On our roads, most often you can find cars that consume gasoline and diesel fuel. The time for electric cars has not yet come. Therefore, consider the principle of operation of an internal combustion engine (ICE). Its distinctive feature is the transformation of explosion energy into mechanical energy.

When working with gasoline power plants, there are several ways to form the fuel mixture. In one case, this happens in the carburetor, and then it's all fed into the engine cylinders. In another case, gasoline is injected through special nozzles (injectors) directly into the manifold or combustion chamber.

To fully understand the operation of an internal combustion engine, you need to know that there are several types of modern motors that have proven their effectiveness in work:

- gasoline engines;

- engines consuming diesel fuel;

- gas installations;

- gas-diesel devices;

- rotary options.

The principle of operation of these types of internal combustion engines is almost the same.

ICE cycles

Each has fuel that explodes in the combustion chamber, expands and pushes a piston mounted on a crankshaft. Further, this rotation is transmitted to the wheels of the car through additional mechanisms and nodes.

As an example, we will consider a four-stroke gasoline engine, since it is the most common power plant option in cars on our roads.

So you:

- the intake opening opens and the combustion chamber is filled with the prepared fuel mixture

- the chamber is sealed and its volume decreases in the compression stroke

- the mixture explodes and pushes the piston, which receives an impulse of mechanical energy

- the combustion chamber is freed from combustion products

Each of these stages of the work of the internal combustion engine has its own, several simultaneous processes take place. In the first case, the piston is in its lowest position, while all valves that inlet fuel are open. The next stage begins with the complete closing of all holes and the movement of the piston to the maximum upper position. At the same time, everything is compressed.

Reaching the extreme top position of the piston again, voltage is applied to the candle, and it creates a spark, igniting the mixture for an explosion. The force of this explosion pushes the piston down, while the outlet openings open and the chamber is cleared of residual gas. Then everything repeats.

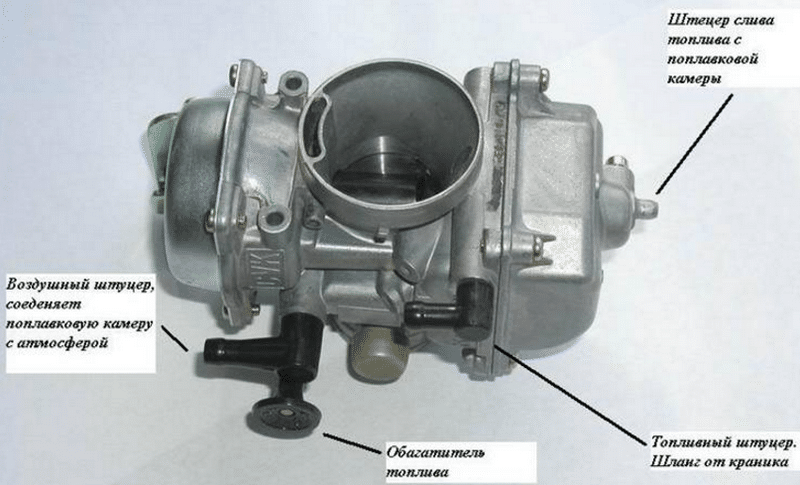

Carburetor operation

The formation of the fuel mixture in the cars of the first half of the last century took place with the help of a carburetor. To understand how an internal combustion engine works, you need to know that automotive engineers designed the fuel system so that an already prepared mixture was fed into the combustion chamber.

Carburetor device

The carburetor was engaged in its formation. He mixed gasoline and air in the right proportions and sent it all to the cylinders. Such a relative simplicity of the system design allowed it to remain an indispensable part of gasoline units for a long time. But later, its shortcomings began to prevail over the merits and did not meet the increasing requirements for cars in general.

Disadvantages of carburetor systems:

- it is not possible to provide economical modes with sudden changes in driving modes;

- exceeding the limits of harmful substances in exhaust gases;

- low power of cars due to inconsistency of the prepared mixture with the condition of the car.

They tried to compensate for these shortcomings by direct supply of gasoline through the injectors.

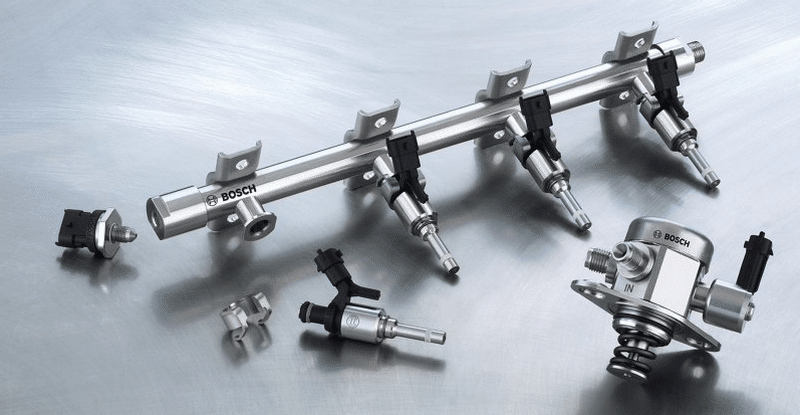

The operation of injection engines

The principle of operation of the injection engine is the direct injection of gasoline into the intake manifold or combustion chamber. Visually, everything is similar to the operation of a diesel installation, when the supply is metered and only into the cylinder. The only difference is that the injection units have spark plugs.

Injector design

The stages of operation of gasoline engines with direct injection do not differ from the carburetor version. The difference is only in the place where the mixture is formed.

Due to this design option, the advantages of such engines are provided:

- an increase in power up to 10% with similar technical characteristics with a carburetor;

- noticeable savings in gasoline;

- improvement of environmental performance in terms of emissions.

But with such advantages, there are also disadvantages. The main ones are maintenance, maintainability and customization. Unlike carburetors, which can be disassembled, assembled and adjusted independently, injectors require special expensive equipment and a large number of different sensors installed in the car.

Fuel injection methods

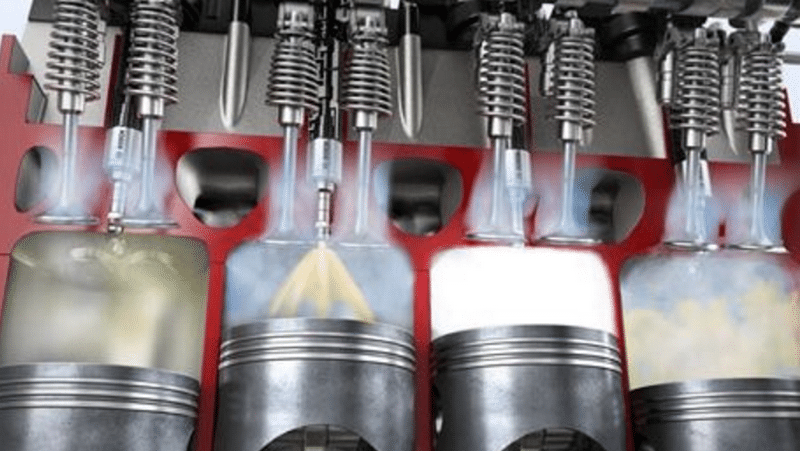

In the course of the evolution of the fuel supply to the engine, this process has been constantly approaching the combustion chamber. In the most modern internal combustion engines, the point of supply of gasoline and the place of combustion have merged. Now the mixture is no longer formed in the carburetor or intake manifold, but is injected directly into the chamber. Consider all options for injection devices.

Single point injection option

The simplest design option looks like fuel injection through a single nozzle into the intake manifold. The difference with the carburetor is that the latter delivers the finished mixture. In the injection version, fuel is supplied through the nozzle. The benefit is to save on costs.

Single point fuel supply option

This method also forms the mixture outside the chamber, but here sensors are involved that provide supply directly to each cylinder through the intake manifold. This is a more economical option for using fuel.

Direct injection into the chamber

This variant so far uses the possibilities of the injector design most effectively. The fuel is directly sprayed into the chamber. Due to this, the level of harmful emissions is reduced, and the car receives, in addition to greater gasoline savings, increased power.

The increased degree of system reliability reduces the negative factor regarding maintenance. But such devices need high-quality fuel.