The overall assessment of the condition of the car consists of several parameters. A pleasant impression of a good engine, running gear, as well as an ideal body can ruin a shabby interior. To increase the attractiveness of the car, such tuning as the hauling of car seats will help.

Seat resurfacing is best left to the professionals. However, if the funds do not allow, and the hauling of the seats does not require delay, then you can try to do it yourself. But we warn you right away that this work is not easy and requires skills in pattern blanks and the ability to use a sewing machine.

At the end of this article, you will find a video in which experts show how difficult and time-consuming the process of reupholstering car seats is. And we, in turn, will describe the technology in detail, so that you decide whether you can do this work yourself or not.

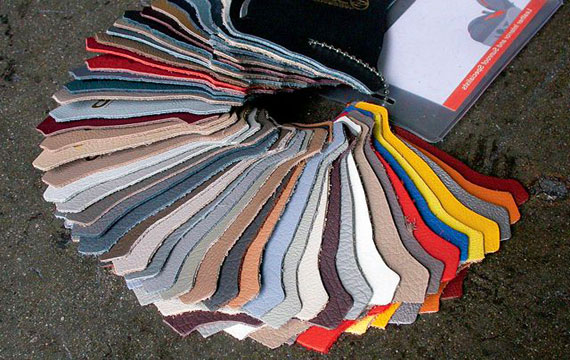

The choice of material for the upholstery of the seats

For upholstery of car seats, the following materials are usually used:

- leather,

- suede leather,

- alcantara,

- velours,

- flock.

The color scheme is matched to the upholstery, but the preferences of the car owner can play a major role here. It is easier to reupholster car seats with one color material. But the use of inserts from other shades gives solidity and individuality to the entire cabin.

The most expensive, but at the same time durable and luxurious material is leather. Only in extreme heat on a leather seat will not be very comfortable and pleasant.

The most economical solution for the upholstery of seats will be the use of velor and Alcantara. Excellent performance characteristics coupled with a low price have allowed these materials to gain popularity among motorists.

Benefits of reupholstery of car seats in the studio

If you need to update the seats in a short time and the money issue is not decisive, then it is best to contact a specialized sewing studio.

Among the main advantages of the upholstery of the seats in the workshop will be:

- performance of work by qualified specialists with many years of experience,

- use of proven quality materials,

- choosing the preferred option

- providing a guarantee for the service,

- minimum turnaround times.

But all these advantages of carrying out hauling in the workshop can be reduced to zero due to the high cost of the service, which may not be affordable for a simple motorist.

Do-it-yourself car seat upholstery technology

Do-it-yourself upholstery of car seats is within the power of assiduous and persistent people. Since the average car owner does not have the skills for such work, everything must be done slowly, following the proven technology.

Seat upholstery preparation

Before you start updating car seats, you first need to perform simple preparatory work:

- Seat removal. Usually fastening is carried out with 4 bolts, however, you must first disconnect the negative terminal of the battery in order to de-energize the security system (airbags). Under the seat, you must also disconnect the electrical wiring terminals, if any, for example, from the electric seat heating.

- Each part of the regular cover is signed with a regular marker. You can also specify the name of the material that will be used in this place of the cover.

- Removing the seat cover from the chair. To carefully remove the old seat trim, you need to squeeze out the metal clips on the back of the chair.

- The old cover is cut at the seams into separate parts that will be used as patterns.

- Material calculation. Now each piece of the old cover can be measured and its area calculated. The total area of the material must be increased by 20-40%, which depends on the measurement accuracy and cutting options.

Making new covers from leather or alcantara

To make new seat covers, you will need some tools and materials:

- gel pen,

- scissors,

- sewing machine,

- foam rubber 5 mm thick,

- glue in a can

- hammer.

The sequence of actions is as follows.

- Each piece of the old cover is placed on the new material and pressed down with weights. The gel pen marks with short dashed lines. The marked elements of the new cover are cut out with scissors. When cutting, it is important to take into account such a feature of Alcantara as the direction of the pile. When combining all the elements, a surface with the same pile direction should be obtained.

- Alcantara and leather are reinforced with fabric-based foam rubber. The connection of the cut parts with foam rubber is carried out using glue. It is impossible to apply the adhesive composition with a brush or roller to the surface of the foam rubber. Therefore, the glue is evenly sprayed from the can.

- The next important step is stitching the patches. It is important to ensure that the edges of adjacent elements are exactly aligned. Here you will need some skills to use a sewing machine.

- The lapels of the seam, divorced to the sides, must be glued on the wrong side. First, excess strips of foam rubber and material are cut off, and the lapels are cleaned and degreased. It remains only to apply glue and press the lapels to each other.

- An important point in the seat constriction will be beating off the seams with an ordinary hammer.

- The lapels are sewn with a double finishing stitch, and the free edges are not trimmed behind the stitching.

Installing a car seat cover

Installation of a new car seat cover is carried out in the following sequence:

- Before installing a new seat cover, you need to thread the straps. The product is twisted and straightened. The cover is first pulled over the back of the seat.

- Now it's the seat's turn. Usually this stage does not cause any problems. It is necessary with plastic clamps threaded through special holes to pull the cover to the base of the chair and fix it by the knitting needle. The edges of the new cover are stretched evenly along the contour of the seat.

- The skin-covering should be completed by heating the material with a jet of hot air. For this, an electric hair dryer is used, the main thing is not to overdo it and not burn the cover. Gradually drying up, the material will stretch like a drum. After that, each chair is steamed with an iron and a damp cloth. Thanks to these thermal operations, the chair cover becomes stretched and absolutely smooth.

- The final operation of the upholstery of the seats will be the cleaning of light leather or Alcantara from the remnants of glue, scuffs and fingerprints.

Carefully tightened car seats will delight the car owner for a long time. During the renovation process, you can change the design of the car seats, as well as update the upholstery of the doors, ceiling and panels. The complex tuning carried out will change the shabby interior beyond recognition, add elegance to the car and increase its value.