Knowing how to check the ignition coil is becoming more and more relevant today. It is because of a faulty or this device that unforeseen stops can occur on the road. A distributor with a coil is one of the vital components that ensure the full functioning of the vehicle. Failure of the device or its defect can lead to a complete stop of the engine or to other serious interruptions in the operation of the vehicle.

The ignition coil, you must arm yourself with a multimeter that has two modes of operation: checking for volts and ohms. As for checking the work in a common “old-fashioned” way, by detecting a spark between a candle and a car body, in some cases it is dangerous and can lead to a complete failure of the device.

Why do you need such a detail

So. Let's see where it is located and why is it needed? The distributor is mounted on top of the engine and low-voltage current is supplied to it. It is clear that the current flows through the on-board network from the battery and, falling on the ignition coil, is converted into high-voltage current. It is here, in the distributor, that, through the slider and contacts on the cover of the device, a high-voltage current is released to the main wire that goes to the spark plug.

Then the following happens: a spark is fed into the combustion chamber of the fuel mixture, where ignition occurs. And in this case, much depends on the quality of the current, its power. Firstly, this same current must be supplied in a timely manner, otherwise ignition will not occur, and secondly, the coil must provide the necessary “voltage” of the current.

If the current is not supplied correctly, which is caused by inefficient operation of the coil or the entire ignition system, the starter rotates the crankshaft intensively, but the engine does not start. In addition, there may be a smell of gasoline coming from the muffler, which indicates a problem with the ignition of the air-fuel mixture.

Reasons for failure

What can cause an element to fail? And there may be several reasons, but the most important is either coils or a violation of the circuit during ignition and a spark arrives to the desired point. It may also be that the reason lies in poor-quality candles or broken wires.

A well-known and common method for checking the ignition coil involves the following steps:

- unscrewing some kind of candle and high-voltage wire;

- threading and applying to the car body in order to analyze the spark;

- the engine starts at the same time, and if a spark jumps between the candle and the body, then everything is in order (otherwise the coil does not give current and it should be repaired or replaced).

The above test method is quite common among ordinary motorists who are not too versed in the intricacies of the entire operation of the ignition system, engine, etc. And they are unlikely to know that this method is not suitable for checking all distributor ignition systems. There are also systems where, after such a check, even the working coil will immediately fail (for example, on a 2001 Honda).

The engine may stall for another reason. It may be, as mentioned above, not related to the coil. Therefore, before blaming everything on her, you should carefully check the wires in which there may be breakdowns.

Novice motorists often, due to forgetfulness and inexperience, in the absence of fuel in the tank, continue to check the performance of the candle or try to change the coil. At the same time, they are unaware of checking the gas tank. In addition, an experienced driver will check all these components in his garage, since it is extremely undesirable to carry out all this in the field.

Competent inspection of the coil and checking with a multimeter

After all the components on which the current supply depends are checked, and the result is the same, you should proceed to inspect the coil. To begin with, it will be useful to consider what it consists of. It is clear that any device must consist of a housing that must not pass current. In our case, such a material as ebonite successfully copes with this matter.

Any coil is crowned with a cover on top, inside of which there is a central terminal. Also inside the device is the central terminal spring, core, screws, insulating material and more.

As a rule, the device fails due to some internal damage. But it also happens that the current breaks through the case.

To correctly check the operation of this element, it is necessary to bend the latch and disconnect the wiring harness block from the distributor. After that, you need to take a multimeter and set it to the voltmeter mode, and then attach one end to the output of the coil, and the other to the car body, that is, the mass. In this case, the voltage should show 12 volts.

If there is no voltage at all, then the ECM or the electrical circuit of the distributor is faulty in this case.

On the video - checking the ignition coil:

Go ahead. We check the primary winding of the coil for an open circuit. To do this, switch the multimeter to the ohmmeter mode and set it to the coil terminals: first A / B, and then to B / C. In both cases, the resistance should not fall below 2 ohms. Otherwise, there is a break and the device must already be replaced.

In the same way, a break in the secondary winding is also checked. Only in this case, the ohmmeter readings should not fall below 5 ohms.

The distributor must also be checked for the closure of two windings. Again, we connect the leads of the multimeter in ohmmeter mode to one of the high-voltage outputs and to the output A of the coil. In this case, the resistance should tend to infinity, which will indicate that the circuit is open.

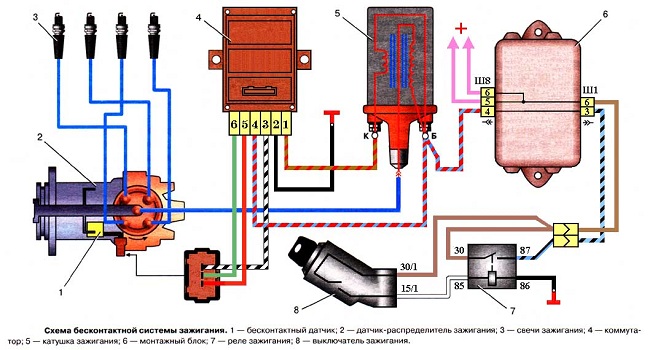

Contactless ignition system

You should know that, in addition to the contact, there is also a non-contact ignition system. In such a system, the principle of operation implies the rotation of a magnet, the number of poles of which must be equal to the number of cylinders. When the magnet rotates, an alternating current appears in the winding of a special sensor.

This type can work at different temperatures: from minus 40 degrees Celsius to plus 80. And it is correct to place such a system in the engine compartment. But the installation of the sensor and the ignition coil is carried out on the ground for a standard, conventional ignition system.

Needless to say, BSZ is much more efficient than conventional contact ignition systems and surpasses them in terms of service life.

On the video - replacing the ignition coil in case of its malfunction:

Ignition basically involves checking for an open in the wires between the sensor and the switch. This scheme of the ignition system is designed so that the malfunction can also be associated with a break in the wires connecting the switch to the switch or the coil itself.

In conclusion, I would like to give a couple of tips, especially for novice motorists. Recall again that the test method, which involves threading a candle into a high-voltage wire and analyzing the appearance of a spark, is not suitable for all ignition systems and it is better not to risk it. In addition, the coil should be checked with a multimeter. And the smell of a burnt winding, and without any checks, will tell you that it has become unusable.