Although both of these types of transmissions remember the dawn of the automotive industry, the question in the title is still relevant. In fact, it is impossible to give a clear answer to it - it is enough to know the features of each design in order to correlate the pros and cons for yourself. Naturally, we do not touch on the extreme applications of cars: for example, it is unlikely that you will be able to see a Top Fuel class dragster without a two-stage automatic or a jeeper “cutlet” without mechanics, but here the whole car is built for a specific purpose.

Mechanical transmissions: pros and cons

Historically, this is the oldest type of transmission in general, multi-stage gearboxes were invented even before the advent of cars as such. Having gone through a certain evolution and weeded out all unviable ideas, the classic layout of a manual transmission has not changed for several decades.

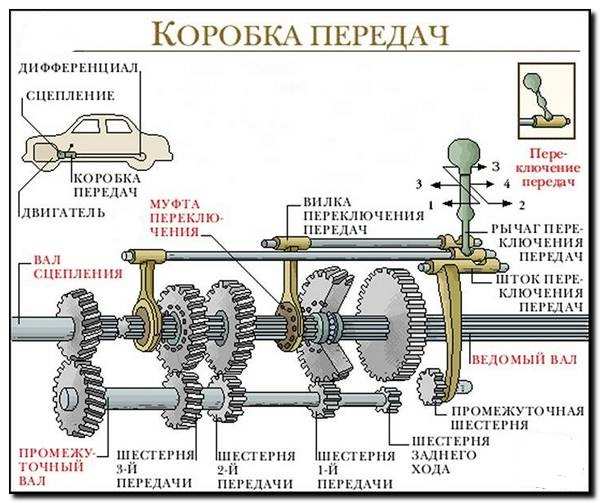

The basis of the manual transmission is two shafts with gears on them: the primary one connected to the engine through a clutch or, as an exotic option, through a torque converter (about them below), and the secondary one connected to the differential or cardan shaft, depending on the selected drive. The fundamental difference between the shafts is that on the primary shaft all the gears are rigidly fixed, and on the secondary shaft they rotate freely. When a certain gear is selected, one of the gears is connected to the clutch, which is rigidly connected to the secondary shaft, the rest continue to rotate freely.

From the obvious simplicity of such a solution, the main drawback of such a transmission also follows: at the moment of gear shifting, the clutch rotating at the same speed as the output shaft must engage with the gear, the speed of which may be completely different. Therefore, the rigidity of the shift can be overcome either by a clear alignment of the speeds of the gears, that is, by shifting gears at strictly defined revolutions, or by introducing an additional unit - a synchronizer that helps to align the speeds of the gears until the gear is engaged.

Due to convenience, at least all forward speeds on passenger cars must have synchronizers, but they are one of the weakest points of the manual transmission. It is not for nothing that on heavy American trucks, where only the passport life of the transmission is a million miles, there are no synchronizers in mechanical boxes: they inevitably wear out, making the gears more and more difficult.

Video: 5 things to NEVER do with a Manual Transmission!

But the advantages of manual transmission are obvious:

- Firstly, a minimum of transmission links between the engine and the wheels provides cars with "mechanics" high efficiency.

- Secondly, even in the event of a breakdown, the manual transmission can be easily sorted out: it is not difficult to understand its structure.

- Add to this the ease of changing gear ratios (just a couple of gears is enough to change), the ability to run on low-quality oil and tolerance for rough handling: it is very difficult to “kill” a well-designed manual transmission. And at the same time, manual transmissions are the cheapest, which makes the choice of transmission in the budget segment completely uncontested.

Automatic transmissions

Hydromechanics

Speaking of "automatic", we usually mean a hydromechanical planetary transmission - the oldest type of automobile "automatic" comes from the 30s. Such transmissions are based on the property of a planetary gearbox to change its gear ratio when one of its elements (sun gear, pinion gear or driven gear) is braked. Since all gears remain in constant engagement, the gear ratio changes smoothly and without shock - which is why automatic transmissions began to develop actively in those days when the “mechanics” did not have synchronizers and required considerable skill in handling the “poker” of gear shifting and clutch .

From the principle of operation of the planetary gearbox, it is clear that only three gear ratios can be obtained from it - it is not without reason that all “automatic machines” were three-stage for a very long time. In reality, the gear ratio at each speed in cars changed more. How so? The fact is that to connect the box with the engine without a clutch, a torque converter was used - a device of two wheels (forcing and turbine), closed in the volume of oil. Such a mechanism allows the turbine wheel to rotate at a speed lower than the speed of the blower, that is, in fact, the speed varied even before the three-stage gearbox.

Video: Automatic or mechanic. Which is better, pros and cons. Just about complex

Selective braking and connection to the output shaft of the gearbox of one or another planetary gear assembly is performed by a set of friction clutches and brake bands - in old automatic transmissions they were controlled purely mechanically, now the oil pressure in the drives is distributed by valves controlled by their controller. But the essence of the hydromechanical transmission, although now receiving up to 8 steps, remains the same: alas, high losses in the torque converter cannot be avoided, and fuel consumption with such a box will be higher than with mechanics.

The mechanism itself is very demanding on the quality and quantity of oil - even a viscosity deviation is already capable of disrupting the operation of control mechanisms, causing familiar “shocks” and “thoughtfulness” to many. This does not mean the unreliability of automatic transmissions: with proper care, they are able to demonstrate a huge resource. But the convenience of such a box is obvious, especially in city traffic jams, and the introduction of additional stages and forced blocking of the torque converter makes it possible to bring their efficiency closer to “mechanics”. A clear contraindication for hydromechanical automatic machines is harsh operation (aggressive driving, off-road) - if overheating or constant rolling (back and forth without a pause between switching on) are not terrible for manual transmission, then the “automatic” in such conditions will have to prepare for an accelerated replacement clutches and brake bands.

robotic boxes

Attempts to automate gear shifting at manual transmissions have been made for a long time, but they all ran into one pitfall: if low-power and slow hydraulic drives could control the clutches and automatic transmission belts, then manual transmissions needed high-speed drives. Therefore, actually workable designs appeared on the market only in the 90s, and in essence they were ordinary “mechanics”, where powerful electromagnets controlled the gear shift clutches and the clutch drive.

Alas, it was these "robots" that spoiled the reputation of the idea: "thoughtfulness" and bumps when shifting gears only progressed with time, since the clutch release mechanism could not adequately adapt to the wear of its discs. Added to this were regular problems with the solenoids themselves.

Only preselective DSG boxes were able to somehow correct the situation - in them the next gear was selected before the current one was turned off, and two clutches worked simultaneously: the first broke the torque of the current gear, the second connected the next one. In terms of comfort and speed, such boxes have already been able to compare with "mechanics", but in terms of complexity they have already caught up with hydromechanical machines. Problems with reliability have remained the scourge of "robots" to this day.