The spectacular exterior of the car excites almost every motorist. Therefore, many car owners perform various types of tuning in order to make their car special, to distinguish it from the mass of others, to give it individuality. One of the common types of tuning is shiny or nickel, which covers various parts in the car's structure. On many cars, we can see chrome inside and outside, a shiny radiator grille, etc. Therefore, chrome plating at home and by the factory method is in great demand among car enthusiasts.

Technology of chrome plating of car parts

Due to the wide popularity of such tuning, motorists often have questions about where and how to chrome parts. You can do chrome plating by contacting specialists in this field - everyone who has encountered a similar problem is aware of this. However, not everyone wants to give such work into the wrong hands. The reasons may be financial considerations or the desire to tune your car yourself. Therefore, there is a category of drivers who are interested in do-it-yourself chrome plating at home.

Some general information

Chrome plating is the saturation of chromium by diffusion or its deposition on parts in an electrolyte under the influence of an electric current.

This is done for decorative purposes or in order to reduce the likelihood of corrosion, increase hardness. Chrome plating, as a rule, metal and plastic surface - the technology allows this.

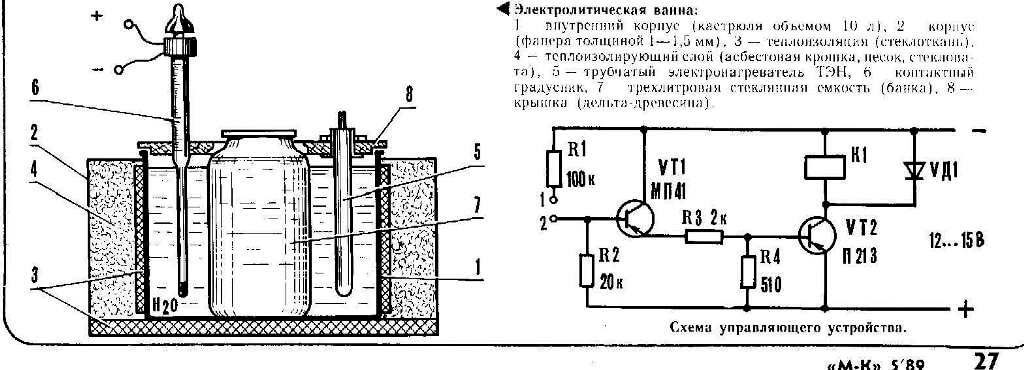

electrolytic bath

electrolytic bath Do-it-yourself chrome plating at home is a complex, time-consuming procedure, but quite doable. Many craftsmen have mastered chrome plating at home. They successfully apply it by tuning details in the design of their car. Let's take a closer look at how you can do this work at home.

Preparing the workplace and equipment

Chrome plating at home requires a specially equipped workplace. Before making the first attempt, you must fully equip the place and make sure that it meets all safety requirements.

A side effect of chromium plating at home is fumes that are harmful to the human body. Therefore, it is very important to take care of the availability of high-quality ventilation - it must be.

Chrome plating at home requires the following things:

- 3 liter glass jar;

- plastic buckets or basins where you can place a jar;

- insulated box made of wood with thermal insulation made of mineral wool or fiberglass;

- heat electric heater;

- thermometer, designed for temperatures from 1 C to 100 C;

- a sheet of wood or plywood;

- a cathode in the form of a clamp and an anode in the form of a rod or plate;

- a latch that will help ensure the "suspended" state of the part in the bank. This is necessary in order to chrome it evenly in all areas.

Before you take the first steps to prepare the electrolyte, you must put on overalls:

- tight apron;

- latex gloves;

- protective glasses;

- respirator.

Chrome plastic bumper

Chrome plastic bumper Electrolyte preparation

Let's talk about how to make an electrolyte. To do this, you will need to follow the algorithm below:

- fill the jar with water heated to 60 C;

- pour and thoroughly stir chromic anhydride at the rate of 250 g per 1 liter of water;

- pour and stir sulfuric acid at the rate of 2.5 g per 1 liter of water;

- drive the solution through an electric field for 3 hours. The current strength should be 6.5 A per 1 liter. The readiness of the solution will be indicated by its burgundy color;

- to defend the electrolyte for 24 hours.

Electrolyte preparation

Electrolyte preparation Surface preparation

Before chrome plating parts, they should be properly prepared. To do this, each part is subjected to the following operations:

- clean off dust, dirt and rust;

- wash and dry thoroughly;

- perform a complete degreasing by wiping the surface with gasoline.

Surface preparation for chrome plating

Surface preparation for chrome plating Chrome plating process

Chrome plating of plastic at home is no different from working with metal surfaces.

Do-it-yourself chrome plating of parts occurs according to the following algorithm:

- heat the electrolyte to 50 - 60 C;

- place the parts in it so that they are “suspended” and do not touch the edges of the container anywhere;

- apply voltage;

- after the process is completed, wash the finished products and dry thoroughly.

The result of chrome plating of body elements

The result of chrome plating of body elements Conclusion

You can cover products with chrome not only at the factory, but also at home. The technology is not easy, the process is very time-consuming, but it is possible. Chrome plating plastic at home is no more difficult than metal - everyone who has been tuning their car on their own knows this.

In order for the work to be crowned with success, it is necessary to observe the technological process and safety requirements to the smallest detail. If you make a mistake, it will affect the quality of the coverage. But you can fix it by redoing the work.