"John Deere-8430" is a heavy universal row-cultivator designed to perform energy-intensive technological operations. Due to its high power and productivity, this model is intended only for large farms. Those who have significant areas under crops and are interested in using powerful equipment that is easily aggregated with advanced high-performance trailer complexes. Such a tractor is a powerful energy production tool. In order to load it and achieve maximum profitability, you need to have not only extensive fields, but also modern trailer and attachments. All the details about the "John Deere-8430" and the specific experience of its use - below.

On average, one tractor "John Deere-8430" is designed for complex processing of 1.5-2 thousand hectares of land per season, and such a load pays off in 2-3 years. Under the condition of normal operation and timely maintenance, it is able to work 15 thousand hours before the first major overhaul. Along with the tilled modification 8430, a tracked version was also produced - 8430T.

Deere & Company is a multinational engineering corporation headquartered in Moline, in the US state of Illinois. It produces agricultural, industrial, logging tractors, trailers and attachments for them; harvesters; construction, gardening, snow removal equipment. As for agricultural machinery, it is the largest manufacturer in the world.

The company is named after its founder (in 1837, an American blacksmith and inventor opened his business in Moline, and in the future - an industrialist - John Deere). During the 19th and early 20th centuries, Deere & Company produced steel plows, cultivators, seeders and other agricultural equipment.

The first John Deere tractor was assembled in 1918, after the company bought the Waterloo tractor factory. Soon it was tractors for agriculture that for a long time, one might say, "forever", became the main specialization of the corporation. The traditional green and yellow colors of the "Dir" technology have long been well known throughout the world.

The company has old ties with our country. The first delivery of John Deere agricultural equipment to Russia was made back in 1880. The company's specialists also established trade with the new Russia: in the period 1923-1932, the RSFSR purchased annually several thousand tractors of this brand. In our time, assembly plants for John Deere tractors and combines were opened in the Moscow and Orenburg regions, and Samuel Allen, chairman of the board of directors and executive director of the company, personally met with Vladimir Putin in 2010.

Not only assembly plants, but also plants of the full production cycle, owned by Deer and Company, operate all over the world: in the USA and Canada, European countries, India and, of course, China. "North American Distribution Center" "Deere & Company", which is located in Rock Island, Illinois, this giant product warehouse, spread over an area of 246 thousand square meters and is on the 4th place in the list of the largest buildings and structures on the planet (by their area directly on the ground).

Tractors "John Deere-8430" were produced from 2005 to 2009, as part of the 8030 series of energy-saturated universal row-crop tractors. This series included four models: 8230 - 250 hp; 8330 - 280 hp; 8340 - 305 HP and 8530 - 330 hp Currently, they have been replaced by a new generation of powerful "Dir" tractors - the 8R series. It includes heavy tractors of models 8270R, 8295R, 8320R, 8335R, 8345R, 8370R, also differing in engine power, and their caterpillar versions RT.

The high versatility of the John Deere-8430 is achieved through successful aggregation with popular tillage implements, plows and seeders, high-quality and efficient hydraulics.

The undoubted advantages of this model include its saturation with advanced technologies, high power combined with fuel economy and work efficiency, and versatility. Among the innovative technologies used in John Deere-8430 are: fuel injection control by an electronic system; satellite positioning system in the Precision Agriculture automatic control system; telematic system for remote monitoring of the operation of the tractor and its systems.

The tractor is prepared for the special navigation system "Auto-Trac", which guarantees the most accurate (+/- 3-10 cm) run boundaries and makes it possible to work smoothly, including at night, with terrain mapping. This will require additional installation of GreenStar equipment.

Namely, there are several options for signal accuracy:

- SF1 system- this is in the basic configuration, the accuracy from pass to pass is about 30 cm (15 minutes from pass to pass); the rest are additional options:

- SF2 system– pass-to-pass accuracy ±10 cm (15 minutes pass-to-pass);

- StarFire RTK System– real-time kinematics with an accuracy of less than 2 cm (within 10 km from the base station and 68% of the time).

These technologies help increase productivity, reduce the area of mutual overlap of adjacent passages, reducing diesel fuel and other components of the production cost. In addition, GreenStar driving systems allow the operator to pay more attention to the attachments and monitor the quality of their functioning.

"John Deere-8430" is capable of performing any agrotechnical operations with wide-cut agricultural implements for cultivating the land. The machine provides the main means of mechanization of work in the conditions of intensive and classical technologies for growing a full range of agricultural crops. The tractor flexibly fits into the specific parameters of any field, is equipped with a complete set of necessary settings for all types of work.

In combination with agricultural implements appropriate for their intended purpose, a tractor with maximum efficiency:

- cultivates the soil (plows, harrows, cultivates, etc.) on large fields of large peasant farms and agricultural holdings;

- tows multi-row planting units, equipment for harvesting green forage and harvesting;

- loosens, weeds, fertilizes, performing such work without damaging the rows of plantings, which allows the parameters of the chassis of the machine, its agrotechnical clearance;

- fills and forms pits for silage;

- transports significant volumes of cargo for a wide variety of purposes in conventional and dump trailers.

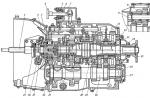

The tractor is equipped with a 9-liter four-stroke diesel engine "John Deere Power Tech Plus" ("PE 6068B"). This is an in-line 6-cylinder 24-valve engine with a turbocharging system and intercooling of charge air, variable geometry and liquid cooling. Direct fuel injection and removal of combustion products provide 4 valves on each cylinder.

The John Deere Power Tech Plus engine is equipped with a Common Rail direct fuel injection system manufactured by Denso. Also, this power unit is equipped with an automatic fuel pumping system "Auto-Prime".

This motor has an accurate and verified response to changing loads. The Power Tech Plus motor only needs to drop 500 rpm to develop maximum torque. Thanks to this, the increase in torque is accelerated by 35 percent. The response time to load changes becomes shorter, as a result of which the performance of the power unit increases.

Power Tech Plus engine parameters in numbers:

- Rated power. (EC 97/98) - 305 horsepower, or 225 kilowatts.

- Maximum torque - 1028 N.m.

- Torque reserve - 35%.

- Constant power range - 600 rpm (1500 - 2100 rpm).

- Cylinder diameter - 118 mm, piston stroke - 136 mm.

- Compression ratio: 16.3:1.

Among other features of the John Deere-8430 tractor engine:

- The high pressure fuel rail (HP-CR) fuel system promotes instantaneous load response for additional fuel economy.

- The air-cooled intercooler improves engine performance and efficiency.

- An electronic fuel pump that automatically bleeds air after changing fuel filters reduces downtime.

- A viscous-coupled cooling fan and an improved Vari-Cool fan drive also contribute to fuel economy.

- The dry air filter has an inlet on the cab support.

- Separate injection pumps.

- Fuel tank cooler.

The design of the tractor "John Deere-8430" provides for two types of gearboxes: "Automatic Power Shift" - automatic speed manual transmission; "Auto Power" - automatic continuously variable hydrostatic-mechanical gearbox. Both transmission options allow the operator to move off smoothly and reach maximum speed without using the clutch at all.

The first option, a 16-speed transmission, was developed by John Deere specialists based on the Power Shift system that appeared in 1994. Thanks to the built-in electronics and closed-loop gearshifting, gear shifting occurs in a smooth rhythm.

This gearbox has sufficient strength to operate under sudden and high-torque loads, while maintaining the speed of response to the control action and the reliability of gear changes. When the engine power is reduced or the load on the tractor changes, gear shifting occurs automatically, within the selected range. In total - 16 forward and 5 reverse gears.

The stepless gearbox "Auto Power", unlike the first version of the gearbox, was not included in the standard equipment of the John Deere-8430 tractor and was offered as an additional option. The machine operator only needs to select the required speed in the range from 0 to 42 km/h. (1.8 - 17 km / h - for reverse). Gear changes are easy and smooth.

There is a special "Power Zero" function designed to hold the tractor in place in the event of braking on a slope. This version of the gearbox has a positive effect on the patency of the car, due to its instant response to changing loads. Operates in four modes - manual, PTO, high traction control and low traction control, economical transport mode. However, this transmission is very expensive and has a complex design.

Tractors "John Deere-8430" implemented an independent lever-articulated suspension "ILS", automatically adjustable. The “ILS” independent front axle suspension maximizes power transfer to the ground, for consistently high performance, even when operating in very uneven terrain. Suspension system is hydro-pneumatic, constant action, with automatic leveling, automatic load compensation and active traction geometry for three-point hitch implements.

The rear axle on the 8030 series can have an axle with a length of 2438 mm. An axle of 2438 mm is provided for mounting single rear wheels on the rear axle of the tractor, and an axle with a length of 3002 mm is provided for mounting dual wheels.

The front steering axle is also the leading one. Torque is supplied to the front-wheel drive at all gearbox speeds in the following three modes:

- forced connection;

- automatic - when changing the parameters of the roadway;

- braking optimization - activated when both brake pedals are pressed.

The tires used are 800/70 R38 and 600/70 R30.

The brakes on this tractor are multi-disc. They work separately for the rear wheels, and are mounted on a shaft axle between the differential and the final drive of the bead. They are controlled by hydraulics, duplication goes through a mechanical drive.

The hydraulic system of the John Deere-8430 tractors is equipped with a load sensing system based on an adjustable pump. Thanks to the new hydraulic pump, which has a capacity of 161 l / min, a high speed of transfer of oil flows to the equipment is ensured. Type of hydraulics - closed center, PFC.

The hydraulic system holds 36 liters, or 54.9 liters with the aux reservoir. The feed pump delivers 120 liters per minute. Total flow: 166.5 l/min; 227.1 l/min (optional).

Three-point rear hitch - electro-hydraulic, with full electronic lower link traction control, hitch damping, external fender switches.

Lifting capacity - 7847 kg; or 8300 kg (additional option). The maximum lifting capacity on hooks is 10788 kg (105.8 kN). The OECD load capacity at 610 mm is 9519 kg (93.35 kN).

The rear power take-off shaft is independent, multi-plate type, with independent oil cooling, blocking and braking is carried out by an electro-hydraulic system. PTO type - 1000 rpm, 20 spline 45 mm shaft, or 2 speed. Does not require disassembly of the gearbox. 1000 rpm and 540 rpm - with 45 and 35 mm shafts.

Specifications in numbers

- Cabin height - 3.053 m;

- Width - 2.484 m;

- Length - 5.739 m.

- Operating weight - 10.346 tons.

- Gross weight, with ballast - 15.263 tons.

- Load distribution: on the front axle - 40%, on the rear axle - 60%.

- Wheelbase - 302 cm (ILS); 305 cm (MFWD).

- Ground clearance - 44 cm

- Turning radius - 5.35 m.

- The output power of the tractor on the PTO at 1000 rpm is 190 kW (255 hp).

- Fuel tank capacity - 681 liters.

John Deere-8430 tractors are equipped with a spacious and comfortable cabin of the CommandView series. This is a heat and sound insulated cabin. Vibration protection, ventilation, air conditioning and heating units create comfortable working conditions. The noise figure is really very low - 69 dB(A). As a result, workdays become noticeably less stressful. Frontal and rear solid glass, lighting of the working area for all 360 ° make it possible to constantly visually monitor the operation of the tools used.

In addition, the tractor seat equipped with air suspension not only has all the necessary settings, but can also be rotated by 40 degrees. There is also a full-sized "trainee" seat.

The cab on these tractors is equipped with a four-position suspension, equipped with four adjustable shock absorbers, with a stroke of 5 cm up and 5 cm down. It adapts to rough terrain conditions automatically. The lower parallel rods guarantee the longitudinal stability and longitudinal position of the cabin.

The following information is displayed on the split screen in the John Deere-8430 tractor cab: time, speed, slip percentage, engine speed in rpm, hours since last service, total engine hours, coolant temperature, oil pressure, system voltage, transmission oil temperature, rear hitch position, PTO speed, implement width, area worked per hour, fuel consumption per hour, fuel calculation by field area, distance counter, total area worked, approx. This is the time remaining until the fuel tank is empty.

The John Deere 1270D harvester is a special equipment designed for logging and final thinning work.

The John Deere 1270D model has become a benchmark of quality and a role model. To date, the 1270D technique is considered the most powerful, and there is no doubt about its performance at all.

With the new 1270E harvester, logging will never be the same again. A powerful 9 liter diesel engine and dual pump hydraulic system give this machine excellent performance.

The harvester is equipped with the TimberMatic H-12 intelligent measurement and control system, which allows you to use shortcut keys to the main functions of the machine, as well as adjust the parameters of the attachment.

Operator comfort, ergonomic controls, excellent visibility – this machine is all about productivity. Try it and see for yourself.

One of the characteristics of the 1270D harvester is the most modern cab automation. All work processes are carried out with the help of a computer, as a result of which the efficiency of the machine is greatly increased. In addition to complete comfort for the operator (air conditioning, noise protection system, etc.), the 1270D harvester has a maximum throughput, a powerful engine, thanks to which it easily copes with the most difficult jobs.

The mass of John Deere 1270 harvesters is 18.4 tons. The harvester is equipped with a powerful 6-cylinder engine with 228 hp and a volume of 9 liters. The improved CH7 manipulator has a maximum boom reach of 8.6 / 10, 11.7 m. The boom rotation angle is 220⁰. The hydraulic system is load controlled. The transmission is equipped with a differential lock on the rear and front axles.

Two cab options are offered: fixed and swivel with the ability to level. The cab is characterized by low noise and vibration levels, and is also equipped with air conditioning and other options that make the operator's work more comfortable.

Operator's cabin

Spacious, bright, comfortable with an ergonomic seat, equipped with easy-to-use mini-joystick controls. Equipped with efficient heating and air conditioning. Provides good visibility of the working area and good working conditions for the operator. The cab is safety tested to ISO industry standards (ROPS, FOPS, OPS, BC).

The noise level in the cabin complies with the international standard. The cabin is equipped with a radio radio, has tinted windows made of impact-resistant material and a jack for connecting a cell phone. As an option, the John Deere 1270D harvester is equipped with an automatic cabin leveling and turning system, which increases the level of ergonomics and reduces the likelihood of damage to the cabin by trees that remain during selective felling.

Engine

John Deere JD 6081 HTJ D3 turbocharged, diesel, six-cylinder, displacement 8.1 l, maximum power 160 kW at 2000 rpm, 1100 Nm torque at 1400 rpm, fuel tank capacity 480 l.

The engine torque allows you to simultaneously turn on the harvester head feed motors and use the functions of the hydraulic arm, which allows you to increase the productivity of the harvester. Under operational conditions, the engine can be operated at lower engine speeds, resulting in lower fuel consumption, longer crankshaft life, and lower noise levels.

Transmission

Hydrostatic-mechanical with a dual-range transfer gearbox. Travel speed V = 0…24 km/h, maximum tractive effort Рк = 160 kN. The transmission includes a hydraulic pump and engine, a two-stage transfer case (high and low gears), cardan shafts. The hydrostatic transmission element includes a hydraulic pump and a hydraulic motor, which are connected to each other by a suction and discharge circuit.

Hydraulic pump and piston type motor - variable displacement. The working volume of the hydraulic pump is in the range of 0...100 cm3, the engine - 140...160 cm3. When starting, the hydraulic motor always has the maximum displacement. The transfer case distributes torque from the hydraulic motor between the front and rear axles. It is a mechanical gear train and provides high and low gear ranges, and also allows you to disable the drive to the front axle.

Hydraulic system

Constant pressure, sensitive to load, working pressure - 24 ... 28 MPa. The pump capacity is 288 l/min at a rotational speed of 1800 min-1 of the hydraulic pump shaft. The hydraulic system of the harvester includes:

- hydraulic motor pump;

- hydraulic valve HV09 movement of the manipulator;

- hydraulic motor;

- pressure accumulators;

- hydraulic valves;

- brakes, etc.

Brake system

Hydraulic. Service and service (auxiliary) brakes are multi-disc in oil bath with hydraulic drive. The front axle is equipped with service brakes in front of the differential. During the processing of wood, in order to ensure the same force on all wheels, the differential lock is activated simultaneously with the brakes. The service brakes of the rear axle are mounted on the hubs. The parking brake is mounted in front of the rear axle housing and has mechanical spring engagement and hydraulic disengagement.

Steering

Stepless with electric drive, carried out with the help of a manual manipulator of the "joystick" type by turning the articulated semi-frames with two hydraulic cylinders. Angle of rotation of semi-frames ±42º.

Hydraulic manipulator

With parallel action boom models TJ 210H90, 210H97, 210H115 with maximum outreach (with head) 9.3; 10 and 11.8 m and lifting moment (gross) 178 kNm. The angle of rotation of the boom is 220º, the angle of inclination of the hydraulic manipulator stand is 25º forward and 13º back /

electrical equipment

Generator 288V/140A; two rechargeable batteries of 140 A each and a voltage of 24 V. There are 14 double working headlights and four single ones on a hydraulic manipulator with illumination in the working area at night of at least 30 lux.

Harvester (processor) heads

A wide range of harvester heads allows the John Deere 1270D harvester to be used in a variety of conditions. The powerful H762 and 758 heads are designed for use in final fellings, while the H754, 745 and H752D heads are designed for use in thinnings. Harvester heads 758, H754 and 745 allow you to work with trees that have twisted trunks with thick branches.

The head is equipped with four movable delimbing knives, a powerful four-roller drive, hydraulic brakes, and a hydrostatically driven chain saw.

Felling and bucking mechanism of the harvester head

Includes hydrostatic chain saw. The length of the saw bar is 750 mm, the pitch of the saw chain is 10 mm, the speed of the saw chain is 40 m/s, the recommended capacity of the harvester hydraulic pump is 250 l/min at a working pressure in the system of 24 MPa. The maximum diameter of a tree cut (for one cutting step) is 56 cm.

Tree pulling mechanism

It includes four hydraulic motors that work together and drive two fixed on the frame and two movable broaching rollers. Pulling force - 22.0 ... 27.0 kN. The tree pulling speed is 4.7 m/s, the maximum opening of the broaching rollers is 70 cm.

Harvester head delimbing mechanism

Includes four movable hydraulic delimbing knives. The diameter of the tree trunk in the delimbing zone, covered by 100% delimbing knives, is 48 cm. A double potentiometer located above the delimbing knives, a measuring wheel pressed against the tree trunk, accurately measure its diameter and length.

Specifications John Deere 1270D

| Engine | ||

| brand | John Deere | |

| Model | 6090HTJ | |

| Power | 160 kW | |

| Power | kW | |

| Power | 1400 rpm | |

| Displacement | 9 l | |

| Max Torque | 1100 Nm | |

| At a rotational speed | 1400 rpm | |

| Supercharging | Turbocharged | |

| Number of cylinders | 6 | |

| Operating parameters | ||

| Operating weight | 17499 kg | |

| Fuel tank volume | 480.7 l | |

| Hydraulic fluid capacity | 290 l | |

| Cooling volume | 28 l | |

| Working voltage | 24 V | |

| Current generator, in amperes | 140 amps | |

| Max Speed | 24.9 km/h | |

| Chassis | ||

| Ground clearance | 624 mm | |

| ground pressure | 69.6 kPa | |

| DRIVE SYSTEM | ||

| Tire Size-front | 600 x 26.5, 20 PR Forest King F NK | |

| Tire Size - rear | 600 x 34, 14 PR TRS NK | |

| Arrow | ||

| Maximum range | 9296 mm | |

| Dimensions | ||

| Lean forward | 11 degrees | |

| Tilt to the side | 15 degrees | |

| Height to top of cab | 3709 mm | |

| Overall width | 2767 mm | |

| Wheelbase | 4038 mm |

Video review of harvester John Deere 1270D

Tractors and other agricultural equipment are represented by dozens of brands, and one of the most popular in the world is the John Deere tractor. The equipment presented by the company performs a variety of tasks, mainly the manufacturer produces models with wheeled and tracked types. The main advantages of the model range include excellent reliability, performance and comfort at all stages of work. But before discussing the main models of John Deere, consider the history of the company.

John Deere Company

The company is considered one of the oldest tractors on the market, having been founded in 1837. It all started with a small shop in Illinois, where a man named John Deere decided to sell various equipment (ploughs, shovels, etc.). Many years later, namely in 1842, John Deere and his partner opened their own factory. The first products of the factory were seeders and cultivators, and only since 1912 were the first attempts to create agricultural machinery.

The first model was introduced in 1918, the range has increased significantly and now John Deere tractors have a lineup of several dozen models manufactured in 27 countries. There is a suitable equipment for the buyer, ranging from universal tractors to powerful all-wheel drive machines.

Advantages and disadvantages

Of course, such a well-known brand has many advantages, which are proved by thousands of positive reviews and an excellent reputation. Among the main ones are:

- corporate quality and reliability;

- a variety of available equipment;

- modern hydraulic system and powerful motors;

- all presented models fully fulfill their duties, they are tested for a long time before release;

- unpretentiousness to maintenance due to the excellent quality of parts.

Flaws

Although the technique has won the favor of many customers, there are several drawbacks to the John Deere brand:

- in modern models there is a lot of electronic equipment that requires a lot of knowledge for management and maintenance;

- some models are not suitable for the Russian consumer due to the poor quality of domestic gasoline.

John Deere tractor series

Today, the manufacturer produces 6 different series of its tractors, including 6B, 6D, 6M, 7030, 8R(RT) and 9R. Each of the series fulfills its functionality by 100%, you can choose agricultural machinery to suit your requirements and working conditions.

Series 7030

The tractors of this series are classified as universal, in total there are 3 different tractors in the series. All of them are represented by a variety of basic and additional attachments. Of particular note is the 7830 tractor, which is classified as a 3rd power class. It is based on a PowerTech Plus engine with 200 horsepower and 957 Nm of torque. The engine capacity is no less impressive - as much as 6.8 liters. It features a large number of gears - 20 forward and 20 reverse, the control is convenient thanks to the proprietary PowerQuad Plus transmission.

The dimensions of the 7830 model are impressive, the tractor is not only huge, but also has a large wheelbase. Thanks to these indicators and a powerful motor, the equipment has received incredible cross-country ability and is used for professional purposes. There are many attachments available, which are mounted on the rear or front hitch. Unfortunately, the model has not been produced since 2011, but the John Deere 7830 is still one of the best models in the series. Other modifications include models 7730 and 7930.

Series 6D

The operation of the John Deere tractor is presented as a universal technique for agriculture, the 6D series is based on diesel power units with a unique Common Rail system. At the moment, two different modifications have been released - 6115D and 6130D. PowerTech M and PowerTech E motors are used respectively.

A big advantage is the ability to work with important attachments, for example, work perfectly with a mounted loader and 3-point hitch. Depending on the choice of the client, it is possible to order all-wheel drive or mono-wheel drive on one axle.

If we consider the 6115D model, we can distinguish a motor with a power of 113 horses, 9 gears forward and backward and a weight of 4,260 kg. A comfortable ride is made possible by the PowerRewers transmission.

Series 6B

One of the most affordable and easy series for private use, John Deere tractors come in three models: 6095B, 6110B and 6135B. All tractors are offered in two different trim levels - Standard and Premium. Despite the simple characteristics, the 6B series equipment turned out to be very reliable and productive, very easy to operate and maintain. Each model is equipped with a diesel engine with incredible quality and service life.

Tractors are equipped with all-wheel drive, which provided good cross-country ability in various conditions. Front BOM can be selected as an option. If desired, the driver connects the front axle. When using the rear linkage, the carrying capacity of the device ranges from 4,100 to 5,400 kg, a good indicator for such a seemingly simple tractor. For control, a Top Shaft Synchronized mechanical transmission is provided. The Standard package has 12 forward gears, 4 reverse gears, the Premium package has 28 and 8 gears, respectively. Motor power differs depending on the model:

- tractor 6095 - 95 hp;

- tractor 6110 - 110 hp;

- tractor 6135 - 135 hp

Series 8R and 8RT

One of the most powerful and modern series, it is represented by universal tractors, available in two versions - tracked and wheeled. An excellent opportunity to choose the ideal model for agriculture. The manufacturer believes that this series is one of the most advanced and modern, because the tractors now use the latest technologies that provide ideal work with the ground.

Regardless of the model of the 8R series, the tractors remained economical, of high quality, and have a minimum emission of gases into the atmosphere. The manufacturer positions the modification with a wheelbase as R, caterpillar tractors are designated RT.

Today there are 4 main models:

- John Deere 8260 - PowerTech motor with 260 hp and a torque of 1,217 Nm;

- John Deere 8285R - PowerTech engine with 285 horsepower, 1,334 Nm of torque;

- John Deere 8310 - PowerTech engine with 310 hp thrust, 1,452 Nm of torque;

- John Deere 8335 - PowerTech motor with 335 hp and a torque of 1,569 Nm.

All of them received a manual or automatic transmission (optional) with 16 forward gears and 5 reverse gears. The drive is 4D full, the wheelbase was 3050 mm. Excellent series for the Russian user.

Series 9R

Belong to the class of heavy tractors, equipped with all-wheel drive and a powerful high-torque engine. The most successful model produces power up to 560 horses, with excellent design features, the tractor easily cultivates huge tracts of land. Many different attachments are installed on the tractors, for example, in all models except 9410, you can install a special scraper for leveling the soil. The powerful models of the 9R series are available in both tracked and wheeled versions.

Even considering the huge weight and dimensions, the tractor is able to reach speeds of up to 40 km / h, which is more than a good indicator for heavy agricultural machinery. Regardless of the model, they are all equipped with a comfortable spacious cabin, modern electronics and an economical engine.

The main models of the 9D series include tractors John Deere 9410R, 9510R, 9460R, 9560R. Track versions are available in the 9460RT, 9510RT and 9560RT models. I would especially like to note the model 9420.

Tractor John Deere 9420

It is based on a 6-cylinder diesel engine, turbocharged fuel injection is installed. The tractor has an on-board computer through which all equipment control and even fuel consumption are carried out. With proper operation, the tractor consumes 420 grams per 1 hour of operation, which is more than a good indicator.

The total weight of the tractor was 15.5 tons, when installed with a 3-point hitch, the load capacity is up to 6 thousand kg. Modern technologies have also reached the transmission, which is controlled electronically. An automatic transmission is installed, if desired, manual mode is activated.

Video

The John Deere company is famous all over the world for the production of high-quality tractors for various purposes. The model range includes special equipment that meets all the criteria of economy, versatility, and has a long service life. The official website of the Russian seller https://www.deere.ru/ru/ presents a wide range of models that are successfully used in the agricultural, construction and utility industries.

Specifications of John Deere Tractors

The Jondir series includes two main versions of all-wheel drive tractors on caterpillar and wheel tracks. In addition, you can expand the functionality of special equipment with the help of suspended and trailed equipment.

Aggregated with the entire range of attachments

The advantages of the range are as follows:

- Thanks to powerful power units, the equipment is able to perform various construction and agricultural work of any complexity. Also, with the help of these tractors, it becomes possible to transport heavy loads over long distances.

- Due to the high automated transmission, engine power is used with maximum efficiency.

- The design features of the hydraulic system and mounting system ensure compatibility with various attachments.

- The workplace of the machine operator is equipped with all the necessary devices for comfortable work.

- The automated driving system in combination with a navigation device will make it possible to perform labor-intensive work in a short time and with saving fuel and lubricant mixtures.

- Thanks to on-board computer equipment, the operation of the engine and power systems of special equipment is optimized.

All mechanical components are ergonomically positioned in relation to each other, which ensures ease of access to each of them. This design significantly reduces the time and cost of maintenance. In addition, due to the fact that each mechanism is installed at a distance in relation to the others, they do not fray and serve for a longer time.

When choosing a modification, you should first of all be guided by the purpose of the equipment and the type of work for which it is planned to use it. Be sure to take into account the power of special equipment.

VIDEO: John Deere - the most powerful, comfortable and easy-to-drive tractors

John Deere 6

John Deere 6210R

John Deere tractors of the sixth class have a fairly simple design, due to which its cost is somewhat less than other series. The line includes 2 models with different power ratings and performance.

The estimated cost of these modifications varies within $95,000.

John Deere 6V

The manufacturer produces three models with standard equipment and premium. This is an economical and compact special equipment with a PT power unit. The engine produces power of 85-95 hp. With. while having a torque margin of 30%. Versions are great for working with ground soil, cargo. The John Deere tractor can be equipped with a loader from this company and similar suspension devices.

John Deere 6D

This version of John Deere tractors is distinguished by a high level of energy saturation. Therefore, it is often used for equipment with wide-cut devices, attachments and hook-on devices. In the modifications there is a powerful power unit and an automatic type of transmission called Power Reverser.

The design features of the transmission in combination with electro-hydraulics provide a wide range of high-speed positions for all strokes. John Deere tractors are equipped with a two-level PTO, a clutch with a long service life.

John Deere 6M

The series includes 3 models with Power Tech-E and a power unit providing 115-205 hp. With. The advantages of the technique include a reliable frame design, three-arm suspension, a wide range of wheels in size, and an improved auxiliary brake mechanism.

|

Options |

|||||||

|

Fuel tank volume, l |

|||||||

|

Dimensions, cm |

|||||||

|

Wheelbase, cm |

|||||||

|

Rated torque, Nm |

|||||||

|

Maximum allowable weight, t |

|||||||

John Deere 7

In the John Deere range of the seventh class, there are modifications equipped with a Power Tech + version of the power unit, which produces 180-202 hp. With. At the same time, the models are distinguished by economical consumption of fuel and lubricants, increased torque.

John Deere 8

This line includes all models in the name of which there is a symbol "R" and "T". John Deere tractors are equipped with an intelligent control system, a 400-horsepower engine, fasteners for equipping various suspension devices.

The series differ only in the power of the power unit, dimensions and fuel consumption. The range includes the following models:

- 82-95R - 295 liters. s., consumption 56 l / h, dimensions 6.22x3.48x3.28 m;

- 85-30R - 330 HP s., 63 l / h., 5.56x2.48x3.12 m;

- 83-10R - 310 HP s., 60 l / h., 3.2x2.43x2.43 m;

- 85-20R - 295 HP s., 59 l / h, 5.38x2.6x3.1 m;

- 84-20R-RT - 320 l. s., 65 l / h, 6.22x3.5x3.28 m;

- 84-30R - 305 l. s., 56.4 l / hour, 5.6x2.5x3.1 m;

- 83-35R - 335 HP s., 68 l / h., 6.2x2.4x2.4 m.

From the photo you can determine that outwardly the models have almost complete similarity.

John Deere 9

The power index of John Deere models included in this classification is 375-620 hp. With. The line itself includes six versions of special equipment, three on tracks and the rest on wheels. These versions were developed according to new improved technologies using modern devices, a seventeen-inch multimedia screen and controllers that track the entire process of work.

|

Options |

Model name John Deere |

||||||

|

Power indicator, kW, l. With. |

|||||||

|

Fuel consumption, l / hour |

|||||||

|

Dimensions, m |

|||||||

|

Wheel base, mm |

|||||||

|

Lifting, t |

|||||||

|

Ground clearance, mm |

|||||||

VIDEO: A giant of agricultural and forestry equipment

"John Deere-8430" is a heavy universal row-cultivator designed to perform energy-intensive technological operations. Due to its high power and productivity, this model is intended only for large farms. Those who have significant areas under crops and are interested in using powerful equipment that is easily aggregated with advanced high-performance trailer complexes. Such a tractor is a powerful energy production tool. In order to load it and achieve maximum profitability, you need to have not only extensive fields, but also modern trailer and attachments. All the details about the "John Deere-8430" and the specific experience of its use - below.

On average, one John Deere-8430 tractor is designed for complex processing of 1.5-2 thousand hectares of land per season, and such a load pays off in 2-3 years. Under the condition of normal operation and timely maintenance, it is able to work 15 thousand hours before the first major overhaul. Along with the tilled modification 8430, a tracked version was also produced - 8430T.

About Deer & Company Corporation

Deere & Company is a multinational engineering corporation headquartered in Moline, in the US state of Illinois. It produces agricultural, industrial, logging tractors, trailers and attachments for them; harvesters; construction, gardening, snow removal equipment. As for agricultural machinery, it is the largest manufacturer in the world. The company is named after its founder (in 1837, an American blacksmith and inventor opened his business in Moline, and in the future - an industrialist - John Deere). During the 19th and early 20th centuries, Deere & Company produced steel plows, cultivators, seeders and other agricultural equipment. The first John Deere tractor was assembled in 1918, after the company bought the Waterloo tractor factory. Soon it was tractors for agriculture that for a long time, one might say, "forever", became the main specialization of the corporation. The traditional green and yellow colors of the "Dir" technology have long been well known throughout the world.

The company has old ties with our country. The first delivery of John Deere agricultural equipment to Russia was made back in 1880. The company's specialists also established trade with the new Russia: in the period 1923-1932, the RSFSR purchased annually several thousand tractors of this brand. In our time, assembly plants for John Deere tractors and combines were opened in the Moscow and Orenburg regions, and Samuel Allen, chairman of the board of directors and executive director of the company, personally met with Vladimir Putin in 2010. Not only assembly plants, but also plants of the full production cycle, owned by Deer and Company, operate all over the world: in the USA and Canada, European countries, India and, of course, China. "North American Distribution Center" "Deere & Company", which is located in Rock Island, Illinois, this giant product warehouse, spread over an area of 246 thousand square meters and is on the 4th place in the list of the largest buildings and structures on the planet (by their area directly on the ground).

The place of the tractor in the model range of the plant. Model Features

Tractors "John Deere-8430" were produced from 2005 to 2009, as part of the 8030 series of energy-saturated universal row-crop tractors. This series included four models: 8230 - 250 hp; 8330 - 280 hp; 8340 - 305 HP and 8530 - 330 hp Currently, they have been replaced by a new generation of powerful "Dir" tractors - the 8R series. It includes heavy tractors of models 8270R, 8295R, 8320R, 8335R, 8345R, 8370R, also differing in engine power, and their caterpillar versions RT. The high versatility of the John Deere-8430 is achieved through successful aggregation with popular tillage implements, plows and seeders, high-quality and efficient hydraulics.

The undoubted advantages of this model include its saturation with advanced technologies, high power combined with fuel economy and work efficiency, and versatility. Among the innovative technologies used in John Deere-8430 are: fuel injection control by an electronic system; satellite positioning system in the Precision Agriculture automatic control system; telematic system for remote monitoring of the operation of the tractor and its systems. The tractor is prepared for the special navigation system "Auto-Trac", which guarantees the most accurate (+/- 3-10 cm) run boundaries and makes it possible to work smoothly, including at night, with terrain mapping. This will require additional installation of GreenStar equipment.

Scope of tractor «John Deere-8430»

"John Deere-8430" is capable of performing any agrotechnical operations with wide-cut agricultural implements for cultivating the land. The machine provides the main means of mechanization of work in the conditions of intensive and classical technologies for growing a full range of agricultural crops. The tractor flexibly fits into the specific parameters of any field, is equipped with a complete set of necessary settings for all types of work.

Tractor engine "John Deere-8430"

The tractor is equipped with a 9-liter four-stroke diesel engine "John Deere Power Tech Plus" ("PE 6068B"). This is an in-line 6-cylinder 24-valve engine with a turbocharging system and intercooling of charge air, variable geometry and liquid cooling. Direct fuel injection and removal of combustion products provide 4 valves on each cylinder. The John Deere Power Tech Plus engine is equipped with a Common Rail direct fuel injection system manufactured by Denso. Also, this power unit is equipped with an automatic fuel pumping system "Auto-Prime".

This motor has an accurate and verified response to changing loads. The Power Tech Plus motor only needs to drop 500 rpm to develop maximum torque. Thanks to this, the increase in torque is accelerated by 35 percent. The response time to load changes becomes shorter, as a result of which the performance of the power unit increases.

Features of the Power Tech Plus engine: Rated power. (EC 97/98) - 305 horsepower, or 225 kilowatts. Maximum torque - 1028 N.m. Torque reserve - 35%. Constant power range - 600 rpm (1500 - 2100 rpm). Cylinder diameter - 118 mm, piston stroke - 136 mm. Compression ratio: 16.3:1. Among other features of the John Deere-8430 tractor engine: The high pressure fuel rail (HP-CR) fuel system promotes instantaneous load response for additional fuel economy. The air-cooled intercooler improves engine performance and efficiency. An electronic fuel pump that automatically bleeds air after changing fuel filters reduces downtime. A viscous-coupled cooling fan and an improved Vari-Cool fan drive also contribute to fuel economy. The dry air filter has an inlet on the cab support. Separate injection pumps. Fuel tank cooler.Tractor transmission "John Deere-8430"

The design of the tractor "John Deere-8430" provides for two types of gearboxes: "Automatic Power Shift" - automatic speed manual transmission; "Auto Power" - automatic continuously variable hydrostatic-mechanical gearbox. Both transmission options allow the operator to move off smoothly and reach maximum speed without using the clutch at all. The first option, a 16-speed transmission, was developed by John Deere specialists based on the Power Shift system that appeared in 1994. Thanks to the built-in electronics and closed-loop gearshifting, gear shifting occurs in a smooth rhythm. This gearbox has sufficient strength to operate under sudden and high-torque loads, while maintaining the speed of response to the control action and the reliability of gear changes. When the engine power is reduced or the load on the tractor changes, gear shifting occurs automatically, within the selected range. In total - 16 forward and 5 reverse gears.

The stepless gearbox "Auto Power", unlike the first version of the gearbox, was not included in the standard equipment of the John Deere-8430 tractor and was offered as an additional option. The machine operator only needs to select the required speed in the range from 0 to 42 km/h. (1.8 - 17 km / h - for reverse). Gear changes are easy and smooth. There is a special "Power Zero" function designed to hold the tractor in place in the event of braking on a slope. This version of the gearbox has a positive effect on the patency of the car, due to its instant response to changing loads. Operates in four modes - manual, PTO, high traction control and low traction control, economical transport mode. However, this transmission is very expensive and has a complex design.

Suspension, chassis, axles, brakes

Tractors "John Deere-8430" implemented an independent lever-articulated suspension "ILS", automatically adjustable. The “ILS” independent front axle suspension maximizes power transfer to the ground, for consistently high performance, even when operating in very uneven terrain. Suspension system is hydro-pneumatic, constant action, with automatic leveling, automatic load compensation and active traction geometry for three-point hitch implements.

The rear axle on the 8030 series can have an axle with a length of 2438 mm. An axle of 2438 mm is provided for mounting single rear wheels on the rear axle of the tractor, and an axle with a length of 3002 mm is provided for mounting dual wheels. The front steering axle is also the leading one. Torque is applied to the front-wheel drive at all gearbox speeds in the following three modes: forced connection; automatic - when changing the parameters of the roadway; braking optimization - activated when both brake pedals are pressed. The tires used are 800/70 R38 and 600/70 R30. The brakes on this tractor are multi-disc. They work separately for the rear wheels, and are mounted on a shaft axle between the differential and the final drive of the bead. They are controlled by hydraulics, duplication goes through a mechanical drive.

Hydraulic system, PTO, hitch

The hydraulic system of the John Deere-8430 tractors is equipped with a load sensing system based on an adjustable pump. Thanks to the new hydraulic pump, which has a capacity of 161 l / min, a high speed of transfer of oil flows to the equipment is ensured. Type of hydraulics - closed center, PFC. The hydraulic system holds 36 liters, or 54.9 liters with the aux reservoir. The feed pump delivers 120 liters per minute. Total flow: 166.5 l/min; 227.1 l/min (optional).

Three-point rear hitch - electro-hydraulic, with full electronic lower link traction control, hitch damping, external fender switches. Lifting capacity - 7847 kg; or 8300 kg (additional option). The maximum lifting capacity on hooks is 10788 kg (105.8 kN). The OECD load capacity at 610 mm is 9519 kg (93.35 kN). The rear power take-off shaft is independent, multi-plate type, with independent oil cooling, blocking and braking is carried out by an electro-hydraulic system. PTO type - 1000 rpm, 20 spline 45 mm shaft, or 2 speed. Does not require disassembly of the gearbox. 1000 rpm and 540 rpm - with 45 and 35 mm shafts.

Specifications in numbers

Cabin height - 3.053 m; Width - 2.484 m; Length - 5.739 m. Operating weight - 10.346 tons. Gross weight, with ballast - 15.263 tons. Load distribution: front axle - 40%, rear axle - 60%. Wheelbase - 302 cm (ILS); 305 cm. (MFWD). Ground clearance - 44 cm. Turning radius - 5.35 m. Output power of the tractor on the PTO at 1000 rpm -190kW (255hp). Fuel tank capacity - 681 liters.Cabin of tractor "John Deere-8430"

John Deere-8430 tractors are equipped with a spacious and comfortable cabin of the CommandView series. This is a heat and sound insulated cabin. Vibration protection, ventilation, air conditioning and heating units create comfortable working conditions. The noise figure is really very low - 69 dB(A). As a result, workdays become noticeably less stressful. Frontal and rear solid glass, lighting of the working area for all 360 ° make it possible to constantly visually monitor the operation of the tools used. In addition, the tractor seat equipped with air suspension not only has all the necessary settings, but can also be rotated by 40 degrees. There is also a full-sized "trainee" seat.

The cab on these tractors is equipped with a four-position suspension, equipped with four adjustable shock absorbers, with a stroke of 5 cm up and 5 cm down. It adapts to rough terrain conditions automatically. The lower parallel rods guarantee the longitudinal stability and longitudinal position of the cabin. The following information is displayed on the split screen in the John Deere-8430 tractor cab: time, speed, slip percentage, engine speed in rpm, hours since last service, total engine hours, coolant temperature, oil pressure, system voltage, transmission oil temperature, rear hitch position, PTO speed, implement width, area worked per hour, fuel consumption per hour, fuel calculation by field area, distance counter, total area worked, approx. This is the time remaining until the fuel tank is empty.