possible to use serial designs of the GTES-16P packaged power plant for its placement.

The noise and heat insulating casing (when placed in capital premises) ensures the acoustic characteristics of the GTPP at the level provided for by sanitary standards.

The first engine is currently undergoing a series of special tests. The gas generator of the engine has already passed the first stage of equivalent-cyclic tests and has started the second stage after the revision of the technical condition, which will be completed in the spring of 2007.

The power turbine as part of a full-size engine passed the first special test, during which 7 throttle characteristics and other experimental data were taken.

According to the test results, a conclusion was made about the operability of the ST and its compliance with the declared parameters.

In addition, according to the test results, some adjustments were made to the design of the ST, including a change in the cooling system of the hulls to reduce heat release into the station room and ensure fire safety, as well as to optimize the radial clearances to increase efficiency, adjust the axial force.

The next test of the power turbine is scheduled for summer 2007.

Gas turbine plant GTE-16PA

on the eve of special tests

The utility model makes it possible to increase the efficiency of a bypass turbojet engine (TEF) by guaranteeing cooling of the last turbine stage at maximum modes (for example, in takeoff mode) and increasing efficiency in cruising modes of operation. The cooling system of the last stage of the axial low-pressure turbine of the turbofan engine contains an air intake from the outer circuit of the engine and an additional air intake behind one of the intermediate compressor stages. The cooling system is equipped with a device for regulating the air supply to the cavity adjacent to the rear surface of the turbine disk of the last stage. The control device contains a rotary ring with a drive. The swivel ring contacts the end wall of the turbine support. Two holes are made in the end wall of the support. One hole is connected to the annular cavity of the turbine support of the last stage, and the other is connected to the cavity of the air collector located in the annular cavity of the turbine support. The swivel ring of the control device is provided with a through elliptical hole located with the possibility of alternate communication with one of the two through holes of the end wall of the turbine support.

The utility model relates to aircraft engine element cooling systems, and more specifically to the cooling system of a low-pressure turbine (LPT) of a bypass turbojet engine (TRDD).

Cooling air is used to cool the hot structural elements of turbojet engines.

A well-known turbine cooling system of a turbojet bypass engine, in which air is used to cool the turbine blades, taken from the intermediate or last stage of the high pressure compressor (HPC) (see, for example, "The design of the turbocharger TRDDF", MAI Publishing House, 1996, pp. 27-28). The cooling air taken from the HPC has a sufficiently high pressure (compared to the place of its release into the turbine flow path), which ensures its guaranteed supply to all cooling surfaces. In this regard, the efficiency of such a cooling system is very high.

The disadvantage of using such a cooling system is to reduce the specific thrust at maximum modes and efficiency in cruising modes. This decrease occurs due to the fact that part of the power of the high pressure turbine, which goes to compress the LPT cooling air, is lost and is not used either to rotate the high pressure compressor (HPC) or to create engine thrust. For example, if the flow rate of the HPP cooling blades is ~5% of the air flow rate at the HPC inlet, and air is taken from its last stage, the power loss can be ~5%, which is equivalent to reducing the turbine efficiency by the same amount.

The closest to the claimed technical solution is the turbine cooling system of a turbojet bypass engine, in which air taken from the channel of the outer circuit is used to cool the low-pressure turbine blades (see, for example, "Turbojet bypass engine with an afterburner AL-31F" Tutorial, publishing house of VVIA named after N.E. Zhukovsky, 1987, pp. 128-130). Turbine cooling is carried out in all engine operating modes. With this variant of cooling air extraction, no additional turbine power is consumed for its compression in the HPC, therefore, a larger amount of potential energy of the gas flow behind the turbine can be converted in the jet nozzle into the kinetic energy of the exhaust jet, which, in turn, will lead to an increase in engine thrust and its efficiency.

The disadvantage of using such a cooling system is to reduce the cooling efficiency due to insufficient air pressure taken from the channel of the external cooling air circuit at engine operating modes close to maximum (for example, takeoff mode). In these operating modes, the optimal ratio for the efficiency of the engine (the maximum value of the specific thrust of the engine) is the ratio of pressures in the channel of the outer circuit and at the outlet of the low-pressure turbine is close to one. Such a pressure difference, taking into account losses in the supply channels and nozzles, is not enough to implement effective cooling of the LPT engine working blade in these modes.

Known technical solutions have limited capabilities, as they lead to a decrease in the efficiency of the engine.

The utility model is based on the task of increasing the efficiency of the turbofan engine by guaranteeing cooling of the last turbine stage at maximum modes (for example, takeoff) and increasing efficiency in cruising modes of operation.

The technical result is an increase in the efficiency of the turbofan engine.

The problem is solved by the fact that the cooling system of the last stage of the axial low-pressure turbine of the bypass turbojet engine contains an air intake from the outer circuit of the engine. The air intake communicates through the cavities of the racks and the annular cavity of the last stage turbine support, provided with a front end wall, with the cavity adjacent to the rear surface of the turbine disk, and through the pressure disk with the internal cavities of the blades. The end wall of the turbine support has through holes, and the outer surface of the turbine housing of the last stage is made in the form of a part of the inner surface of the channel of the outer contour of the engine.

What is new in the utility model is that the cooling system is additionally provided at the inlet with an air intake behind one of the intermediate stages of the compressor, connected by a pipeline to a hollow air collector at the outlet. The cooling system is equipped with a device for regulating the air supply to the cavity adjacent to the rear surface of the turbine of the last stage. The control device contains a rotary ring with a drive. The swivel ring contacts the end wall of the turbine support. Two holes are made in the end wall of the support. One hole is connected to the annular cavity of the turbine support of the last stage, and the other is connected to the cavity of the air collector located in the annular cavity of the turbine support. The swivel ring of the control device is provided with a through elliptical hole located with the possibility of alternate communication with one of the two through holes of the end wall of the turbine support.

The implementation of the cooling system of the last stage of the axial low-pressure turbine of a bypass turbojet engine in accordance with the claimed utility model provides:

Additional supply of the cooling system at the inlet with an air intake behind one of the intermediate stages of the compressor, connected by a pipeline to a hollow air collector at the outlet, communicating with the cavity, of the rear surface of the disk of the last turbine stage, ensures guaranteed cooling at maximum modes, including takeoff mode;

The supply of the cooling system with a device for regulating the air supply to the cavity adjacent to the rear surface of the disk of the last turbine stage from the intermediate stage of the compressor or from the external circuit ensures efficient cooling of the LPT rotor blade in all engine operating modes. The control device allows you to combine the positive qualities of both cooling systems, that is, by connecting in series various cooling air supply channels, it is most rational to ensure the operability and efficiency of the turbine cooling system in the entire range of engine operating modes and thereby improve the traction, economic and resource characteristics of the engine. Thus, in take-off mode, the control device is connected in such a way that cooling air from the intermediate stage of the compressor is supplied with a pressure sufficient to effectively cool the last stage of the turbine. This makes it possible either to increase the service life of the turbine and the entire engine at a fixed cooling air flow rate, or to reduce the cooling air flow rate and thereby increase the traction characteristics of the engine. The air in the duct of the outer circuit does not have the overpressure necessary for effective cooling. In cruising mode, the control device ensures the supply of cooling air from the channel of the external circuit, while the channel for air from the compressor is blocked (the position of the ring is switched by a signal depending on the speed of the low-pressure turbine shaft of the engine n nd and the stagnation temperature of the air at the engine inlet T * H). Due to the fact that the cooling air does not undergo compression in the compressor, the required HPC power decreases and the free energy of the working fluid behind the turbine increases; this leads to an increase in engine thrust and its efficiency. In addition, the air from the channel of the outer circuit has a large cooling resource, which will either increase the life of the turbine and the entire engine as a whole at a fixed flow rate of cooling air, or reduce the consumption of cooling air and thereby further increase the efficiency of the engine.

Thus, the problem posed in the utility model has been solved - increasing the efficiency of the turbofan engine by guaranteeing cooling of the last turbine stage at maximum modes (for example, takeoff) and increasing efficiency in cruising operating modes compared to known analogues.

The present utility model is explained by the following detailed description of the cooling system and its operation with reference to the drawings shown in figures 1-3, where

figure 1 schematically shows a longitudinal section of the last stage of the axial low-pressure turbine of a bypass turbojet engine and its cooling system;

figure 2 - view A in figure 1;

figure 3 - section B-B in figure 2.

The cooling system of the last stage of the axial low-pressure turbine of a bypass turbojet engine contains (see figure 1) the air intake 1 from the outer circuit 2 of the engine. The air intake 1 communicates with the cavity 3 adjacent to the rear surface of the disk 4 of the turbine through the cavity 5 of the racks 6 and the annular cavity 7 of the turbine support of the last stage, provided with a front end wall 8 with through holes 9 (see Fig.2, 3) of the turbine, and through the channels 10 in the disk 4 with the internal cavities of the blades 11.

The cooling system of the last stage of the low-pressure axial turbine of the bypass turbojet engine additionally contains an air intake behind one of the intermediate compressor stages at the inlet (the air intake and the intermediate stages of the compressor are not shown in figure 1). This air intake is connected by a pipeline 12 with a hollow air collector 13 at the outlet adjacent to the end wall 8 of the turbine support with through holes 14 (see Fig.2, 3).

Moreover, the cooling system is equipped with a device for regulating the air supply to the cavity 3 adjacent to the rear surface of the disk 4 of the turbine of the last stage. The control device is made in the form of a rotary ring 15 (see Fig.1-3) with a drive (drive not shown) in contact with the end wall 8 of the turbine support, where the hole 9 provides communication cavity 3 with the annular cavity 7, and the hole 14 provides communication cavity 3 with the cavity 16 of the air collector 13 located in the annular cavity 7 of the turbine support. The drive of the rotary ring 15 can be made, for example, in the form of a pneumatic motor or a drive of a similar type. The swivel ring 15 of the control device has a through elliptical hole 17, which allows alternate communication with the through holes 9, 14 in the end wall 8 of the turbine support.

The proposed cooling system contains an air intake a (air intake not shown in figure 1) behind one of the intermediate stages of the compressor, air intake 1 b from the channel of the outer circuit 2. The operation of the cooling air supply system is described below.

The cooling system of the last stage of the axial low-pressure turbine of a bypass turbojet engine operates as follows. Ring 15 can be in two positions. When the ring 15 is turned to position I (see Fig.2) (takeoff mode of the engine), air a enters through the pipe 12, under the influence of a pressure difference, through the air collector 13, the hole 14 in the wall 8 and the hole 17 in the ring 15 into the cavity 3 adjacent to the rear surface of the disk 4. In this case, the passage into the cavity 3 of the air b is blocked by the ring 15. When the ring 15 is turned to position II (not) (cruising mode), the hole 17 is rotated so that the hole 14 is blocked by the ring 15, and air b enters the cavity 3 through the hole 9 and the hole 17 in the ring 15. In this case, the air a, taken after the intermediate stage of the compressor, does not enter the cavity 3.

Switching ring 15 to position I or II is carried out by a signal depending on the speed n of the shaft of the low-pressure turbine of the engine and the stagnation temperature of the air at the engine inlet T* N. At high values of the parameter (take-off engine operation), ring 15 is in position I, at low values of the parameter  (cruising mode) - in position II.

(cruising mode) - in position II.

The implementation of the cooling system in accordance with the claimed technical solution allows you to provide the necessary cooling of the last stage of the low-pressure turbine in all modes of engine operation, while increasing the efficiency and economy of its operation.

The cooling system of the last stage of the axial low-pressure turbine of the bypass turbojet engine, comprising an air intake from the outer contour of the engine, communicating through the cavities of the racks and the annular cavity of the turbine support of the last stage, provided with a front end wall, with a cavity adjacent to the rear surface of the turbine disk, and through the pressure disk with the internal cavities of the blades, where the end wall of the turbine support has through holes, characterized in that the cooling system is additionally provided with and at the inlet with an air intake behind one of the intermediate stages of the compressor, connected by a pipeline to a hollow air collector at the outlet, and a device for regulating the air supply to the cavity adjacent to the rear surface of the turbine of the last stage, where the control device is made in the form of a rotary ring with a drive in contact with the end wall of the turbine support, two holes are made in the end wall of the support, where one hole is connected to the annular cavity of the turbine support of the last stage, and the other - to the air intake cavity nick located in the annular cavity of the turbine support, the rotary ring of the control device is provided with a through elliptical hole located with the possibility of alternate communication with one of the two through holes of the end wall of the turbine support.

The invention relates to low-pressure turbines of gas turbine engines for aviation applications. The low-pressure turbine of a gas turbine engine includes a rotor, a stator with a rear support, a labyrinth seal with internal and external flanges on the rear support of the stator. The labyrinth seal of the turbine is made in two levels. The inner tier is formed by two labyrinth sealing combs directed towards the turbine axis, and the working surface of the labyrinth seal inner flange directed towards the turbine flow path. The outer tier is formed by the sealing combs of the labyrinth directed towards the flow path of the turbine, and the working surface of the outer flange of the labyrinth seal directed towards the axis of the turbine. The sealing combs of the labyrinth of the inner tier of the labyrinth seal are made with parallel inner walls, between which a damping ring is installed. The outer flange of the labyrinth seal is made with an outer closed annular air cavity. Between the flow path of the turbine and the outer flange of the labyrinth seal there is an annular barrier wall mounted on the rear support of the stator. The working surface of the inner flange of the labyrinth seal is located in such a way that the ratio of the inner diameter at the outlet of the flow path of the turbine to the diameter of the working surface of the inner flange of the labyrinth seal is 1.05 1.5. The invention improves the reliability of the low-pressure turbine of a gas turbine engine. 3 ill.

Drawings to the RF patent 2507401

The invention relates to low-pressure turbines of gas turbine engines for aviation applications.

A low-pressure turbine of a gas turbine engine with a rear support is known, in which the labyrinth seal separating the rear discharge cavity of the turbine from the flow path at the outlet of the turbine is made in the form of a single tier. (S.A. Vyunov, "Design and design of aircraft gas turbine engines", Moscow, "Engineering", 1981, p. 209).

The disadvantage of the known design is the low pressure stability in the unloading cavity of the turbine due to the unstable value of the radial gaps in the labyrinth seal, especially in variable engine operating modes.

Closest to the claimed design is a low-pressure turbine of a gas turbine engine, including a rotor, a stator with a rear support, a labyrinth seal with inner and outer labyrinth flanges mounted on the rear support of the stator (US patent No. 7905083, F02K 3/02, 03/15/2011).

The disadvantage of the known design, taken as a prototype, is the increased value of the axial force of the turbine rotor, which reduces the reliability of the turbine and the engine as a whole due to the low reliability of the angular contact bearing, which perceives the increased axial force of the turbine rotor.

The technical result of the claimed invention is to increase the reliability of the low-pressure turbine of a gas turbine engine by reducing the magnitude of the axial force of the turbine rotor and ensuring the stability of the axial force when operating in transient conditions.

The specified technical result is achieved by the fact that in a low-pressure turbine of a gas turbine engine, including a rotor, a stator with a rear support, a labyrinth seal made with inner and outer flanges mounted on the rear support of the stator, the labyrinth seal of the turbine is made in two tiers, while the inner tier of the labyrinth seal is formed by two sealing combs of the labyrinth directed towards the axis of the turbine, and the working surface of the inner flange of the labyrinth seal directed towards the pro the exact part of the turbine, and the outer tier of the labyrinth seal is formed by the sealing combs of the labyrinth directed to the flow path of the turbine, and the working surface of the outer flange of the labyrinth seal directed to the axis of the turbine, and the sealing combs of the labyrinth of the inner tier of the labyrinth seal are made with parallel inner walls, between which a damping ring is installed, and the outer flange of the labyrinth seal is made with an external closed annular air floor at the same time, between the flow path of the turbine and the outer flange of the labyrinth seal, there is an annular barrier wall mounted on the rear support of the stator, and the working surface of the inner flange of the labyrinth seal is located in such a way that the following condition is met:

where D is the inner diameter at the outlet of the flow path of the turbine,

The implementation of the labyrinth seal at the outlet of the low-pressure turbine as a two-tier one, arranging the seal tiers in such a way that the inner tier is formed by two labyrinth sealing scallops directed towards the turbine axis and the working surface of the labyrinth seal inner flange directed towards the flow part of the turbine, and the outer tier is formed by the labyrinth sealing scallops directed towards the turbine flow part and the working surfaces of the labyrinth seal outer flange directed towards the turbine axis, allows ensure reliable operation of the labyrinth seal during transient operation of the turbine, which ensures the stability of the axial force acting on the turbine rotor and increases its reliability.

The implementation of the sealing scallops of the labyrinth of the inner seal tier with parallel inner walls, between which a damping ring is installed, reduces vibration stresses in the labyrinth and reduces the radial gaps between the scallops of the labyrinth and the flanges of the labyrinth seal.

The implementation of the outer flange of the labyrinth seal with an external closed air cavity, as well as the placement of an annular barrier wall between the flow path of the turbine and the outer flange of the labyrinth seal, mounted on the rear support of the stator, can significantly reduce the rate of heating and cooling of the outer flange of the labyrinth seal in transient modes, thus bringing it closer to the rate of heating and cooling of the outer tier of the labyrinth seal, which ensures the stability of the radial gaps between the stator and the rotor in the seal and improves reliability low-pressure turbines by maintaining a stable pressure in the unloading after-turbine cavity.

The choice of the ratio D/d=1.05 1.5 is due to the fact that at D/d<1,05 снижается надежность работы лабиринтного уплотнения из-за воздействия на уплотнение высокотемпературного газа, выходящего из турбины низкого давления.

When D/d>1.5 reduces the reliability of the gas turbine engine by reducing the axial unloading force acting on the rotor of the low-pressure turbine.

Figure 1 shows a longitudinal section of a low-pressure turbine of a gas turbine engine.

Figure 2 - element I in figure 1 in an enlarged view.

Figure 3 - element II in figure 2 in an enlarged view.

The low-pressure turbine 1 of the gas turbine engine consists of a rotor 2 and a stator 3 with a rear support 4. To reduce the axial forces from the gas forces acting on the rotor 2 at its outlet, between the disk of the last stage 5 of the rotor 2 and the rear support 4, an unloading cavity 6 of increased pressure is made, which is inflated with air due to the intermediate stage of the compressor (not shown) and is separated from the flow part 7 of the turbine 1 by a two-tier labier screw seal, and the seal labyrinth 8 is fixed by a threaded connection 9 on the disk of the last stage 5 of the rotor 2, and the inner flange 10 and the outer flange 11 of the labyrinth seal are fixed on the rear support 4 of the stator 3. The inner tier of the labyrinth seal is formed by the working surface 12 of the inner flange 10 directed (facing) towards the flow path 7 of the turbine 1, and two sealing combs 13, 14 of the labyrinth 8 directed towards the axis 15 of the turbine 1. The inner walls 16,17 respectively of the combs 13, 14 are made parallel to each other. A damping ring 18 is installed between the inner walls 16 and 17, which helps to reduce vibration stresses in the labyrinth 8 and reduce the radial gaps 19 and 20, respectively, between the labyrinth 8 of the rotor 2 and the flanges 10, 11. scallops 22 of the labyrinth 8 directed towards the flow path 7 of the turbine 1. The outer flange 11 of the labyrinth seal is made with an outer closed annular air cavity 23 bounded on the outside by the wall 24 of the outer flange 11. stator 3 and protecting the outer flange 11 from the high-temperature gas stream 26 flowing in the flow path 7 of the turbine 1.

The working surface 12 of the inner flange 10 of the labyrinth seal is located in such a way that the condition is met:

where D is the inner diameter of the flow part 7 of the turbine 1 (at the outlet of the flow part 7);

d is the diameter of the working surface 12 of the inner flange 10 of the labyrinth seal.

The device works as follows.

When the low-pressure turbine 1 is operating, the temperature state of the outer flange 11 of the labyrinth seal can be affected by a change in the temperature of the gas flow 26 in the flow path 7 of the turbine 1, which could significantly change the radial clearance 19 and the axial force acting on the rotor 2 due to changes in air pressure in the unloading cavity 6. However, this does not happen, since the inner flange 10 of the inner tier of the labyrinth seal is inaccessible to the influence of the gas flow 26, which contributes to the stability of the radial clearance 20 between the inner flange 10 and the labyrinth combs 13, 14, as well as the stability of the pressure in the cavity 6 and the stability of the axial force acting on the rotor 2 of the turbine 1.

CLAIM

A low-pressure turbine of a gas turbine engine, comprising a rotor, a stator with a rear support, a labyrinth seal with inner and outer flanges mounted on the rear support of the stator, characterized in that the labyrinth seal of the turbine is made in two tiers, while the inner tier of the labyrinth seal is formed by two sealing combs of the labyrinth directed towards the axis of the turbine, and the working surface of the inner flange of the labyrinth seal directed towards the flow path of the turbine, and the outer tier of the labyrinth seal is formed by the sealing combs of the labyrinth directed to the flow path of the turbine, and the working surface of the outer flange of the labyrinth seal directed to the axis of the turbine, and the sealing combs of the labyrinth of the inner tier of the labyrinth seal are made with parallel inner walls, between which a damping ring is installed, and the outer flange of the labyrinth seal is made with an outer closed annular air cavity, while between the flow The second part of the turbine and the outer flange of the labyrinth seal have an annular barrier wall mounted on the rear support of the stator, and the working surface of the inner flange of the labyrinth seal is located in such a way that the following condition is met:

D/d=1.05 1.5, where

D is the inner diameter at the outlet of the flow path of the turbine,

d is the diameter of the working surface of the inner flange of the labyrinth seal.