The vast majority of car owners are thinking about changing the appearance of their car. And often they start with a simpler and more affordable tuning - replacing stamped wheels with beautiful cast ones. When choosing a disc, many drivers are guided by the appearance and diameter, but do not think that there are other important parameters, a deviation from which can adversely affect the technical condition of the car and even controllability. Such an important, but little known parameter is the disc offset - ET.

ET (OFFSET) - this abbreviation stands for disc offset, indicated in millimeters.

The smaller the value of this parameter, the more the wheel rim will protrude outward. And, vice versa, the higher the departure parameters, the deeper the disk “burrows” inside the machine.

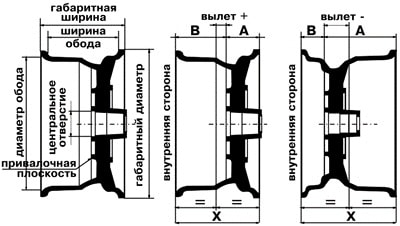

Departure - this is the gap between the plane (attachment), with which the disc comes into contact with the surface of the hub when installed on it, and the represented plane, located in the center of the disc rim.

Types and mechanical characteristics

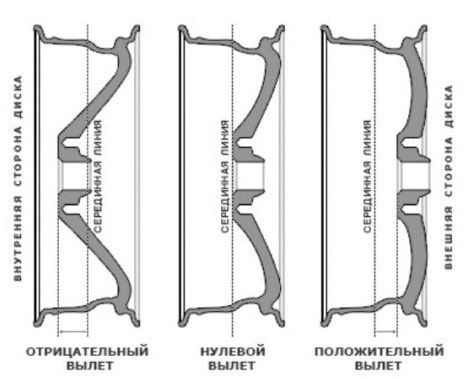

Departure of the rim is of 3 types:

- null;

- positive;

- negative.

The offset coding (ET) is located on the surface of the rim, and the numbers located next to it indicate its parameters.

A positive overhang means that the vertical axis of the rim is a certain distance from the point of contact with the hub.

The zero parameter ET reports that the axis of the disk and its mating plane are identical.

With a negative parameter ET, the surface of the disc attachment to the hub is moved beyond the limits of the vertically located axis of the disc.

The most common offset is a positive offset, while a negative offset is extremely rare.

The size of the overhang is a significant nuance in the design of rims, so a special formula is used to calculate it to eliminate a possible error.

What affects wheel offset

Manufacturers of rims, even in the design process, calculate the possibility of some indentation during installation of the rim, therefore, they determine the maximum possible dimensions.

Proper installation of wheels on a car requires knowledge and understanding of the type and size of the wheel. Only if all the installation instructions are followed, as well as the coincidence of all disk parameters, including the offset, specified by the vehicle manufacturer, is it considered correct to mount the wheel.

Among other parameters, the offset value affects the size of the wheelbase and, as a result, the symmetrical position of all the wheels of the machine. The offset is not affected by the diameter of the disk, nor its width, nor tire parameters.

Most wheel sellers don't know or hide the impact of a departure on a car's technical condition, handling or safety.

An incorrect departure can lead to various negative consequences, sometimes very dangerous.

The main consequences of an incorrectly selected disc offset:

- reduction of the service life of bearings;

- increased wear of rubber;

- changing the location of the steering axle;

- a significant reduction in the service life of the undercarriage of vehicles, including the suspension;

- deterioration of vehicle controllability, directional stability and the possibility of precise maneuvering, which can lead to sad consequences in the form of an accident.

How to calculate departure parameters yourself

To independently calculate the departure, a very simple formula is used:

ET=(a+b)/2-b=(a-b)/2

A- the distance between the inner side of the disk and the plane of its contact with the hub.

b is the width of the disk.

If for some reason there are no ET values on the disk, it is not difficult to calculate them yourself.

This will require a flat rail, a little longer than the diameter of the disk and a tape measure or ruler for measuring. If the disc is on the vehicle, it will need to be removed, which requires a jack, wheel wrench, and shoes to prevent rollback.

Measurement results must be carried out in millimeters.

First of all, it is necessary to turn the rim over with the outer side down and attach the rail to the rim of the rim. Then it is necessary to measure the distance from the mating part of the disk to the lower edge of the rail with a tape measure.

This figure is the rear indent A. For clarity of calculation, let's assume that this value is 114 mm.

After calculating the first parameter, it is necessary to turn the disc face up and also attach the rail to the rim. The measurement procedure is practically the same as the previous one. It turns out the parameter b. For clarity of calculations, we consider it equal to 100 mm.

We calculate the wheel offset using the measured parameters, according to the formula:

ET=(a+b)/2-b=(114+100)/2-100=7mm

According to the dimensions, the overhang is positive and equal to 7 mm.

Is it possible to put discs with a smaller or different overhang

Sellers of rims basically assure that the removal of the rim does not affect the condition of the car and other parameters, but they should not be trusted.

Their main goal is to sell wheels, and the fact that there are more than a dozen departure parameters - they are silent for several reasons, including the possible difficulty in selecting a product according to the necessary parameters or a banal lack of knowledge about such parameters and their impact on the car.

As proof of the need to comply with the disc offset set by the factory, it can be considered that for some brands of cars, but in different configurations, various spare parts are produced, especially for the running gear of the car.

Even if the transport differs only in the engine, this is already reflected in the weight of the car, and, as a result, in the numerous parameters that the designers recalculate for each configuration. Nowadays, in the production of cars, they are trying to reduce the cost, which affects the resource of parts, and independent tuning of a car without taking into account the parameters laid down by the manufacturer mainly leads to the approach of repair, sometimes very soon.

There is an option for installing a disk with a different offset - the use of special spacers. They look like flat metal circles of various thicknesses and are installed between the disc and the hub. Having chosen the required thickness of the spacer, you can not worry about the incorrect operation of the suspension and other units if wheel rims with an offset other than the factory one were purchased.

The only caveat in this case is that you may have to look for spacers of the required thickness, since not every disc dealer has them.

When replacing disks, you should take into account the removal parameter - ET, which is indicated on it. But it is easy to measure it yourself with the help of simple devices that every car owner has. To select and install new shoes on a car, you must adhere to the manufacturer's requirements.

The offset of the disc affects the performance of many components of the chassis, but more importantly, an incorrectly selected ET reduces the controllability of the machine, worsens directional stability and can lead to serious consequences.

If the stem is different from the factory, this can be fixed with special wheel spacers.