As you know, "meet by clothes." Many car owners see the purpose of their existence in the constant tuning and addition of the car, creating a unique image. Today we will talk about those cases, the hand of the master gets to one more element in the cars, and the brake calipers are painted.

How to paint brake calipers?

We already wrote earlier about the numerous ways to paint your own vehicle (we advise those who are interested to read the articles about and with help). This time we will try to answer such a question as "painting brake calipers". How best to carry it out, is it possible to do this without using the expensive services of service centers, and most importantly, what is needed for successful painting of calipers. But first things first.

The reasons seem to have been sorted out, but what to do with security? After all, it is not in vain that it is believed that automobile calipers are almost the most important component of a safe ride, since together with the pads and cylinders they are responsible for braking the entire car. To complete the picture, it should be said that painting this part of the car is safe and does not violate the principle of operation of the brake system. However, when working during painting, you need to be extremely careful, since erroneous actions can result in significant damage not only to the brake system, but also to other very important components.

Preparing for painting. Required components.

So you've decided to paint your brake calipers at home. This process in itself is not so much difficult as painstaking. It is very important to pay attention to the smallest details during the painting process. Otherwise, the paint can be subjected to numerous corrosions, such paint will quickly fall off, and the meaning of the work done will remain only for future experience.

What do you need before painting? To begin with, it will not be superfluous to get a jack and the necessary keys to dismantle the caliper. The next step is to prepare the paint, or other types of staining that you have chosen as a basis. Get an electric drill, with a set of nozzles for grinding. Also, for work, you need adhesive tape (preferably masking tape) and White Spirit (or another cleaner similar in principle). Do not forget about your own protection in the form of a mask and gloves.

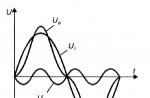

Special attention should be paid to the choice of paint for future tuning, since not all of those presented in stores will work. When buying powder paint, or liquid paint, it is necessary to take into account the heating temperature of the cylinder and caliper. The melting temperature of the paint should be as high as possible, so try to take the paint with the highest values. Ideally, it should be over 600 degrees Celsius.

Removing the caliper

Having previously acquired the keys and the jack, it is necessary to remove the calipers from the car. First of all, you need to dismantle the wheel, and rid it of dirt, grease, dust and other foreign masses and bodies. Be careful with nitrous removal, as if this factor is ignored, your paint will not last long.

Be extremely careful when separating the caliper itself from the car, as in case of negligence, you can break the hose connecting them. Don't forget to clean the boot, but don't over-retract the pistons (don't let the brake fluid leak out).

Painting calipers with liquid paint

A fairly popular staining method that is suitable for home conditions. You can carry out this method of painting using:

- brushes - consider the possibility of streaks and smudges

- can - practical and convenient, but it is advisable to get acquainted with the principle of operation of the can on test fixtures, etc.

- spray gun - professional equipment designed for such operations.

When choosing a room, consider the toxicity of the applicable paint. The place of work should be well lit to see the level of staining of the object, and also be well ventilated. In addition, it is best to paint at a temperature of 18-25 degrees Celsius. In this case, the paint hardens better, and will last longer than usual.

Depending on the staining method chosen, you need to be careful about the process. Painting should be carried out in two or more layers. The first, preliminary, will give an idea of future shortcomings, places of possible runoff. After a 20-30 minute pause between stages, a new coat of paint should be reapplied, taking into account the shortcomings of the first time. It is best to apply paint smoothly, at an angle of 90 degrees to the first layer. Thus, we remove possible divorces.

Coating calipers with powder paint

Despite the particular popularity of this method, we would not advise him to choose. It's all about the previously discussed features of the temperature effect on the paint from overheated brake calipers. Powder paints tend to have a low melting point, and those that meet the requirements are overpriced.

In view of such reasoning, painting calipers with powder paint, and liquid paint of a similar composition and the same physical characteristics, but at a lower price, looks like a waste of money. In addition, powder paint must be applied in at least 4 layers, the interval between which is 15-20 minutes.

Every car owner wants to make his vehicle original so that it attracts the eyes of others. To do this, the existing design is supplemented with interesting elements, the car is painted in a different, brighter color. When transforming their vehicles, car owners often ask themselves the question: how to paint new or old car brake drums? For this purpose, a special heat-resistant paint is often used.

Characteristics of heat resistant paint

The modern market offers heat-resistant paint from various manufacturers, which differs in properties, color and quality. It has a number of advantages, which makes it very popular:

This is what heat resistant paint looks like. Click on the photo to enlarge.

- painted drums will not be exposed to corrosion, including chemical corrosion, which occurs in the case of the use of anti-icing agents. The factor is fundamental for those who use chemicals;

- after painting, the brake elements have better heat dissipation. This is due to the porous structure of the original caliper, which becomes clogged with dirt, causing a decrease in heat dissipation. It is not possible to constantly wash brake drums, and after painting their pores will be filled with paint, as a result of which the surface becomes smooth and the elements resist dirt.

Types of heat-resistant paint

Consumers can choose from two types of heat-resistant paint. One of them is a 3-component composition:

- 150 ml of paint;

- 50 ml hardener;

- 400 ml cleaning spray.

The other is presented in the form of a spray with a capacity of 400 ml, where the hardener and paint are in the same container, but are mixed only after pressing a special button before painting the drums. The kit does not include brake cleaners.

Thanks to a wide range of heat-resistant paint, each car owner can choose what color to paint. The paint is highly resistant to chemicals, oils, corrosion and high temperatures. The manufacturer indicates that one package is enough to paint 4 drums, but, as practice shows, it is enough for 8.

Color solutions

Painted brake calipers look best when paired with forged or cast chrome wheels. Today, a large number of car owners prefer to paint drums in bright colors.

Despite the fact that the brake elements are resistant to rust due to heat-resistant paint, it still has not a practical value, but an aesthetic one. Those. the painting is meant to make the car unique, and the protective feature is a "bonus". Painted drums look spectacular, but they need to be regularly cleaned of road dust.

For ordinary car owners, the fashion to paint calipers came from the world of motorsport. After all, the brake elements of sports cars have been painted in bright colors for many years. Some companies that produce parts for brakes have decided to produce them in color.

For example, Brembo drums are painted bright red. You can paint not only in one color, but also in two, and even in three. In the west, cars with such original coloring are often found. Many car owners often ask themselves the question: “Which color of the proposed options is better to paint the brake drums ?. It all depends on the color of the car itself and the personal preferences of its owner. As a rule, bright shades of red or yellow are used.

Successful color combinations

A good combination of colors for the caliper and disc. Click on the photo to enlarge.

There are some standards, guided by which, you can harmoniously paint the brake elements. If the car body is white, then the drums can have absolutely any shade. If the vehicle is red, it is recommended to give preference to white, yellow, blue or black paint.

The braking elements of warm colored cars (orange or yellow) can be painted in colors such as white, mauve, light blue, indigo or violet. Women who have a pink car should prefer pale blue or white. The most practical is a vehicle with a black body: drums of any shade are suitable for it, as well as for a white body.

When repainting the brake elements of a car in dark blue, it is worth using paint in gray, white, blue, yellow or red. But if the body is light blue, then its drums should be pink, orange, white or yellow. For green cars, it is recommended to choose white, orange, yellow or brown paint.

The above recommendations are just an example of a successful color combination. In practice, every car owner has the right to choose the appropriate shades to paint the drums. The vehicle will stand out from the rest, and the views of others will be riveted by the original brake elements.

In an article about, we noted that the big disadvantages of cast iron are their gradual oxidation and, as a result, rust. It should be noted that this is on almost all machines. Sooner or later they bloom and after three or four years they are simply covered with “rusty dots”, which, of course, does not look very neat. Therefore, the question often arises - what and how to paint the drums? So that the "maximum" does not rust? Let's figure it out...

To be honest, it’s not so difficult to paint wheels, but it’s almost impossible to completely protect them from rust. Cast iron, of course, prevents this phenomenon for a long time, but still it is not a non-ferrous metal and rust is a completely understandable process of its life, and under the wheels of a car, especially in winter, we can observe a salt-sand mixture that fights ice, but also makes cars rust and rot faster, and drums are no exception. So 100% protection will not work, but you can try for a sufficiently long period.

Initial data

Well, there is an ordinary car, and now "drums" are installed on many models. Starting with our AVTOVAZ, ending with the popular RIO, SOLARIS, POLO, ALMERA, AVEO. Often, of course, they are cast iron, and therefore in two to three years they will rust. We need to restore them with our own hands. What exactly are we going to do today.

What will be needed?

In order to paint them, we first need to prepare. So what do we need:

- A metal brush, you can use a drill, you can use a regular hand brush.

- Mounting tape, usually paper.

- , for disk handling.

- High-temperature primer, well, or ordinary.

- High temperature paint.

- Degreaser, usually "thinner" or "white spirit"

- I recommend gloves and a respirator.

Everything about everything will take about 500-700 rubles, maybe a little less, because at home, most likely, there is a solvent and gloves. So the main price will fall on the paint and primer.

What paint and primer, choose the right one

What I want to note about paint and primer, the choice must be right, I would even say ordinary paint will not work here, I'm talking about enamels that are sold in spray cans. Here you need to choose high-temperature compounds. What does it mean?

During operation, the drums get very hot, the temperature can reach up to 100 - 110 degrees Celsius. Ordinary paint will start to leak or even burn, thus the appearance of the brake drums will only worsen (not improve), there will be constant smudges that will mix with dust and dirt.

Therefore, we definitely buy high-temperature paint, it can withstand temperatures from 120 to 150 degrees Celsius, does not flow and does not burn.

It can also be sold in spray cans, and the method of application is no different from ordinary enamel.

What else I want to say - nevertheless, spray cans are very convenient to use, you can’t just apply paint in cans, it’s quite difficult. Of course, you can “turn on the collective farm” and paint everything with a brush, but really nothing good will come of it.

I also want to say a few words about the color, many write that you can only paint black, white or silver. The rest of the colors don't seem to fit. Guys, I will say this - now you can paint with any color, even purple, high-temperature paints are available in almost any shade, so we choose to our liking and “go ahead”. However, think about what will suit your car and what will not! I mean, if your car is blue, you shouldn't paint your drums green, although that's a purely personal approach.

Painting process

Now I will tell you the whole process point by point, and there is nothing complicated here, even for a beginner:

- It is desirable to carry out work in a garage or a box closed from dust. Still, we do not need dust, because dots will remain on the surface of the paint. Of course, they will not be particularly visible, but still there is no need for this.

- We raise the side and remove the wheel, it is advisable to put something insuring next to the jack, for example, a wooden "block".

- We see a disc in front of us, we need to remove all rust from it, and if there is old paint, it is advisable to remove it as well. The process is dusty, so you can wear a respirator.

- After all this, we begin to process the disk. I read that before degreasing, you need to wipe the drum with a rust converter and then wait about an hour. For the conversion process to be successful.

- Next, degrease the surface. To do this, simply wipe it with a “solvent” or “white spirit”. After processing, we wait until everything dries for about 30 - 40 minutes.

- Then we need to cover with masking tape all the parts that protrude, usually the hub nut, holes or bolts for the disc. I would also seal the wing around the perimeter, you never know what. "Sizing" occurs in order to avoid getting paint on important surfaces. For example, a thread, because if it gets there, tightening a bolt or nut will not be very easy.

- After preparation, we begin to prime the drums. The primer is applied in order to give a smooth, deep surface, and also to make the paint adhere better. A couple of layers of soil are enough. No need to “press” on the spray can, paint one place for a long time, this will cause the primer to flow over the surface. It is necessary to apply quick and light “streaks”, for example, from right to left. The first layer will be thin, we need to wait until it dries, usually about 30 minutes. Then we apply the second one, we also wait. Now we have a surface in the ground. Of course, many do without it, but I think it's not right! Still, the paint will lay down much better with it.

- After the primer dries, you can start applying paint. The process is the same as with a primer, that is, you need to paint in several layers, usually three or four are enough (with breaks for drying), it makes no sense to apply more because the layer will already be thick and less reliable. It is also applied from right to left, with quick movements.

- After the surface has dried, you need to remove the masking tape and you can hang the wheel.

Besides being memorable, .com domains are unique: This is the one and only .com name of its kind. Other extensions usually just drive traffic to their .com counterparts. To learn more about premium .com domain valuations, watch the video below:

Turbocharge your website. Watch our video to learn how.

Improve Your Web Presence

Get noticed online with a great domain name

73% of all domains registered on the Web are .coms. The reason is simple: .com is the where most of Web traffic happens. Owning a premium .com gives you great benefits including better SEO, name recognition, and providing your site with a sense of authority.

Here's What Others Are Saying

Since 2005, we've helped thousands of people get the perfect domain name

- Take about 2 days to get the domain. Quick enough for me. - Huy Pham, 9/2/2019

- I saw the domain for sale. I contacted customer service. Feedback in 24hrs.Easy purchasing process fast domain transfer and set-up in minutes. I strongly believe Hugedomains.com has a very good value for money. - Andrew, 8/27/2019

- very good. Thanks - Duong Hoang, 8/27/2019

- More

It is possible to paint the working surface of the brake device only on a training sample for clarity. Painting brake discs is an operation in which the caliper and other planes that are not involved in the braking mechanism itself fall into the field of activity. The need for this operation is required after the acquisition of alloy wheels. The thing is that the elements of the brake device under the cast discs can be seen better than under the stamped ones. A rusting mechanism carries a negative. But the problems are not only in aesthetics. Regular restoration of the paintwork is required for high-quality protection of the caliper from mechanical damage, which is usually carried by stones, gravel and corrosion. Remember that this part works in special conditions. When braking, it can heat up to 620 degrees. Simple household paint will not withstand such heat. The technique for preparing the plane has significant differences than standard painting. Just disassembling the node already says a lot. Surfaces hidden from the eye need special, specific preparation.

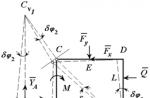

Dismantling

For this operation, it is required to raise the machine on jacks and firmly fix it in weight. Wheels are removed. Then the technical condition of the drums and caliper is studied. Nitrous, which prevents the movement of the caliper along the guides, is filled with WD-40. The grandfather's method is to knock with a hammer. In almost all designs, the caliper is mounted on a pair of bolts and connected to the machine with a rubber hose. It is important to disconnect it and prevent rupture or other damage.

The caliper moves along the guide bushings. A typical design has two bushings that are disguised in anthers. And it's not easy to get close to them. But it is very desirable to get them and lubricate them. Due to the lack of security, the sleeve sticks so that all of the above methods will not help. In this state of affairs, they try to completely disassemble and heat the entire assembly in the furnace. From these actions, the old paint, which is not resistant to temperature, will leave the caliper.

During this operation, the disks are cleaned of rust and the anthers of the caliper are cleaned of dirt. During cleaning, the pistons must not be removed completely. Otherwise, all the brake fluid will leak out. Lubrication should be done with a special substance that is in the kit with disc brakes. If this remedy is not available, lithol or other substances can be used. They must contain lithium soap elements.

Caliper painting

Painting the caliper does not involve the complete removal of the mechanism. When processing the outside, it is only necessary to remove the rims. Planes that will be completely repaired are treated with a rust converter and metal brushes. You can use acid. Used paint and rust can be removed by hand. If possible, use or buy a drill attachment, carefully walk it along the repair plane. The metal will become smooth and very shiny. This will be the sign to complete the cleanup.

Painting the caliper does not involve the complete removal of the mechanism. When processing the outside, it is only necessary to remove the rims. Planes that will be completely repaired are treated with a rust converter and metal brushes. You can use acid. Used paint and rust can be removed by hand. If possible, use or buy a drill attachment, carefully walk it along the repair plane. The metal will become smooth and very shiny. This will be the sign to complete the cleanup.

The mechanical cleaning method is omitted if there is no rust. But sanding is a must! After all, the coloring matter will not lie on a plane without preparation. Often degreasers come in a set with colorants. But you can deal with a simple cleaner or natural white spirit. After purchasing the paint, the following components will be needed:

- masking tape,

- container for mixing paint and hardener - a bucket with a stick. But they don't have to be plastic

- cotton cloths or rags for cleaning the surface.

Color selection

There are motorists who talk about painting the brake mechanism with powder paint. These statements are not credible. Powder paint has merit, but it bakes at a temperature lower than the temperature of an actively working caliper. Not every such paint will withstand such inferno. They take only one that can withstand temperatures of 610-650 degrees. How to paint if it is not possible to purchase such material in a car shop? Go to a hardware store and ask for stove paint or a primus stove.

There are motorists who talk about painting the brake mechanism with powder paint. These statements are not credible. Powder paint has merit, but it bakes at a temperature lower than the temperature of an actively working caliper. Not every such paint will withstand such inferno. They take only one that can withstand temperatures of 610-650 degrees. How to paint if it is not possible to purchase such material in a car shop? Go to a hardware store and ask for stove paint or a primus stove.

The choice of color is up to you. Some owners prefer bright colors, but such a wheel will look strange. It is desirable not to conduct such experiments with design. It is better to choose dark, masking tones. The ideal option is dark blue or black. Heat resistant paint for brake calipers is expensive, a great offer from Foliatec. The price is about 2000 rubles.

Paint coating

Many heat-resistant paints become smooth under the influence of friction and are not worse than automotive grease. If paint gets on the working surface of the disc, this threatens with an accident, braking will be ineffective. The brake mirror and other parts that are not subject to paintwork must be covered with masking tape. They also need to cover all the hoses.

Many heat-resistant paints become smooth under the influence of friction and are not worse than automotive grease. If paint gets on the working surface of the disc, this threatens with an accident, braking will be ineffective. The brake mirror and other parts that are not subject to paintwork must be covered with masking tape. They also need to cover all the hoses.

Do-it-yourself work should be carried out in a well-lit and well-ventilated area. The presence of dust and dirt is excluded. You can pre-wet the walls and ceiling, and put a filter on the hood. The temperature should be above 15 degrees. Ideal: + 22 degrees. High humidity will have a bad effect on the process. The procedure itself looks like this:

- the main tool is a brush,

- The container with paint is opened strictly before work. The hardener is mixed with paint in the ratio specified in the instructions,

- after mixing, the substance settles for 20 minutes, then shaken and mixed again,

- the paint is applied twice, after a pause of no more than 25 minutes.

During the procedure, it is important to be careful and avoid smudges. The ingress of paint on the functional surface of the discs must be completely excluded. Drying takes several days, but you can ride after 24 hours - if absolutely necessary! Remember to protect yourself and avoid getting paint on your body.