Without a properly functioning generator, the car will not be able to drive for a long time. The battery charge will quickly be used up, and you will have to look for ways to evacuate the vehicle. This means that the generator must always be in good condition.

Almost any car owner will be able to repair the generator with their own hands, with even a minimal set of tools and spare parts. Many damaged components are identified after disassembling the hull and visual diagnostics.

There are some of the most common reasons why a car alternator fails. The following symptoms are the result:

- low voltage at the output terminals;

- the generator began to work noticeably noisier;

- devices are being recharged;

- lost consumer charging;

- charging is in progress, but there is a warning light on the instrument panel.

Most of their described effects have valid reasons. They can be direct or indirect, and can also be related to mechanical or electrical problems.

Troubleshooting and Troubleshooting

Timely repair of the car generator will ensure the smooth operation of all related vehicle systems.

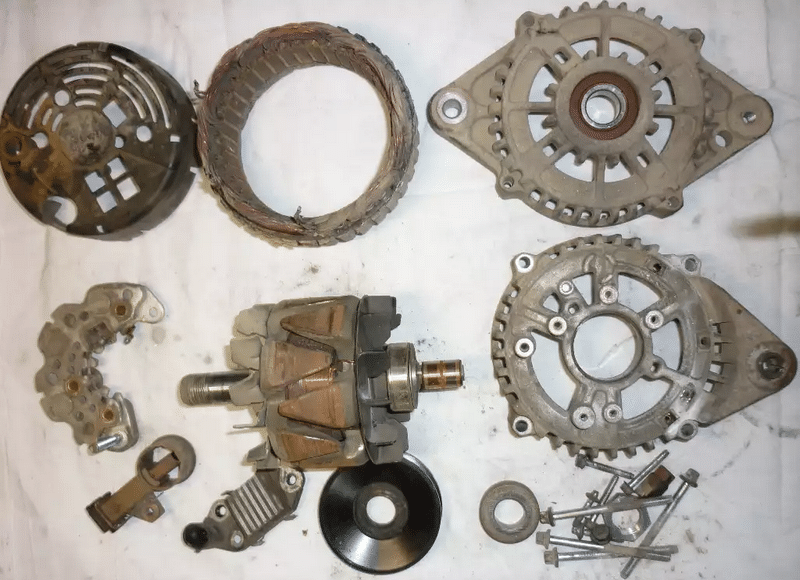

No charge on the battery is due to the fact that the fuse in the circuit has blown or moved away from mechanical shaking. Breakage or wear of the brushes may also not give the desired voltage to charge the battery. The electrical part affects this process in that diodes can burn out, breaks are created in the stator / rotor windings, or, conversely, a short circuit.

For brush diagnostics visual control is often enough, and to detect short circuits or open circuits, you need a multimeter. You can restore a failed diode by soldering a new working element in its place, and some experts are ready to rewind the winding for a small amount. If the service costs more than buying a new generator, then the choice is obvious.

Ring making

Conduct rotor repair you can on your own. Most often, a chain break occurs near the slip rings. Still happens desoldering the ends of the windings. Repair of this problem begins with the fact that we carefully unwind one turn of wire. We solder the broken tip from its place, and in its place, by means of soldering, we fasten the prepared wire from the unwound turn.

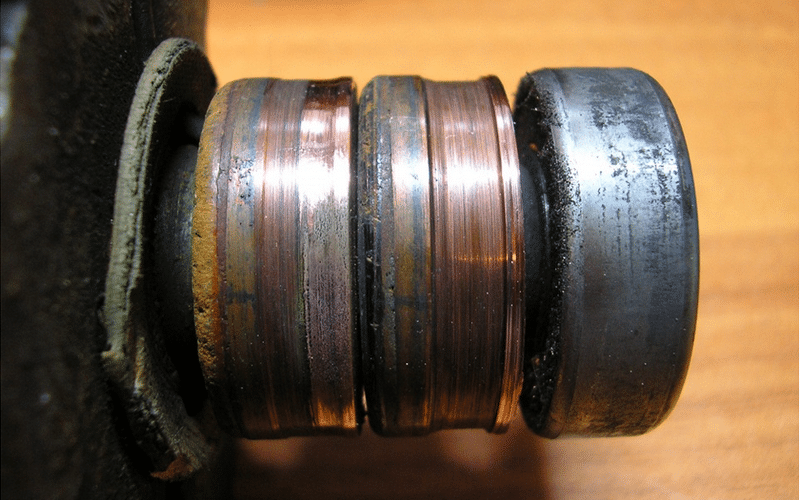

Often it is not even necessary to reduce the number of turns, since the contact is desoldered, which is corrected with a soldering iron. You can additionally clean the contact rings with sandpaper "zero". Noticeable furrows are eliminated with a set of flat files.

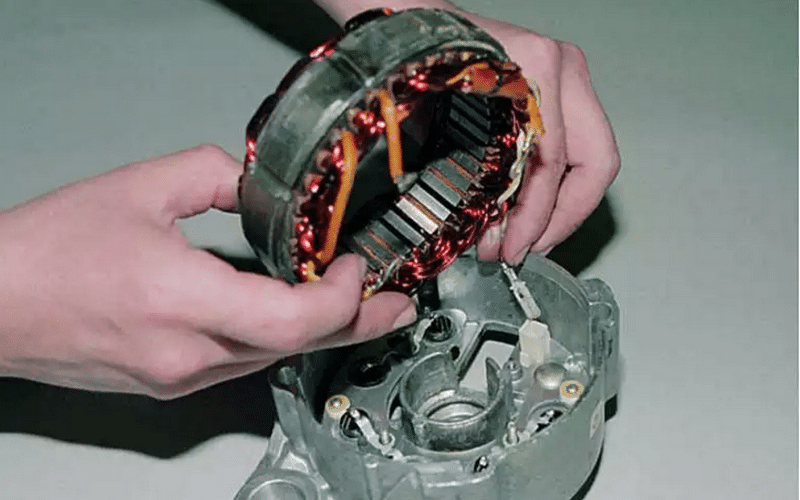

Inspection of the generator stator

The culprits for the significantly increased noise in the generator are rotary bearings. If they are clearly worn, they must be replaced. In cases where there is no noticeable play on them, it is enough to dismantle the bearings, flush them, apply a sufficient amount of high-quality lubricant and install them in their place.

Problems with no charge or its greater extent are solved by replacing the regulator relay. This reason is also affected by the performance of the diode bridge or its individual elements. A test with a multimeter and noticeable punched diodes will restore performance.

Disassembled generator

When dashboard control indicates problems with the battery charge, this is evidence of a breakdown of one of the additional diodes in the circuit. To get to the board with diodes, you need to unscrew a few nuts from the winding, and then disconnect the nut that fixes the positive output. After that, the board with the bridge will become available for replacement or repair.

Conclusion

Most problems can be fixed on your own. However, some types of generator repair, such as stator winding replacement, may not be cost effective. In this case, a complete replacement of the generator is carried out. A video on this topic can be viewed on this page.